ASTM D242-04

(Specification)Standard Specification for Mineral Filler For Bituminous Paving Mixtures

Standard Specification for Mineral Filler For Bituminous Paving Mixtures

SCOPE

1.1 This specification covers mineral filler added as a separate ingredient for use in bituminous paving mixtures.

1.2 The values stated in SI units are to be regarded as the standard. Inch-pound units, shown in parentheses, are for information only.

1.3 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 242 – 04

Standard Specification for

1

Mineral Filler For Bituminous Paving Mixtures

This standard is issued under the fixed designation D 242; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

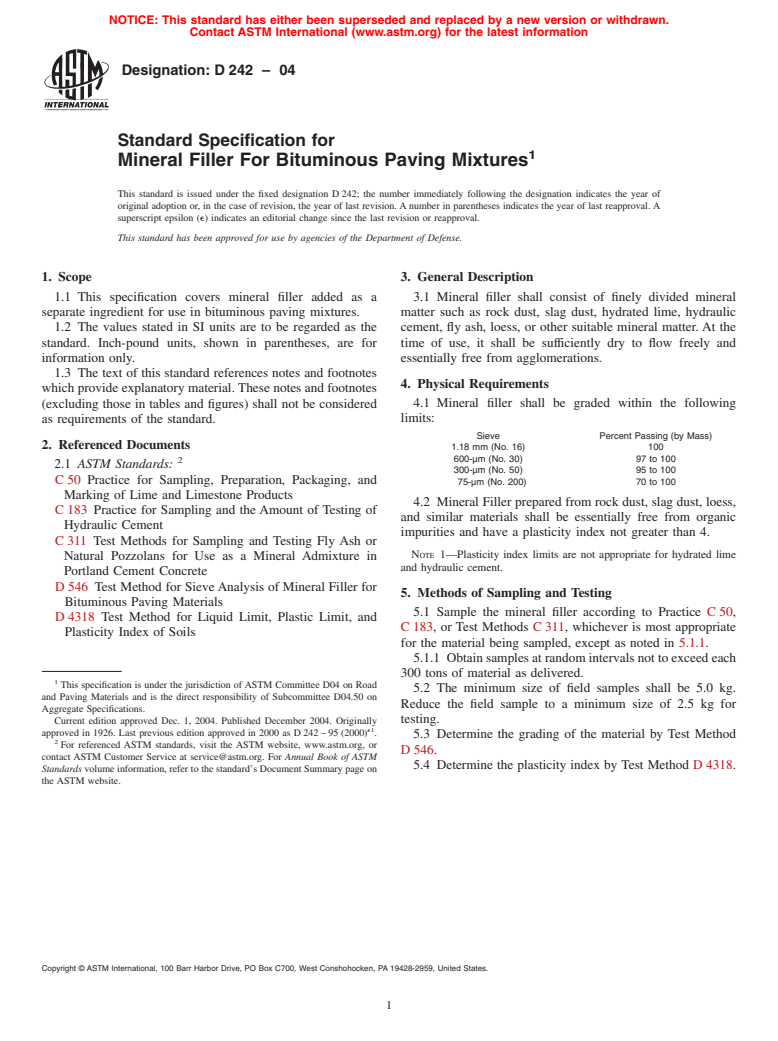

1. Scope 3. General Description

1.1 This specification covers mineral filler added as a 3.1 Mineral filler shall consist of finely divided mineral

separate ingredient for use in bituminous paving mixtures. matter such as rock dust, slag dust, hydrated lime, hydraulic

1.2 The values stated in SI units are to be regarded as the cement, fly ash, loess, or other suitable mineral matter. At the

standard. Inch-pound units, shown in parentheses, are for time of use, it shall be sufficiently dry to flow freely and

information only. essentially free from agglomerations.

1.3 The text of this standard references notes and footnotes

4. Physical Requirements

which provide explanatory material. These notes and footnotes

4.1 Mineral filler shall be graded within the following

(excluding those in tables and figures) shall not be considered

as requirements of the standard. limits:

Sieve Percent Passing (by Mass)

2. Referenced Documents

1.18 mm (No. 16) 100

600-µm (No. 30) 97 to 100

2

2.1 ASTM Standards:

300-µm (No. 50) 95 to 100

C50 Practice for Sampling, Preparation, Packaging, and 75-µm (No. 200) 70 to 100

Marking of Lime and Limestone Products

4.2 Mineral Filler prepared from rock dust, slag dust, loess,

C 183 Practice for Sampling and the Amount of Testing of

and similar materials shall be essentially free from organic

Hydraulic Cement

impurities and have a plasticity index not greater than 4.

C311 Test Methods for Sampling and Testing Fly Ash or

NOTE 1—Plasticity index limits are not appropriate for hydrated lime

Natural Pozzolans for Use as a Mineral Admixture in

and hydraulic cement.

Portland Cement Concrete

D 546 Test Method for Sieve Analysis of Mineral Filler for

5. Methods of Sampling and Testing

Bituminous Paving Materials

5.1 Sample the mineral filler according to Practice C50,

D 4318 Test Method for Liquid Limit, Plastic Limit, and

C 183, or Test MethodsC311, w

...

This May Also Interest You

SIGNIFICANCE AND USE

3.1 Recycling of deteriorated asphalt pavements is being used as a routine method of maintenance and rehabilitation. Utilization of existing materials as the major component of this procedure may yield benefits in quality, economy, and preservation of natural resources. Recycling takes many forms: hot, cold, in-situ, central plant, and surface. This practice may be used for various recycling methods.

3.2 This practice describes emulsified recycling (ER) agents as belonging to three groups: ER-1, ER-2, and ER-3 as shown in Table 1. The range of recycling methods demands several emulsified recycling agents. The groups should provide adequate freedom of selection for most recycling methods. (A) ER-1 shall be certified for dilution with potable water.(B) This specification allows a variety of emulsified asphalts. The engineer should take the steps necessary to keep incompatible materials from co-mingling in tanks or other vessels. It would be prudent to have the chemical charge nature certified by the supplier.(C) RTFO shall be the referee method. When approved by the engineer, the thin-film oven test (Test Method D1754/D1754M) may be substituted for compliance testing.

3.2.1 ER-1 is a material whose main function is to rejuvenate aged asphalt. The material is a petroleum derivative, and highly compatible with asphalts. It is classified by viscosity.

3.2.2 ER-2 and ER-3 are materials that combine rejuvenators and asphalt components in one emulsified asphalt. These soft residues are classified by low temperature penetration after aging. They are typically used in recycling where there is an increased demand for asphalt as when new aggregates are added, or where immediate cohesiveness is desired.

3.3 The choice of ER will be determined by the properties of the asphalt binder in the aged pavement, the methods of recycling planned, the amount, if any, of new aggregates, and other design needs.

SCOPE

1.1 This practice identifies emulsified petroleum products that may be used as recycling agents in recycled mixes. These materials are classified by viscosity or by low temperature penetration after aging.

1.2 This practice addresses emulsified materials designed specifically for use in recycling. The use of emulsified materials for recycling shall not be limited to this practice. For instance, the emulsified asphalts specified in Specifications D977 and D2397/D2397M may be used.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 The flash point is one measure of the tendency of the test specimen to form a flammable mixture with air under controlled laboratory conditions. It is only one of a number of properties that should be considered in assessing the overall flammability hazard of a material.

5.2 Flash point is used in shipping and safety regulations to define flammable and combustible materials. Consult the particular regulation involved for precise definitions of these classifications.

5.3 Flash point can indicate the possible presence of highly volatile and flammable materials in a relatively nonvolatile or nonflammable material.

5.4 Skin prevention technique involves assembling a restraining ring over a centrally-holed qualitative filter paper that is laid at the bottom of the COC (Cleveland open cup) test cup, prior to introduction of the sample specimen into the cup. This allows a column of the hot sample specimen to move up constantly, through the hole, to the surface of the test specimen so that the surface is maintained in the hot condition to prevent skin formation. (See 9.6).

5.5 Skin-forming asphalts may not be limited to those which are air blown/oxidized, polymerized or non-homogeneous materials that, although infrequently, exhibit some unique behavior and characteristics, as far as manifestation of flash point is concerned. At the flash point stage, this behavior may involve flame propagation across the surface or just a flame appearing at one or more points on the surface.

5.6 This test method shall be used to measure and describe the properties of materials, products, or assemblies in response to heat and a test flame under controlled laboratory conditions and shall not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test method may be used as elements of a fire risk assessment that takes into account all of the factors that are pertinent to an ass...

SCOPE

1.1 This test method describes the determination of the flash point and fire point of asphalt by a manual Cleveland open cup apparatus or an automated Cleveland open cup apparatus.

Note 1: Apparatus is the same as described in Test Method D92 with the addition of the materials for the skin prevention technique.

1.2 This test method is applicable to asphalts that can form a skin, and those that do not form a skin during heat treatment.

1.3 This test method is applicable to products with flash points above 79 °C (174 °F) and below 400 °C (752 °F), except fuel oils.

1.4 The precision has been determined over the temperature range of 300 °C to 370 °C (572 °F to 698 °F).

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 6.4, 7.1, 11.1, 11.2.3, and 11.3.4.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard8 pagesEnglish languagesale 15% off

SCOPE

1.1 This specification covers mineral filler added as a separate ingredient for use in asphalt mixtures.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification2 pagesEnglish languagesale 15% off

- Technical specification2 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 A standard procedure is necessary to establish property changes for spilled oils or petroleum products at different oil weathering stages.

5.2 This procedure employs standardized equipment, and test procedures.

5.3 This procedure should be performed at the stages of weathering corresponding to the spill conditions of interest.

SCOPE

1.1 This guide summarizes methods to fractionate oil by evaporative weathering and then measure the properties and behavior of the weathered oil. The results of this guide can provide oil behavior data for input into oil spill models and response method selection.

1.2 This guide covers general procedures for oil weathering and behavior and does not cover all possible procedures which may be applicable to this topic.

1.3 The results obtained using this guide are intended to provide baseline data for the behavior of oil and petroleum products when spilled and input to oil spill models.

1.4 The results obtained using this guide can be used directly to predict certain facets of oil spill behavior or as input to oil spill models.

1.5 The accuracy of the guide depends very much on the representative nature of the oil sample used. Certain oils can have different properties depending on their chemical contents at the moment a sample is taken.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Guide4 pagesEnglish languagesale 15% off

- Guide4 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 Many petroleum products, and some non-petroleum materials, are used as lubricants, and the correct operation of the equipment depends upon the appropriate viscosity of the liquid being used. In addition, the viscosity of many petroleum fuels is important for the estimation of optimum storage, handling, and operational conditions. Thus, the accurate determination of viscosity is essential to many product specifications.

SCOPE

1.1 This test method specifies a procedure for the determination of the kinematic viscosity, ν, of liquid petroleum products, both transparent and opaque, by measuring the time for a volume of liquid to flow under gravity through a calibrated glass capillary viscometer. The dynamic viscosity, η, can be obtained by multiplying the kinematic viscosity, ν, by the density, ρ, of the liquid.

Note 1: For the measurement of the kinematic viscosity and viscosity of bitumens, see also Test Methods D2170 and D2171.

Note 2: ISO 3104 corresponds to Test Method D445 – 03.

1.2 The result obtained from this test method is dependent upon the behavior of the sample and is intended for application to liquids for which primarily the shear stress and shear rates are proportional (Newtonian flow behavior). If, however, the viscosity varies significantly with the rate of shear, different results may be obtained from viscometers of different capillary diameters. The procedure and precision values for residual fuel oils, which under some conditions exhibit non-Newtonian behavior, have been included.

1.3 The range of kinematic viscosities covered by this test method is from 0.2 mm2/s to 300 000 mm2/s (see Table A1.1) at all temperatures (see 6.3 and 6.4). The precision has only been determined for those materials, kinematic viscosity ranges and temperatures as shown in the footnotes to the precision section.

1.4 The values stated in SI units are to be regarded as standard. The SI unit used in this test method for kinematic viscosity is mm2/s, and the SI unit used in this test method for dynamic viscosity is mPa·s. For user reference, 1 mm2/s = 10-6 m2/s = 1 cSt and 1 mPa·s = 1 cP = 0.001 Pa·s.

1.5 WARNING—Mercury has been designated by many regulatory agencies as a hazardous substance that can cause serious medical issues. Mercury, or its vapor, has been demonstrated to be hazardous to health and corrosive to materials. Use Caution when handling mercury and mercury-containing products. See the applicable product Safety Data Sheet (SDS) for additional information. The potential exists that selling mercury or mercury-containing products, or both, is prohibited by local or national law. Users must determine legality of sales in their location.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard16 pagesEnglish languagesale 15% off

- Standard16 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 Heat capacities obtained by this method are those at atmospheric pressure. However, because the temperature range is low, the calculated values are similar to saturated liquid heat capacities in the temperature-pressure range required for most engineering design.

SCOPE

1.1 This test method covers the calculation of liquid heat capacity, Btu/lb · °F (kJ/kg · K), at atmospheric pressure, of petroleum fuels for which distillation data may be obtained in accordance with Test Method D86 without reaching a decomposition point prior to obtaining 90 % by volume distilled.

1.2 This test method is not applicable at temperatures less than 0 °F (−18 °C) and greater than 60 °F (16 °C) above the volumetric average boiling point of the fuel.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard3 pagesEnglish languagesale 15% off

- Standard3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 A petroleum products, liquid fuels, and lubricants testing laboratory plays a crucial role in product quality management and customer satisfaction. It is essential for a laboratory to provide quality data. This document provides guidance for establishing and maintaining a quality management system in a laboratory.

4.1.1 The word ‘customer’ can refer to both customers internal and external to the laboratory or organization.

SCOPE

1.1 This practice covers the establishment and maintenance of the essentials of a quality management system in laboratories engaged in the analysis of petroleum products, liquid fuels, and lubricants. It is designed to be used in conjunction with Practice D6299.

Note 1: This practice is based on the quality management concepts and principles advocated in ANSI/ISO/ASQ Q9000 standards, ISO/IEC 17025, ASQ Manual,2 and ASTM standards such as D3244, D4182, D4621, D6299, D6300, D7372, E29, E177, E456, E548, E882, E994, E1301, E1323, STP 15D,3 and STP 1209.4

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory requirements prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard14 pagesEnglish languagesale 15% off

- Standard14 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 The boiling range distribution of light and medium petroleum distillate fractions provides an insight into the composition of feed stocks and products related to petroleum refining process, This gas chromatographic determination of boiling range can be used to replace conventional distillation methods for control of refining operations. This test method can be used for product specification testing with the mutual agreement of interested parties.

5.2 This test method extends the scope of boiling range determination by gas chromatography to include light and medium petroleum distillate fractions beyond the scope of Test Method D2887 (538 °C) and below Test Method D6352 (700 °C).

5.3 Boiling range distributions obtained by this test method are theoretically equivalent to those obtained by true boiling point (TBP) distillation (see Test Method D2892). They are not equivalent to results from low efficiency distillation such as those obtained with Test Method D86 or D1160.

SCOPE

1.1 This test method covers the determination of the boiling range distribution of petroleum products. This test method is applicable to petroleum distillates having an initial boiling point greater than 100 °C and a final boiling point less than 615 °C at atmospheric pressure as measured by this test method.

1.2 The test method is not applicable for analysis of petroleum distillates containing low molecular weight components (for example, naphthas, reformates, gasolines, crude oils). Materials containing heterogeneous components (for example, alcohols, ethers, acids or esters) or residue are not to be analyzed by this test method. See Test Methods D7096, D2887, D6352, or D7169.

1.3 This test method uses the principles of simulated distillation methodology.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard16 pagesEnglish languagesale 15% off

- Standard16 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 The bromine number is useful as a measure of aliphatic unsaturation in petroleum samples. When used in conjunction with the calculation procedure described in Annex A2, it can be used to estimate the percentage of olefins in petroleum distillates boiling up to approximately 315 °C (600 °F).

5.2 The bromine number of commercial aliphatic monoolefins provides supporting evidence of their purity and identity.

SCOPE

1.1 This test method3 covers the determination of the bromine number of the following materials:

1.1.1 Petroleum distillates that are substantially free of material lighter than isobutane and that have 90 % distillation points (by Test Method D86) under 327 °C (626 °F). This test method is generally applicable to gasoline (including leaded, unleaded, and oxygenated fuels), kerosine, and distillates in the gas oil range that fall in the following limits:

90 % Distillation Point, °C (°F)

Bromine Number, max3

Under 205 (400)

175

205 to 327 (400 to 626)

10

1.1.2 Commercial olefins that are essentially mixtures of aliphatic mono-olefins and that fall within the range of 95 to 165 bromine number (see Note 1). This test method has been found suitable for such materials as commercial propylene trimer and tetramer, butene dimer, and mixed nonenes, octenes, and heptenes. This test method is not satisfactory for normal alpha-olefins.

Note 1: These limits are imposed since the precision of this test method has been determined only up to or within the range of these bromine numbers.

1.2 The magnitude of the bromine number is an indication of the quantity of bromine-reactive constituents, not an identification of constituents; therefore, its application as a measure of olefinic unsaturation should not be undertaken without the study given in Annex A1.

1.3 For petroleum hydrocarbon mixtures of bromine number less than 1.0, a more precise measure for bromine-reactive constituents can be obtained by using Test Method D2710. If the bromine number is less than 0.5, then Test Method D2710 or the comparable bromine index methods for industrial aromatic hydrocarbons, Test Methods D1492 or D5776 must be used in accordance with their respective scopes. The practice of using a factor of 1000 to convert bromine number to bromine index is not applicable for these lower values of bromine number.

1.4 The values stated in SI units are to be regarded as the standard.

1.4.1 Exception—The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see Sections 7, 8, and 9.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard10 pagesEnglish languagesale 15% off

- Standard10 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 Predicting the viscosity of a blend of components is a common problem. Both the Wright Blending Method and the ASTM Blending Method, described in this practice, may be used to solve this problem.

5.2 The inverse problem, predicating the required blend fractions of components to meet a specified viscosity at a given temperature may also be solved using either the Inverse Wright Blending Method or the Inverse ASTM Blending Method.

5.3 The Wright Blending Methods are generally preferred since they have a firmer basis in theory, and are more accurate. The Wright Blending Methods require component viscosities to be known at two temperatures. The ASTM Blending Methods are mathematically simpler and may be used when viscosities are known at a single temperature.

5.4 Although this practice was developed using kinematic viscosity and volume fraction of each component, the dynamic viscosity or mass fraction, or both, may be used instead with minimal error if the densities of the components do not differ greatly. For fuel blends, it was found that viscosity blending using mass fractions gave more accurate results. For base stock blends, there was no significant difference between mass fraction and volume fraction calculations.

5.5 The calculations described in this practice have been computerized as a spreadsheet and are available as an adjunct.3

SCOPE

1.1 This practice covers the procedures for calculating the estimated kinematic viscosity of a blend of two or more petroleum products, such as lubricating oil base stocks, fuel components, residual fuel oil with kerosene, crude oils, and related products, from their kinematic viscosities and blend fractions.

1.2 This practice allows for the estimation of the fraction of each of two petroleum products needed to prepare a blend meeting a specific viscosity.

1.3 This practice may not be applicable to other types of products, or to materials which exhibit strong non-Newtonian properties, such as viscosity index improvers, additive packages, and products containing particulates.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 Logarithms may be either common logarithms or natural logarithms, as long as the same are used consistently. This practice uses common logarithms. If natural logarithms are used, the inverse function, exp(×), must be used in place of the base 10 exponential function, 10×, used herein.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and to determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard9 pagesEnglish languagesale 15% off

- Standard9 pagesEnglish languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.