ASTM D5141-96(1999)

(Test Method)Standard Test Method for Determining Filtering Efficiency and Flow Rate of a Geotextile for Silt Fence Application Using Site-Specific Soil

Standard Test Method for Determining Filtering Efficiency and Flow Rate of a Geotextile for Silt Fence Application Using Site-Specific Soil

SCOPE

1.1 This test method is used to determine the filtering efficiency and the flow rate of a geotextile used exclusively in silt fence or silt barrier application. Note 1-The terms silt fence and silt barrier are used synonomously.

1.1.1 The results are shown as a percentage for filtering efficiency and cubic metres per square metre per minute (m /m /min) or gallons per square foot per minute (gal/ ft /min) for flow rate.

1.1.2 The filtering efficiency indicates the percent of sediment removed from sediment-laden water.

1.1.3 The flow rate is the average rate of passage of the sediment-laden water through the geotextile.

1.2 This test method requires several specialized pieces of equipment, such as an integrated water sampler and an analytical balance, and site specific soil from the construction project.

1.3 The values stated in SI units are the standard, while the inch-pound units are provided for information. The values expressed in each system may not be exact equivalents; therefore, each system must be used independently of the other, without combining values in any way.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5141 – 96 (Reappoved 1999)

Standard Test Method for

Determining Filtering Efficiency and Flow Rate of a

Geotextile for Silt Fence Application Using Site-Specific

Soil

This standard is issued under the fixed designation D5141; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D4439 Terminology for Geosynthetics

D4354 Practice for Sampling of Geosynthetics forTesting

1.1 This test method is used to determine the filtering

D4759 Practice for Determining the Specification Con-

efficiency and the flow rate of a geotextile used exclusively in

formance of Geosynthetics

silt fence or silt barrier application.

2.2 American Public Health Association (APHA) Standard:

NOTE 1—The terms silt fence and silt barrier are used synonomously.

208D TotalNonfiltrableResidueDriedat103–105°C(Total

1.1.1 The results are shown as a percentage for filtering Suspended Matter)

efficiency and cubic metres per square metre per minute

3 2 2 3. Terminology

(m /m /min)orgallonspersquarefootperminute(gal/ft /min)

for flow rate. 3.1 Definitions:

3.1.1 filtration—See filter.

1.1.2 The filtering efficiency indicates the percent of sedi-

ment removed from sediment-laden water. 3.1.2 filter—See Terminology D653.

3.1.3 geosynthetic, n—a planar product manufactured from

1.1.3 The flow rate is the average rate of passage of the

sediment-laden water through the geotextile. polymeric material used with foundation soil, rock, earth, or

any other geotechnical engineering related material as an

1.2 This test method requires several specialized pieces of

equipment, such as an integrated water sampler and an ana- integral part of a man-made project, structure, or system. (See

Practice D4759.)

lytical balance, and site specific soil from the construction

project. 3.1.4 geotextile, n—any permeable textile material used

with foundation, soil, rock, earth, or any other geotechnical

1.3 The values stated in SI units are the standard, while the

inch-pound units are provided for information. The values engineering related material, as an integral part of a man-made

expressed in each system may not be exact equivalents; project, structure, or system.

3.1.5 performance property, n—a result obtained by con-

therefore,eachsystemmustbeusedindependentlyoftheother,

without combining values in any way. ducting a performance test.

3.1.6 performance test, n—in geosynthetics, a laboratory

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the procedure which simulates selected field conditions which can

be used in design.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 3.1.7 For definitions of other terms relating to geosynthet-

ics, refer to Terminology D4439. For definitions of textile

bility of regulatory limitations prior to use.

terms, refer to Terminology D123. For definitions of soil

2. Referenced Documents

terms, refer to Terminology D653.

2.1 ASTM Standards: 3.2 Definitions of Terms Specific to This Standard:

D123 Terminology Relating to Textile Materials 3.2.1 filtering effıciency, FE, n—in geosynthetics, the per-

D653 Terminology Relating to Soil, Rock, and Contained cent of sediment removed from sediment-laden water by a

Fluids geotextile over a specified period of time.

3 −2 −1

3.2.2 flow rate, FR [L L T ], n—in geosynthetics, the

volume of fluid per unit time, expressed as an average, which

passes through a cross-sectional plane perpendicular to the

This test method is under the jurisdiction ofASTM Committee D-35 Geosyn-

fluid flow.

thetics and is the direct responsibility of Subcommittee D35.03 on Permeability and

Filtration.

Current edition approved May 10, 1996. Published June 1996. Originally

published as D5141–91. Last previous edition D5141–91. Annual Book of ASTM Standards, Vol 04.13.

2 5

Annual Book of ASTM Standards, Vol 07.01. Available fromAmerican Public HealthAssociation (APHA), 1015 Eighteenth

Annual Book of ASTM Standards, Vol 04.08. St. NW, Washington, DC 20036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5141 – 96 (Reappoved 1999)

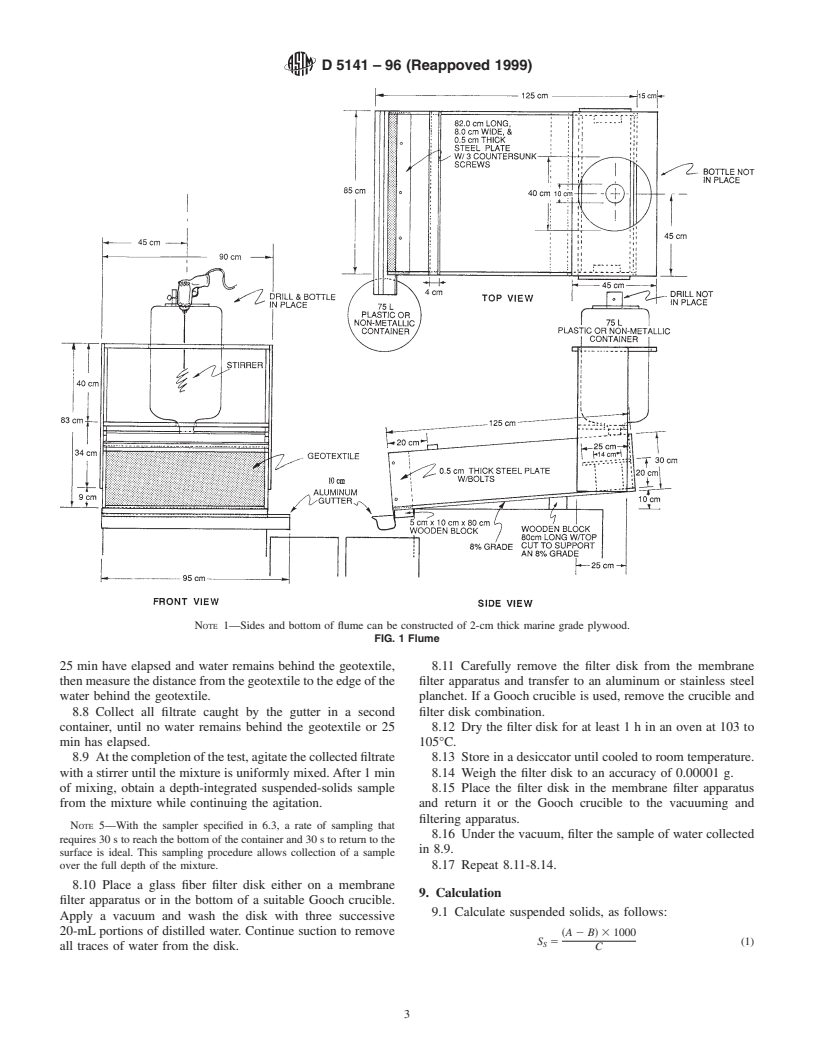

3.2.3 flume, n—an apparatus that carries a liquid to an 6.7 Sediment-Free Water, containing no flocculent agents.

outlet.

NOTE 3—Flocculent agents used in water treatment may cause errone-

3.2.4 silt fence, n—in geosynthetics, a temporary sediment

ous results by affecting the settling rate of soil particles in the water.

control measure used to remove soil from runoff.

6.8 Soil, site-specific.

6.9 Gooch Crucible.

4. Summary of Test Method

6.10 Membrane Filter Apparatus.

4.1 A geotextile specimen is placed across a flume while

6.11 Vacuum Pump.

sediment-laden water is passed through the specimen.

6.12 Planchet, aluminum or stainless steel.

4.1.1 The time that water flows through the geotextile and

6.13 Desiccator.

the amount of soil passed by the geotextile are measured. The

6.14 Analytical Balance, sensitivity of 0.00001 g.

amount of soil retained, filtering efficiency, and flow rate are

calculated from these measured values.

7. Sampling

4.2 Soil from the construction project should be used in this

7.1 Geotextile:

test method.

7.1.1 Lot Sample—Divide the product into lots and take the

lot sample as directed in Practice D4354.

5. Significance and Use

7.1.2 Laboratory Sample—After first discarding a mini-

5.1 This test method is used to determine the filtering

mum of 1 m (3.3 ft) of geotextile from the end of the roll, cut

efficiencyandflowrateofageotextileusedinasiltfenceorsilt

off sufficient length of the roll to get the appropriate number of

barrier installation for specific soil conditions.

test specimens. If holes or damaged areas are evident, then

5.2 This test method may be used for the design of a silt

damaged material should be discarded and additional material

fenceorsiltbarriertomeetrequirementsofregulatoryagencies

sampled.

in filtering efficiency or flow rate for specific soil conditions.

7.1.3 Test Specimens—Cuttheappropriatenumberofspeci-

5.2.1 Thedesignercanusethistestmethodtodeterminethe

mens to be tested from the machine direction of the laboratory

spacing between silt fences or silt barriers.

sample by a random method. Each test specimen should be cut

5.3 Thistestmethodisintendedforperformanceevaluation,

(1 m long by 0.3 m wide (3.3 ft long by 12 in. wide)) to fit the

as the results will depend on the specific soil evaluated. It is

flume.

recommendedthattheuserorrepresentativeperformthetestto

NOTE 4—No specimen should be within 0.2 m (6 in.) of a selvage.

pre-approved products, as geotextile manufacturers are not

typically equipped to handle or test soil requirements.

7.2 Soil—Obtain representative samples of the site-specific

5.4 This test method provides a means of evaluating geo-

soil that is significant to the design of the silt barriers or silt

textiles with different soils under various conditions that

fencesontheconstructionproject.Thesizeandtypeofsample

simulate the conditions that exist in a silt fence or silt barrier

requiredisdependentuponthenumberofteststobeperformed

installation. This test method may be used to simulate several

and the percent of coarse particles in the sample.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.