ASTM D2899-12

(Practice)Standard Practice for Establishing Allowable Stresses for Round Timber Piles

Standard Practice for Establishing Allowable Stresses for Round Timber Piles

SIGNIFICANCE AND USE

This practice is intended for use by associations, technical societies and other groups that develop national design standards and use recommendations for round timber piles.

In using allowable stresses established under this practice, factors specific to each end use which may affect the performance of the pile system shall be considered. Such factors include the location of the critical section, the bearing capacity of the soil, the ability of the pile to withstand driving forces and conditions of service.

SCOPE

1.1 This practice contains procedures for establishing allowable stresses for round timber piles starting with clear wood strength properties.

1.2 Stresses established under this practice are applicable to piles conforming to the quality, straightness, spiral grain, knot, check, shake, and split provisions of Specification D25.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2899 − 12

Standard Practice for

1

Establishing Allowable Stresses for Round Timber Piles

This standard is issued under the fixed designation D2899; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope into a pile. A positive skin friction refers to pile loads

distributed to the soil. Negative skin friction distributes load to

1.1 Thispracticecontainsproceduresforestablishingallow-

the pile when soil strata subside or consolidate.

able stresses for round timber piles starting with clear wood

strength properties.

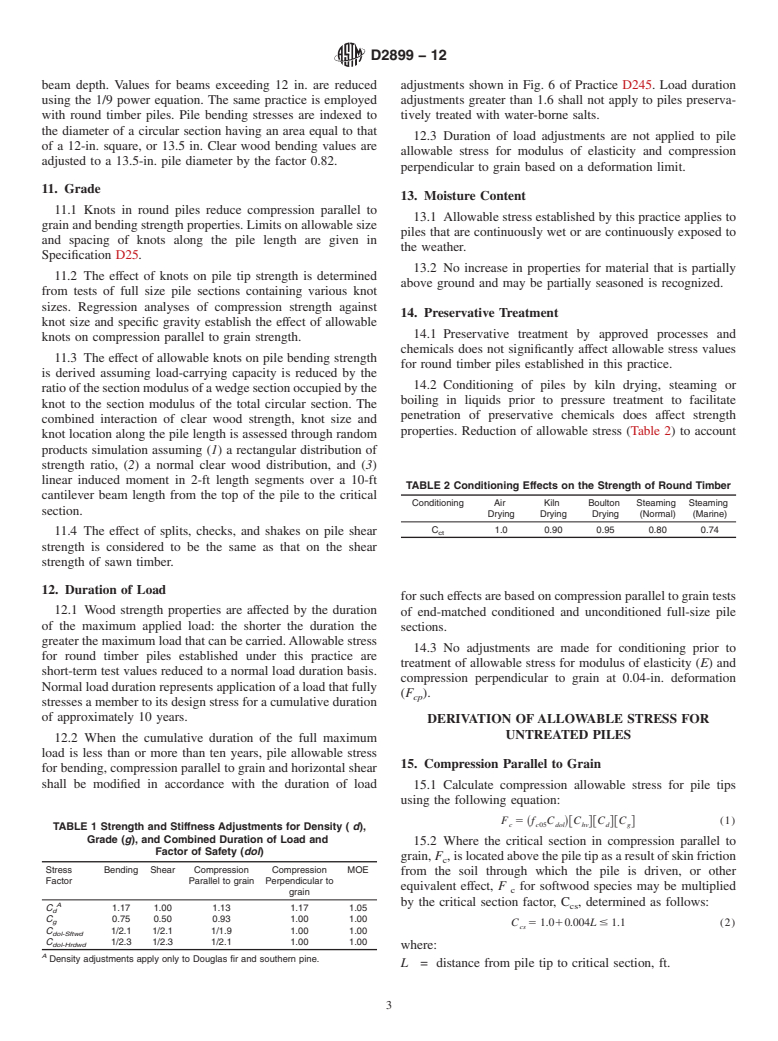

3.2 Symbols: C = adjustment for small clear compression

cp

perp for annual ring orientation (1/1.67)

1.2 Stresses established under this practice are applicable to

C = conditioning factor

ct

piles conforming to the quality, straightness, spiral grain, knot,

C = adjustment for duration of load and factor of safety

dol

check, shake, and split provisions of Specification D25.

C = adjustment for density applied for Douglas fir and

d

1.3 This standard does not purport to address all of the

Southern pine only

safety concerns, if any, associated with its use. It is the

C = combined adjustment for form and size (= 0.97)

fs

responsibility of the user of this standard to establish appro-

C = adjustment for grade characteristics applied to all

g

priate safety and health practices and determine the applica-

species including bending (0.75), compression (0.93), and

bility of regulatory limitations prior to use.

shear (0.50)

C = adjustment for height in the tree (= 0.96 if softwoods

2. Referenced Documents h

and = 1.0 for hardwoods)

2

2.1 ASTM Standards:

C = adjustment for height and for reduced variability

hv

D25 Specification for Round Timber Piles

(MOR = 0.91forsoftwoods,1.05forhardwoods, C// = 0.91for

D245 Practice for Establishing Structural Grades and Re-

softwoods, 1.05 for hardwoods, Shear = 0.99 for softwoods,

lated Allowable Properties for Visually Graded Lumber

1.03 for hardwoods)

D2555 PracticeforEstablishingClearWoodStrengthValues

C = load sharing adjustment (structural engineers option)

ls

C = size adjustment

3. Terminology s

C = adjustment for shear deflection in calculation for bend-

v

3.1 Definitions:

ing modulus of elasticity (= 1.06)

3.1.1 allowable stress—the numeric value of pile strength

D = diameter of a round timber pile

that is appropriate for use in structural analysis.

E = clear wood unseasoned average modulus of elasticity

3.1.2 end-bearing—compression-parallel-to-the-grain stress

from Test Methods D2555

resulting when pile load is not carried to the soil through skin

MOE = modulus of elasticity (average)

friction.

F = allowable stress for stress designated by the subscript β

β

3.1.3 load sharing—the distribution of load in proportion to F = allowable compression stress for pile tips

c

pile stiffness. This results in piles that perform as a group f = small clear lower 5 % exclusion compression strength

c05

reducing effects of between-pile variability and increasing in accordance with Test Methods D2555

system reliability over that of piles which perform indepen- f = lower 5 % exclusion value for stress “x” determined

i05

dently. using the green, small clear strength and standard deviation

values reported in Test Methods D2555

3.1.4 skin friction—the interaction between the pile surface

β = stress value subscripts, c = compression parallel,

and the soil which serves to distribute load either away from or

cp = compression perpendicular, b = bending, v = shear

1

This practice is under the jurisdiction of ASTM Committee D07 on Wood and

4. Significance and Use

is the direct responsibility of Subcommittee D07.04 on Pole and Pile Products.

Current edition approved April 1, 2012. Published April 2012. Originally

4.1 This practice is intended for use by associations, tech-

approved in 1970 as D2899 – 70 T. Last previous edition approved in 2011 as

nical societies and other groups that develop national design

D2899 – 11. DOI: 10.1520/D2899-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or standards and use recommendations for round timber piles.

contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM

4.2 In using allowable stresses established under this

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. practice, factors specific to each end use which may affect the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2899 − 12

performance of the pile system shall b

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D2899–11 Designation:D2899–12

Standard Practice for

1

Establishing Allowable Stresses for Round Timber Piles

This standard is issued under the fixed designation D2899; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Thispracticecontainsproceduresforestablishingallowablestressesforroundtimberpilesstartingwithclearwoodstrength

properties.

1.2 Stresses established under this practice are applicable to piles conforming to the quality, straightness, spiral grain, knot,

check, shake, and split provisions of Specification D25.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D25 Specification for Round Timber Piles

D245 Practice for Establishing Structural Grades and Related Allowable Properties for Visually Graded Lumber

D2555 Practice for Establishing Clear Wood Strength Values

3. Terminology

3.1 Definitions:

3.1.1 allowable stress—the numeric value of pile strength that is appropriate for use in structural analysis.

3.1.2 end-bearing—compression-parallel-to-the-grain stress resulting when pile load is not carried to the soil through skin

friction.

3.1.3 load sharing—the distribution of load in proportion to pile stiffness.This results in piles that perform as a group reducing

effects of between-pile variability and increasing system reliability over that of piles which perform independently.

3.1.4 skin friction—the interaction between the pile surface and the soil which serves to distribute load either away from or into

a pile. A positive skin friction refers to pile loads distributed to the soil. Negative skin friction distributes load to the pile when

soil strata subside or consolidate.

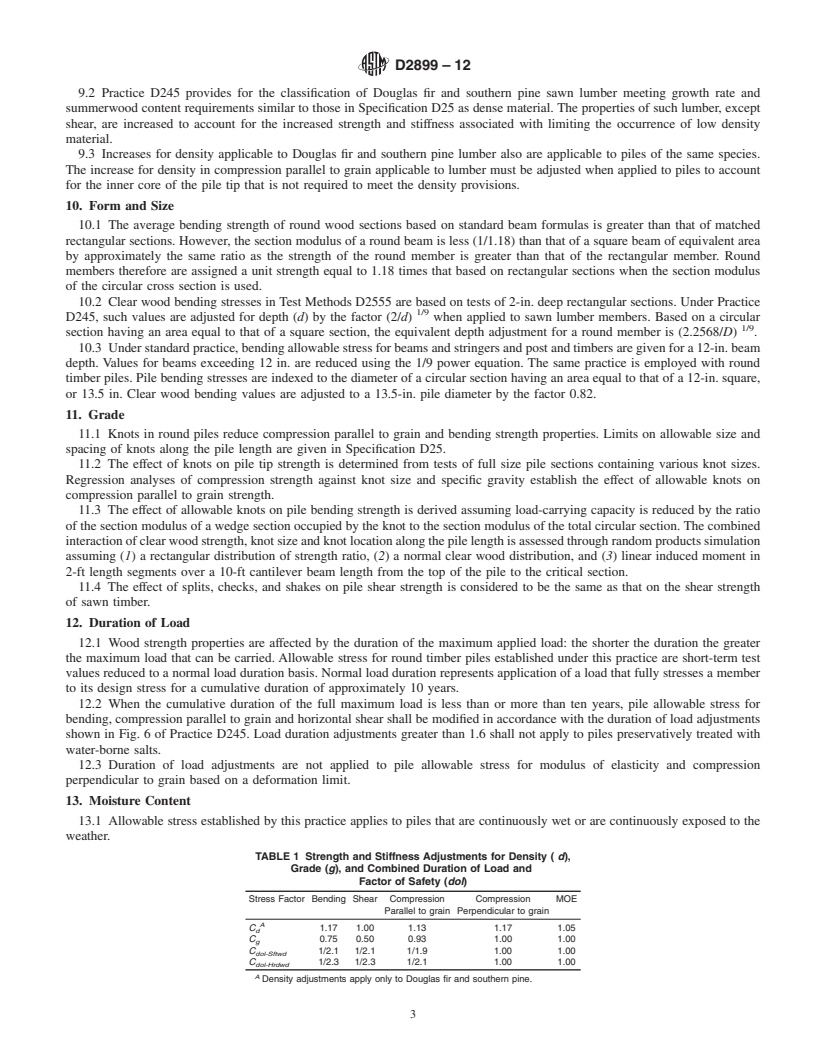

3.2 Symbols:

C = adjustment for small clear compression perp for annual ring orientation (1/1.67)

cp

C = conditioning factor

ct

C = adjustment for duration of load and factor of safety

dol

C = adjustment for density applied for Douglas fir and Southern pine only

d

C = combined adjustment for form and size (= 0.97)

fs

C = adjustment for grade characteristics applied to all species including bending (0.75), compression (0.93), and shear (0.50)

g

C = adjustment for height in the tree (= 0.96 if softwoods and = 1.0 for hardwoods)

h

C = adjustment for height and for reduced variability (MOR = 0.91 for softwoods, 1.05 for hardwoods, C// = 0.91 for

hv

softwoods, 1.05 for hardwoods, Shear = 0.99 for softwoods, 1.03 for hardwoods)

C = load sharing adjustment (structural engineers option)

ls

C = size adjustment

s

C = adjustment for shear deflection in calculation for bending modulus of elasticity (= 1.06)

v

D = diameter of a round timber pile

1

This practice is under the jurisdiction of ASTM Committee D07 on Wood and is the direct responsibility of Subcommittee D07.04 on Pole and Pile Products.

Current edition approved Nov. 15, 2011. Published December 2011. Originally approved in 1970 as D2899–70T. Last previous edition approved in 2003 as D2899–03.

DOI: 10.1520/D2899-11.

Current edition approvedApril 1, 2012. PublishedApril 2012. Originally approved in 1970 as D2899 – 70 T. Last previous edition approved in 2011 as D2899 – 11. DOI:

10.1520/D2899-12.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2899–12

E = clear wood unseasoned average modulus of elasticity from Test Methods D2555

MOE = modulus of elasticity (average)

F = allowable stress for stress designated by the subscript b

b

F = allowable compression stress for pile tips

c

f = small clear lower 5 % exclusion compression strength in accordance with Test Methods D2555

c05

f = lower 5 % exclusion value for stress “x” determined using the green, small clear strength and standard deviation values

i05

reported in Test Methods D2555

b = stress value subscrip

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.