ASTM C469-02

(Test Method)Standard Test Method for Static Modulus of Elasticity and Poisson's Ratio of Concrete in Compression

Standard Test Method for Static Modulus of Elasticity and Poisson's Ratio of Concrete in Compression

SCOPE

1.1 This test method covers determination of (1) chord modulus of elasticity (Young's) and ( 2) Poisson's ratio of molded concrete cylinders and diamond-drilled concrete cores when under longitudinal compressive stress. Chord modulus of elasticity and Poisson's ratio are defined in Terminology E 6.

1.2 The values stated in inch-pound units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C469–02

Standard Test Method for

Static Modulus of Elasticity and Poisson’s Ratio of Concrete

1

in Compression

This standard is issued under the fixed designation C 469; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Significance and Use

1.1 This test method covers determination of (1) chord 3.1 This test method provides a stress to strain ratio value

modulus of elasticity (Young’s) and (2) Poisson’s ratio of and a ratio of lateral to longitudinal strain for hardened

molded concrete cylinders and diamond-drilled concrete cores concrete at whatever age and curing conditions may be

when under longitudinal compressive stress. Chord modulus of designated.

elasticity and Poisson’s ratio are defined in Terminology E 6. 3.2 The modulus of elasticity and Poisson’s ratio values,

1.2 The values stated in inch-pound units are to be regarded applicable within the customary working stress range (0 to

as the standard. 40 % of ultimate concrete strength), are used in sizing of

1.3 This standard does not purport to address all of the reinforced and nonreinforced structural members, establishing

safety concerns, if any, associated with its use. It is the the quantity of reinforcement, and computing stress for ob-

responsibility of the user of this standard to establish appro- served strains.

priate safety and health practices and determine the applica- 3.3 The modulus of elasticity values obtained will usually

bility of regulatory limitations prior to use. be less than moduli derived under rapid load application

(dynamic or seismic rates, for example), and will usually be

2. Referenced Documents

greater than values under slow load application or extended

2.1 ASTM Standards: load duration, given other test conditions being the same.

C 31/C 31M Practice for Making and Curing Concrete Test

2

4. Apparatus

Specimens in the Field

C 39/C 39M Test Method for Compressive Strength of Cy- 4.1 Testing Machine—Use a testing machine capable of

2

lindrical Concrete Specimens imposing a load at the rate and of the magnitude prescribed in

C 42/C 42M Test Method for Obtaining and Testing Drilled 6.4. The machine shall conform to the requirements of Prac-

2

Cores and Sawed Beams of Concrete tices E 4 (Constant-Rate of-Traverse CRT-Type Testing Ma-

C 174/C 174M Test Method for Measuring Thickness of chines section). The spherical head and bearing blocks shall

2

Concrete Elements Using Drilled Concrete Cores conform to theApparatus Section ofTest Method C 39/C 39M.

5

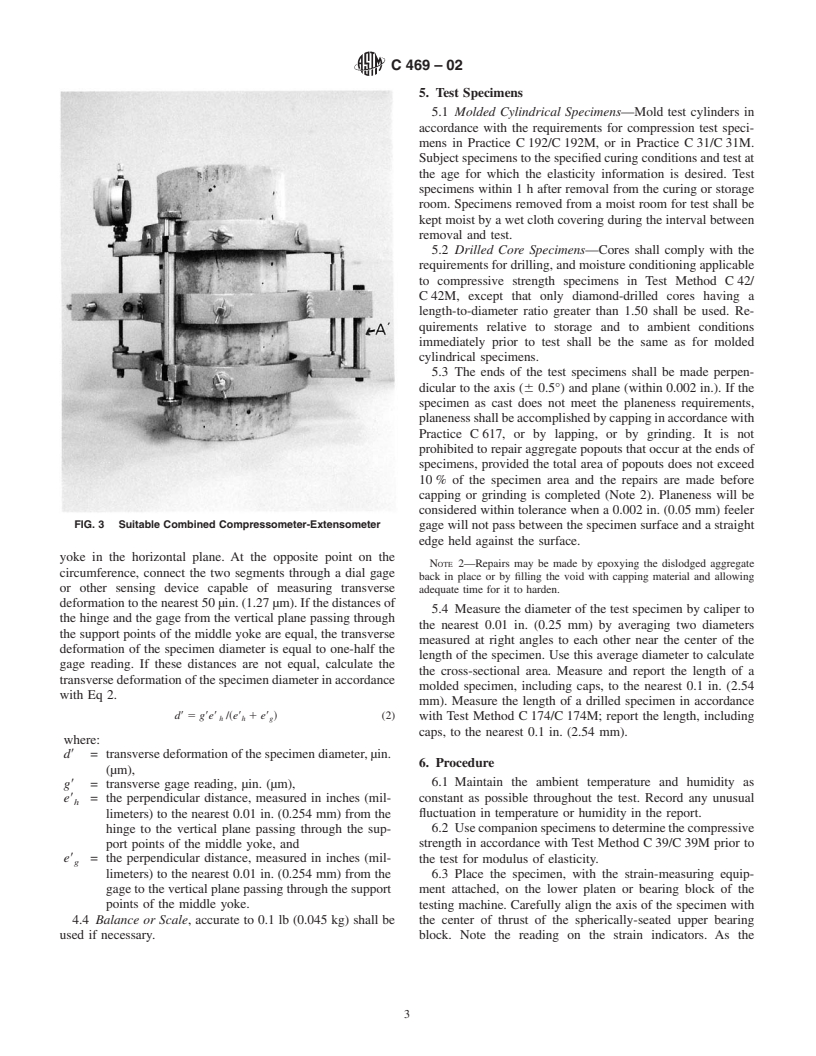

C 192/C 192M Practice for Making and Curing Concrete 4.2 Compressometer —For determining the modulus of

2

Test Specimens in the Laboratory elasticity use a bonded (Note 1) or unbonded sensing device

C 617 Practice for Capping Cylindrical Concrete Speci- that measures to the nearest 5 millionths the average deforma-

2

mens tion of two diametrically opposite gage lines, each parallel to

3

E 4 Practices for Force Verification of Testing Machines the axis, and each centered about midheight of the specimen.

E 6 Terminology Relating to Methods of Mechanical Test- The effective length of each gage line shall be not less than

3

ing three times the maximum size of the aggregate in the concrete

E 83 Practice for Verification and Classification of Exten- nor more than two thirds the height of the specimen; the

3

someter preferred length of the gage line is one half the height of the

E 177 Practice for Use of the Terms Precision and Bias in specimen. Either use gage points embedded in or cemented to

4

ASTM Test Methods the specimen, and read deformation of the two lines indepen-

dently; or use a compressometer (such as is shown in Fig. 1)

consisting of two yokes, one of which (see B, Fig. 1) is rigidly

1

This test method is under the jurisdiction of ASTM Committee C09 on

attached to the specimen and the other (see C, Fig. 1) attached

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee

at two diametrically opposite points so that it is free to rotate.

C09.61 on Testing for Strength.

Current edition approved Aug. 10, 2002. Published October 2002. Originally

e1

published as C469 – 61. Last previous edition C469 – 94 .

2 5

Annual Book of ASTM Standards, Vol 04.02. Copies of working drawings of strain measuring apparatus are available from

3

Annual Book of ASTM Standards, Vol 03.01. ASTM International Headquarters, 100 Barr Harbor Drive,West Conshohocken, PA

4

Annual Book of ASTM Standards, Vol 14.02. 19428. Request adjunct No. ADJC0469.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, Uni

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.