ASTM B187-00e1

(Specification)Standard Specification for Copper Bar, Bus Bar, Rod, and Shapes

Standard Specification for Copper Bar, Bus Bar, Rod, and Shapes

SCOPE

1.1 This specification establishes the requirements for copper bar, bus bar, rod, and shapes for electrical and nonelectrical applications.

1.1.1 The products for electrical applications shall be made from the following coppers:Copper UNS No. Reference DesignationC10100OFEC10200OFC10300OFXLPC10400, C10500, C10700OFSC10920, C10930, C10940—C11000ETPC11300, C11400, C11500, C11600STPC14420—

The product may be furnished from any copper listed unless otherwise specified in the contract or purchase order.

1.1.2 The product for nonelectrical applications shall be made from the following coppers:Copper UNS No.Reference DesignationC10800OFLPC12000DLPC12200DHP

The product may be furnished from any copper listed unless otherwise specified in the contract or purchase order.

1.2 The inch-pound units are standard for this specification.

1.3 This specification is the companion to SI (Metric) Specification B 187M; therefore no SI equivalents are presented herein.

Note 1—Material for hot forging will be found in Specification B 224.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: B 187 – 00

Standard Specification for

1

Copper Bar, Bus Bar, Rod, and Shapes

This standard is issued under the fixed designation B 187; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

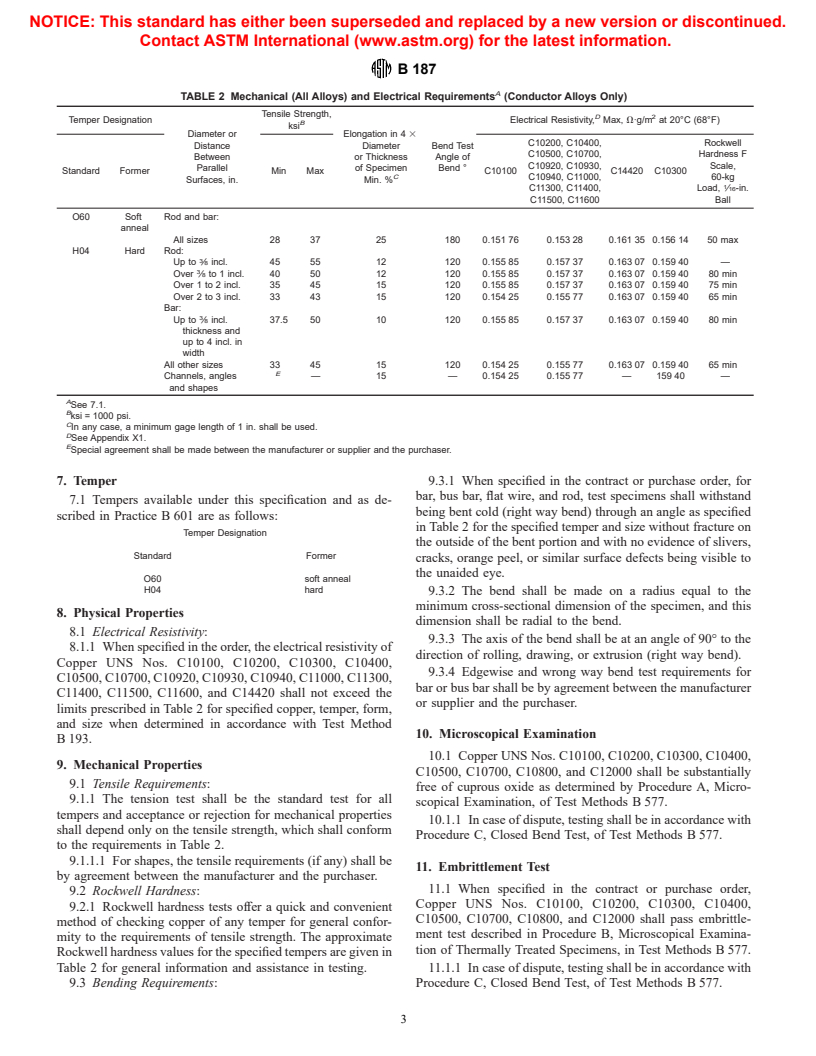

e NOTE—Tables 2 and X1.1 were editorially corrected in August 2001.

1. Scope 2. Referenced Documents

2

1.1 This specification establishes the requirements for cop- 2.1 ASTM Standards:

per bar, bus bar, rod, and shapes for electrical and nonelectrical 2.1.1 The following documents in the current issue of the

applications. Book of Standards form a part of this specification to the extent

1.1.1 The products for electrical applications shall be made referenced herein.

3

from the following coppers: B 170 Specification for Oxygen-Free Electrolytic Copper—

4

3

Refinery Shapes

Copper UNS No. Reference Designation

B 187M Specification for Copper Bar, Bus Bar, Rod and

C10100 OFE

4

Shapes [Metric]

C10200 OF

B 193 Test Method for Resistivity of Electrical Conductor

C10300 OFXLP

5

C10400, C10500, C10700 OFS

Materials

C10920, C10930, C10940 —

B 216 Specification for Tough-Pitch Fire-Refined Copper—

C11000 ETP

4

Refinery Shapes

C11300, C11400, C11500, STP

4

C11600

B 224 Classification of Coppers

C14420 —

B 249/B 249M Specification for General Requirements for

1.1.1.1 The product may be furnished from any copper

Wrought Copper and Copper-Alloy Rod, Bar, Shapes and

4

listed unless otherwise specified in the contract or purchase

Forgings

order.

B 577 Test Methods for Detection of Cuprous Oxide (Hy-

4

1.1.2 The product for nonelectrical applications shall be

drogen Embrittlement Susceptibility) in Copper

made from the following coppers:

B 601 Practice for Temper Designations for Copper and

4

3

Copper UNS No. Reference Designation Copper Alloys—Wrought and Cast

6

E 53 Methods for Chemical Analysis of Copper

C10800 OFLP

E 62 Test Methods for Chemical Analysis of Copper and

C12000 DLP

6

C12200 DHP

Copper Alloys (Photometric Methods)

E 255 Practice for Sampling Copper and Copper Alloys for

1.1.2.1 The product may be furnished from any copper

6

the Determination of Chemical Composition

listed unless otherwise specified in the contract or purchase

E 478 Test Methods for Chemical Analysis of Copper

order.

6

Alloys

1.2 The inch-pound units are standard for this specification.

7

E 527 Practice for Numbering Metals and Alloys (UNS)

1.3 This specification is the companion to SI (Metric)

Specification B 187M; therefore no SI equivalents are pre-

3. Terminology

sented herein.

3.1 Definitions:

NOTE 1—Material for hot forging will be found in Specification B 224.

3.1.1 bus bar, n—includes material of solid rectangular or

square cross section or a solid section with two plane parallel

surfaces and round or other simple regular shaped edges up to

and including 12 in. in width and 0.090 in. and over in

1

This specification is under the jurisdiction of ASTM Committee B05 on Copper

thickness.

and Copper Alloys and is the direct responsibility of Subcommittee B05.02 on Rod,

Bar, Wire, Shapes and Forgings.

Current edition approved March 2000. Published April 2000. Originally pub-

lished as B 187 – 44 T. Last previous edition B 187 – 97.

4

2 Annual Book of ASTM Standards, Vol 02.01.

For ASME Boiler and Pressure Vessel Code applications, see related Specifi-

5

Annual Book of ASTM Standards, Vol 02.03.

cation SB-133 in Section II of that Code.

6

3 Annual Book of ASTM Standards, Vol 03.05.

Refer to Practice E 527 for an explanation of the Unified Numbering System.

7

Annual Book of ASTM Standards, Vol 01.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B 187

3.1.2 bus conductor stock, n—a bar, rod, or shape of high 4.1.7 When material is purchased for agencies of the U.S.

conductivity copper used to make electrical conductors. Government (see Section 12).

3.1.3 bus rod, n—includes solid round and regular polygons

4.2 The following options are available and should be

of six and eight sides.

specified in the contract or purchase order when required:

3.1.4 bus shapes, n—a solid section other than regular rod,

4.2.1 Heat identification or traceability details required,

bar, plate, sheet, strip, or flat wire, that may be oval, half oval,

4.2.2 Hydrogen embrittlement test,

half round, triangular, pentagonal, or of any spec

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.