ASTM F2227-02

(Test Method)Standard Test Method for Non-Destructive Detection of Leaks in Non-sealed and Empty Medical Packaging Trays by CO2 Tracer Gas Method

Standard Test Method for Non-Destructive Detection of Leaks in Non-sealed and Empty Medical Packaging Trays by CO<sub>2 </sub> Tracer Gas Method

SCOPE

1.1 This non-destructive test method detects pinhole leaks in trays, as small as 50 m (0.002 in.) in diameter, or equivalently sized cracks, subject to trace gas concentration in the tray, tray design and manufacturing tolerances.

1.2 The values stated in SI units are to be regarded as standard units. Values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2227–02

Standard Test Method for

Non-Destructive Detection of Leaks in Non-sealed and

Empty Medical Packaging Trays by CO Tracer Gas Method

This standard is issued under the fixed designation F 2227; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Significance and Use

1.1 This non-destructive test method detects pinhole leaks 5.1 Harmful biological or particulate contaminants may

in trays, as small as 50 µm (0.002 in.) in diameter, or enter the package through imperfections such as pinholes or

equivalently sized cracks, subject to trace gas concentration in cracks in trays.

the tray, tray design and manufacturing tolerances. 5.2 After initial instrument set-up and calibration, the op-

1.2 The values stated in SI units are to be regarded as erations of individual tests and test results do not need operator

standard units. Values in parentheses are for information only. interpretation.

1.3 This standard does not purport to address all of the 5.3 Leak test results that exceed the permissible threshold

safety concerns, if any, associated with its use. It is the setting are indicated by audible or visual signal responses, or

responsibility of the user of this standard to establish appro- both, or by other means.

priate safety and health practices and determine the applica- 5.4 This non-destructive test method may be performed in

bility of regulatory limitations prior to use. either laboratory or production environments and may be

undertaken on either a 100 % or a statistical sampling basis.

2. Referenced Documents

This test method, in single instrument use and current imple-

2.1 ASTM Standards:

mentation, may not be fast enough to work on a production

D 996 Terminology of Packaging and Distribution Environ- packaging line, but is well suited for statistical testing as well

ments

as package developmental design work.

F 1327 TerminologyRelatingtoBarrierMaterialsforMedi-

6. Apparatus

cal Packaging

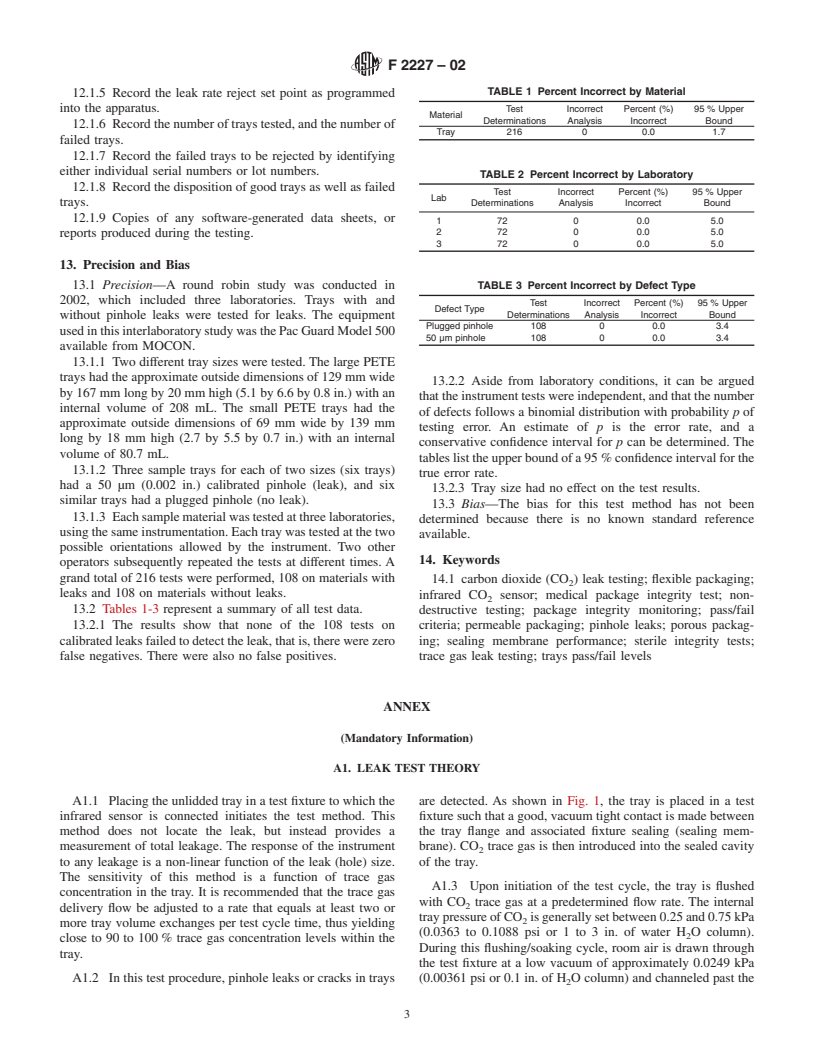

6.1 Non-destructive Trace Gas Leak Detection Apparatus—

3. Terminology

The apparatus’ test fixture consists of three major elements and

3.1 General Term Definitions—For definitions used in this is shown in Fig. 1.

test method, see Terminologies D 996 and F 1327, Sections 3.

6.2 Sealing Membrane—The purpose of the membrane is to

3.2 Definitions of Terms Specific to This Standard: seal off the tracer gas transmission out of the top of the open

3.2.1 trace gas—a compound selected solely for use to

tray.

identify leakage flow. 6.3 Control Trays—Calibrated pinholes, or leaks, con-

structedincontroltraysforinstrumentcalibrationaswellasfor

4. Summary of Test Method

test procedure verification.

4.1 This test method utilizes CO sensing techniques in the

6.4 Test Fixture—Apparatus, which must be designed to

detection of a CO trace gas to quantify leaks in medical

ensure detection of a calibrated leak.

packaging trays. The test method provides a qualitative

7. Preparation of Apparatus

(accept/reject) inspection method to evaluate trays for pinholes

and cracks. Further information on the “Leak Test Theory” 7.1 Thetestapparatusistobestarted,warmed-up,andmade

may be found in Annex A1.

ready according to the manufacturer’s specifications. The

instrument must be operated in an environment as described in

the instrument’s user manual.

This test method is under the jurisdiction ofASTM Committee F02 on Flexible

Barrier Materials and is the direct responsibility of Subcommittee F02.40 on

8. Reagents and Materials

Package Integrity.

Current edition approved Dec. 10, 2002. Published February 2003.

8.1 CO Trace Gas Cylinder and Regulator—A cylinder of

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

“Commercial” or “Bone Dry” grade carbon dioxide with a

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

minimum of 206.84-kPa (30-psi) pressure is required for

Standards volume information, refer to the standard’s Document Summary page on

calibration and testing.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2227–02

FIG. 1 Schematic of Test Fixture and Test Tray

8.2 Sealing Membrane—The sealing membrane must ex- 11.2 Select and implement the properly sized test fixture for

hibit the correct pliability and tackiness in order to form a the trays to be tested. Verify that the instrument and associated

gas-tight bond without leaving a residue on the tray-sealing test fixture have been calibrated for the trays to be tested. The

surface after removal from the test fixture. test fixture is too large when the instrument is unable to detect

a calibrated control pinhole leak.

9. Hazards 11.3 Adjust the instrument baseline settings determined in

calibration.

9.1 As the test fixture is closed, it may present pinch-point

11.4 Place the tray to be tested into the test fixture making

hazards.

certain that the tray is centered in the fixture and that good

9.2 CO , although inert and non-toxic, can cause danger of

sealing contact is made between the tray flange and the fixture

suffocation if it is allowed to displace oxygen. Thus it is

incorporated sealing.

recommendedthatthespentcarbondioxidebenaturallyvented

away from the test area and that adequate ventilation be

NOTE 1—The sealing membrane needs to be clean in order to develop

provided. a good seal with the sealing flange of the tray. Laboratory conditions may

cause dust or debris to be collected on the sealing membrane. These

conditions thus will warrant frequent inspection and cleaning of the

10. Calibration and Standardization

sealing membrane with a lint-free cloth soaked with a solvent recom-

10.1 Before any measurements are made, the apparatus

mended by the manufacturer of the equipment.

must be calibrated. The calibration procedure is used for

11.5 Close the top cover of the test fixture.

overall system checkout, as well as to establish an initial

11.6 Start the test.

reference profile for simulated pinhole leaks, and to determine

11.7 Note the pass or fail indicator and record results. Set

test limits for each different tray geometry to be tested using a

aside any “failed/defective” trays for further evaluation. Fur-

specific test fixture. The calibration procedure is performed to

ther evaluation should include re-testing of the tray.

establish the sensitivity setting of the instrumentation. It is

11.8 Select another tray and repeat the testing process.

expected that the calibration procedures be carried out fre-

quently; typically, at least one or more times a day, preferably 12. Report

at the beginning of every shift.

12.1 The report shall include the following:

10.2 Refer to the instrument manufacturer’s operating in-

12.1.1 A statement indicating that the tests were performed

structionsregardingpreparationofCalibrationStandards,Con-

in accordance with ASTM Standard F 2227, except where

ditioning of Calibration Trays and Instrument Calibration used

noted.

in establishing baseline settings.

12.1.2 The serial numbers, calibration values and most

recent calibration dates for all calibration standards used.

11. Procedure

12.1.3 Record the date, time, l

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.