ASTM D6828-02(2019)

(Test Method)Standard Test Method for Stiffness of Fabric by Blade/Slot Procedure

Standard Test Method for Stiffness of Fabric by Blade/Slot Procedure

SIGNIFICANCE AND USE

5.1 This test method is considered satisfactory for quality control testing.

5.2 If there are differences of practical significance between reported test results for two laboratories, comparative tests should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, use test samples as homogeneous as possible, drawn from the material from which the disparate test results were obtained, and randomly assigned in equal number to each laboratory for testing. The test results from the two laboratories should be compared using a statistical test for unpaired data, at a probability level chosen prior to the testing series. If a bias is found, either its cause must be found and corrected, or future results for the source material must be adjusted in consideration of the known bias.

5.3 The stiffness of fabric relates to its resistance to bending with further processing and use. It measures the fiber and yarn bending capabilities, the cohesion of individual fibers and yarns relative to their displacement and binders or finishes that hold them in place.

SCOPE

1.1 This test method covers the determination of the stiffness of fabrics by measuring the force required to push a specimen into a slot of predetermined width with a metal blade working at a predetermined capacity.

Note 1: For other methods for testing stiffness, refer to Test Methods D1388, D4032, and D5732.

1.2 This test method is applicable to fabrics of any fiber content whose stiffness does not exceed the capacity of the Penetrator Beam apparatus. Specimens can be taken from fabrics, rolls, or end products.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6828 − 02 (Reapproved 2019)

Standard Test Method for

Stiffness of Fabric by Blade/Slot Procedure

This standard is issued under the fixed designation D6828; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Method that Produces Normally Distributed Data (With-

drawn 2008)

1.1 This test method covers the determination of the stiff-

D2906 Practice for Statements on Precision and Bias for

ness of fabrics by measuring the force required to push a

Textiles (Withdrawn 2008)

specimen into a slot of predetermined width with a metal blade

D4032 Test Method for Stiffness of Fabric by the Circular

working at a predetermined capacity.

Bend Procedure

NOTE 1—For other methods for testing stiffness, refer to Test Methods

D4850 Terminology Relating to Fabrics and Fabric Test

D1388, D4032, and D5732.

Methods

1.2 This test method is applicable to fabrics of any fiber

D5732 Test Method for Stiffness of Nonwoven Fabrics

content whose stiffness does not exceed the capacity of the 3

Using the Cantilever Test (Withdrawn 2008)

Penetrator Beam apparatus. Specimens can be taken from

2.2 Statistical Analysis Software:

fabrics, rolls, or end products.

1.3 The values stated in SI units are to be regarded as

standard. The values given in parentheses after SI units are 3. Terminology

provided for information only and are not considered standard.

3.1 Definitions:

1.4 This standard does not purport to address all of the 3.1.1 For definitions of textile terms used in this method

refer to Terminology D4850. For other terms used in this

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- method, refer to Terminology D123.

priate safety, health, and environmental practices and deter-

4. Summary of Test Method

mine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accor-

4.1 A swatch of fabric rests on two flat plate supports

dance with internationally recognized principles on standard- separated by a fixed distance. A force is applied to the fabric

ization established in the Decision on Principles for the

swatch midway between the supports by means of a blade

Development of International Standards, Guides and Recom- attached to a motor driven beam. The maximum force needed

mendations issued by the World Trade Organization Technical

to push the fabric through the supports is measured as a

Barriers to Trade (TBT) Committee. resistance to bending of the fabric.

5. Significance and Use

2. Referenced Documents

5.1 This test method is considered satisfactory for quality

2.1 ASTM Standards:

control testing.

D123 Terminology Relating to Textiles

D1388 Test Method for Stiffness of Fabrics

5.2 If there are differences of practical significance between

D1776 Practice for Conditioning and Testing Textiles

reported test results for two laboratories, comparative tests

D2904 Practice for Interlaboratory Testing of a Textile Test

should be performed to determine if there is a statistical bias

between them, using competent statistical assistance. As a

minimum,usetestsamplesashomogeneousaspossible,drawn

from the material from which the disparate test results were

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

and is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods, obtained, and randomly assigned in equal number to each

Specific.

laboratoryfortesting.Thetestresultsfromthetwolaboratories

Current edition approved July 1, 2019. Published July 2019. Originally approved

should be compared using a statistical test for unpaired data, at

in 2002. Last previous edition approved in 2015 as D6828 – 02(2015). DOI:

10.1520/D6828-02R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM The last approved version of this historical standard is referenced on

Standards volume information, refer to the standard’s Document Summary page on www.astm.org.

the ASTM website. SAS Institute, Box 8000, Cary, NC 27511.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6828 − 02 (2019)

a probability level chosen prior to the testing series. If a bias is 6.2 Specimen Marking Template,102by100 65.0mm(4.0

found, either its cause must be found and corrected, or future by 4.0 6 0.2 in.).

results for the source material must be adjusted in consider-

7. Sampling and Test Specimens

ation of the known bias.

7.1 Primary Sampling Unit—Consider material as put-up

5.3 The stiffness of fabric relates to its resistance to bending

for shipment to be the primary sampling unit, such as rolls,

with further processing and use. It measures the fiber and yarn

bolts or pieces of fabric, or carton of garments or flat goods, as

bending capabilities, the cohesion of individual fibers and

applicable. (See Annex A1.)

yarns relative to their displacement and binders or finishes that

hold them in place.

7.2 Laboratory Sampling Unit—As a laboratory sampling

unit take from rolls at least one full-width piece of fabric that

6. Apparatus

is1m(1yd)in length along the selvage (machine direction),

after first removinga1m(1yd) length.

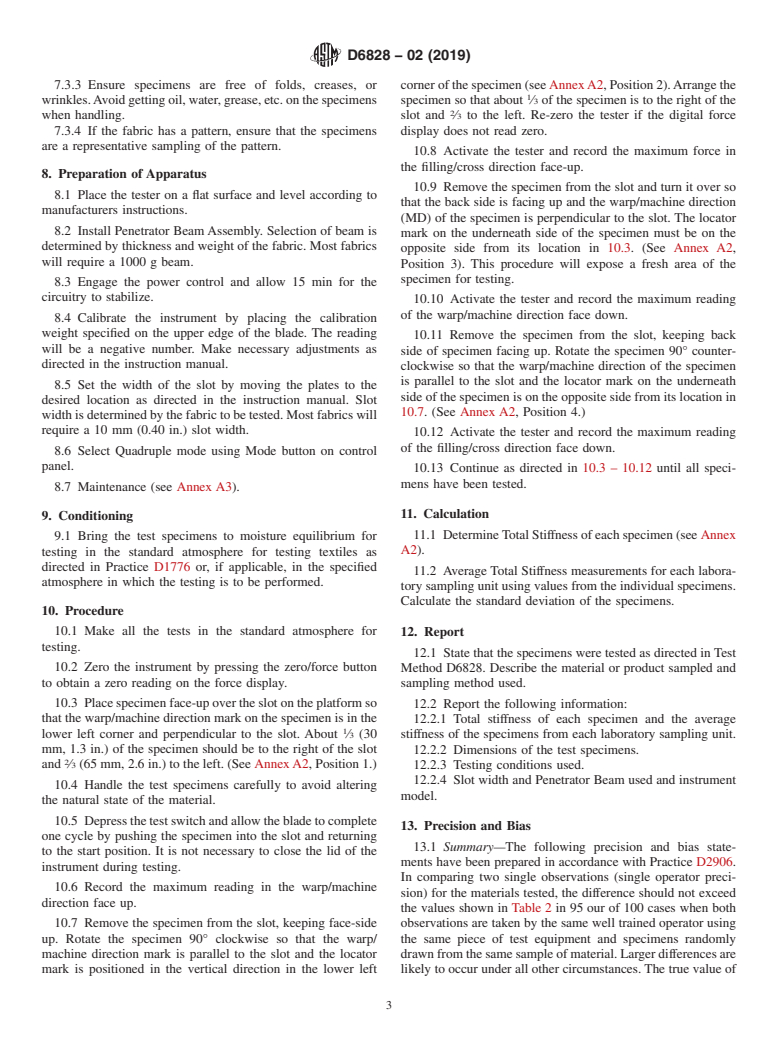

6.1 Handle-O-Meter Tester, (Fig. 1), having the following

parts:

7.3 Test Specimens—From each laboratory sampling unit,

6.1.1 SpecimenPlatform,consistingoftwoadjustableplates

take five specimens 100 by 100 6 2.5 mm (4 by 4 6 0.1 in.).

capable of forming an opening between the two plates.

Take specimens representing a broad distribution from differ-

6.1.2 Penetrating Blade, to force the fabric into the slot

ent positions diagonally across the width of the laboratory

between the plates.

sampling unit. Specimens should be staggered in such a

6.1.3 Penetrator Beam, to move the Penetrator Blade.

manner that no specimens contain the same yarns. With the

6.1.4 ForceMeasuringDevice,operatingatapredetermined

face of the specimen up, place a small locator mark in the

capacity, to measure the force required to force the fabric into

lower right hand corner of the specimen parallel to the

the slot.

warp/machine direction (MD). (See AnnexA2.) The mark will

6.1.5 Calibration Weight, for calibration of the force appro-

be used to correctly position the specimen prior to testing so

priate for the Penetrator Blade.

that the stiffness of four different areas of the specimen can be

determined. Label specimen to maintain identity.

7.3.1 For fabric widths 100 mm (4 in.) or more, take no

specimens closer than 25 mm (1 in) from the selvage edges of

5 the laboratory sampling unit.

The sole source of supply of the apparatus known to the committee at this time

7.3.2 For fabric widths less than 150 mm (4 in.), use the

is Thwing-Albert Instrument Co., Philadelphia, PA. If you are aware of alternative

suppliers, please provide this information to ASTM International Headquarters.

entire width of the laboratory sampling unit for specimens.

Your comments will receive careful consideration at a meeting of the responsible

technical committee , which you may attend.

FIG. 1 Handle-O-Meter Tester

D6828 − 02 (2019)

7.3.3 Ensure specimens are free of folds, creases, or cornerofthespecimen(seeAnnexA2,Position2).Arrangethe

wrinkles.Avoidgettingoil,water,grease,etc.onthespecimens specimen so that about ⁄3 of the specimen is to the right of the

when handling. slot and ⁄3 to the left. Re-zero the tester if the digital force

7.3.4 If the fabric has a pattern, ensure that the specimens display does not read zero.

are a representative sampling of the pattern.

10.8 Activate the tester and record the maximum force in

the filling/cross direction face-up.

8. Preparation of Apparatus

10.9 Remove the specimen from the slot and turn it over so

8.1 Place the tester on a flat surface and level according to

that the back side is facing up and the warp/machine direction

manufacturers instructions.

(MD) of the specimen is perpendicular to the slot. The locator

8.2 Install Penetrator BeamAssembly. Selection of beam is

mark on the underneath side of the specimen must be on the

determined by thickness and weight of the fabric. Most fabrics

opposite side from its location in 10.3. (See Annex A2,

will require a 1000 g beam.

Position 3). This procedure will expose a fresh area of the

specimen for testing.

8.3 Engage the power control and allow 15 min for the

circuitry to stabilize.

10.10 Activate the tester and record the maximum reading

of the warp/machine direction face down.

8.4 Calibrate the instrument by placing the calibration

weight specified on the upper edge of the blade. The reading

10.11 Remove the specimen from the slot, keeping back

will be a negative number. Make necessary adjustments as

side of specimen facing up. Rotate the specimen 90° counter-

directed in the instruction manual.

clockwise so that the warp/machine direction of the specimen

is parallel to the slot and the locator mark on the underneath

8.5 Set the width of the slot by moving the plates to the

side of the specimen is on the opposite side from its location in

desired location as directed in the instruction manual.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.