ASTM D1159-07(2012)

(Test Method)Standard Test Method for Bromine Numbers of Petroleum Distillates and Commercial Aliphatic Olefins by Electrometric Titration

Standard Test Method for Bromine Numbers of Petroleum Distillates and Commercial Aliphatic Olefins by Electrometric Titration

SIGNIFICANCE AND USE

The bromine number is useful as a measure of aliphatic unsaturation in petroleum samples. When used in conjunction with the calculation procedure described in Annex A2, it can be used to estimate the percentage of olefins in petroleum distillates boiling up to approximately 315°C (600°F).

The bromine number of commercial aliphatic monoolefins provides supporting evidence of their purity and identity.

SCOPE

1.1 This test method covers the determination of the bromine number of the following materials:

1.1.1 Petroleum distillates that are substantially free of material lighter than isobutane and that have 90 % distillation points (by Test Method D86) under 327°C (626°F). This test method is generally applicable to gasoline (including leaded, unleaded, and oxygenated fuels), kerosine, and distillates in the gas oil range that fall in the following limits: 90 % Distillation Point, °C (°F)Bromine Number, max2 Under 205 (400)175 205 to 327 (400 to 626) 10

1.1.2 Commercial olefins that are essentially mixtures of aliphatic mono-olefins and that fall within the range of 95 to 165 bromine number (see Note 1). This test method has been found suitable for such materials as commercial propylene trimer and tetramer, butene dimer, and mixed nonenes, octenes, and heptenes. This test method is not satisfactory for normal alpha-olefins.

Note 1—These limits are imposed since the precision of this test method has been determined only up to or within the range of these bromine numbers.

1.2 The magnitude of the bromine number is an indication of the quantity of bromine-reactive constituents, not an identification of constituents; therefore, its application as a measure of olefinic unsaturation should not be undertaken without the study given in Annex A1.

1.3 For petroleum hydrocarbon mixtures of bromine number less than 1.0, a more precise measure for bromine-reactive constituents can be obtained by using Test Method D2710. If the bromine number is less than 0.5, then Test Method D2710 or the comparable bromine index methods for industrial aromatic hydrocarbons, Test Methods D1492 or D5776 must be used in accordance with their respective scopes. The practice of using a factor of 1000 to convert bromine number to bromine index is not applicable for these lower values of bromine number.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see Sections 7, 8, and 9.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1159 −07 (Reapproved 2012)

Designation: 130/98

Standard Test Method for

Bromine Numbers of Petroleum Distillates and Commercial

Aliphatic Olefins by Electrometric Titration

This standard is issued under the fixed designation D1159; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* constituents can be obtained by using Test Method D2710.If

2 the bromine number is less than 0.5, then Test Method D2710

1.1 This test method covers the determination of the

or the comparable bromine index methods for industrial

bromine number of the following materials:

aromatic hydrocarbons, Test Methods D1492 or D5776 must

1.1.1 Petroleum distillates that are substantially free of

be used in accordance with their respective scopes. The

material lighter than isobutane and that have 90 % distillation

practice of using a factor of 1000 to convert bromine number

points (by Test Method D86) under 327°C (626°F). This test

to bromine index is not applicable for these lower values of

method is generally applicable to gasoline (including leaded,

bromine number.

unleaded,andoxygenatedfuels),kerosine,anddistillatesinthe

gas oil range that fall in the following limits: 1.4 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

90 % Distillation Point, °C (°F) Bromine Number, max

Under 205 (400) 175

only.

205 to 327 (400 to 626) 10

1.5 This standard does not purport to address all of the

1.1.2 Commercial olefins that are essentially mixtures of

safety concerns, if any, associated with its use. It is the

aliphatic mono-olefins and that fall within the range of 95 to

responsibility of the user of this standard to establish appro-

165 bromine number (see Note 1). This test method has been

priate safety and health practices and determine the applica-

found suitable for such materials as commercial propylene

bility of regulatory limitations prior to use. For specific

trimerandtetramer,butenedimer,andmixednonenes,octenes,

warning statements, see Sections 7, 8, and 9.

and heptenes. This test method is not satisfactory for normal

alpha-olefins. 2. Referenced Documents

2.1 ASTM Standards:

NOTE 1—These limits are imposed since the precision of this test

method has been determined only up to or within the range of these

D86 Test Method for Distillation of Petroleum Products at

bromine numbers.

Atmospheric Pressure

D1193 Specification for Reagent Water

1.2 The magnitude of the bromine number is an indication

of the quantity of bromine-reactive constituents, not an iden- D1492 Test Method for Bromine Index of Aromatic Hydro-

carbons by Coulometric Titration

tificationofconstituents;therefore,itsapplicationasameasure

of olefinic unsaturation should not be undertaken without the D2710 Test Method for Bromine Index of Petroleum Hydro-

carbons by Electrometric Titration

study given in Annex A1.

D5776 Test Method for Bromine Index of Aromatic Hydro-

1.3 For petroleum hydrocarbon mixtures of bromine num-

carbons by Electrometric Titration

ber less than 1.0, a more precise measure for bromine-reactive

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

This test method is under the jurisdiction of ASTM Committee D02 on

3.1.1 bromine number—the number of grams of bromine

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.06 on Analysis of Liquid Fuels and Lubricants.

that will react with 100 g of the specimen under the conditions

In the IP, this test method is under the jurisdiction of the Standardization

of the test.

Committee.

Current edition approved April 15, 2012. Published April 2012. Originally

approved in 1951. Last previous edition approved in 2007 as D1159–07. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/D1159-07R12. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Dubois, H. D., and Skoog, D. A., “Determination of Bromine Addition Standards volume information, refer to the standard’s Document Summary page on

Numbers,” Analytical Chemistry, Vol 20, 1948, pp. 624–627. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1159−07 (2012)

4. Summary of Test Method sufficiently high purity to permit its use without lessening the

accuracy of the determination.

4.1 A known weight of the specimen dissolved in the

selected solvent (see 8.1) maintained at 0 to 5°C (32 to 41°F) 7.2 PurityofWater—Unlessotherwiseindicated,references

is titrated with standard bromide-bromate solution. The end to water shall be understood to mean reagent water as defined

point is indicated by a sudden change in potential on an by Type III of Specification D1193.

electrometric end point titration apparatus due to the presence

7.3 Acetic Acid, Glacial—(Warning—Poison, corrosive-

of free bromine.

combustible, may be fatal if swallowed. Causes severe burns,

harmful if inhaled.)

5. Significance and Use

7.4 Bromide-Bromate, Standard Solution(0.2500 M as Br )

5.1 The bromine number is useful as a measure of aliphatic

—Dissolve 51.0 g of potassium bromide (KBr) and 13.92 g of

unsaturation in petroleum samples. When used in conjunction

potassium bromate (KBrO ) each dried at 105°C (220°F) for

withthecalculationproceduredescribedinAnnexA2,itcanbe

30 min in water and dilute to 1 L.

used to estimate the percentage of olefins in petroleum distil-

7.4.1 If the determinations of the bromine number of the

lates boiling up to approximately 315°C (600°F).

reference olefins specified in Section 8 using this solution do

5.2 The bromine number of commercial aliphatic monoole-

not conform to the prescribed limits, or if for reasons of

fins provides supporting evidence of their purity and identity.

uncertainties in the quality of primary reagents it is considered

desirable to determine the molarity of the solution, the solution

6. Apparatus

shall be standardized and the determined molarity used in

6.1 Electrometric End Point Titration Apparatus—Any ap-

subsequent calculations. The standardization procedure shall

paratus designed to perform titrations to pre-set end points (see

be as follows:

Note 2) may be used in conjunction with a high-resistance

7.4.1.1 To standardize, place 50 mL of glacial acetic acid

polarizing current supply capable of maintaining approxi-

and 1 mL of concentrated hydrochloric acid ( Warning—

mately 0.8 V across two platinum electrodes and with a

Poison corrosive. May be fatal if swallowed. Liquid and vapor

sensitivity such that a voltage change of approximately 50 mV

causes severe burns. Harmful if inhaled; relative density 1.19.)

at these electrodes is sufficient to indicate the end point. Other

in a 500-mL iodine number flask. Chill the solution in a bath

types of commercially available electronic titrimeters, includ-

for approximately 10 min and, with constant swirling of the

ing certain pH meters, have also been found suitable.

flask, add from a 10-mL calibrated buret, 5 6 0.01 mL of the

bromide-bromate standard solution at the rate of 1 or 2 drops

NOTE 2—Pre-set end point indicated with polarized electrodes provides

per second. Stopper the flask immediately, shake the contents,

a detection technique similar to the dead stop technique specified in

previous versions of this test method.

place it again in the ice bath, and add 5 mL of Kl solution in

the lip of the flask. After 5 min remove the flask from the ice

6.2 Titration Vessel—Ajacketed glass vessel approximately

bath and allow the Kl solution to flow into the flask by slowly

120mmhighand45mmininternaldiameterandofaformthat

removing the stopper. Shake vigorously, add 100 mL of water

can be conveniently maintained at 0 to 5°C (32 to 41°F).

in such a manner as to rinse the stopper, lip and walls of the

6.3 Stirrer—Any magnetic stirrer system.

flask, and titrate promptly with sodium thiosulfate (Na S O )

2 2 3

6.4 Electrodes—A platinum wire electrode pair with each

solution. Near the end of the titration, add 1 mL of starch

wire approximately 12 mm long and 1 mm in diameter. The

indicator solution and titrate slowly to disappearance of the

wires shall be located 5 mm apart and approximately 55 mm

blue color. Calculate the molarity of the bromide-bromate

below the level of the titration solvent. Clean the electrode pair

solution as follows:

at regular intervals with 65 % nitric acid and rinse with

AM

distilled water before use.

M 5 (1)

~5!~2!

6.5 Buret—Any delivery system capable of measuring

where:

titrant in 0.05 mL or smaller graduations.

M = molarity of the bromide-bromate solution, as Br ,

1 2

7. Reagents A = millilitresofNa S O solutionrequiredfortitrationof

2 2 3

the bromide-bromate solution, and,

7.1 Purity of Reagents—Reagent grade chemicals shall be

M = molarity of Na S O solution,

2 2 2 3

used in all tests. Unless otherwise indicated, it is intended that

5 = millilitres of bromide—bromate solution, and

all reagents shall conform to the specifications of the commit-

2 = number of electrons transferred during redox titration

tee onAnalytical Reagents of theAmerican Chemical Society,

of bromide-bromate solution.

where such specifications are available. Other grades may be

Repeat the standardization until duplicate determinations do

used, provided it is first ascertained that the reagent is of

not differ from the mean by more than 60.002 M.

7.5 Methanol—(Warning—Flammable. Vapor harmful.

Reagent Chemicals, American Chemical Society Specifications, American

Canbefatalorcauseblindnessifswallowedorinhaled.Cannot

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

listed by the American Chemical Society, see Annual Standards for Laboratory be made non-poisonous.)

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

7.6 Potassium Iodide Solution(150g/L)—Dissolve150gof

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

MD. potassium iodide (Kl) in water and dilute to 1 L.

D1159−07 (2012)

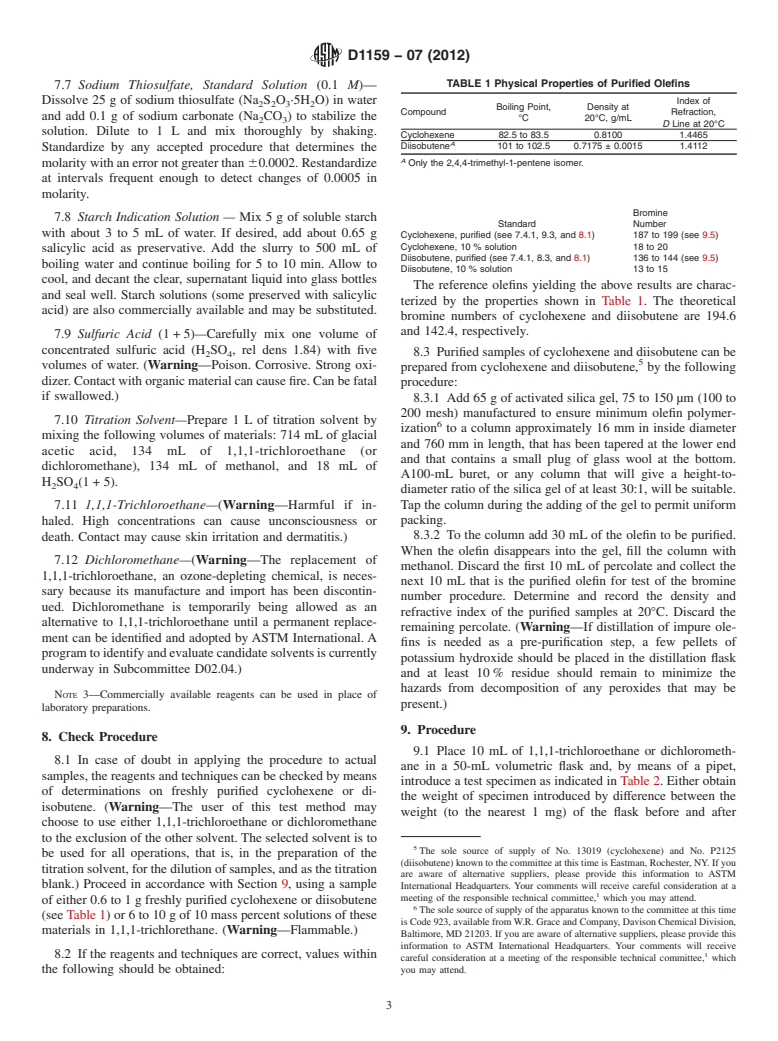

TABLE 1 Physical Properties of Purified Olefins

7.7 Sodium Thiosulfate, Standard Solution (0.1 M)—

Dissolve 25 g of sodium thiosulfate (Na S O ·5H O) in water Index of

2 2 3 2

Boiling Point, Density at

Compound Refraction,

and add 0.1 g of sodium carbonate (Na CO ) to stabilize the

°C 20°C, g/mL

2 3

D Line at 20°C

solution. Dilute to 1 L and mix thoroughly by shaking.

Cyclohexene 82.5 to 83.5 0.8100 1.4465

A

Diisobutene 101 to 102.5 0.7175 ± 0.0015 1.4112

Standardize by any accepted procedure that determines the

A

molaritywithanerrornotgreaterthan 60.0002.Restandardize Only the 2,4,4-trimethyl-1-pentene isomer.

at intervals frequent enough to detect changes of 0.0005 in

molarity.

Bromine

7.8 Starch Indication Solution —Mix5gof soluble starch

Standard Number

with about 3 to 5 mL of water. If desired, add about 0.65 g

Cyclohexene, purified (see 7.4.1, 9.3, and 8.1) 187 to 199 (see 9.5)

Cyclohexene, 10 % solution 18 to 20

salicylic acid as preservative. Add the slurry to 500 mL of

Diisobutene, purified (see 7.4.1, 8.3, and 8.1) 136 to 144 (see 9.5)

boiling water and continue boiling for 5 to 10 min. Allow to

Diisobutene, 10 % solution 13 to 15

cool, and decant the clear, supernatant liquid into glass bottles

The reference olefins yielding the above results are charac-

and seal well. Starch solutions (some preserved with salicylic

terized by the properties shown in Table 1. The theoretical

acid) are also commercially available and may be substituted.

bromine numbers of cyclohexene and diisobutene are 194.6

and 142.4, respectively.

7.9 Sulfuric Acid (1+5)—Carefully mix one volume of

concentrated sulfuric acid (H SO , rel dens 1.84) with five

2 4 8.3 Purified samples of cyclohexene and diisobutene can be

volumes of water. (Warning—Poison. Corrosive. Strong oxi-

prepared from cyclohexene and diisobutene, by the following

dizer.Contactwithorganicmaterialcancausefire.Canbefatal

procedure:

if swallowed.)

8.3.1 Add 65 g of activated silica gel, 75 to 150 µm (100 to

200 mesh) manufactured to ensure minimum olefin polymer-

7.10 Titration Solvent—Prepare 1 L of titration solvent by

ization to a column approximately 16 mm in inside diameter

mixing the following volumes of materials: 714 mL of glacial

and 760 mm in length, that has been tapered at the lower end

acetic acid, 134 mL of 1,1,1-trichloroethane (or

and that contains a small plug of glass wool at the bottom.

dichloromethane), 134 mL of methanol, and 18 mL of

A100-mL buret, or any column that will give a height-to-

H SO (1 + 5).

2 4

diameter ratio of the silica gel of at least 30:1, will be suitable.

7.11 1,1,1-Trichloroethane—(Warning—Harmful if in- Tap the column during the adding of the gel to permit uniform

packing.

haled. High concentrations can cause unconsciousness or

death. Contact may cause skin irritation and dermatitis.) 8.3.2 To the column add 30 mL of the olefin to be purified.

When the olefin disappears into the gel, fill the column with

7.12 Dichloromethane—(Warning—The replacement of

methanol. Discard the first 10 mL of percolate and collect the

1,1,1-trichloroethane, an ozone-depleting chemical, is neces-

next 10 mL that is the purified olefin for test of the bromine

sary because its manufacture and import has been discontin-

number procedure. Determine and record the density and

ued. Dichloromethane is temporarily being allowed as an

refractive index of the purified samples at 20°C. Discard the

alternative to 1,1,1-trichloroethane until a permanent replace-

remaining percolate. (Warning—If distillation of impure ole-

ment can be identified and adopted by ASTM International. A

fins is needed as a pre-purification step, a few pellets of

programtoidentifyandevaluatecandidatesolventsiscurrently

potassium hydroxide should be placed in the distillation flask

underway in Subcommittee D02.04.)

and at least 10 % residue should remain to minimize the

hazards from decomposition of any peroxides that may be

NOTE 3—Commercially available reagents can be used in place of

present.)

laboratory preparations.

9. Procedure

8. Check Procedure

9.1 Place 10 mL of 1,1,1-trichloroethane or dichlorometh-

8.1 In case of doubt in applying the procedure to actual

ane in a 50-mL volumetric flask and, by means of a pipet,

samples, the reagents and techniques can be checked by means

introduce

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.