ASTM D7447-08(2023)

(Practice)Standard Practice for Symbolizing Adhesive Applications

Standard Practice for Symbolizing Adhesive Applications

SIGNIFICANCE AND USE

3.1 An adhesive symbol provides an efficient means of placing complete information about adhesives on engineering drawings. The joint is the basis of reference for the symbol to which the arrow line is pointed. The reference line of the symbol is used to designate the type of adhesive to be used, including information about its physical form, chemical technology family, requirements for surface preparation, application method (bead versus roll coat), and cure method. The optional tail (shown at left in Fig. 1) provides a place to include additional information about the adhesive that is not referenced in other notations.

FIG. 1 Standard Locations of Elements of the Adhesive Symbol

3.2 Refer to Fig. 1 for an overview schematic of the adhesive symbol denoted by a mast supporting a circle with the letter “A” inside for adhesive. Detail behind each of the elements noted (for example, FORM, CHEM, APPL METH) can be found in corresponding tables in Section 5.

SCOPE

1.1 This practice covers a standard symbol that may be used by the design-engineering community on engineering drawings to indicate a bonded assembly for any type of adhesive.

1.2 This design is based on criteria contained in ANSI/AWS A2.4 as well as ISO 15785.

1.3 The values given in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7447 − 08 (Reapproved 2023)

Standard Practice for

1

Symbolizing Adhesive Applications

This standard is issued under the fixed designation D7447; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope nology family, requirements for surface preparation, applica-

tion method (bead versus roll coat), and cure method. The

1.1 This practice covers a standard symbol that may be used

optionaltail(shownatleftinFig.1)providesaplacetoinclude

bythedesign-engineeringcommunityonengineeringdrawings

additional information about the adhesive that is not referenced

to indicate a bonded assembly for any type of adhesive.

in other notations.

1.2 This design is based on criteria contained inANSI/AWS

3.2 Refer to Fig. 1 for an overview schematic of the

A2.4 as well as ISO 15785.

adhesivesymboldenotedbyamastsupportingacirclewiththe

1.3 The values given in SI units are to be regarded as the

letter “A” inside for adhesive. Detail behind each of the

standard. The values in parentheses are for information only.

elements noted (for example, FORM, CHEM, APPL METH)

1.4 This standard does not purport to address all of the

can be found in corresponding tables in Section 5.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Elements of the Adhesive Symbol

priate safety, health, and environmental practices and deter-

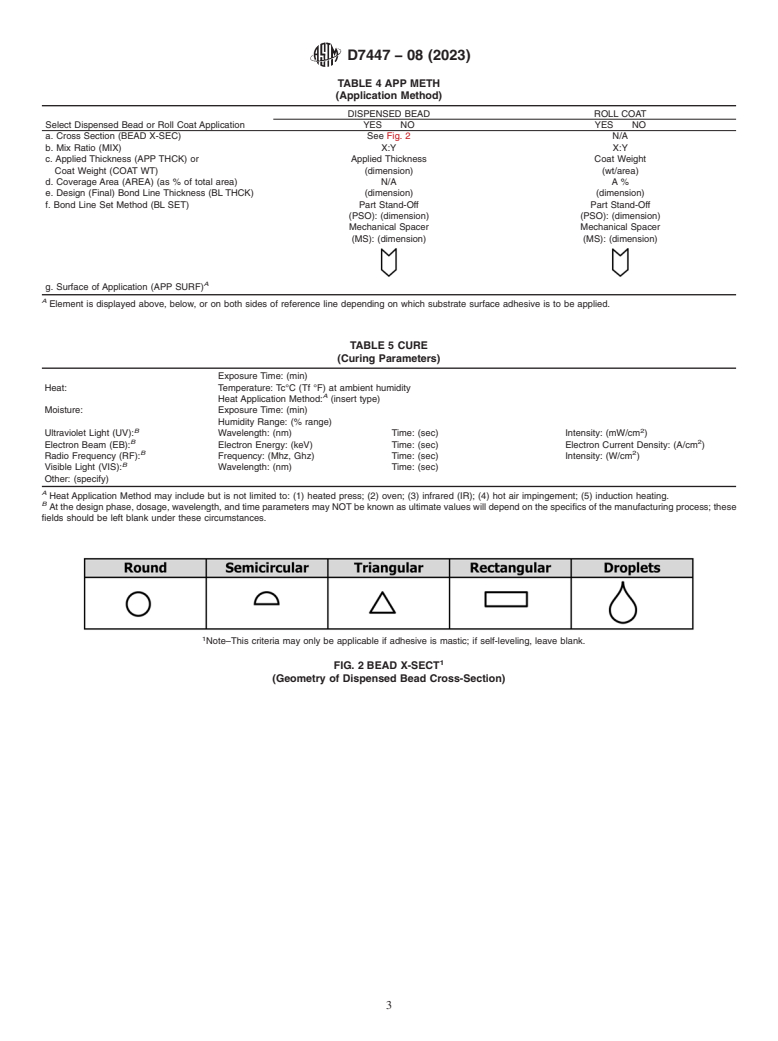

4.1 The elements represented in Fig. 1 are explained in

mine the applicability of regulatory limitations prior to use.

greater detail in Tables 1-5 and Fig. 2.

1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard-

4.2 Fig. 3 illustrates an expanded view of the parameters

ization established in the Decision on Principles for the

detailed in the tables described in Tables 1-5 and Fig. 2.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

5. References and Other Notations

Barriers to Trade (TBT) Committee.

5.1 Symbols With References—When specifications,

2. Referenced Documents

processes, or other references are used with the adhesive

2

symbol, the notation is placed in the tail (see “T” symbol in

2.1 ANSI/AWS Standard:

Fig. 1 or Fig. 3). This notation may reflect information about a

ANSI/AWS A2.4 Symbols for Welding and Nondestructive

particular manufacturer’s product or other pertinent data not

Testing

2

contained in the symbol elements.

2.2 ISO Standard:

ISO15785 TechnicalDrawings—SymbolicPresentationand

5.2 Symbols Without References—Symbols may be used

Indication of Adhesive, Fold and Pressed Joints

without specifications, processes, or other references when:

5.2.1 A note appears on the drawing: “Unless otherwise

3. Significance and Use

designated, all adhesive bonds are to be made in accordance

3.1 An adhesive symbol provides an efficient means of

with Specification No .”

placing complete information about adhesives on engineering

5.2.2 The bonding procedure to be used is described else-

drawings. The joint is the basis of reference for the symbol to

where such as in shop instructions and process sheets: “Refer

which the arrow line is pointed. The reference line of the

to Instruction for bonding procedure.”

symbol is used to designate the type of adhesive to be used,

5.3 OrientationofBondJoint—The horizontal orientation is

including information about its physical form, chemical tech-

default (“parallel line” element should be omitted) or the

element is present only when either inclined or vertical:

1

This practice is under the jurisdiction of ASTM Committee D14 on Adhesives

5.3.1 If vertical orientation, display lines as “| |” or

and is the direct responsibility of Subcommittee D14.60 on Adhesive Material

Classification System.

5.3.2 If inclined orientation, display lines as “//.”

Current edition approved Jan. 1, 2023. Published January 2023. Originally

approved in 2008. Last previous edition approved in 2014 as D7447 – 08 (2014).

5.4 Symbol Attachments to the Reference Line:

DOI: 10.1520/D7447-08R23.

2

5.4.1 Geometry of cross section of the dispensed bead style

Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. [BEAD X-SECT] and

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.