ASTM D5897-96(2001)

(Test Method)Standard Test Method for Determination of Percent Hydroxyl on Cellulose Esters by Potentiometric Titration—Alternative Method

Standard Test Method for Determination of Percent Hydroxyl on Cellulose Esters by Potentiometric Titration—Alternative Method

SCOPE

1.1 This test method covers a procedure for determining the percent hydroxyl on cellulose esters by potentiometric titration. The typical range of percent hydroxyl measured is 0.7 to 10.0%.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5897–96(Reapproved2001)

Standard Test Method for

Determination of Percent Hydroxyl on Cellulose Esters by

Potentiometric Titration—Alternative Method

This standard is issued under the fixed designation D 5897; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope solutionatthepointofhydrolysisandbeforetitration.Thiswill

prevent erroneous results from material that may have refluxed

1.1 This test method covers a procedure for determining the

into the joint.

percenthydroxyloncelluloseestersbypotentiometrictitration.

The typical range of percent hydroxyl measured is 0.7 to

6. Apparatus

10.0 %.

6.1 Titrator, equipped with Glass Electrode, or equivalent.

2. Referenced Documents 6.2 Heating/Stirring Module, six-place.

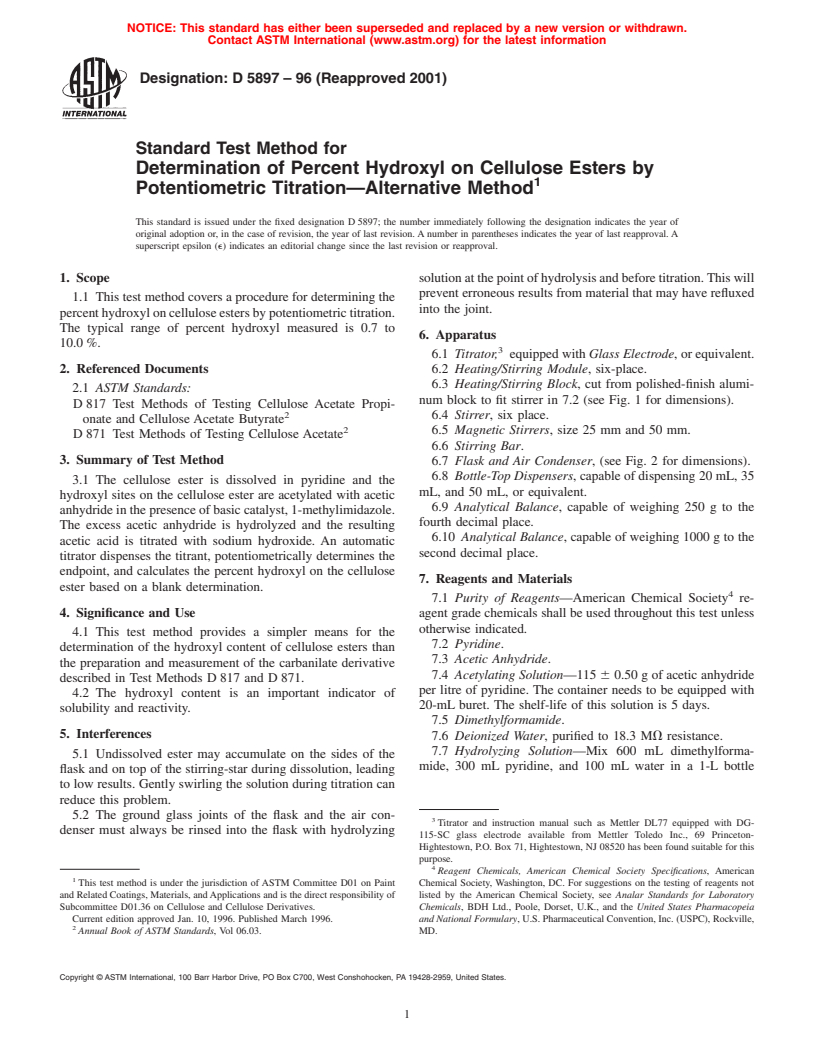

6.3 Heating/Stirring Block, cut from polished-finish alumi-

2.1 ASTM Standards:

num block to fit stirrer in 7.2 (see Fig. 1 for dimensions).

D 817 Test Methods of Testing Cellulose Acetate Propi-

6.4 Stirrer, six place.

onate and Cellulose Acetate Butyrate

2 6.5 Magnetic Stirrers, size 25 mm and 50 mm.

D 871 Test Methods of Testing Cellulose Acetate

6.6 Stirring Bar.

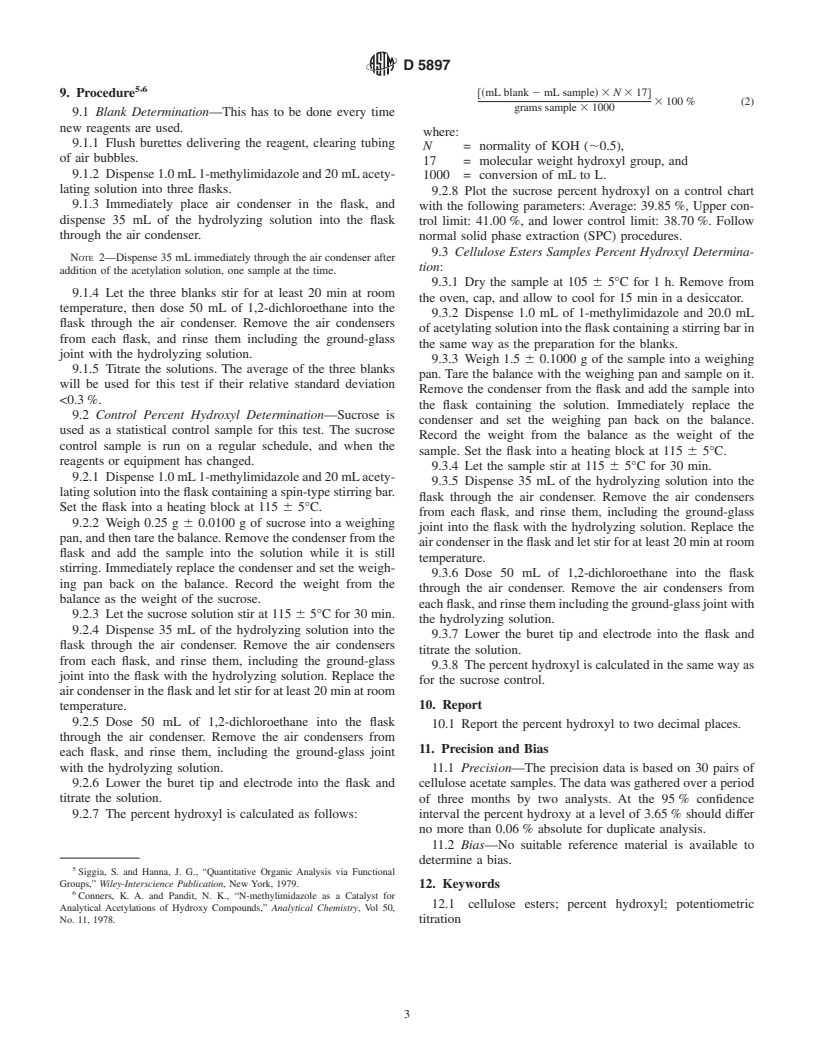

3. Summary of Test Method 6.7 Flask and Air Condenser, (see Fig. 2 for dimensions).

6.8 Bottle-Top Dispensers, capable of dispensing 20 mL, 35

3.1 The cellulose ester is dissolved in pyridine and the

mL, and 50 mL, or equivalent.

hydroxyl sites on the cellulose ester are acetylated with acetic

6.9 Analytical Balance, capable of weighing 250 g to the

anhydride in the presence of basic catalyst, 1-methylimidazole.

fourth decimal place.

The excess acetic anhydride is hydrolyzed and the resulting

6.10 Analytical Balance, capable of weighing 1000 g to the

acetic acid is titrated with sodium hydroxide. An automatic

second decimal place.

titrator dispenses the titrant, potentiometrically determines the

endpoint, and calculates the percent hydroxyl on the cellulose

7. Reagents and Materials

ester based on a blank determination.

7.1 Purity of Reagents—American Chemical Society re-

4. Significance and Use agent grade chemicals shall be used throughout this test unless

otherwise indicated.

4.1 This test method provides a simpler means for the

7.2 Pyridine.

determination of the hydroxyl content of cellulose esters than

7.3 Acetic Anhydride.

the preparation and measurement of the carbanilate derivative

7.4 Acetylating Solution—115 6 0.50 g of acetic anhydride

described in Test Methods D 817 and D 871.

per litre of pyridine. The container needs to be equipped with

4.2 The hydroxyl content is an important indicator of

20-mL buret. The shelf-life of this solution is 5 days.

solubility and reactivity.

7.5 Dimethylformamide.

5. Interferences

7.6 Deionized Water, purified to 18.3 MV resistance.

7.7 Hydrolyzing Solution—Mix 600 mL dimethylforma-

5.1 Undissolved ester may accumulate on the sides of the

mide, 300 mL pyridine, and 100 mL water in a 1-L bottle

flask and on top of the stirring-star during dissolution, leading

to low results. Gently swirling the solution during titration can

reduce this problem.

5.2 The ground glass joints of the flask and the air con-

Titrator and instruction manual such as Mettler DL77 equipped with DG-

denser must always be rinsed into the flask with hydrolyzing

115-SC glass electrode available from Mettler Toledo Inc., 69 Princeton-

Hightestown, P.O. Box 71, Hightestown, NJ 08520 has been found suitable for this

purpose.

Reagent Chemicals, American Chemical Society Specifications, American

This test method is under the jurisdiction of ASTM Committee D01 on Paint Chemical Society, Washington, DC. For suggestions on the testing of reagents not

and Related Coatings, Materials, andApplications and is the direct responsibility of listed by the American Chemical Society, see Analar Standards for Laboratory

Subcommittee D01.36 on Cellulose and Cellulose Derivatives. Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

Current edition approved Jan. 10, 1996. Published March 1996. and National Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville,

Annual Book of ASTM Standards, Vol 06.03. MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5897

FIG. 1 Heating/Stirring Block Dimensions

equipped with a bottle top dispenser capable of dosing 35 mL.

Stir for at least 10 min prior to use. The shelf-life of this

solution is 1 month.

7.8 1-Methylimidazole.

7.9 Sucrose.

7.10 Acetone.

7.11 Potassium Acid Phthalate (KHP), National Institute of

Standards and Technology primary standard grade. Store in

desiccator, after drying for1hat 105°C (65°C).

7.12 Methanol.

7.13 Sodium Hydroxide, 0.5 N in methanol. This solution

has a shelf life of 2 weeks.

7.14 Traceable Buffers, pH 4 and pH 7, available from

National Institute of Standards and Technology.

7.15 Potassium Chloride (KCl),5 M, weigh 37.3 g

(60.3000 g) of KCl into a 100-mL volumetric flask. Dilute to

the mark with purified water. Shake into solution.

7.16 1,2-Dichloroethane.

8. Calibration and Standardization

8.1 Calibration of the Electrode:

NOTE 1—If the electrode is new, perforate the nipple on the rubber cap

and soak the electrode in 5 M potassium chloride for 1 h. Store in pH 4

buffer until use.

FIG. 2 Flask and Air Condensor Dimensions

8.1.1 Select from the titrator menu the procedure for cali-

bration of the electrode.

8.1.2 Add about 50 mL of pH 4 buffer into a titration cup

8.2.2 Ensure that the burette is flushed with the 0.5 N

and lower the electrode into it.

NaOH.

8.1.3 Run the procedure for the titrator to read the correct

8.2.3 Titrate the sample.

pH.

8.2.4 Normality is calculated as follows:

8.1.4 Repeat process 9.1.1-9.1.3 for buffer pH 7.

8.1.5 Make sure that the calibration is done when a new

W 3 1000

N 5 (1)

electrode is put into use and then check once/month thereafter

mL 3 204.23

or when a problem is suspected.

where:

8.2 Standardization of Methanolic 0.5 N Sodium Hydroxide:

W = weight of KHP in g,

8.2.1 Weigh approximately 1.5 6 0.1000 g of KHP into a

mL = volume of titrant used for titration, and

titration cup and record the weight. Add about 35 mL of

204.23 = formula weight

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.