ASTM D4378-97

(Practice)Standard Practice for In-Service Monitoring of Mineral Turbine Oils for Steam and Gas Turbines

Standard Practice for In-Service Monitoring of Mineral Turbine Oils for Steam and Gas Turbines

SCOPE

1.1 This practice covers the requirements for the effective monitoring of mineral turbine oils in service in steam and gas turbines used for power generation. It includes sampling and testing schedules and recommended action steps, as well as information on how oils degrade.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4378 – 97 An American National Standard

Standard Practice for

In-Service Monitoring of Mineral Turbine Oils for Steam and

Gas Turbines

This standard is issued under the fixed designation D 4378; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The in-service monitoring of turbine oils has long been recognized by the power-generation industry

as being necessary to ensure long trouble-free operation of turbines.

The two main types of stationary turbines used for power generation are steam and gas turbines. The

lubrication requirements are quite similar but there are important differences in that gas turbine oils

are subjected to significantly higher localized “hot spot” temperatures and water contamination is less

likely. Steam turbine oils are normally expected to last for many years. In some turbines up to 20 years

of service life has been obtained. Gas turbine oils by comparison have a shorter service life. Many of

the monitoring tests used for steam turbine oils are applicable to gas turbine oils.

This practice is designed to assist the user to understand how oils deteriorate and to carry out a

meaningful program of sampling and testing of oils in use. Also covered are some important aspects

of interpretation of results and suggested action steps so as to maximize service life.

1. Scope by Potentiometric Titration

D 665 Test Method for Rust-Preventing Characteristics of

1.1 This practice covers the requirements for the effective

Inhibited Mineral Oil in the Presence of Water

monitoring of mineral turbine oils in service in steam and gas

D 892 Test Method for Foaming Characteristics of Lubri-

turbines used for power generation. It includes sampling and

cating Oils

testing schedules and recommended action steps, as well as

D 943 Test Method for Oxidation Characteristics of Inhib-

information on how oils degrade.

ited Mineral Oils

1.2 This standard does not purport to address all of the

D 974 Test Method for Acid and Base Number by Color-

safety concerns, if any, associated with its use. It is the

Indicator Titration

responsibility of the user of this standard to establish appro-

D 1401 Test Method for Water Separability of Petroleum

priate safety and health practices and determine the applica-

Oils and Synthetic Fluids

bility of regulatory limitations prior to use.

D 1500 Test Method for ASTM Color of Petroleum Prod-

2. Referenced Documents

ucts (ASTM Color Scale)

D 1533 Test Methods for Water in Insulating Liquids (Karl

2.1 ASTM Standards:

Fischer Reaction Method)

D 92 Test Method for Flash and Fire Points by Cleveland

D 1744 Test Method for Water in Liquid Petroleum Prod-

Open Cup

ucts by Karl Fischer Reagent

D 95 Test Method for Water in Petroleum Products and

D 2272 Test Method for Oxidation Stability of Steam Tur-

Bituminous Materials by Distillation

bine Oils by Rotating Bomb

D 130 Test Method for Detection of Copper Corrosion from

D 2422 Classification of Industrial Fluid Lubricants by

Petroleum Products by the Copper Strip Tarnish Test

Viscosity System

D 445 Test Method for Kinematic Viscosity of Transparent

D 4057 Practice for Manual Sampling of Petroleum and

and Opaque Liquids (and the Calculation of Dynamic

Petroleum Products

Viscosity)

D 4241 Practice for Design of Gas Turbine Generator Lu-

D 664 Test Method for Acid Number of Petroleum Products

bricating Oil Systems

D 4248 Practice for Design of Steam Turbine Generator Oil

This practice is under the jurisdiction of ASTM Committee D-2 on Petroleum 4

Systems

Products and Lubricantsand is the direct responsibility of Subcommittee D02.Con

Turbine Oils.

Current edition approved Apr. 10, 1997. Published October 1997. Originally

published as D 4378 – 84. Last previous edition D 4378 – 92. Annual Book of ASTM Standards, Vol 10.03.

2 4

Annual Book of ASTM Standards, Vol 05.01. Annual Book of ASTM Standards, Vol 05.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 4378

F 311 Practice for Processing Aerospace Liquid Samples for 5.1.2.1 The individual components of a lubrication system

Particulate Contamination Analysis Using Membrane Fil- are usually delivered on-site before the system is installed. The

ters length of on-site storage and means taken to preserve the

F 312 Methods for Microscopical Sizing and Counting integrity of the intended oil wetted surfaces will determine the

Particles from Aerospace Fluids on Membrane Filters total amount of contamination introduced during this period,

2.2 International Organization for Standardization: the magnitude of the task of cleaning and flushing prior to use,

and the detrimental effects of the contaminants. Guidance on

ISO 4406 Hydraulic Fluid Power-Fluids—Method for cod-

ing level of contamination by solid particles contamination control, flushing, and purification may be sought

from the equipment supplier or other industry experts.

2.3 Other Standard:

National Aerospace Standard 1638 5.1.2.2 Turbine oil system contamination prior to startup

usually consists of preservatives, paint, rust particles, and the

3. Significance and Use

various solids encountered during construction which can

range from dust and dirt to rags, bottles, and cans. Their effect

3.1 This practice is intended to assist the user, in particular

on turbine oil systems is obvious.

the power-plant operator, to maintain effective lubrication of

5.1.3 Original Oil Quality:

all parts of the turbine and guard against the onset of problems

associated with oil degradation and contamination. 5.1.3.1 Use of a high-quality oil is the best assurance of

potentially long service life. Oils meeting recognized standards

4. Properties of Turbine Oils

are generally available, and one that at least meets the

requirements of the turbine manufacturer shall be used.

4.1 Most turbine oils consist of a highly refined paraffinic

5.1.3.2 It is advisable to obtain typical test data from the oil

mineral oil compounded with oxidation and rust inhibitors.

supplier. Upon receipt of the first oil charge, a sample of oil

Depending upon the performance level desired, small amounts

should be taken to confirm the typical test data and to use as a

of other additives such as metal deactivators, pour depressants,

baseline for future comparisons with used oil information. This

extreme pressure additives, and foam suppressants can also be

is most important! Recommended tests for new oil are given in

present.

the schedules of this practice (see Table 1 and Table 2).

4.2 New turbine oils should exhibit good resistance to

oxidation, inhibit sludge formation, and provide adequate 5.1.3.3 When new turbine oil is to be mixed with a charge

antirust, water separability, and nonfoaming properties. How- of a different composition prior checks should be made to

ever, these properties cannot be expected to remain unchanged ensure no loss of expected properties due to incompatibility.

during the life of the oil. Some deterioration can be tolerated These should include functional tests and checks for formation

without prejudice to the safety or efficiency of the system. of insolubles.

Reinhibition may improve some properties of the oil. Good

5.1.4 System Operating Conditions:

monitoring procedures are necessary to determine when the

5.1.4.1 The most important factors affecting the anticipated

properties have changed sufficiently to warrant corrective

service life of a given lubricating oil in a given turbine system

action.

are the operating conditions within the system. Air (oxygen),

elevated temperatures, metals, and water are always present to

5. Operational Factors Affecting Service Life

some extent in these oil systems. These elements promote oil

5.1 The factors that affect the service life of turbine lubri-

degradation.

cating oils are as follows: (1) type and design of system, (2)

5.1.4.2 Most turbine oil systems are provided with oil

condition of system on startup, (3) original oil quality, (4)

coolers to control temperature. In many cases, bulk oil tem-

system operating conditions, (5) contamination, and (6) oil

peratures are maintained so low [below 60°C (140°F)] that

makeup rate.

moisture condensation can occur. Even with low bulk oil

5.1.1 Type and Design of System—Most modern turbine

temperatures, however, there can be localized hot spots such as

lubricating systems are similar in design, especially for the

in bearings, at gas seals, and in throttle control mechanisms

larger units. For lubrication, the usual practice is to pressure-

that can cause oil degradation and eventually cause system oil

feed oil directly from the main oil pump. The rest of the system

to show signs of deterioration.

consists of a reservoir, oil cooler, strainer, piping and additional

5.1.4.3 Under the higher temperature conditions which are

purification or filtration equipment, or a combination thereof.

present in gas and steam turbines, oxidation of the oil can be

Miscellaneous control and indicating equipment completes the

accelerated by thermal-oxidative cracking leading to the pro-

system. If there is an opportunity to participate in system

duction of viscous resins and deposits particularly at the point

design, it is recommended that appropriate practices be con-

of initiation.

sulted (see Practice D 4241 and Practice D 4248).

5.1.5 Contamination:

5.1.2 Condition of System on Start-up:

5.1.5.1 Contamination of turbine oils occurs both from

outside the system and from within due to oil degradation and

moisture condensation or leaks. Development of a clean

Annual Book of ASTM Standards, Vol 14.02.

turbine oil system on start-up or following maintenance is

Available from American National Standards Institute, 11 W. 42nd St., 13th

essential. Once attained, the danger of external contamination

Floor, New York, NY 10036.

is less but should be guarded against. The oil can be contami-

Available from Aerospace Industries Association of America, Inc., 1725 De

Sales St., N.W., Washington, DC. nated by the introduction of different type oils which are of the

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 4378

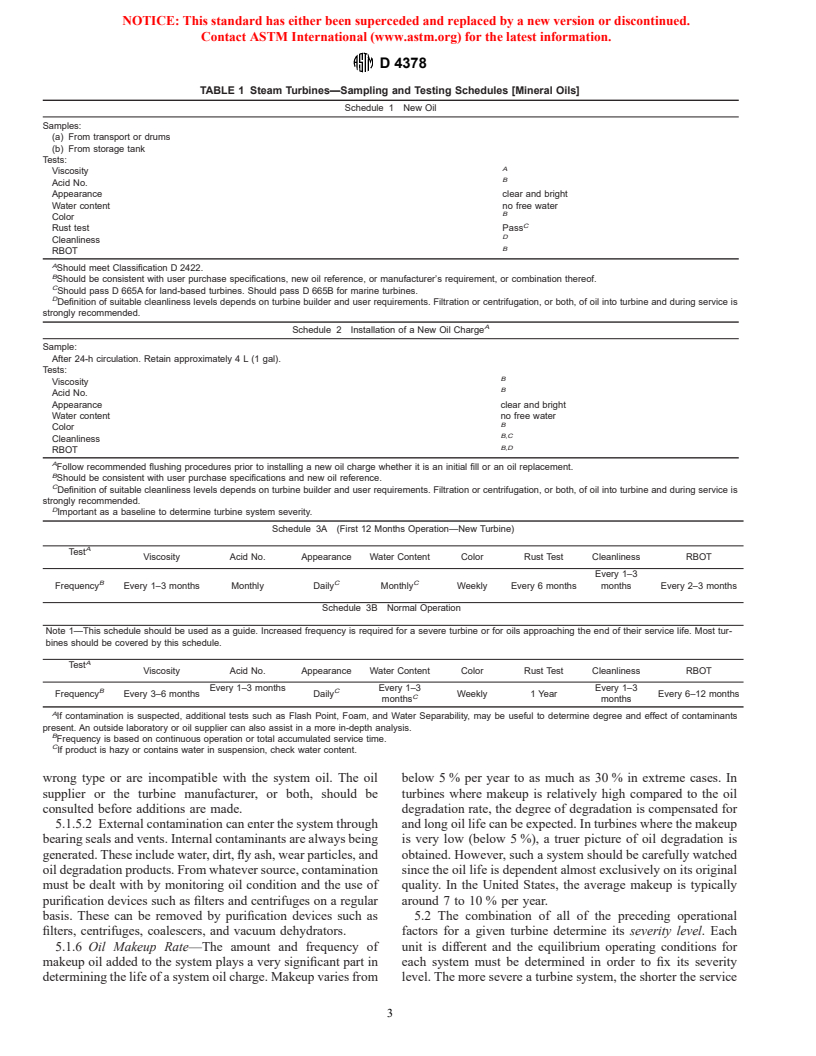

TABLE 1 Steam Turbines—Sampling and Testing Schedules [Mineral Oils]

Schedule 1 New Oil

Samples:

(a) From transport or drums

(b) From storage tank

Tests:

A

Viscosity

B

Acid No.

Appearance clear and bright

Water content no free water

B

Color

C

Rust test Pass

D

Cleanliness

B

RBOT

A

Should meet Classification D 2422.

B

Should be consistent with user purchase specifications, new oil reference, or manufacturer’s requirement, or combination thereof.

C

Should pass D 665A for land-based turbines. Should pass D 665B for marine turbines.

D

Definition of suitable cleanliness levels depends on turbine builder and user requirements. Filtration or centrifugation, or both, of oil into turbine and during service is

strongly recommended.

A

Schedule 2 Installation of a New Oil Charge

Sample:

After 24-h circulation. Retain approximately 4 L (1 gal).

Tests:

B

Viscosity

B

Acid No.

Appearance clear and bright

Water content no free water

B

Color

B,C

Cleanliness

B,D

RBOT

A

Follow recommended flushing procedures prior to installing a new oil charge whether it is an initial fill or an oil replacement.

B

Should be consistent with user purchase specifications and new oil reference.

C

Definition of suitable cleanliness levels depends on turbine builder and user requirements. Filtration or centrifugation, or both, of oil into turbine and during service is

strongly recommended.

D

Important as a baseline to determine turbine system severity.

Schedule 3A (First 12 Months Operation—New Turbine)

A

Test

Viscosity Acid No. Appearance Water Content Color Rust Test Cleanliness RBOT

Every 1–3

B C C

Frequency Every 1–3 months Monthly Daily Monthly Weekly Every 6 months months Every 2–3 months

Schedule 3B Normal Operation

Note 1—This schedule should be used as a guide. Increased frequency is required for a severe turbine or for oils approaching the end of their service life. Most tur-

bines should be covered by this schedule.

A

Test

Viscosity Acid No. Appearance Water Content Color Rust Test Cleanliness RBOT

Every 1–3 months Every 1–3 Every 1–3

B C

Frequency Every 3–6 months Daily Weekly 1 Year Every 6–12 months

C

months months

A

If contamination is suspected, additional tests such as Flash Point, Foam, and Water Separability, may be useful to determine degree and effect of contaminants

present. An outside laboratory or oil supplier can also assist in a more in-depth analysis.

B

Frequency is based on continuous operation or total accumulated service time.

C

If product is hazy or contains water in suspension, check water content.

wrong type or are incompatible with the system oil. The oil below 5 % per year to as much as 30 % in extreme cases. In

supplier or the turbine manufacturer, or both, should be turbines where makeup is relatively high compared to the oil

consulted before additions are made. degradation rate, the degree of degradation is compensated for

5.1.5.2 External contamination can enter the system through and long oil life can be expected. In turbines where the makeup

bearing seals and vents. Internal contaminants are always being is very low (below 5 %), a truer picture of oil degradation is

generated. These include water, dirt, fly ash, wear particles, and obtained. However, such a system should be carefully watched

oil degradation products. From whatever source, contamination since the oil life is dependent almost exclusively on its original

must be dealt with by monitoring oil condition and the use of quality. In the United States, the average makeup is typically

purification devices such as filters and centrifuges on a regular around 7 to 10 % per year.

basis. These can be removed by purification devices such as 5.2 The combination of all of the preceding operational

filters, centrifuges, coalescers, and vacuum dehydrators. factors for a given turbine determine its severity level. Each

5.1.6 Oil Makeup Rate—The amount and frequency of unit is different and the equilibrium operating conditions for

makeup oil added to the system plays a very significant part in each system must be determined in order to fix its severity

det

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.