ASTM E111-04(2010)

(Test Method)Standard Test Method for Young's Modulus, Tangent Modulus, and Chord Modulus

Standard Test Method for Young's Modulus, Tangent Modulus, and Chord Modulus

SIGNIFICANCE AND USE

The value of Young's modulus is a material property useful in design for calculating compliance of structural materials that follow Hooke's law when subjected to uniaxial loading (that is, the strain is proportional to the applied force).

For materials that follow nonlinear elastic stress-strain behavior, the value of tangent or chord modulus is useful in estimating the change in strain for a specified range in stress.

Since for many materials, Young's modulus in tension is different from Young's modulus in compression, it shall be derived from test data obtained in the stress mode of interest.

The accuracy and precision of apparatus, test specimens, and procedural steps should be such as to conform to the material being tested and to a reference standard, if available.

Precise determination of Young's modulus requires due regard for the numerous variables that may affect such determinations. These include (1) characteristics of the specimen such as orientation of grains relative to the direction of the stress, grain size, residual stress, previous strain history, dimensions, and eccentricity; (2) testing conditions, such as alignment of the specimen, speed of testing, temperature, temperature variations, condition of test equipment, ratio of error in applied force to the range in force values, and ratio of error in extension measurement to the range in extension values used in the determination; and (3) interpretation of data (see Section 9).

When the modulus determination is made at strains in excess of 0.25 %, correction should be made for changes in cross-sectional area and gage length, by substituting the instantaneous cross section and instantaneous gage length for the original values.

Compression results may be affected by barreling (see Test Methods E9). Strain measurements should therefore be made in the specimen region where such effects are minimal.

SCOPE

1.1 This test method covers the determination of Young's modulus, tangent modulus, and chord modulus of structural materials. This test method is limited to materials in which and to temperatures and stresses at which creep is negligible compared to the strain produced immediately upon loading and to elastic behavior.

1.2 Because of experimental problems associated with the establishment of the origin of the stress-strain curve described in 8.1, the determination of the initial tangent modulus (that is, the slope of the stress-strain curve at the origin) and the secant modulus are outside the scope of this test method.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E111 − 04 (Reapproved 2010)

Standard Test Method for

Young’s Modulus, Tangent Modulus, and Chord Modulus

ThisstandardisissuedunderthefixeddesignationE111;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope rials at Room Temperature

2 E21TestMethodsforElevatedTemperatureTensionTestsof

1.1 This test method covers the determination of Young’s

Metallic Materials

modulus, tangent modulus, and chord modulus of structural

E83Practice for Verification and Classification of Exten-

materials.Thistestmethodislimitedtomaterialsinwhichand

someter Systems

to temperatures and stresses at which creep is negligible

E231Method for Static Determination of Young’s Modulus

comparedtothestrainproducedimmediatelyuponloadingand

of Metals at Low and Elevated Temperatures (Withdrawn

to elastic behavior.

1985)

1.2 Because of experimental problems associated with the

E1012Practice for Verification of Testing Frame and Speci-

establishment of the origin of the stress-strain curve described

men Alignment Under Tensile and Compressive Axial

in 8.1, the determination of the initial tangent modulus (that is,

Force Application

the slope of the stress-strain curve at the origin) and the secant

2.2 General Considerations—While certain portions of the

modulus are outside the scope of this test method.

standards and practices listed are applicable and should be

1.3 The values stated in SI units are to be regarded as

referred to, the precision required in this test method is higher

standard. No other units of measurement are included in this

than that required in general testing.

standard.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to establish appro-

3.1 Definitions:

priate safety and health practices and determine the applica-

3.1.1 accuracy—the degree of agreement between an ac-

bility of regulatory requirements prior to use.

cepted standard value of Young’s modulus (the average of

many observations made according to this method, preferably

2. Referenced Documents

by many observers) and the value determined.

2.1 ASTM Standards:

3.1.1.1 Increasedaccuracyisassociatedwithdecreasedbias

E4Practices for Force Verification of Testing Machines

relativetotheacceptedstandardvalue;twomethodswithequal

E6Terminology Relating to Methods of MechanicalTesting

bias relative to the accepted standard value have equal accu-

E8Test Methods for Tension Testing of Metallic Materials

racyevenifonemethodismoreprecisethantheother.Seealso

E9Test Methods of Compression Testing of Metallic Mate-

bias and precision.

3.1.1.2 The accepted standard value is the value ofYoung’s

modulus for the statistical universe being sampled using this

This test method is under the jurisdiction of ASTM Committee E28 on

method. When an accepted standard value is not available,

Mechanical Testing and is the direct responsibility of Subcommittee E28.04 on

Uniaxial Testing. accuracy cannot be established.

Current edition approved Sept. 15, 2010. Published January 2011. Originally

3.1.2 bias, statistical—a constant or systematic error in test

approved in 1955. Last previous edition approved in 2004 as E111–04. DOI:

results.

10.1520/E0111-04R10

3.1.2.1 Bias can exist between the accepted standard value

ThistestmethodisarevisionofE111–61(1978),“Young’sModulusatRoom

Temperature” and includes appropriate requirements of E231–69(1975), “Static

andatestresultobtainedfromthistestmethod,orbetweentwo

Determination of Young’s Modulus of Metals at Low and Elevated Temperatures”

test results obtained from this test method, for example,

to permit the eventual withdrawal of the latter method. Method E231 is under the

between operators or between laboratories.

jurisdiction of ASTM-ASME Joint Committee on Effect of Temperature on the

Property of Metals.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E111 − 04 (2010)

3.1.3 precision—the degree of mutual agreement among 5. Significance and Use

individual measurements made under prescribed like condi-

5.1 The value of Young’s modulus is a material property

tions.

useful in design for calculating compliance of structural

3.1.4 Young’s modulus—the ratio of tensile or compressive

materials that follow Hooke’s law when subjected to uniaxial

stress to corresponding strain below the proportional limit (see

loading (that is, the strain is proportional to the applied force).

Fig. 1a).

5.2 For materials that follow nonlinear elastic stress-strain

3.1.4.1 tangent modulus—theslopeofthestress-straincurve

behavior, the value of tangent or chord modulus is useful in

at any specified stress or strain (see Fig. 1b).

estimating the change in strain for a specified range in stress.

3.1.4.2 chord modulus—the slope of the chord drawn be-

tween any two specified points on the stress-strain curve (see 5.3 Sinceformanymaterials,Young’smodulusintensionis

Fig. 1c). different from Young’s modulus in compression, it shall be

3.2 For definitions of other terms used in this test method, derived from test data obtained in the stress mode of interest.

refer to Terminology E6.

5.4 Theaccuracyandprecisionofapparatus,testspecimens,

and procedural steps should be such as to conform to the

4. Summary of Test Method

material being tested and to a reference standard, if available.

4.1 Auniaxial force is applied to the test specimen and the

force and strain are measured, either incrementally or continu- 5.5 Precise determination of Young’s modulus requires due

ously. The axial stress is determined by dividing the indicated regard for the numerous variables that may affect such deter-

force by the specimen’s original cross-sectional area. The minations. These include (1) characteristics of the specimen

appropriate slope is then calculated from the stress-strain such as orientation of grains relative to the direction of the

curve, which may be derived under conditions of either stress, grain size, residual stress, previous strain history,

increasing or decreasing forces (increasing from preload to dimensions, and eccentricity; (2) testing conditions, such as

maximum applied force or decreasing from maximum applied alignment of the specimen, speed of testing, temperature,

force to preload). temperature variations, condition of test equipment, ratio of

FIG. 1 Stress-Strain Diagrams Showing Straight Lines Corresponding to (a) Young’s Modulus, (b) Tangent Modulus, and (c) Chord

Modulus

E111 − 04 (2010)

6.3 Loading Fixtures—Gripsandotherdevicesforobtaining

andmaintainingaxialalignmentareshowninTestMethodsE8

and E9. It is essential that the loading fixtures be properly

designed and maintained. Procedures for verifying the align-

ment are described in detail in Practice E1012. The allowable

bending as defined in Practice E1012 shall not exceed 5%.

6.4 Extensometers—Class B-1 or better extensometers as

described in Practice E83 shall be used. Corrections may be

applied for proven systematic errors in strain and are not

considered as a change in class of the extensometer. Either an

averaging extensometer or the average of the strain measured

by at least two extensometers arranged at equal intervals

aroundthecrosssectionbeused.Iftwoextensometersareused

on other than round sections, they shall be mounted at ends of

an axis of symmetry of the section. If a force-strain recorder,

strain-transfer device, or strain follower is used with the

extensometer, they shall be calibrated as a unit in the same

manner in which they are used for determination of Young’s

modulus. The gage length shall be determined with an accu-

racy consistent with the precision expected from the modulus

determination and from the extensometer.

NOTE 1—The accuracy of the modulus determination depends on the

precision of the strain measurement. The latter can be improved by

increasing the gage length. This may, however, present problems in

maintaining specimen tolerances and temperature uniformity.

6.5 Furnaces or Heating Devices—When determining

Young’s modulus at elevated temperature, the furnace or

heating device used shall be capable of maintaining a uniform

temperature in the reduced section of the test specimen so that

avariationofnotmorethan 61.5°Cfortemperaturesuptoand

including 900°C, and not more than 63.0°C for temperatures

above 900°C, occurs. (Heating by self-resistance is not ac-

cepted.) Minimize temperature variations and control changes

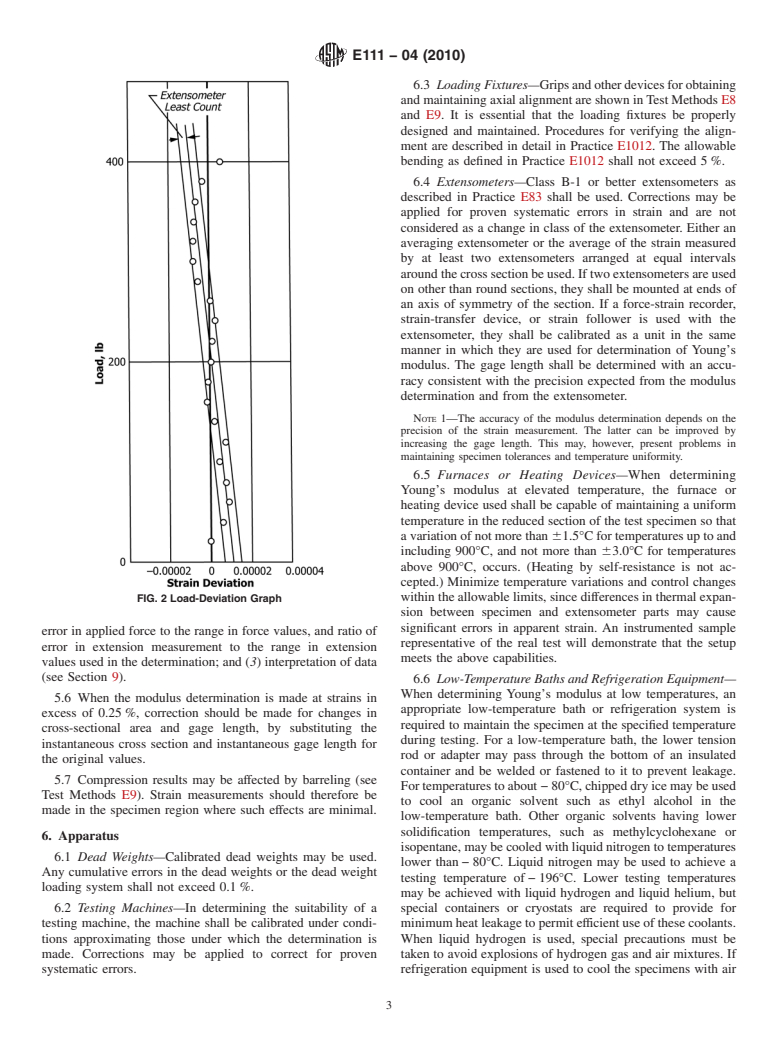

FIG. 2 Load-Deviation Graph withintheallowablelimits,sincedifferencesinthermalexpan-

sion between specimen and extensometer parts may cause

significant errors in apparent strain. An instrumented sample

error in applied force to the range in force values, and ratio of

representative of the real test will demonstrate that the setup

error in extension measurement to the range in extension

meets the above capabilities.

values used in the determination; and (3) interpretation of data

(see Section 9).

6.6 Low-Temperature Baths and Refrigeration Equipment—

When determining Young’s modulus at low temperatures, an

5.6 When the modulus determination is made at strains in

appropriate low-temperature bath or refrigeration system is

excess of 0.25%, correction should be made for changes in

required to maintain the specimen at the specified temperature

cross-sectional area and gage length, by substituting the

during testing. For a low-temperature bath, the lower tension

instantaneous cross section and instantaneous gage length for

rod or adapter may pass through the bottom of an insulated

the original values.

container and be welded or fastened to it to prevent leakage.

5.7 Compression results may be affected by barreling (see

Fortemperaturestoabout−80°C,chippeddryicemaybeused

Test Methods E9). Strain measurements should therefore be

to cool an organic solvent such as ethyl alcohol in the

made in the specimen region where such effects are minimal.

low-temperature bath. Other organic solvents having lower

solidification temperatures, such as methylcyclohexane or

6. Apparatus

isopentane,maybecooledwithliquidnitrogentotemperatures

6.1 Dead Weights—Calibrated dead weights may be used.

lower than−80°C. Liquid nitrogen may be used to achieve a

Any cumulative errors in the dead weights or the dead weight

testing temperature of−196°C. Lower testing temperatures

loading system shall not exceed 0.1%.

may be achieved with liquid hydrogen and liquid helium, but

6.2 Testing Machines—In determining the suitability of a special containers or cryostats are required to provide for

testing machine, the machine shall be calibrated under condi- minimumheatleakagetopermitefficientuseofthesecoolants.

tions approximating those under which the determination is When liquid hydrogen is used, special precautions must be

made. Corrections may be applied to correct for proven taken to avoid explosions of hydrogen gas and air mixtures. If

systematic errors. refrigeration equipment is used to cool the specimens with air

E111 − 04 (2010)

as the cooling medium, it is desirable to have forced air mustbementionedinthereportsection.Iftheintentofthetest

circulation to provide uniform cooling. is to verify the performance of a product, the heat treatment

proceduremaybeomitted.Recordtheconditionofthematerial

NOTE 2—At low temperatures, when using a coolant bath, immersion-

tested, including any heat treatment, in the test report.

type extensometers are recommended.

6.7 Temperature measuring, controlling, and recording in-

8. Procedure

struments shall be calibrated periodically against a secondary

8.1 For most loading systems and test specimens, effects of

standard, such as a precision potentiometer. Lead-wire error

backlash, specimen curvature, initial grip alignment, etc.,

shouldbecheckedwiththeleadwiresinplaceastheynormally

introduce significant errors in the extensometer output when

are used.

applying a small force to the test specimen. Measurements

7. Test Specimens

shall therefore be made from a small force or preload, known

to be high enough to minimize these effects, to some higher

7.1 Selection and Preparation of Specimens—Special care

appliedforce,stillwithineithertheproportionallimitorelastic

shall be taken to obtain representative specimens which are

limit of the material. For linearly elastic materials, the slope of

straight and uniform in cross section. If straightening of the

the straight-line portion of the stress-strain curve shall be

material for the specimen is required, the resultant residual

established between the preload and the proportional limit to

stresses shall be removed by a subsequent stress relief heat

define Young’s modulus. If the actual stress-strain curve is

treatment which shall be reported with the test results.

desired, this line can appropriately be shifted along the strain

7.2 Dimensions—The recommended specimen length (and

axis to coincide with the origin. For nonlinearly elastic

filletradiusinthecaseoftensionspecimens)isgreaterthanthe

materials the tangent or chord modulus may be established

minimum requirements for general-purpose specimens. In

betweentheappropriatestressvaluesonthestressstraincurve.

addition, the ratio of length to cross section of compression

8.2 Measurement of Specimens—Make the measurements

specimens should be such as to avoid buckling (see Test

for the determination of average cross-sectional area at the

Methods E9).

ends of the gage length and at least at one intermediate

NOTE3—Forexamplesoftensionandcompressionspecimens,seeTest

location. Use any means of measuring that is capable of

Methods E8 and E9.

producing area calculations within 1% accuracy.

7.3 For tension specimens, the center lines of the grip

8.3 Alignment—Take special care to ensure as nearly axial

sections and of the threads of threaded-end specimens shall be

loading as possible. The strain increments between the initial-

concentric with the center line of the gage section within close

load and the final-load measurement on opposite sides of the

tolerance

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.