ASTM D4894-98a

(Specification)Standard Specification for Polytetrafluoroethylene (PTFE) Granular Molding and Ram Extrusion Materials

Standard Specification for Polytetrafluoroethylene (PTFE) Granular Molding and Ram Extrusion Materials

SCOPE

1.1 This specification covers granular resins of polytetrafluoroethylene (PTFE) that have never been preformed or molded and are normally processed by methods similar to those used in powder metallurgy or ceramics, or by special extrusion processes. These PTFE resins are homopolymers of tetrafluoroethylene, or, in some cases, modified homopolymers containing not more than one percent by weight of other fluoromonomers. The usual methods of processing thermoplastics generally are not applicable to these materials because of their viscoelastic properties at processing temperatures. The materials included herein do not include mixtures of PTFE resin with additives such as colorants, fillers or plasticizers; nor do they include reprocessed or reground resin or any fabricated articles. The methods and properties included are those required to identify the various types of resins. Additional procedures are provided in the Appendix for further characterization of the resins.

1.2 The materials covered by this specification formerly were covered in Specification D1457 as Types I, IV, V, VI, VII and VIII.

1.3 The values stated in SI units as detailed in Practice E380 are to be regarded as the standard, and the practices of E380 are incorporated herein.

1.4 The following precautionary caveat pertains only to the Specimen Preparation section, Section 9, and the Test Methods section, Section 10, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See Notes 1, 3 and 9 for specific cautionary statements. Note 1-Most of the technical content of this standard is included as part of ISO 12086-1 and ISO 12086-2 Part 2. These standards have been approved for publication and are in the final editing process.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4894 – 98a

Standard Specification for

Polytetrafluoroethylene (PTFE) Granular Molding and Ram

Extrusion Materials

This standard is issued under the fixed designation D 4894; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope * D 638M Test Method for Tensile Properties of Plastics

[Metric]

1.1 This specification covers granular resins and test meth-

D 792 Test Methods for Density Specific Gravity (Relative

ods for polytetrafluoroethylene (PTFE) that have never been

Density) and Density of Plastics by Displacement

preformed or molded and are normally processed by methods

D 883 Terminology Relating to Plastics

similar to those used in powder metallurgy or ceramics, or by

D 1505 Test Method for Density by the Density-Gradient

special extrusion processes. These PTFE resins are homopoly-

Technique

mers of tetrafluoroethylene, or, in some cases, modified ho-

D 1895 Test Methods for Apparent Density, Bulk Factor,

mopolymers containing not more than one percent by weight of

and Pourability of Plastic Materials

other fluoromonomers. The usual methods of processing ther-

D 3295 Specification for PTFE Tubing

moplastics generally are not applicable to these materials

D 3892 Practice for Packaging/Packing of Plastics

because of their viscoelastic properties at processing tempera-

D 4441 Specification for Aqueous Dispersions of Polytet-

tures. The materials included herein do not include mixtures of

,

4 5

rafluoroethylene

PTFE resin with additives such as colorants, fillers or plasti-

D 4591 Test Method for Determining Temperatures and

cizers; nor do they include reprocessed or reground resin or any

Heats of Transitions of Fluoropolymers by Differential

fabricated articles. The methods and properties included are

Scanning Calorimetry

those required to identify the various types of resins. Addi-

D 4895 Specification for Polytetrafluoroethylene (PTFE)

tional procedures are provided in the Appendix for further

4,5

Resins Produced From Dispersion

characterization of the resins.

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

1.2 The values stated in SI units as detailed in IEEE/ASTM

poses

SI-10 are to be regarded as the standard, and the practices of

E 177 Practice for Use of the Terms Precision and Bias in

IEEE/ASTM SI-10 are incorporated herein.

ASTM Test Methods

1.3 The following precautionary caveat pertains only to the

IEEE/ASTM SI 10-1997 Standard for Use of the Interna-

Specimen Preparation section, Section 9, and the Test Methods

tional System of Units (SI): The Modern Metric System

section, Section 10, of this specification: This specification

2.2 ISO Standards:

does not purport to address all of the safety concerns, if any,

ISO 12086-1 Plastics—Fluoropolymer Dispersions and

associated with its use. It is the responsibility of the user of this

Moulding and Extrusion Materials—Part 1: Designation

standard to establish appropriate safety and health practices

System and Basis for Specification

and determine the applicability of regulatory limitations prior

ISO 12086-2 Test Methods for Fluoropolymers

to use. See Notes 3 and 9 for specific cautionary statements.

NOTE 1—Information in this specification is technically equivalent to 3. Terminology

related information in ISO 12086-1 and ISO 12086-2.

3.1 Definitions:

3.1.1 The terminology given in Terminology D 883 is ap-

2. Referenced Documents

plicable to this specification.

2.1 ASTM Standards:

D 618 Practice for Conditioning Plastics and Electrical

Insulating Materials for Testing

Annual Book of ASTM Standards, Vol 08.02.

Annual Book of ASTM Standards, Vol 08.03.

1 5

This specification is under the jurisdiction of Committee D-20 on Plastics and Specifications for other forms of polytetrafluoroethylene may be found in

is the direct responsibility of Subcommittee D20.15 Thermoplastic Materials. Specifications D 4441 and D 4895.

Current edition approved Nov. 10, 1998. Published March 1999. Originally Annual Book of ASTM Standards, Vol 14.02.

published as D 4894 – 89. Last previous edition D 4894 – 98. Available from American National Standards Institute, 11 W. 42nd St., 13th

Annual Book of ASTM Standards, Vol 08.01. Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4894

3.2 Descriptions of Terms Specific to This Standard: 4.1.4 Type IV—Free-flowing resins. Generally made by

3.2.1 bulk density—the mass (in grams) per litre of resin treatment of finely divided resin to produce free-flowing

measured under the conditions of the test. agglomerates.

3.2.2 extended specific gravity (ESG)—the specific gravity 4.1.5 Type V—Presintered. Resin that has been treated

of a specimen of PTFE material molded as described in this thermally at or above the melting point of the resin at

specification and sintered (g.v.) for an extended period of time, atmospheric pressure without having been previously pre-

compared to the sintering time for the measurement of standard formed.

specific gravity (SSG), using the appropriate sintering schedule 4.1.6 Type VI—Resin, not presintered, but for ram extrusion

given in this specification. only.

3.2.3 lot, n—one production run or a uniform blend of two

NOTE 2—See Tables 1 and 2 for division of Types by Grades, and

or more production runs.

footnotes to Tables 1 and 2 (and Table X2.1 in Appendix X2.) for former

3.2.4 preforming—compacting powdered PTFE material

classifications.

under pressure in a mold to produce a solid object, called a

4.2 A one-line system may be used to specify materials

preform, that is capable of being handled. Molding and

covered by this specification. The system uses predefined cells

compaction are terms used interchangeably with preforming

to refer to specific aspects of this specification, illustrated as

for PTFE.

follows:

3.2.5 reground resin—that produced by grinding PTFE

Specification

material that has been preformed but has never been sintered.

Standard Number Block : Type : Grade : Class : Special notes

3.2.6 reprocessed resin—that produced by grinding PTFE

:: : : :

material that has been both preformed and sintered.

Example: ASTM III 2

3.2.7 sintering—as it applies to PTFE, a thermal treatment

D4894–97

during which the PTFE is melted and recrystallized by cooling

with coalescence occurring during the treatment.

For this example, the line callout would be ASTM

3.2.8 skiving—a machining operation during which a con-

D 4894 – 97, III2, and would specify a granular polytetrafluo-

tinuous film of PTFE material is peeled from the lateral surface

roethylene that has all of the properties listed for that Type and

of a cylindrical sintered molding.

Grade in the appropriate specified properties, Tables, or both,

3.2.9 standard specific gravity (SSG)—the specific gravity

in this specification. In this case there is no Class item so the

of a specimen of PTFE material molded as described in this

cell position for class is left blank. A comma is used as the

specification and sintered using the appropriate sintering

separator between Standard Number and Type. Separators are

schedule given in this specification.

not needed between Type, Grade, and Class. Provision for

3.2.10 thermal instability index (TII)—a measure of the

Special Notes is included so that other information can be

decrease in molecular weight of PTFE material which has been

provided when required. An example would be in Specification

heated for a prolonged period of time.

D 3295 where dimensions and tolerances are specified for each

AWG size within Type and Class. When Special Notes are

4. Classification

used, they should be preceded by a comma.

4.1 This specification covers the following six types of

PTFE generally used for compression molding or ram extru- 5. Mechanical Properties

sion, or both:

5.1 The resins covered by this specification shall conform to

4.1.1 Type I—Resin used for general-purpose molding and

the requirements prescribed in Tables 1 and 2 when tested by

ram extrusion.

the procedures specified herein. Table 1 lists tests to be carried

4.1.2 Type II—Finely divided resin with an average particle

out on resins. Table 2 lists tests requiring specimens molded as

size less than 100 micrometers.

described in Section 3.1.1.

4.1.3 Type III—Modified resins, either finely divided or

free-flowing, typically used in applications requiring improved

resistance to creep and stress-relaxation in end-use. See the ASTM Form and Style Manual, available from ASTM Headquarters.

A

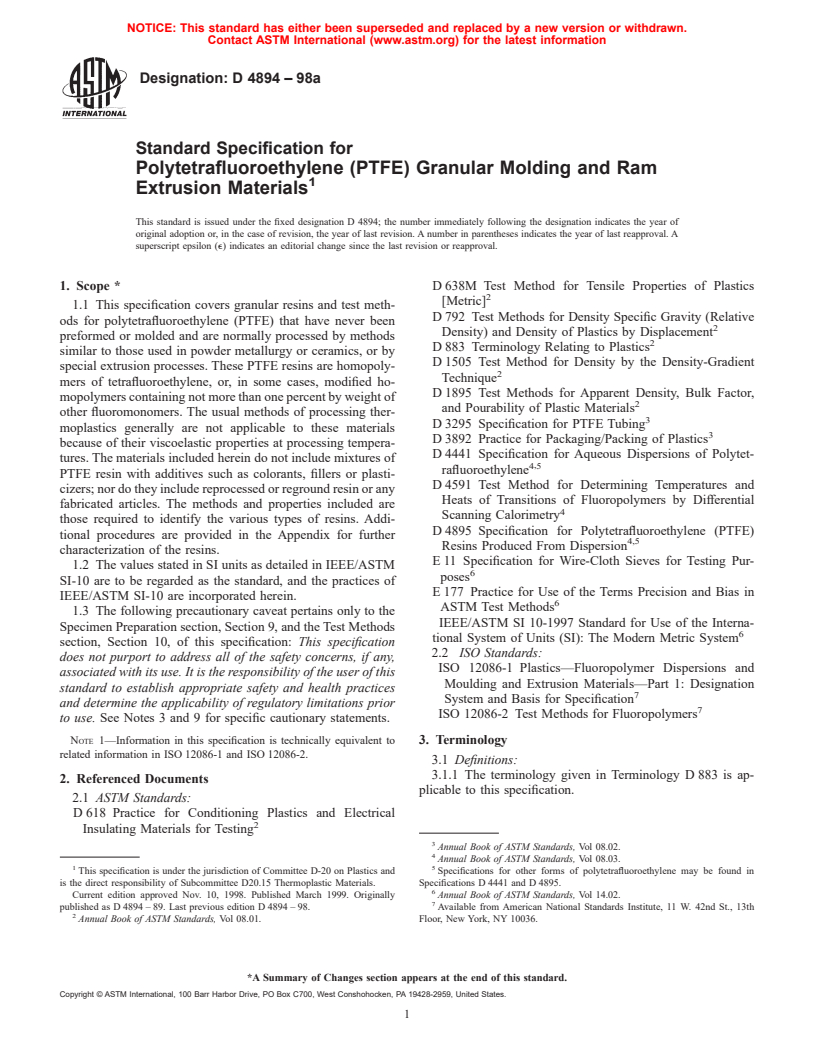

TABLE 1 Detail Requirements for Tests on Resins

Melting Peak Temperature

Particle Size, Average Diameter,

Type Grade Bulk Density, g/L Water Content, max, %

μm

Initial °C Second °C

A

I 1 700 6 100 500 6 150 0.04 327 6 10

A

2 675 6 50 375 6 75 0.04 327 6 10

A

II . . . . . . <100 0.04 327 6 10

A

III 1 400 6 125 <100 0.04 327 6 10

2 850 6 50 500 6 100 0.04 335 327 6 5

A

IV 1 650 6 150 550 6 225 0.04 327 6 10

A

2 >800 . . . 0.04 327 6 10

A

3 580 6 80 200 6 75 0.04 327 6 10

V . 635 6 100 500 6 250 0.04 327 6 10 327 6 10

VI . . . 650 6 150 800 6 250 0.04 335 327 6 5

A

>5°C above the second melting peak temperature.

D 4894

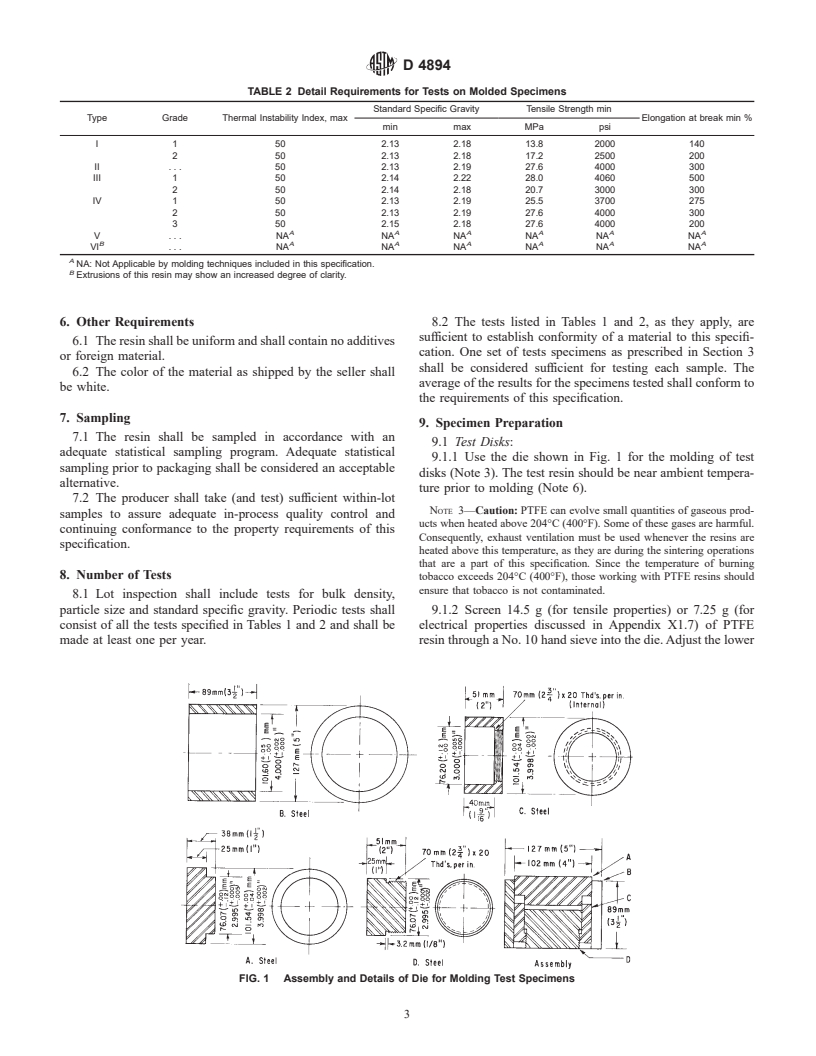

TABLE 2 Detail Requirements for Tests on Molded Specimens

Standard Specific Gravity Tensile Strength min

Type Grade Thermal Instability Index, max Elongation at break min %

min max MPa psi

I 1 50 2.13 2.18 13.8 2000 140

2 50 2.13 2.18 17.2 2500 200

II . . . 50 2.13 2.19 27.6 4000 300

III 1 50 2.14 2.22 28.0 4060 500

2 50 2.14 2.18 20.7 3000 300

IV 1 50 2.13 2.19 25.5 3700 275

2 50 2.13 2.19 27.6 4000 300

3 50 2.15 2.18 27.6 4000 200

A A A A A A

V . NA NA NA NA NA NA

B A A A A A A

VI . NA NA NA NA NA NA

A

NA: Not Applicable by molding techniques included in this specification.

B

Extrusions of this resin may show an increased degree of clarity.

6. Other Requirements 8.2 The tests listed in Tables 1 and 2, as they apply, are

sufficient to establish conformity of a material to this specifi-

6.1 The resin shall be uniform and shall contain no additives

cation. One set of tests specimens as prescribed in Section 3

or foreign material.

shall be considered sufficient for testing each sample. The

6.2 The color of the material as shipped by the seller shall

average of the results for the specimens tested shall conform to

be white.

the requirements of this specification.

7. Sampling

9. Specimen Preparation

7.1 The resin shall be sampled in accordance with an

9.1 Test Disks:

adequate statistical sampling program. Adequate statistical

9.1.1 Use the die shown in Fig. 1 for the molding of test

sampling prior to packaging shall be considered an acceptable

disks (Note 3). The test resin should be near ambient tempera-

alternative.

ture prior to molding (Note 6).

7.2 The producer shall take (and test) sufficient within-lot

NOTE 3—Caution: PTFE can evolve small quantities of gaseous prod-

samples to assure adequate in-process quality control and

ucts when heated above 204°C (400°F). Some of these gases are harmful.

continuing conformance to the property requirements of this

Consequently, exhaust ventilation must be used whenever the resins are

specification.

heated above this temperature, as they are during the sintering operations

that are a part of this specification. Since the temperature of burning

8. Number of Tests

tobacco exceeds 204°C (400°F), those working with PTFE resins should

ensure that tobacco is not contaminated.

8.1 Lot inspection shall include tests for bulk density,

particle size and standard specific gravity. Periodic tests shall 9.1.2 Screen 14.5 g (for tensile properties) or 7.25 g (for

consist of all the tests specified in Tables 1 and 2 and shall be electrical properties discussed in Appendix X1.7) of PTFE

made at least one per year. resin through a No. 10 hand sieve into the die. Adjust the lower

FIG. 1 Assembly and Details of Die for Molding Test Specimens

D 4894

plug height so that the resin in the die can be leveled by 12.0 6 0.1-g sample. Insert the die in a suitable hydraulic press

drawing a straightedge in contact with the top of the die across and apply pressure gradually (Note 4) until a pressure of 34.5

the top of the die cavity. Insert the die in a suitable hydraulic

MPa (5000 psi) is attained. Hold this pressure for 2 min.

press and apply pressure gradually (Note 4) until a total of 34.5

Remove the preform from the die. A wax pencil may be used

MPa (5000 psi) is attained. Hold this pressure for 3 min.

to write the sample identification on the preform at this time.

Remove the disk identification on the disk at this time.

9.2.3 Sinter the preforms according to Table 3 (Note 5).

NOTE 4—As a guide, increasing the pressure at a rate of 3.45 MPa (500

9.2.3.1 For SSG specimens use Procedure B for Types I, II

psi)/min is suggested until the desired maximum pressure is attained.

and IV and Procedure C for Type III.

9.1.3 Sinter the preforms according to Table 3 (Note 5).

9.2.3.2 For ESG specimens use Procedure F for Types I, II

9.1.3.1 Use Procedure B for Types I, II and IV and Proce-

and IV and Procedure G for Type III.

dure C for Type III.

NOTE 7—Improved precision in SSG and ESG test results has been

NOTE 5—Although the rate of heating application is not critical, the

obtained with the use of an upright, cylindrical oven and an aluminum

cooling cycle is most important and the conditions cited in these

sintering rack. The cylindrical oven has an inside diameter of 140 mm (5.5

procedures must be followed very closely. If they are not followed, the

in.) and an inside depth of 203 mm (8 in.) plus additional depth to

crystallinity of the disks and the resulting physical properties may be

accommodate a 50.8-mm (2-in.) thick cover, and is equipped with suitable

markedly changed. Therefore, the use of a programmed oven is recom-

heaters and controllers to sinter specimens according to the Procedures in

mended for the most precise sintering cycle control so that the hood

Table 3. The rack, as shown in Fig. 2, allows preforms to be placed

window may be left down during the entire sintering procedure, the latter

symmetrically in the center region of the oven. Place six preforms on each

being an important safety consideration.

of the middle oven rack shelves (if six or fewer preforms are to be

9.2 Test Specimens for Standard Specific Gravity (SSG) and sintered, place them on the middle rack, filling in with “dummies” as

needed). Place “dumm

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.