ASTM E1317-08

(Test Method)Standard Test Method for Flammability of Marine Surface Finishes

Standard Test Method for Flammability of Marine Surface Finishes

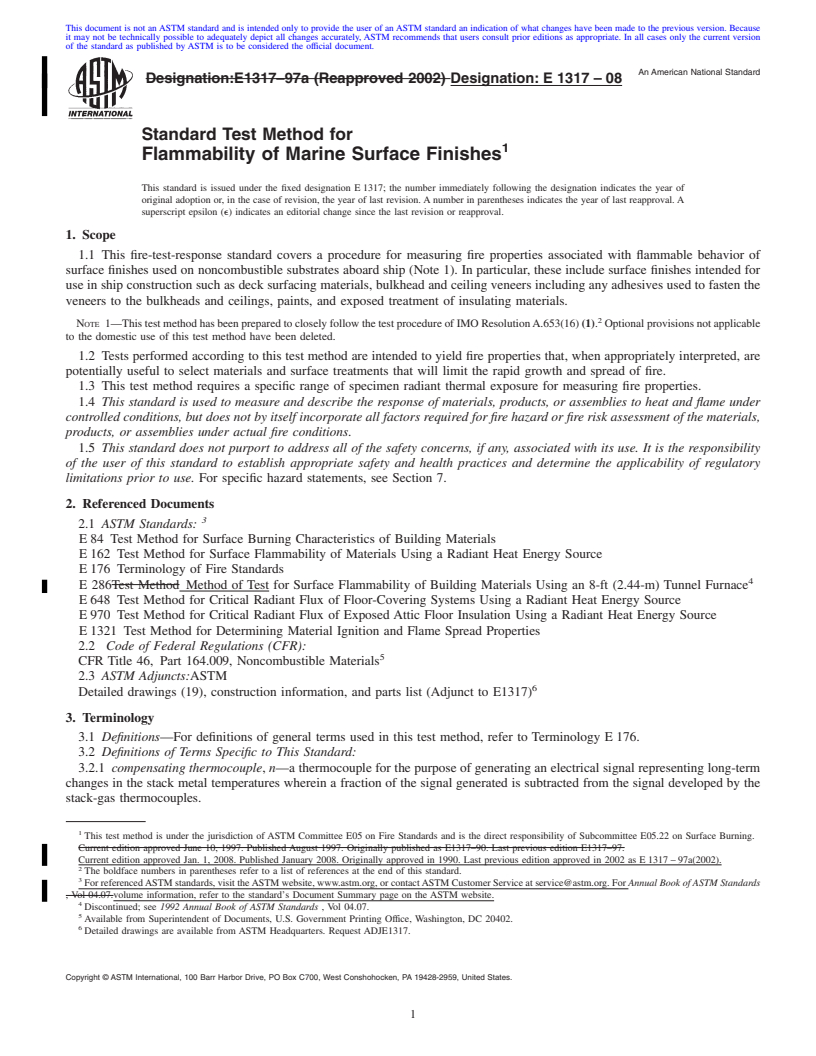

SIGNIFICANCE AND USE

This test method provides a means for evaluation of the flammable performance of surface finish materials used in constructing and outfitting ships.

A specimen of the surface finish of concern is mounted on the support material contemplated for use and subjected to a controlled significant radiant-flux exposure.

All specimens are tested while mounted in a vertical plane.

The following surfaces are exposed to test:

Bulkhead specimens having surface veneers, fabrics, or painted finishes are tested on one or both exposed sides.

Ceiling finish materials shall be tested on the lower exposed surface.

For ceiling finish materials which are perforated and air backed, tests also shall be conducted on the back (upper) surface of the material.

Deck finish and flooring materials are tested on the upper exposed surface.

Protective membranes or finishes on insulation materials are tested on the air-exposed face or faces.

This test method provides fire properties that relate to the flammability of the specimens tested. These include ignitability, heat exposure for continued burning, critical flux at extinguishment, and heat-release behavior under varying flux-exposure conditions applied.

This test method does not provide:

Full information on fire properties of surface-finish materials supported by backing materials other than those tested.

Full information on surface-finish materials when used in other thicknesses than those tested.

Methods for using the fire property measurements as a measure for classifying the fire risk or hazard of the specimens tested.

SCOPE

1.1 This fire-test-response standard covers a procedure for measuring fire properties associated with flammable behavior of surface finishes used on noncombustible substrates aboard ship (Note 1). In particular, these include surface finishes intended for use in ship construction such as deck surfacing materials, bulkhead and ceiling veneers including any adhesives used to fasten the veneers to the bulkheads and ceilings, paints, and exposed treatment of insulating materials.

Note 1—This test method has been prepared to closely follow the test procedure of IMO Resolution A.653(16) (1). Optional provisions not applicable to the domestic use of this test method have been deleted.

1.2 Tests performed according to this test method are intended to yield fire properties that, when appropriately interpreted, are potentially useful to select materials and surface treatments that will limit the rapid growth and spread of fire.

1.3 This test method requires a specific range of specimen radiant thermal exposure for measuring fire properties.

1.4 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products, or assemblies under actual fire conditions.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 7.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:E1317–08

Standard Test Method for

1

Flammability of Marine Surface Finishes

This standard is issued under the fixed designation E1317; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

3

1.1 This fire-test-response standard covers a procedure for 2.1 ASTM Standards:

measuring fire properties associated with flammable behavior E84 Test Method for Surface Burning Characteristics of

of surface finishes used on noncombustible substrates aboard Building Materials

ship (Note 1). In particular, these include surface finishes E162 Test Method for Surface Flammability of Materials

intended for use in ship construction such as deck surfacing Using a Radiant Heat Energy Source

materials, bulkhead and ceiling veneers including any adhe- E176 Terminology of Fire Standards

sives used to fasten the veneers to the bulkheads and ceilings, E286 MethodofTestforSurfaceFlammabilityofBuilding

4

paints, and exposed treatment of insulating materials. Materials Using an 8-ft (2.44-m) Tunnel Furnace

E648 Test Method for Critical Radiant Flux of Floor-

NOTE 1—This test method has been prepared to closely follow the test

2 Covering Systems Using a Radiant Heat Energy Source

procedure of IMO Resolution A.653(16) (1). Optional provisions not

E970 Test Method for Critical Radiant Flux of Exposed

applicable to the domestic use of this test method have been deleted.

AtticFloorInsulationUsingaRadiantHeatEnergySource

1.2 Tests performed according to this test method are

E1321 Test Method for Determining Material Ignition and

intended to yield fire properties that, when appropriately

Flame Spread Properties

interpreted, are potentially useful to select materials and

2.2 Code of Federal Regulations (CFR):

surfacetreatmentsthatwilllimittherapidgrowthandspreadof

5

CFR Title 46, Part 164.009, Noncombustible Materials

fire.

2.3 ASTM Adjuncts:ASTM

1.3 This test method requires a specific range of specimen

Detailed drawings (19), construction information, and parts

radiant thermal exposure for measuring fire properties.

6

list (Adjunct to E1317)

1.4 This standard is used to measure and describe the

response of materials, products, or assemblies to heat and

3. Terminology

flame under controlled conditions, but does not by itself

3.1 Definitions—For definitions of general terms used in

incorporate all factors required for fire hazard or fire risk

this test method, refer to Terminology E176.

assessment of the materials, products, or assemblies under

3.2 Definitions of Terms Specific to This Standard:

actual fire conditions.

3.2.1 compensating thermocouple, n—a thermocouple for

1.5 This standard does not purport to address all of the

the purpose of generating an electrical signal representing

safety concerns, if any, associated with its use. It is the

long-term changes in the stack metal temperatures wherein a

responsibility of the user of this standard to establish appro-

fraction of the signal generated is subtracted from the signal

priate safety and health practices and determine the applica-

developed by the stack-gas thermocouples.

bility of regulatory limitations prior to use. For specific hazard

3.2.2 critical flux at extinguishment, n— a flux level at the

statements, see Section 7.

specimen surface corresponding to the distance of farthest

advance and subsequent self-extinguishment of the flame on

the centerline of a specimen.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This test method is under the jurisdiction of ASTM Committee E05 on Fire Standards volume information, refer to the standard’s Document Summary page on

Standards and is the direct responsibility of Subcommittee E05.22 on Surface the ASTM website.

4

Burning. Discontinued; see 1992 Annual Book of ASTM Standards , Vol 04.07.

5

Current edition approved Jan. 1, 2008. Published January 2008. Originally Available from Superintendent of Documents, U.S. Government Printing

approved in 1990. Last previous edition approved in 2002 as E1317–97a(2002). Office, Washington, DC 20402.

2 6

The boldface numbers in parentheses refer to a list of references at the end of Detailed drawings are available from ASTM Headquarters. Request

this standard. ADJE1317.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E1317–08

3.2.2.1 Discussion—The flux reported is based on calibra- 3.2.12 viewing rakes—a set of bars with w

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:E1317–97a (Reapproved 2002) Designation:E1317–08

Standard Test Method for

1

Flammability of Marine Surface Finishes

This standard is issued under the fixed designation E1317; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This fire-test-response standard covers a procedure for measuring fire properties associated with flammable behavior of

surface finishes used on noncombustible substrates aboard ship (Note 1). In particular, these include surface finishes intended for

use in ship construction such as deck surfacing materials, bulkhead and ceiling veneers including any adhesives used to fasten the

veneers to the bulkheads and ceilings, paints, and exposed treatment of insulating materials.

2

NOTE 1—ThistestmethodhasbeenpreparedtocloselyfollowthetestprocedureofIMOResolutionA.653(16)(1). Optionalprovisionsnotapplicable

to the domestic use of this test method have been deleted.

1.2 Tests performed according to this test method are intended to yield fire properties that, when appropriately interpreted, are

potentially useful to select materials and surface treatments that will limit the rapid growth and spread of fire.

1.3 This test method requires a specific range of specimen radiant thermal exposure for measuring fire properties.

1.4 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under

controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials,

products, or assemblies under actual fire conditions.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazard statements, see Section 7.

2. Referenced Documents

3

2.1 ASTM Standards:

E84 Test Method for Surface Burning Characteristics of Building Materials

E162 Test Method for Surface Flammability of Materials Using a Radiant Heat Energy Source

E176 Terminology of Fire Standards

4

E 286Test Method Method of Test for Surface Flammability of Building Materials Using an 8-ft (2.44-m) Tunnel Furnace

E648 Test Method for Critical Radiant Flux of Floor-Covering Systems Using a Radiant Heat Energy Source

E970 Test Method for Critical Radiant Flux of Exposed Attic Floor Insulation Using a Radiant Heat Energy Source

E1321 Test Method for Determining Material Ignition and Flame Spread Properties

2.2 Code of Federal Regulations (CFR):

5

CFR Title 46, Part 164.009, Noncombustible Materials

2.3 ASTM Adjuncts:ASTM

6

Detailed drawings (19), construction information, and parts list (Adjunct to E1317)

3. Terminology

3.1 Definitions—For definitions of general terms used in this test method, refer to Terminology E176.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 compensating thermocouple, n—a thermocouple for the purpose of generating an electrical signal representing long-term

changes in the stack metal temperatures wherein a fraction of the signal generated is subtracted from the signal developed by the

stack-gas thermocouples.

1

This test method is under the jurisdiction of ASTM Committee E05 on Fire Standards and is the direct responsibility of Subcommittee E05.22 on Surface Burning.

Current edition approved June 10, 1997. Published August 1997. Originally published as E1317–90. Last previous edition E1317–97.

Current edition approved Jan. 1, 2008. Published January 2008. Originally approved in 1990. Last previous edition approved in 2002 as E1317–97a(2002).

2

The boldface numbers in parentheses refer to a list of references at the end of this standard.

3

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vol 04.07.volume information, refer to the standard’s Document Summary page on the ASTM website.

4

Discontinued; see 1992 Annual Book of ASTM Standards , Vol 04.07.

5

Available from Superintendent of Documents, U.S. Government Printing Office, Washington, DC 20402.

6

Detailed drawings are available from ASTM Headquarters. Request ADJE1317.

Copyright © ASTM International, 100 Ba

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.