ASTM D5732-95(2001)

(Test Method)Standard Test Method for Stiffness of Nonwoven Fabrics Using the Cantilever Test (Withdrawn 2008)

Standard Test Method for Stiffness of Nonwoven Fabrics Using the Cantilever Test (Withdrawn 2008)

SIGNIFICANCE AND USE

This test method may be used for acceptance testing of commercial shipments of nonwoven fabrics, however, caution is advised since information about between-laboratory precision is incomplete. A comparative test as directed in 5.1.1 may be advisable.

5.1.1 In case of a dispute arising from differences in reported test results when using this test method for acceptance testing of commercial shipments, the purchaser and the supplier should conduct a comparative test to determine if there is a statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of test specimens that are as homogeneous as possible and that are from a lot of material of the type in question. Test specimens should then be randomly assigned in equal numbers to each laboratory for testing. The average results from the two laboratories should be compared using the appropriate Student’t-test and an acceptable probability level chosen by the two parties before testing is begun. If a bias is found, either its cause must be found and corrected or the purchaser and the supplier must agree to interpret future test results in the view of the known bias.

This test method measures the drape stiffness of the nonwoven fabric. This test is not, however, suitable for very limp fabrics or those that show a marked tendency to curl or twist.

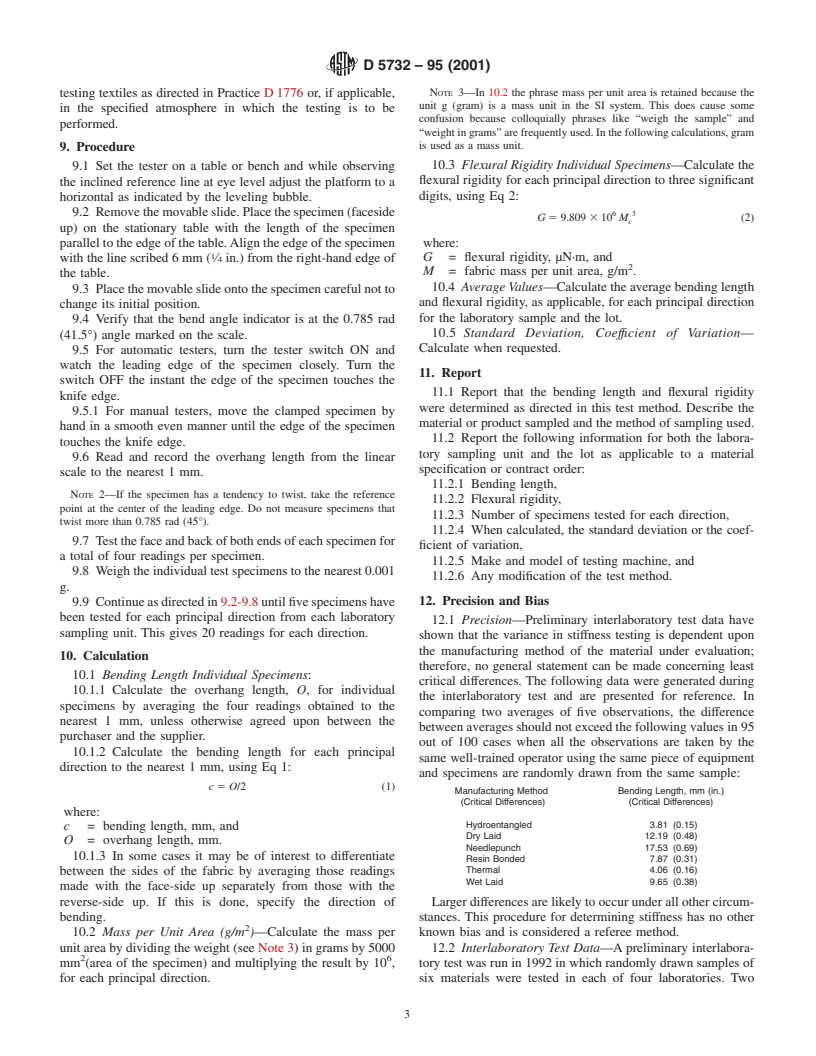

FIG. 1 Cantilever Bending Tester

SCOPE

1.1 This test method covers stiffness properties of nonwoven fabrics by employing the principle of cantilever bending of the fabric under its own weight. Bending length is measured and flexural rigidity calculated.

1.2 This test method applies to most nonwoven fabrics that are treated or untreated, including those heavily sized, coated, or resin-treated.

1.3 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses may be approximate.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers stiffness properties of nonwoven fabrics by employing the principle of cantilever bending of the fabric under its own weight. Bending length is measured and flexural rigidity calculated.

This standard is being withdrawn with no replacement because D13 no longer has the technical expertise to maintain.

Formerly under the jurisdiction of Committee D13 on Textiles, this test method was discontinued in July 2008.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5732–95 (Reapproved 2001)

Standard Test Method for

Stiffness of Nonwoven Fabrics Using the Cantilever Test

This standard is issued under the fixed designation D 5732; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.3 flexural rigidity, n—a measure of stiffness, the couple

on either end of a strip or unit width bent into unit curvature,

1.1 This test method covers stiffness properties of non-

in the absence of any tension.

wovenfabricsbyemployingtheprincipleofcantileverbending

3.1.4 machine direction, MD, n—the direction in the plane

of the fabric under its own weight. Bending length is measured

of the fabric parallel to the direction of manufacture.

and flexural rigidity calculated.

3.1.4.1 Discussion—In nonwoven fabrics, the term machine

1.2 This test method applies to most nonwoven fabrics that

direction is used to refer to the direction analogous to length-

are treated or untreated, including those heavily sized, coated,

wise or warp direction in a woven fabric.

or resin-treated.

3.1.5 nonwoven fabric, n—a textile structure produced by

1.3 The values stated in SI units are to be regarded as the

bonding or interlocking of fibers, or both, accomplished by

standard. The inch-pound units given in parentheses may be

mechanical, chemical, thermal, or solvent means, or combina-

approximate.

tion thereof.

1.4 This standard does not purport to address all of the

3.1.6 stiffness, n—resistance to bending.

safety concerns, if any, associated with its use. It is the

3.2 For definitions of other terms used in this test method,

responsibility of the user of this standard to establish appro-

refer to Terminology D 123.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4. Summary of Test Method

2. Referenced Documents 4.1 A specimen is slid at a specified rate in a direction

parallel to its long dimension, so that its leading edge projects

2.1 ASTM Standards:

from the edge of a horizontal surface. The length of the

D 123 Terminology Relating to Textiles

overhang is measured when the tip of the specimen is de-

D 1776 Practice for Conditioning Textiles for Testing

pressedunderitsownweighttothepointwherethelinejoining

D 2904 Practice for Interlaboratory Testing of a Textile Test

the top to the edge of the platform makes a 0.785 rad (41.5°)

Method That Produces Normally Distributed Data

angle with the horizontal. The stiffer the fabric, the longer it

3. Terminology

takes to bend, thus, the higher numbers indicate a stiffer fabric.

3.1 Definitions:

5. Significance and Use

3.1.1 bending length, n—in textiles, a measure of the

5.1 This test method may be used for acceptance testing of

interaction between fabric weight and fabric stiffness as shown

commercial shipments of nonwoven fabrics, however, caution

by the way in which a fabric bends under its own weight.

is advised since information about between-laboratory preci-

3.1.1.1 Discussion—Bending length reflects the stiffness of

sion is incomplete.Acomparative test as directed in 5.1.1 may

a fabric when bent in one plane under the force of gravity and

be advisable.

is one component of drape.

5.1.1 In case of a dispute arising from differences in

3.1.2 cross-machine direction, CD, n—the direction in the

reported test results when using this test method for acceptance

plane of the fabric perpendicular to the direction of manufac-

testing of commercial shipments, the purchaser and the sup-

ture.

plier should conduct a comparative test to determine if there is

3.1.2.1 Discussion—In nonwoven fabrics, the term cross-

a statistical bias between their laboratories. Competent statis-

machine direction is used to refer to the direction analogous to

tical assistance is recommended for the investigation of bias.

crosswise or filling direction in a woven fabric.

As a minimum, the two parties should take a group of test

specimens that are as homogeneous as possible and that are

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

from a lot of material of the type in question. Test specimens

and is the direct responsibility of Subcommittee D13.90 on Executive.

should then be randomly assigned in equal numbers to each

Current edition approved June 15, 1995. Published September 1995.

laboratory for testing. The average results from the two

Annual Book of ASTM Standards, Vol 07.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5732–95 (2001)

laboratories should be compared using the appropriate Stu- in an applicable material specification or other agreement

dent’s t-test and an acceptable probability level chosen by the between the purchaser and the supplier. Consider the rolls, or

two parties before testing is begun. If a bias is found, either its pieces, of fabric to be the primary sampling units. In the

cause must be found and corrected or the purchaser and the absence of such an agreement, take the number of fabric rolls

suppliermustagreetointerpretfuturetestresultsintheviewof specified in Table 1.

the known bias.

NOTE 1—An adequate specification or other agreement between the

5.2 This test method measures the drape stiffness of the

purchaserandsupplierrequirestakingintoaccountthevariabilitybetween

nonwoven fabric. This test is not, however, suitable for very

rolls or pieces of fabric and between specimens from a swatch from a roll

limp fabrics or those that show a marked tendency to curl or

or pieces of fabric to provide a sampling plan with a meaningful

producer’s risk, consumer’s risk, acceptable quality level, and limiting

twist.

quality level.

6. Apparatus

7.2 Laboratory Sample—For the laboratory sample, take a

6.1 Cantilever Bending Tester (Fig. 1):

swatch extending the width of the fabric and approximately 1

6.1.1 Horizontal Platform, with a minimum area of 38 by

m (1 yd) along the machine direction from each roll, or piece,

200 mm (1.5 by 8 in.) and having a smooth low-friction, flat

in the lot sample. For rolls of fabric, take a sample that will

surface such as polished metal or plastic. A leveling bubble

exclude fabric from the outer wrap of the roll or the inner wrap

shall be incorporated in the platform.

around the core.

6.1.2 Indicator, inclined at an angle of 0.724 rad (41.5°)

7.3 Test Specimens—From each laboratory sampling unit,

below the plane of the platform surface.

take five specimens from the machine direction and five

6.1.3 Movable Slide, consisting of a metal bar not less than

specimens from the cross-machine direction as applicable to a

25 by 200 mm (1 by 8 in.) by approximately 3 mm ( ⁄8 in.)

material specification or contract order. For nonwoven fabrics,

thick and having a mass of 270 6 5 g (0.6 6 0.01 lb).

take specimens only in the machine direction unless otherwise

6.1.4 Scale and Pointer, to measure the length of the

specified.

overhang.

7.3.1 Direction of Test—Consider the long dimension as the

6.1.5 Motorized Specimen Feed Unit, set for 120 mm/min

direction of the test.

(4 ⁄4 in./min), preferred. Manual units are permitted.

7.3.2 Specimen Size and Direction of Test—Cut test speci-

6.2 Analytical Balance, having a capacity and sensitivity to

mens 25 by 200 mm 61mm(1by8in. 6 0.002 in.).Take the

weigh within 6 0.1 % of the weight of the specimens being

specimens for the measurement of the machine direction from

tested.

different positions across the fabric width with the longer

6.3 Cutting Die,25by200mm 61mm(1by8in. 6 0.002

dimension parallel to the machine direction. Take the speci-

in.).

mens for the measurement of the cross-machine direction from

different positions along the length of the fabric with the longer

dimension parallel to the cross-machine direction. Label to

maintain specimen identity.

7.3.2.1 Cut specimens representing a broad distribution

across the width of the laboratory sample and no nearer the

edge than one tenth its width. Ensure specimens are free of

folds, creases, or wrinkles.Avoid getting oil, water, grease, and

so forth, on the specimens when handling.

8. Conditioning

8.1 No conditioning is required unless otherwise specified

in a material specification or contract order.

8.2 When specified, precondition the specimens by bringing

them to approximate moisture equilibrium in the standard

atmosphere for preconditioning textiles as directed in Practice

D 1776.

FIG. 1 Cantilever Bending Tester

8.3 After preconditioning, bring the test specimens to mois-

ture equilibrium for testing in the standard atmosphere for

7. Sampling and Test Specimens

7.1 Lot Sample—As a lot sample for acceptance testing,

TABLE 1 Number of Rolls, or Pieces, of Fabric in the Lot Sample

take at random the number of rolls, or pieces, of fabric directed

Number of Rolls, Number of Rolls or Pieces in Lot,

Pieces in Lot, Inclusive Sample

The F.R.L. cantilever bending tester has been found suitable and is available

1to3 all

from Testing Machines, Inc., 400 Bayview Ave., Amityville, NY 11710; U.S.

4to24 4

Testing, 1415 Park Ave., Hoboken, NJ 07030; and FAST (The Wool Bureau, Inc.,

25 to 50 5

U.S. Branch-International Wool Secretariat, Technical Service Center), 225 Cross- over 50 10 % to a maximum of ten rolls or pieces

ways Park Drive, Woodbury, NY 11797-0403.

D5732–95 (2001)

NOTE 3—In 10.2 the phrase mass per unit area is retaine

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.