ASTM E242-01(2005)e1

(Specification)Standard Reference Radiographs for Appearances of Radiographic Images as Certain Parameters Are Changed

Standard Reference Radiographs for Appearances of Radiographic Images as Certain Parameters Are Changed

SCOPE

1.1 This document describes the appearance of a radiographic image where fundamental components of image quality are changed, that is, variables such as whether an X-ray or gamma ray source was used, the characteristics of the radiographic film and intensifying screens, and the geometrical configuration of the object under investigation as well as its associated radiographic set-up.

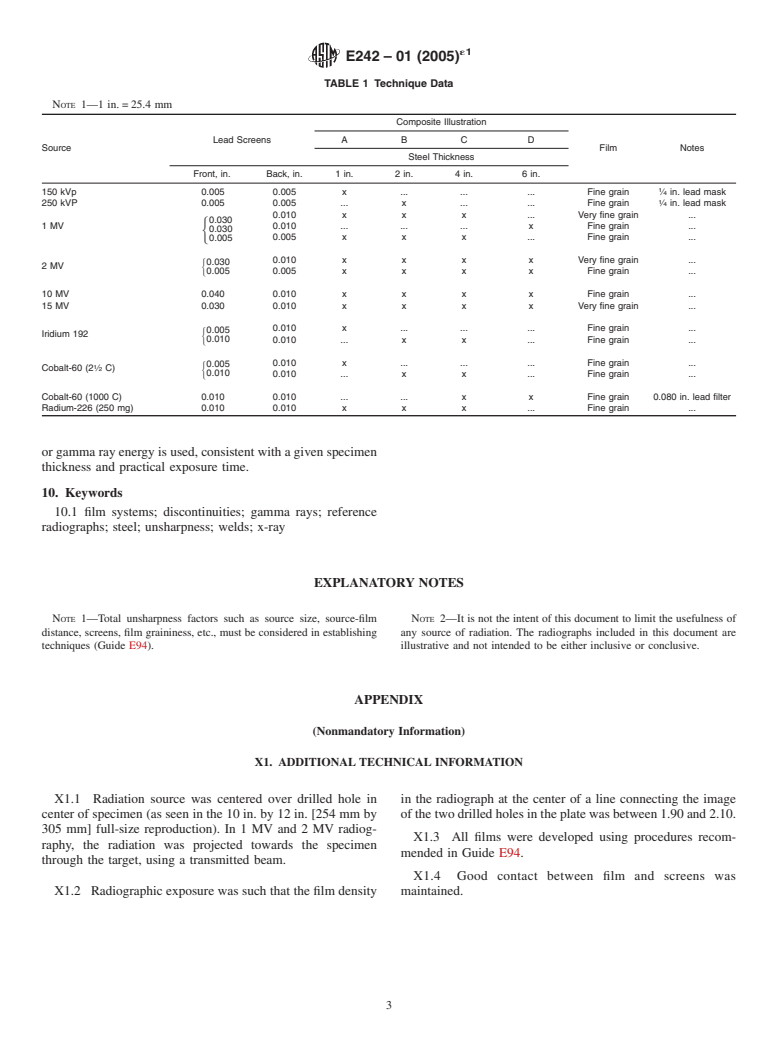

1.2 These reference radiographs consist of four composite illustrations and show how such factors as radiation energy, specimen thickness, and film properties affect the radiographic image. The reference radiograph films are an adjunct to this document and must be purchased separately from ASTM if needed.

1.3 The values stated in inch-pound units are to be regarded as the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:E242–01 (Reapproved 2005)

Standard Reference Radiographs for

Appearances of Radiographic Images as Certain Parameters

are Changed

This standard is issued under the fixed designation E242; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—A sentence about reference radiograph films was editorially added to 1.2 in December 2005.

1. Scope E746 Practice for Determining Relative Image Quality

Response of Industrial Radiographic Imaging Systems

1.1 This document describes the appearance of a radio-

E1316 Terminology for Nondestructive Examinations

graphic image where fundamental components of image qual-

E1815 Test Method for Classification of Film Systems for

ity are changed, that is, variables such as whether an X-ray or

Industrial Radiography

gamma ray source was used, the characteristics of the radio-

2.2 ASTM Adjuncts:

graphic film and intensifying screens, and the geometrical

Reference Radiographs for Appearances of Radiographic

configuration of the object under investigation as well as its

Images as Certain Parameters Are Changed

associated radiographic set-up.

1.2 These reference radiographs consist of four composite

3. Terminology

illustrations and show how such factors as radiation energy,

3.1 Definitions: For definitions of terms used in this docu-

specimen thickness, and film properties affect the radiographic

ment, see Terminology E1316, Section D.

image. The reference radiograph films are an adjunct to this

document and must be purchased separately from ASTM if

4. Significance and Use

needed.

4.1 A key consideration with any radiographic system is its

1.3 The values stated in inch-pound units are to be regarded

capability to resolve detail (that is, sensitivity). The degree of

as the standard.

obtainable sensitivity with a given system is dependent upon

1.4 This standard does not purport to address all of the

several radiographic parameters such as source energy level,

safety concerns, if any, associated with its use. It is the

film system, type and thickness of intensifying screens, and

responsibility of the user of this standard to establish appro-

material thickness radiographed. These reference radiographs

priate safety and health practices and determine the applica-

permit the user to estimate the degree of sensitivity change that

bility of regulatory limitations prior to use.

may be obtained when these parameters are varied from a

specific technique. This standard may also be used in conjunc-

2. Referenced Documents

4 tion with Test Method E1815 or with Test Method E746 to

2.1 ASTM Standards:

provide a basis for developing data for evaluation of a user’s

E94 Guide for Radiographic Examination

specific system. This data may assist a user in determining

appropriate parameters for obtaining desired degrees of radio-

graphic system sensitivity.

These reference radiographs are under the jurisdiction of ASTM Committee

E07 on Nondestructive Testing and is the direct responsibility of Subcommittee

5. Factors Affecting Radiographic Appearance

E07.02 on Reference Radiographs.

Current edition approved Dec. 1, 2005. Published February 2006. Originally

5.1 The final interpretation of the radiograph is greatly

approved in 1964. Last previous edition approved in 2001 as E242 - 01. DOI:

affected by the appearance of a discontinuity.Apoor technique

10.1520/E0242-01R05E01.

2 can minimize the radiographic appearance of a discontinuity

For ASME Boiler and Pressure Code applications see related Reference

and conversely the optimum technique can emphasize this

Radiographs SE-242 in the Code.

Available from ASTM Headquarters. Order RRE0242.

appearance.Theappearanceofaradiographicimageisaffected

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

mainly by:

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1.1 X-ray or gamma ray energy.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 5.1.2 Section thickness,

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

E242–01 (2005)

5.1.3 Unsharpness, and 6.3 Film Deterioration—Radiographic films are subject to

wear and tear from handling and use. The extent to which the

5.1.4 Film and screen combinations.

image deteriorates over time is a function of storage condi-

5.2 The equation that considers most of the above factors is:

tions, care in handling and amount of use. Reference radio-

Dx 5 [c~d 2 d !/Gµ#~kx 1 1! (1)

1 2

graph films are no exception and may exhibit a loss in image

quality over time. The radiographs should therefore be peri-

where:

odically examined for signs of wear and tear, including

Dx = thickness of discontinuity,

scratches, abrasions, stains, and so forth. Any reference radio-

c = constant,

graphs which show signs of excessive wear and tear which

d −d = minimum density change perceptible by eye,

1 2

G = film gradient, could influence the interpretation and use of the radiographs

µ = linear absorption coefficient (effective),

should be replaced.

k = scattering coefficient, and

7. Use of the Reference Radiographs

x = section thickness.

As the above equation shows, the minimum thickness of 7.1 As radiation energy increases, the radiographic appear-

ance of a given discontinuity becomes less distinct because of

detectable discontinuity (Dx) is:

the greater penetration of the radiation; that is, because of

5.2.1 A function of X-ray energy,

decreasingsubjectcontrast.Thereferenceradiographspermita

5.2.2 A function of section thickness, and

comparison of the radiographic appearance of the weld, at

5.2.3 An inverse function of film gradient.

particular thickness over a range of X-ray or gamma ray

5.3 Although not clearly indicated by the above relation, the

energies.

size of detectable discontinuity is also a function of unsharp-

7.2 Another condition that affects radiographic appearance

ness, see Guide E94.

is the variation of thickness for a given X-ray or gamma ray

energy. As the thickness of examined material is increased, a

6. Radiographic Illustrations

discontinuity becomes less distinct in the radiographic image.

This is due to two predominant factors:

6.1 A series of 36 radiographs, each on 10-in. by 12-in.

7.2.1 The X-ray or gamma ray beam divergence which

[254-mm by 305-mm] film, were taken of a 12-in. by 12-in.

produces unsharpness on the film when traversing a large

welded steel plate which contained discontinuiti

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.