ASTM D2899-12(2017)

(Practice)Standard Practice for Establishing Allowable Stresses for Round Timber Piles

Standard Practice for Establishing Allowable Stresses for Round Timber Piles

SIGNIFICANCE AND USE

4.1 This practice is intended for use by associations, technical societies and other groups that develop national design standards and use recommendations for round timber piles.

4.2 In using allowable stresses established under this practice, factors specific to each end use which may affect the performance of the pile system shall be considered. Such factors include the location of the critical section, the bearing capacity of the soil, the ability of the pile to withstand driving forces and conditions of service.

SCOPE

1.1 This practice contains procedures for establishing allowable stresses for round timber piles starting with clear wood strength properties.

1.2 Stresses established under this practice are applicable to piles conforming to the quality, straightness, spiral grain, knot, check, shake, and split provisions of Specification D25.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2899 − 12 (Reapproved 2017)

Standard Practice for

Establishing Allowable Stresses for Round Timber Piles

This standard is issued under the fixed designation D2899; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.3 load sharing—the distribution of load in proportion to

pile stiffness. This results in piles that perform as a group

1.1 Thispracticecontainsproceduresforestablishingallow-

reducing effects of between-pile variability and increasing

able stresses for round timber piles starting with clear wood

system reliability over that of piles which perform indepen-

strength properties.

dently.

1.2 Stresses established under this practice are applicable to

3.1.4 skin friction—the interaction between the pile surface

piles conforming to the quality, straightness, spiral grain, knot,

and the soil which serves to distribute load either away from or

check, shake, and split provisions of Specification D25.

into a pile. A positive skin friction refers to pile loads

1.3 This standard does not purport to address all of the

distributed to the soil. Negative skin friction distributes load to

safety concerns, if any, associated with its use. It is the

the pile when soil strata subside or consolidate.

responsibility of the user of this standard to establish appro-

3.2 Symbols: C = adjustment for small clear compression

cp

priate safety, health, and environmental practices and deter-

perp for annual ring orientation (1/1.67)

mine the applicability of regulatory limitations prior to use.

C = conditioning factor

ct

1.4 This international standard was developed in accor-

C = adjustment for duration of load and factor of safety

dance with internationally recognized principles on standard- dol

C = adjustment for density applied for Douglas fir and

ization established in the Decision on Principles for the d

Southern pine only

Development of International Standards, Guides and Recom-

C = combined adjustment for form and size (= 0.97)

mendations issued by the World Trade Organization Technical fs

C = adjustment for grade characteristics applied to all

Barriers to Trade (TBT) Committee.

g

species including bending (0.75), compression (0.93), and

shear (0.50)

2. Referenced Documents

2 C = adjustment for height in the tree (= 0.96 if softwoods

h

2.1 ASTM Standards:

and = 1.0 for hardwoods)

D25 Specification for Round Timber Piles

C = adjustment for height and for reduced variability

hv

D245 Practice for Establishing Structural Grades and Re-

(MOR = 0.91forsoftwoods,1.05forhardwoods, C// = 0.91for

lated Allowable Properties for Visually Graded Lumber

softwoods, 1.05 for hardwoods, Shear = 0.99 for softwoods,

D2555 PracticeforEstablishingClearWoodStrengthValues

1.03 for hardwoods)

C = load sharing adjustment (structural engineers option)

ls

3. Terminology

C = size adjustment

s

3.1 Definitions:

C = adjustment for shear deflection in calculation for bend-

v

3.1.1 allowable stress—the numeric value of pile strength

ing modulus of elasticity (= 1.06)

that is appropriate for use in structural analysis.

D = diameter of a round timber pile

3.1.2 end-bearing—compression-parallel-to-the-grain stress

E = clear wood unseasoned average modulus of elasticity

resulting when pile load is not carried to the soil through skin

from Test Methods D2555

friction.

MOE = modulus of elasticity (average)

F = allowable stress for stress designated by the subscript β

β

F = allowable compression stress for pile tips

c

This practice is under the jurisdiction of ASTM Committee D07 on Wood and

f = small clear lower 5 % exclusion compression strength

c05

is the direct responsibility of Subcommittee D07.04 on Pole and Pile Products.

in accordance with Test Methods D2555

Current edition approved Oct. 1, 2017. Published October 2017. Originally

f = lower 5 % exclusion value for stress “x” determined

approved in 1970 as D2899 – 70 T. Last previous edition approved in 2012 as

i05

D2899 – 12. DOI: 10.1520/D2899-12R17.

using the green, small clear strength and standard deviation

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

values reported in Test Methods D2555

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

β = stress value subscripts, c = compression parallel,

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. cp = compression perpendicular, b = bending, v = shear

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2899 − 12 (2017)

4. Significance and Use 7.2 For round timber piles, only the between tree compo-

nent of variance is applicable. Clear wood 5 % exclusion

4.1 This practice is intended for use by associations, tech-

values applied to piles are adjusted to account for this reduced

nical societies and other groups that develop national design

variability.

standards and use recommendations for round timber piles.

4.2 In using allowable stresses established under this

8. Minimum Tip and Critical Section Properties

practice, factors specific to each end use which may affect the

8.1 Average clear wood properties given in Test Methods

performance of the pile system shall be considered. Such

D2555 represent volume weighted average whole tree values

factors include the location of the critical section, the bearing

where the average property is that associated with material

capacity of the soil, the ability of the pile to withstand driving

occurringbetweenheightsof8and16ft.Forsoftwoodspecies,

forces and conditions of service.

clear wood strength properties generally decrease as the height

PRINCIPLES INVOLVED IN ESTABLISHING

location in the tree increases.

ALLOWABLE STRESSES

8.2 Forcompressionparalleltograin,theminimumstrength

of the pile occurs at the pile tip, or at a minimum diameter of

5. Species

5 in. For bending and shear strengths, the critical section of the

5.1 This practice applies to any species of piles for which

pile is assumed to occur at a point 10 ft above the pile tip. In

clear wood strength values are given in Test Methods D2555.

terms of location in the tree, both of these sections occur at

heights in the tree which are appreciably greater than the

5.2 Where pile allowable stress is to be established for a

heights associated with the whole tree average property values.

combination of species and or regions, clear wood values

Therefore clear wood average properties obtained from Test

assigned to such combinations are based on the grouping

Methods D2555 must be reduced to account for this height

criteria given in Section 5 of Test Methods D2555.

effect when establishing compression parallel to grain,

bending, shear and modulus of elasticity design stresses for

6. Clear Wood Properties

piles made with softwood species.

6.1 Information on average properties and their variation

given in Test Methods D2555 apply to small, clear, straight-

9. Density

grained wood in the green condition under short-term loading.

9.1 Specification D25 requires the outer 50 % of the radius

6.2 Round timber piles having minimum tip diameters of 5

at the pile tip to have an average rate of growth of at least 6

in. or larger are considered by this practice to be comparable to

rings per inch and an average summerwood content of not less

sawn timbers: General adjustment factors used to establish

than33.3 %.Pileswithlessthan6ringsperinchareacceptable

allowable stress for such timbers under Practice D245 also are

if the average summerwood content in the outer 50 % of the

applied to piles.

pile tip radius is 50 % or more.

6.3 For the properties of bending strength (modulus of

9.2 Practice D245 provides for the classification of Douglas

rupture), compression strength parallel to the grain and hori-

fir and southern pine sawn lumber meeting growth rate and

zontal shear strength, clear-wood 5 % -exclusion values calcu-

summerwood content requirements similar to those in Speci-

lated from Test Methods D2555 are divided by the adjustment

fication D25 as dense material. The properties of such lumber,

factors given in Table 10 of Practice D245 to obtain basic

exceptshear,areincreasedtoaccountfortheincreasedstrength

values for these properties from which pile allowable stress is

and stiffness associated with limiting the occurrence of low

established. The adjustment factors for the three strength

density material.

properties include a reduction for normal duration of load and

a factor of safety.

9.3 Increases for density applicable to Douglas fir and

southern pine lumber also are applicable to piles of the same

6.4 For the properties of modulus of elasticity and compres-

species. The increase for density in compression parallel to

sion perpendicular to grain at 0.04-in. deformation, clear wood

grain applicable to lumber must be adjusted when applied to

average values from Test Methods D2555 are divided by the

piles to account for the inner core of the pile tip that is not

adjustment factors for these properties given in Table 10 of

required to meet the density provisions.

PracticeD245toobtainbasicvaluesfromwhichpileallowable

stress for these properties also are established. The modulus of

10. Form and Size

elasticity factor is a shear deflection adjustment. The compres-

sion perpendicular to grain factor is an adjustment to account

10.1 The average bending strength of round wood sections

for limiting ring position.

based on standard beam formulas is greater than that of

matchedrectangularsections.However,thesectionmodulusof

7. Pile Variability

a round beam is less (1/1.18) than that of a square beam of

7.1 Standard deviations given in Test Methods D2555 and equivalent area by approximately the same ratio as the strength

used to calculate 5 % exclusion values include both variability of the round member is greater than that of the rectangular

in properties between trees and variability in properties occur- member.Roundmembersthereforeareassigned aunitstrength

ring within the cross section and along the length of an equal to 1.18 times that based on rectangular sections when the

individual tree. section modulus of the circular cross section is used.

D2899 − 12 (2017)

10.2 Clear wood bending stresses in Test Methods D2555 for round timber piles established under this practice are

are based on tests of 2-in. deep rectangular sections. Under short-term test values reduced to a normal load duration basis.

Practice D245, such values are adjusted for depth (d) by the Normal load duration represents application of a load that fully

1/9

factor (2/d) when applied to sawn lumber members. Based stresses a member to its design stress for a cumulative duration

on a circular section having an area equal to that of a square of approximately 10 years.

section, the equivalent depth adjustment for a round member is

12.2 When the cumulative duration of the full maximum

1/9

(2.2568/D) .

load is less than or more than ten years, pile allowable stress

10.3 Under standard practice, bending allowable stress for for bending, compression parallel to grain and horizontal shear

beams and stringers and post and timbers are given for a 12-in. shall be modified in accordance with the duration of load

beam depth. Values for beams exceeding 12 in. are reduced adjustments shown in Fig. 6 of Practice D245. Load duration

using the 1/9 power equation. The same practice is employed adjustments greater than 1.6 shall not apply to piles preserva-

with round timber piles. Pile bending stresses are indexed to tively treated with water-borne salts.

the diameter of a circular section having an area equal to that

12.3 Duration of load adjustments are not applied to pile

of a 12-in. square, or 13.5 in. Clear wood bending values are

allowable stress for modulus of elasticity and compression

adjusted to a 13.5-in. pile diameter by the factor 0.82.

perpendicular to grain based on a deformation limit.

11. Grade

13. Moisture Content

11.1 Knots in round piles reduce compression parallel to

13.1 Allowable stress established by this practice applies to

grain and bending strength properties. Limits on allowable size

piles that are continuously wet or are continuously exposed to

and spacing of knots along the pile length are given in

the weather.

Specification D25.

13.2 No increase in properties for material that is partially

11.2 The effect of knots on pile tip strength is determined

above ground and may be partially seasoned is recognized.

from tests of full size pile sections containing various knot

sizes. Regression analyses of compression strength against 14. Preservative Treatment

knot size and specific gravity establish the effect of allowable

14.1 Preservative treatment by approved processes and

knots on compression parallel to grain strength.

chemicals does not significantly affect allowable stress values

11.3 The effect of allowable knots on pile bending strength for round timber piles established in this practice.

is derived assuming load-carrying capacity is reduced by the

14.2 Conditioning of piles by kiln drying, steaming or

ratioofthesectionmodulusofawedgesectionoccupiedbythe

boiling in liquids prior to pressure treatment to facilitate

knot to the section modulus of the total circular section. The

penetration of preservative chemicals does affect strength

combined interaction of clear wood strength, knot size and

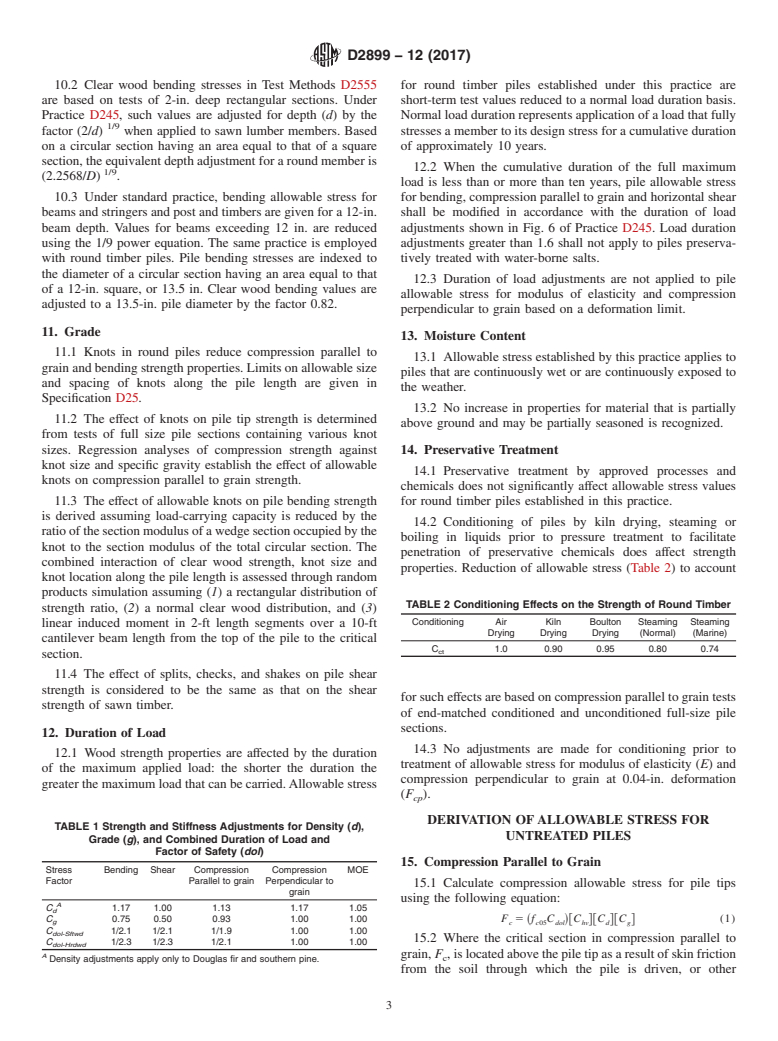

properties. Reduction of allowable stress (Table 2) to account

knot location along the pile length is assessed through random

products simulation assuming (1) a rectangular distribution of

TABLE 2 Conditioning Effects on the Strength of Round Timber

strength ratio, (2) a normal clear wood distribution, and (3)

Conditioning Air Kiln Boulton Steaming Steaming

linear induced moment in 2-ft length segments over a 10-ft

Drying Drying Drying (Normal) (Marine)

cantilever beam length from the top of the pile to the critical

C 1.0 0.90 0.95 0.80 0.74

ct

section.

11.4 The effect of splits, checks, and shakes on pile shear

strength is considered to be the same as that on the shear

for such effects are based on compression parallel to grain tests

strength of sawn timber.

of end-matched conditioned and unconditioned full-size pile

sections.

12. Duration of Load

14.3 No adjustments are made for conditioning prior to

12.1 Wood strength properties are affected by the duration

treatment of al

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.