ASTM B618-99

(Specification)Standard Specification for Aluminum-Alloy Investment Castings

Standard Specification for Aluminum-Alloy Investment Castings

SCOPE

1.1 This specification covers aluminum-alloy investment castings designated as shown in Table 1.

1.2 Alloy and temper designations are in accordance with ANSI H35.1. The equivalent Unified Numbering System alloy designations are in accordance with Practice E527.

1.3 For acceptance criteria for inclusion of new aluminum and aluminum alloys in this specification, see Annex A1 and Annex A2.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 618 – 99

Standard Specification for

Aluminum-Alloy Investment Castings

This standard is issued under the fixed designation B 618; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope E 165 Test Method for Liquid Penetrant Examination

E 227 Test Method for Optical Emission Spectrometric

1.1 This specification covers aluminum-alloy investment

Analysis of Aluminum and Aluminum Alloys by the

castings designated as shown in Table 1.

Point-to-Plane Technique

1.2 Alloy and temper designations are in accordance with

E 527 Practice for Numbering Metals and Alloys (UNS)

ANSI H35.1. The equivalent Unified Numbering System alloy

E 607 Test Method for Optical Emission Spectrometric

designations are in accordance with Practice E 527.

Analysis of Aluminum and Aluminum Alloys by the

1.3 For acceptance criteria for inclusion of new aluminum

Point-to-Plane Technique, Nitrogen Atmosphere

and aluminum alloys and their properties in this specification,

E 716 Practices for Sampling Aluminum and Aluminum

see Annex A1 and Annex A2.

Alloys for Spectrochemical Analysis

1.4 The values stated in inch-pound units are to be regarded

E 1251 Test Method for Optical Emission Spectrometric

as the standard. The values given in parentheses are for

Analysis of Aluminum and Aluminum Alloys by the Argon

information only.

Atmosphere, Point-to-Plane, Unipolar Self-Initiating Ca-

2. Referenced Documents pacitor Discharge

IEEE/ASTM SI 10 Standard for Use of the International

2.1 The following documents of the issue in effect on the

System of Units (SI): The Modern Metric System

date of purchase form a part of this specification to the extent

2.3 ANSI Standard:

referenced herein:

H35.1 Alloy and Temper Designation Systems for Alumi-

2.2 ASTM Standards:

num

B 179 Specification for Aluminum Alloys in Ingot Form for

2.4 Military Standard:

Castings from all Casting Processes

MIL-STD-129 Marking for Shipment and Storage

B 275 Practice for Codification of Certain Nonferrous Met-

2.5 Federal Standard:

als and Alloys, Cast and Wrought

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

B 557 Test Methods for Tension Testing Wrought and Cast

Aluminum- and Magnesium-Alloy Products

3. Terminology

B 597 Practice for Heat Treatment of Aluminum Alloys

3.1 Definition:

B 660 Practices for Packaging/Packing of Aluminum and

3.1.1 investment casting—a metal object produced by sur-

Magnesium Products

rounding (investing) an expendable pattern (usually wax or

E 29 Practice for Using Significant Digits in Test Data to

plastic) with a refractory slurry that sets at room temperature,

Determine Conformance with Specifications

after which the pattern is removed through the use of heat, and

E 34 Test Methods for Chemical Analysis of Aluminum and

then filling the resulting cavity with molten metal and allowing

Aluminum-Base Alloys

it to solidify.

E 88 Practice for Sampling Nonferrous Metals and Alloys

in Cast Form for Determination of Chemical Composition

4. Ordering Information

E 94 Guide for Radiographic Testing

4.1 Orders for material under this specification shall include

E 155 Reference Radiographs for Inspection of Aluminum

5 the following information:

and Magnesium Castings

4.1.1 This specification designation (which includes the

number, the year, and the revision letter, if applicable),

This specification is under the jurisdiction of ASTM Committee B-7 on Light

4.1.2 Alloy (Section 7 and Table 1),

Metals and Alloys and is the direct responsibility of Subcommittee B07.01 on

Aluminum Alloy Ingots and Castings. 4.1.3 Temper (Section 10 and Table 2),

Current edition approved May 10, 1999. Published July 1999. Originally

published as B 618 – 77. Last previous edition B 618 – 98.

2 6

Annual Book of ASTM Standards, Vol 02.02. Annual Book of ASTM Standards, Vol 01.01.

3 7

Annual Book of ASTM Standards, Vol 14.02. Annual Book of ASTM Standards, Vol 03.06.

4 8

Annual Book of ASTM Standards, Vol 03.05. Available from the Standardization Documents Order Desk, Bldg. 4, Section D,

Annual Book of ASTM Standards, Vol 03.03. 700 Robbins Ave., Philadelphia, PA 19111-5094. Attn: NPODS.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

B 618

TABLE 1 Chemical Composition Requirements

NOTE 1—When single units are shown, these indicate the maximum amounts permitted.

NOTE 2—Analysis shall be made for the elements for which limits are shown in this table.

NOTE 3—The following applies to all specified limits in this table: For purposes of acceptance and rejection, an observed value or a calculated value

obtained from analysis should be rounded off to the nearest unit in the last right-hand place of figures used in expressing the specified limit (Practice E 29).

Alloy Composition, %

B

Other

Man- Mag- Chro- Titan-

A Elements

ANSI UNS Aluminum Silicon Iron Copper Nickel Zinc Tin

ganese nesium mium ium

C

Each Total

D

201.0 A02010 remainder 0.10 0.15 4.0–5.2 0.20–0.50 0.15–0.55 . . . . 0.15–0.35 0.05 0.10

204.0 A02040 remainder 0.20 0.35 4.2–5.0 0.10 0.15–0.35 . 0.05 0.10 0.05 0.15–0.30 0.05 0.15

208.0 A02080 remainder 2.5–3.5 1.2 3.5–4.5 0.50 0.10 . 0.35 1.0 . 0.25 . 0.50

222.0 A02220 remainder 2.0 1.5 9.2–10.7 0.50 0.15–0.35 . 0.50 0.8 . 0.25 . 0.35

242.0 A02420 remainder 0.7 1.0 3.5–4.5 0.35 1.2–1.8 0.25 1.7–2.3 0.35 . 0.25 0.05 0.15

295.0 A02950 remainder 0.7–1.5 1.0 4.0–5.0 0.35 0.03 . . 0.35 . 0.25 0.05 0.15

319.0 A03190 remainder 5.5–6.5 1.0 3.0–4.0 0.50 0.10 . 0.35 1.0 . 0.25 . 0.50

328.0 A03280 remainder 7.5–8.5 1.0 1.0–2.0 0.20–0.6 0.20–0.6 0.35 0.25 1.5 . 0.25 . 0.50

E E

355.0 A03550 remainder 4.5–5.5 0.6 1.0–1.5 0.50 0.40–0.6 0.25 . 0.35 . 0.25 0.05 0.15

C355.0 A33550 remainder 4.5–5.5 0.20 1.0–1.5 0.10 0.40–0.6 . . 0.10 . 0.20 0.05 0.15

E E

356.0 A03560 remainder 6.5–7.5 0.6 0.25 0.35 0.20–0.45 . . 0.35 . 0.25 0.05 0.15

A356.0 A13560 remainder 6.5–7.6 0.20 0.20 0.10 0.25–0.45 . . 0.10 . 0.20 0.05 0.15

443.0 A04430 remainder 4.5–6.0 0.8 0.6 0.50 0.05 0.25 . 0.50 . 0.25 . 0.35

B443.0 A24430 remainder 4.5–6.0 0.8 0.15 0.35 0.05 . . 0.35 . 0.25 0.05 0.15

514.0 A05140 remainder 0.35 0.50 0.15 0.35 3.5–4.5 . . 0.15 . 0.25 0.05 0.15

520.0 A05200 remainder 0.25 0.30 0.25 0.15 9.5–10.6 . . 0.15 . 0.25 0.05 0.15

F

535.0 A05350 remainder 0.15 0.15 0.05 0.10–0.25 6.2–7.5 . . . . 0.10–0.25 0.05 0.15

705.0 A07050 remainder 0.20 0.8 0.20 0.40–0.6 1.4–1.8 0.20–0.40 . 2.7–3.3 . 0.25 0.05 0.15

707.0 A07070 remainder 0.20 0.8 0.20 0.40–0.6 1.8–2.4 0.20–0.40 . 4.0–4.5 . 0.25 0.05 0.15

G

710.0 A07100 remainder 0.15 0.50 0.35–0.65 0.05 0.6–0.8 . . 6.0–7.0 . 0.25 0.05 0.15

G

712.0 A07120 remainder 0.30 0.50 0.25 0.10 0.50–0.65 0.40–0.6 . 5.0–6.5 . 0.15–0.25 0.05 0.20

713.0 A07130 remainder 0.25 1.1 0.40–1.0 0.6 0.20–0.50 0.35 0.15 7.0–8.0 . 0.25 0.10 0.25

771.0 A07710 remainder 0.15 0.15 0.10 0.10 0.8–1.0 0.06–0.20 . 6.5–7.5 . 0.10–0.20 0.05 0.15

850.0 A08500 remainder 0.7 0.7 0.7–1.3 0.10 0.10 . 0.7–1.3 . 5.5–7.0 0.20 . 0.30

G

851.0 A08510 remainder 2.0–3.0 0.7 0.7–1.3 0.10 0.10 . 0.3–0.7 . 5.5–7.0 0.20 . 0.30

G

A08520 remainder 0.40 0.7 1.7–2.3 0.10 0.6–0.9 . 0.9–1.5 . 5.5–7.0 0.20 . 0.30

852.0

A

ASTM alloy designations are in Practice B 275.

B

“Others” includes listed elements for which no specific limit is shown as well as unlisted metallic elements. The producer may analyze samples for trace elements not

specified in the specification. However, such analysis is not required and may not cover all metallic “Others” elements. Should any analysis by the producer or the purchaser

establish that an “Others” element exceeds the limit of “Each” or that the aggregate of several “Others” elements exceeds the limit of “Total,” the material shall be considered

nonconforming.

C

Other Elements—Total shall be the sum of unspecified metallic elements 0.010 % or more, rounded to the second decimal before determining the sum.

D

Contains silver 0.40–1.0 %.

E

If iron exceeds 0.45 %, manganese content shall not be less than one half of the iron content.

F

Contains beryllium 0.003–0.007 %, boron 0.002 % max.

G

710.0 formerly A712.0, 712.0 formerly D712.0, 851.0 formerly A850.0, 852.0 formerly B850.0.

4.1.4 Applicable drawing or part number, 4.2.8 Whether certification of chemical analysis and tensile

4.1.5 The quantity in either pieces or pounds. properties is required (see 20.1),

4.2 Additionally, orders for material to this specification 4.2.9 Whether the material shall be packaged or marked, or

shall include the following information when required by the both, in accordance with Practices B 660, MIL-STD-129, and

purchaser: Fed. Std. No. 123 (see 22.3).

4.2.1 Whether castings or test specimens or both may be

5. Responsibility for Quality Assurance

supplied in the artificially aged—T5 temper for alloys 705.0,

707.0, D712.0, and 713.0 (see 10.2), 5.1 Responsibility for Inspection and Tests—Unless other-

4.2.2 Whether test specimens cut from castings are required wise specified in the contract or purchase order, the producer

in addition to or instead of separately cast specimens (see 10.3 shall be responsible for the performance of all inspection and

and 11.2), test requirements specified herein. Except as otherwise speci-

4.2.3 Whether repairs are permissible (see 17.1), fied in the contract or order, the producer may use his own or

4.2.4 Whether inspection is required at the producer’s any other suitable facilities for the performance of the inspec-

works (see 18.1), tion and test requirements specified herein, unless disapproved

4.2.5 Whether surface requirements shall be checked by the purchaser. The purchaser shall have the right to perform

against observational standards where such standards are any of the inspections and tests set forth in this specification

established (see 18.2), where such inspections are deemed necessary to confirm that

4.2.6 Whether liquid penetrant inspection is required (see material conforms to prescribed requirements.

18.4),

6. Materials and Manufacture

4.2.7 Whether radiographic inspection is required (see

18.5), 6.1 The responsibility of furnishing castings that can be laid

B 618

A

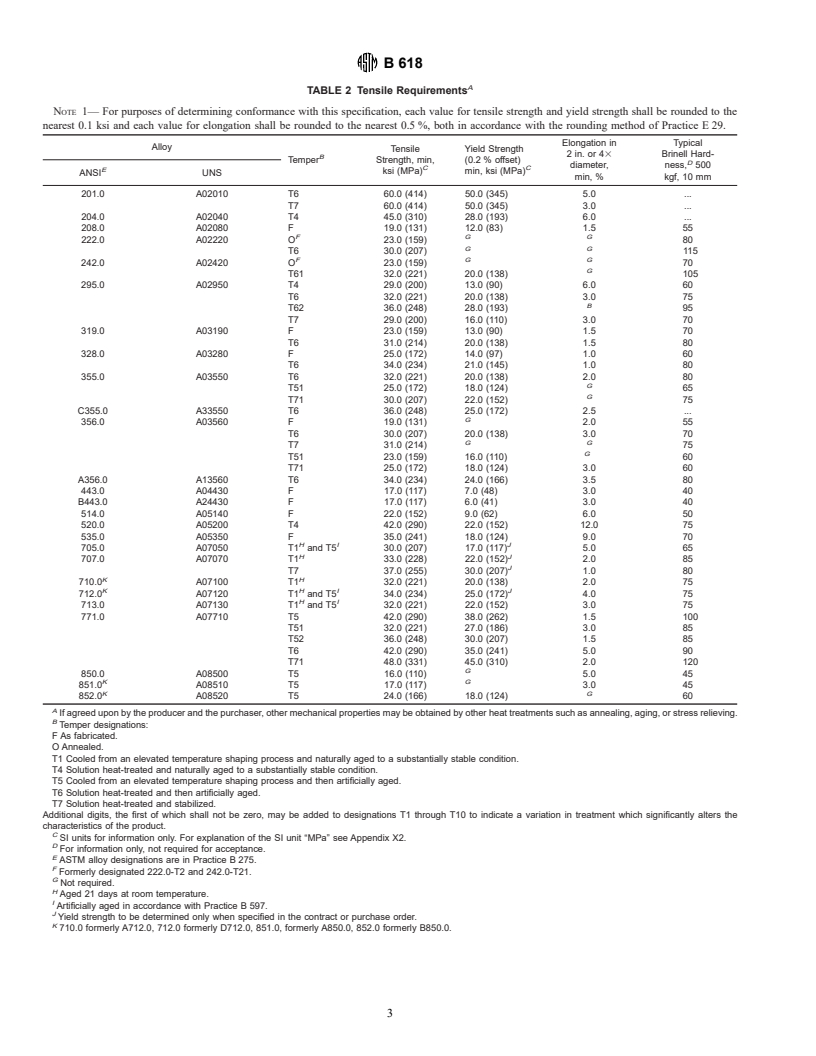

TABLE 2 Tensile Requirements

NOTE 1— For purposes of determining conformance with this specification, each value for tensile strength and yield strength shall be rounded to the

nearest 0.1 ksi and each value for elongation shall be rounded to the nearest 0.5 %, both in accordance with the rounding method of Practice E 29.

Elongation in Typical

Alloy

Tensile Yield Strength

2 in. or 43 Brinell Hard-

B

Temper Strength, min, (0.2 % offset)

D

diameter, ness, 500

C C

E

ksi (MPa) min, ksi (MPa)

ANSI UNS

min, % kgf, 10 mm

201.0 A02010 T6 60.0 (414) 50.0 (345) 5.0 .

T7 60.0 (414) 50.0 (345) 3.0 .

204.0 A02040 T4 45.0 (310) 28.0 (193) 6.0 .

208.0 A02080 F 19.0 (131) 12.0 (83) 1.5 55

F GG

222.0 A02220 O 23.0 (159) 80

GG

T6 30.0 (207) 115

F GG

242.0 A02420 O 23.0 (159) 70

G

T61 32.0 (221) 20.0 (138) 105

295.0 A02950 T4 29.0 (200) 13.0 (90) 6.0 60

T6 32.0 (221) 20.0 (138) 3.0 75

B

T62 36.0 (248) 28.0 (193) 95

T7 29.0 (200) 16.0 (110) 3.0 70

319.0 A03190 F 23.0 (159) 13.0 (90) 1.5 70

T6 31.0 (214) 20.0 (138) 1.5 80

328.0 A03280 F 25.0 (172) 14.0 (97) 1.0 60

T6 34.0 (234) 21.0 (145) 1.0 80

355.0 A03550 T6 32.0 (221) 20.0 (138) 2.0 80

G

T51 25.0 (172) 18.0 (124) 65

G

T71 30.0 (207) 22.0 (152) 75

C355.0 A33550 T6 36.0 (248) 25.0 (172) 2.5 .

G

356.0 A03560 F 19.0 (131) 2.0 55

T6 30.0 (207) 20.0 (138) 3.0 70

GG

T7 31.0 (214) 75

G

T51 23.0 (159) 16.0 (110) 60

T71 25.0 (172) 18.0 (124) 3.0 60

A356.0 A13560 T6 34.0 (234) 24.0 (166) 3.5 80

443.0 A04430 F 17.0 (117) 7.0 (48) 3.0 40

B443.0 A24430 F 17.0 (117) 6.0 (41) 3.0 40

514.0 A05140 F 22.0 (152) 9.0 (62) 6.0 50

520.0 A05200 T4 42.0 (290) 22.0 (152) 12.0 75

535.0 A05350 F 35.0 (241) 18.0 (124) 9.0 70

H I J

705.0 A07050 T1 and T5 30.0 (207) 17.0 (117) 5.0 65

H J

707.0 A07070 T1 33.0 (228) 22.0 (152) 2.0 85

J

T7 37.0 (255) 30.0 (207) 1.0 80

K H

710.0 A07100 T1 32.0 (221) 20.0 (138) 2.0 75

K H I J

712.0 A07120 T1 and T5 34.0 (234) 25.0 (172) 4.0 75

H I

713.0 A07130 T1 and T5 32.0 (221) 22.0 (152) 3.0 75

771.0 A07710 T5 42.0 (290) 38.0 (262) 1.5 100

T51 32.0 (221) 27.0 (186) 3.0 85

T52 36.0 (248) 30.0 (207) 1.5 85

T6 42.0 (290) 35.0 (241) 5.0 90

T71 48.0 (331) 45.0 (310) 2.0 120

G

850.0 A08500 T5 16.0 (110) 5.0 45

K G

851.0 A08510 T5 17.0 (117) 3.0 45

K G

852.0 A08520 T5 24.0 (166) 18.0 (124) 60

A

If agreed upon by the producer and the purchaser, other mechanical properties may be obtained by other heat treatments such as annealing, aging, or stress relieving.

B

Temper designations:

F As fabricated.

O Annealed.

T1 Cooled from an elevated temperature shaping process and naturally aged to a substantially stable condition.

T4 Solution heat-treated and naturally aged to a substantially stable condition.

T5 Cooled from an elevated temperature shaping process and then artificially aged.

T6 Solution heat-treated and then artificially aged.

T7 Solution heat-treated and stabilized.

Additional digits, the first of which shall not be zero, may be added to designations T1 through T10 to indicate a variation in treatment which significantly alters the

characteristics of the product.

C

SI units for information only. For explanation of the SI unit “MPa” see Appendix X2.

D

For information only, not required for acceptance.

E

ASTM alloy designations are in Practice B 275.

F

Formerly designated 222.0-T2 and 242.0-T21.

G

Not required.

H

Aged 21 days at room temperature.

I

Artificially aged in accordance with Practice B 597.

J

Yield strength to be determined only when specified in the contract or purchase order.

K

710.0 formerly A712.0, 712.0 formerly D712.0, 851.0, formerly A850.0, 852.0 formerly B850.0.

B 618

out and machined to the finished dimensions within the tative of the material in accordance with Practice E 88. The

permissible variations specified, as shown on the blueprints or weight of a prepared sample shall be not less than 75 g.

drawings, shall rest with the producer, except where pattern 8.2.2 Samples for Spectrochemical and Other Methods of

equipment is furnished by the purchaser. Analysis—Sampling for spectrochemical analysis shall be in

6.1.1 Unless otherwise specified, only aluminum alloy con- accordance with Practice

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.