ASTM C1298-21

(Guide)Standard Guide for Design and Construction of Brick Liners for Industrial Chimneys

Standard Guide for Design and Construction of Brick Liners for Industrial Chimneys

SIGNIFICANCE AND USE

4.1 History:

4.1.1 For many years, brick liners have been used with an excellent record of performance. For the most part, however, the design and construction of brick liners has been based on past industry practice due to the lack of available information and knowledge of the physical properties of the brick and mortar, the thermal and seismic behavior of brick liners, and many related characteristics that were not properly or accurately defined.

4.1.2 The use of scrubbers, which lower gas temperatures and introduce highly corrosive condensates into the flue gas system, requires many new design considerations. The effect that scrubbers have on brick liners is an ongoing area of study, since a number of liners have experienced growth- and deflection-related problems which may be attributable, at least in part, to nonuniform temperature and moisture conditions within the liners.

4.2 Purpose—The recommendations contained herein represent current industry practices and serve to define the pertinent considerations that should be followed in the design and construction of brick chimney liners.

SCOPE

1.1 This guide covers procedures for the design, construction, and serviceability of brick liners for industrial chimneys. The structural design criteria are applicable to vertical masonry cantilever structures supported only at their base, either by a foundation, a concrete pedestal, or by some means from the outer concrete shell. Excluded from direct consideration are single-wythe, sectional brick linings that are supported on a series of corbels cast in the outer chimney shell.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1298 − 21

Standard Guide for

Design and Construction of Brick Liners for Industrial

1

Chimneys

This standard is issued under the fixed designation C1298; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* C980 Specification for Industrial Chimney Lining Brick

C1314 Test Method for Compressive Strength of Masonry

1.1 This guide covers procedures for the design,

Prisms

construction, and serviceability of brick liners for industrial

E111 Test Method for Young’s Modulus, Tangent Modulus,

chimneys. The structural design criteria are applicable to

and Chord Modulus

vertical masonry cantilever structures supported only at their

2.2 ACI Standard:

base, either by a foundation, a concrete pedestal, or by some

307–88 Practice for the Design and Construction of Cast-In-

means from the outer concrete shell. Excluded from direct

4

Place Reinforced Concrete Chimneys

consideration are single-wythe, sectional brick linings that are

2.3 ASCE Standard:

supportedonaseriesofcorbelscastintheouterchimneyshell.

ASCE7-88 MinimumDesignLoadsforBuildingsandOther

1.2 The values stated in inch-pound units are to be regarded

5

Structures (Formerly ANSI A58.1)

as the standard. The values given in parentheses are for

2.4 Other Standard:

information only.

1991 Uniform Building Code, International Conference of

6

1.3 This standard does not purport to address all of the

Building Code Officials, California

safety concerns, if any, associated with its use. It is the

TMS 402⁄602 Building Code Requirements and Specifica-

7

responsibility of the user of this standard to establish appro-

tions for Masonry Structures

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. 3. Terminology

1.4 This international standard was developed in accor-

3.1 Notations:

dance with internationally recognized principles on standard-

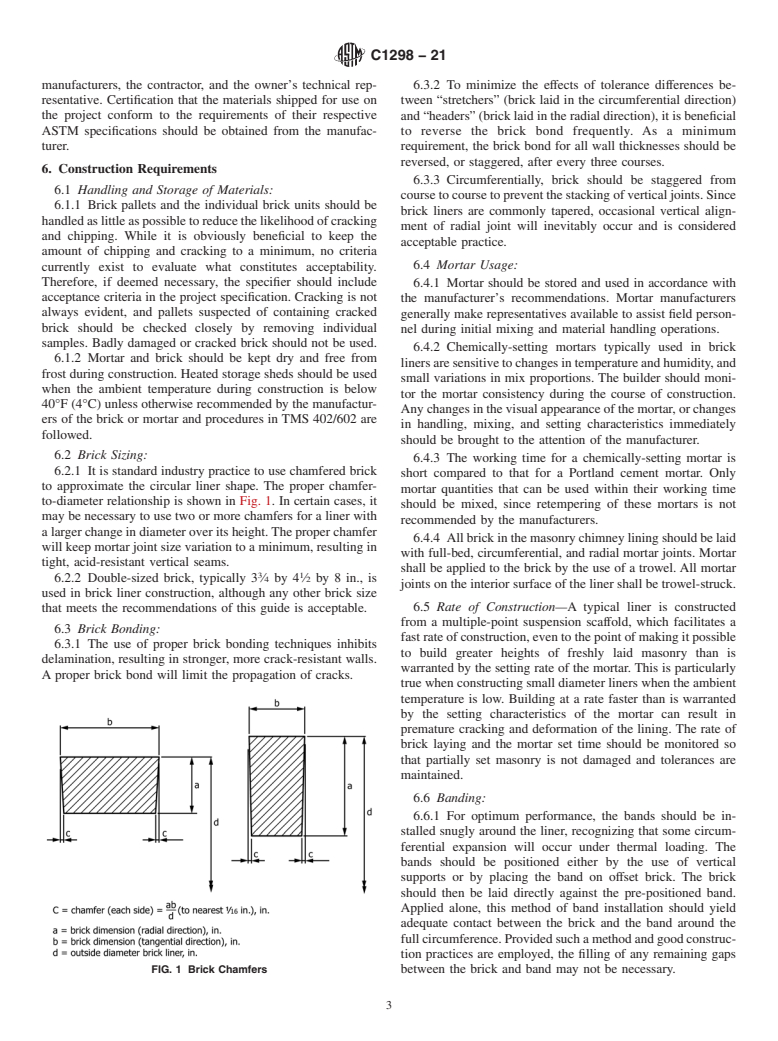

a = brick dimension in radial direction (in.)

ization established in the Decision on Principles for the

b = brick dimension in tangential direction (in.)

Development of International Standards, Guides and Recom-

c = brick chamfer (in.)

C = chimney deflection due to earthquake loads (in.)

e

mendations issued by the World Trade Organization Technical

d = outside diameter of brick liner (in.)

Barriers to Trade (TBT) Committee.

D = mean liner diameter at a given elevation (in.)

E = masonry modulus of elasticity as established by performing brick prism

m

test or by past experience, psi

2. Referenced Documents

f = critical liner buckling stress, psi

b

2

2.1 ASTM Standards: f = maximum vertical compressive stress due to dead load, psi

d

f = maximum vertical compressive stress due to the combined effect of

de

C395 Specification for Chemical-Resistant Resin Mortars

earthquake and dead load, psi

3

(Withdrawn 2021)

f = maximum vertical compressive stress due to the combined effect of

dw

wind and dead load, psi

C466 Specification for Chemically Setting Silicate and

3 f = average ultimate masonry compressive strength established by

m

Silica Chemical-Resistant Mortars (Withdrawn 2021)

performing brick prism test or by past experience, psi

f = maximum shear stress due to wind or earthquake, psi

v

F.S. = factor of safety

h = total liner height (ft)

1

This guide is under the jurisdiction ofASTM Committee C15 on Manufactured

h = height of liner above elevation being checked for buckling (ft)

e

Masonry Units and is the direct responsibility of Subcommittee C15.05 on Masonry

Assemblies.

Current edition approved June 1, 2021. Published June 2021. Originally

4

approved in 1995. Last previous edition approved in 2013 as C1298 – 95 (2013). Available fromAmerican Concrete Institute (ACI), 38800 Country Club Drive,

DOI: 10.1520/C1298-21. Farmington Hills, MI 48331-3439, http:// www.concrete.org.

2 5

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Society of Civil Engineers (ASCE), 1801 Alexander

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Bell Dr., Reston, VA 20191, http://www.asce.org.

6

Standards volume information, refer to the standard’s Document Summary page on Available from International Code Council (ICC), 500 New JerseyAvenue, 6th

the ASTM website. Floor, Washington, DC, 20001, http://www.iccsafe.org.

3 7

The last approved version of this historical standard is referenced on Available from The Masonry Society (TMS), 105 South Sun

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1298 − 95 (Reapproved 2013) C1298 − 21

Standard Guide for

Design and Construction of Brick Liners for Industrial

1

Chimneys

This standard is issued under the fixed designation C1298; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This guide covers procedures for the design, construction, and serviceability of brick liners for industrial chimneys. The

structural design criteria are applicable to vertical masonry cantilever structures supported only at their base, either by a foundation,

a concrete pedestal, or by some means from the outer concrete shell. Excluded from direct consideration are single-wythe, sectional

brick linings that are supported on a series of corbels cast in the outer chimney shell.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

3

C395 Specification for Chemical-Resistant Resin Mortars (Withdrawn 2021)

3

C466 Specification for Chemically Setting Silicate and Silica Chemical-Resistant Mortars (Withdrawn 2021)

C980 Specification for Industrial Chimney Lining Brick

E447C1314 Test Method for Compressive Strength of Laboratory Constructed Masonry Prisms (Withdrawn 1997)

E111 Test Method for Young’s Modulus, Tangent Modulus, and Chord Modulus

2.2 ACI Standard:

4

307–88 Practice for the Design and Construction of Cast-In-Place Reinforced Concrete Chimneys

2.3 ASCE Standard:

5

ASCE 7-88 Minimum Design Loads for Buildings and Other Structures (Formerly ANSI A58.1)

1

This guide is under the jurisdiction of ASTM Committee C15 on Manufactured Masonry Units and is the direct responsibility of Subcommittee C15.05 on Masonry

Assemblies.

Current edition approved June 1, 2013June 1, 2021. Published June 2013June 2021. Originally approved in 1995. Last previous edition approved in 20072013 as

C1298 – 95 (2007).(2013). DOI: 10.1520/C1298-95R13.10.1520/C1298-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

4

Available from American Concrete Institute (ACI), P.O. Box 9094, 38800 Country Club Drive, Farmington Hills, MI 48333-9094, http://www.aci-int.org.48331-3439,

http:// www.concrete.org.

5

Available from American Society of Civil Engineers (ASCE), 1801 Alexander Bell Dr., Reston, VA 20191, http://www.asce.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1298 − 21

2.4 Other Standard:

6

1991 Uniform Building Code, International Conference of Building Code Officials, California

7

TMS 402 ⁄602 Building Code Requirements and Specifications for Masonry Structures

3. Terminology

3.1 Notations:

a = brick dimension in radial direction (in.)

b = brick dimension in tangential direction (in.)

c = brick chamfer (in.)

C = chimney deflection due to earthquake loads (in.)

e

d = outside diameter of brick liner (in.)

D = mean liner diameter at a given elevation (in.)

E = masonry modulus of elasticity as established by performing brick prism

m

test or by past experience, psi

f = critical liner buckling stress, psi

b

f = maximum vertical compressive stress due to dead load, psi

d

f = maximum vertical compressive stress due to the combined effect of

de

earthquake and dead load,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.