ASTM D7248/D7248M-07

(Test Method)Standard Test Method for Bearing/Bypass Interaction Response of Polymer Matrix Composite Laminates Using 2-Fastener Specimens

Standard Test Method for Bearing/Bypass Interaction Response of Polymer Matrix Composite Laminates Using 2-Fastener Specimens

SCOPE

1.1 This test method determines the uniaxial bearing/bypass interaction response of multi-directional polymer matrix composite laminates reinforced by high-modulus fibers by either double-shear tensile loading (Procedures A and C) or single-shear tensile or compressive loading (Procedure B) of a two-fastener specimen. The scope of this test method is limited to net section (bypass) failure modes. Standard specimen configurations using fixed values of test parameters are described for each procedure. A number of test parameters may be varied within the scope of the standard, provided that the parameters are fully documented in the test report. The composite material forms are limited to continuous-fiber or discontinuous-fiber (tape or fabric, or both) reinforced composites for which the laminate is balanced and symmetric with respect to the test direction. The range of acceptable test laminates and thicknesses are described in .

1.2 This test method is consistent with the recommendations of MIL-HDBK-17, which describes the desirable attributes of a bearing/bypass interaction response test method.

1.3 The two-fastener test configurations described in this test method are similar to those in Test Method D 5961/D 5961M as well as those used by industry to investigate the bearing portion of the bearing/bypass interaction response for bolted joints, where the specimen may produce either a bearing failure mode or a bypass failure mode. Should the test specimen fail in a bearing failure mode rather than the desired bypass mode, then the test should be considered to be a bearing dominated bearing/bypass test, and the data reduction and reporting procedures of Test Method D 5961/D 5961M should be used instead of those given in this standard.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text the inch-pound units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7248/D7248M–07

Standard Test Method for

Bearing/Bypass Interaction Response of Polymer Matrix

Composite Laminates Using 2-Fastener Specimens

This standard is issued under the fixed designation D 7248/D 7248M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method determines the uniaxial bearing/bypass

responsibility of the user of this standard to establish appro-

interaction response of multi-directional polymer matrix com-

priate safety and health practices and determine the applica-

posite laminates reinforced by high-modulus fibers by either

bility of regulatory limitations prior to use.

double-shear tensile loading (Procedures A and C) or single-

shear tensile or compressive loading (Procedure B) of a

2. Referenced Documents

two-fastener specimen.The scope of this test method is limited

2.1 ASTM Standards:

to net section (bypass) failure modes. Standard specimen

D 792 TestMethodsforDensityandSpecificGravity(Rela-

configurations using fixed values of test parameters are de-

tive Density) of Plastics by Displacement

scribed for each procedure. A number of test parameters may

D 883 Terminology Relating to Plastics

be varied within the scope of the standard, provided that the

D 2584 Test Method for Ignition Loss of Cured Reinforced

parameters are fully documented in the test report. The

Resins

composite material forms are limited to continuous-fiber or

D 2734 Test Methods for Void Content of Reinforced Plas-

discontinuous-fiber (tape or fabric, or both) reinforced com-

tics

posites for which the laminate is balanced and symmetric with

D 3171 Test Methods for Constituent Content of Composite

respect to the test direction. The range of acceptable test

Materials

laminates and thicknesses are described in 8.2.1.

D 3878 Terminology for Composite Materials

1.2 Thistestmethodisconsistentwiththerecommendations

D 5229/D 5229M Test Method for Moisture Absorption

of MIL-HDBK-17, which describes the desirable attributes of

Properties and Equilibrium Conditioning of Polymer Ma-

a bearing/bypass interaction response test method.

trix Composite Materials

1.3 The two-fastener test configurations described in this

D 5687/D 5687M Guide for Preparation of Flat Composite

test method are similar to those in Test Method D 5961/

Panels with Processing Guidelines for Specimen Prepara-

D 5961M as well as those used by industry to investigate the

tion

bearing portion of the bearing/bypass interaction response for

D 5766/D 5766M Test Method for Open Hole Tensile

boltedjoints,wherethespecimenmayproduceeitherabearing

Strength of Polymer Matrix Composite Laminates

failure mode or a bypass failure mode. Should the test

D 5961/D 5961M Test Method for Bearing Response of

specimen fail in a bearing failure mode rather than the desired

Polymer Matrix Composite Laminates

bypassmode,thenthetestshouldbeconsideredtobeabearing

D 6484/D 6484M Test Method for Open-Hole Compressive

dominated bearing/bypass test, and the data reduction and

Strength of Polymer Matrix Composite Laminates

reporting procedures of Test Method D 5961/D 5961M should

D 6742/D 6742M Practice for Filled-Hole Tension and

be used instead of those given in this standard.

Compression Testing of Polymer Matrix Composite Lami-

1.4 The values stated in either SI units or inch-pound units

nates

are to be regarded separately as standard. Within the text the

E4 Practices for Force Verification of Testing Machines

inch-pound units are shown in brackets. The values stated in

E6 Terminology Relating to Methods of Mechanical Test-

each system are not exact equivalents; therefore, each system

ing

must be used independently of the other. Combining values

E83 Practice for Verification and Classification of Exten-

from the two systems may result in nonconformance with the

someter Systems

standard.

1 2

This test method is under the jurisdiction of ASTM Committee D30 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Composite Materials and is the direct responsibility of Subcommittee D30.05 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Structural Test Methods. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Jan. 1, 2007. Published February 2007. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7248/D7248M–07

E 122 Practice for Calculating Sample Size to Estimate, 3.2.5 bearing force, P [MLT ], n—the in-plane force trans-

With a Specified Tolerable Error, the Average for a mitted by a fastener to a specimen at the fastener hole.

br

Characteristic of a Lot or Process

3.2.6 bearing strain, e, [nd], n—the normalized hole de-

E 177 Practice for Use of the Terms Precision and Bias in

formation in a specimen, equal to the deformation of the

ASTM Test Methods

bearing hole in the direction of the bearing force, divided by

E 456 Terminology Relating to Quality and Statistics

the diameter of the hole.

br_byp

E 1309 Guide for Identification of Fiber-Reinforced

3.2.7 bearing strength, F [ML-1T-2], n—the value of

x

Polymer-Matrix Composite Materials in Databases

bearing stress occurring at the point of bypass (net section)

E 1434 GuideforRecordingMechanicalTestDataofFiber-

failure.

br

Reinforced Composite Materials in Databases

3.2.8 bearing stress, s [ML-1T-2], n—the bearing force

2.2 Other Document:

divided by the bearing area.

MIL-HDBK-17 Polymer Matrix Composites, Vol 1, Sec-

3.2.9 diameter to thickness ratio, D/h [nd], n—in a bearing

tion 7

specimen, the ratio of the hole diameter to the specimen

thickness.

3. Terminology

3.2.9.1 Discussion—The diameter to thickness ratio may be

3.1 Definitions—TerminologyD 3878definestermsrelating

either a nominal value determined from nominal dimensions or

to high-modulus fibers and their composites. Terminology

an actual value determined from measured dimensions.

D 883 defines terms relating to plastics. Terminology E6

3.2.10 edge distance ratio, e/D [nd], n—in a bearing

defines terms relating to mechanical testing. Terminology

specimen, the ratio of the distance between the center of the

E 456 and Practice E 177 define terms relating to statistics. In

hole and the specimen end to the hole diameter.

the event of a conflict between terms, Terminology D 3878

3.2.10.1 Discussion—The edge distance ratio may be either

shall have precedence over the other documents.

a nominal value determined from nominal dimensions or an

NOTE 1—If the term represents a physical quantity, its analytical actual value determined from measured dimensions.

dimensionsarestatedimmediatelyfollowingtheterm(orlettersymbol)in

3.2.11 nominal value, n—a value, existing in name only,

fundamental dimension form, using the following ASTM standard sym-

assigned to a measurable quantity for the purpose of conve-

bology for fundamental dimensions, shown within square brackets: [M]

nient designation. Tolerances may be applied to a nominal

for mass, [L] for length, [T] for time, [u] for thermodynamic temperature,

value to define an acceptable range for the quantity.

and[nd]fornon-dimensionalquantities.Useofthesesymbolsisrestricted

bro

3.2.12 offset bearing strength, F [ML-1T-2], n—the

to analytical dimensions when used with square brackets, as the symbols

x

may have other definitions when used without the brackets.

value of bearing stress, in the direction specified by the

subscript, at the point where a bearing chord stiffness line,

3.2 Definitions of Terms Specific to This Standard—

gr_byp

offset along the bearing strain axis by a specified bearing strain

3.2.1 gross bypass stress, f [ML-1T-2], n—the gross

value, intersects the bearing stress/bearing strain curve.

bypass stress for tensile loadings is calculated from the total

3.2.12.1 Discussion—Unless otherwise specified, an offset

force bypassing the fastener hole.

net_byp

bearing strain of 2 % is to be used in this test method.

3.2.2 net bypass stress, f [ML-1T-2], n—the net by-

pass stress for tensile loading is calculated from the force 3.2.13 width to diameter ratio, w/D [nd], n—in a bearing

bypassing the fastener hole minus the force reacted in bearing specimen, the ratio of specimen width to hole diameter.

at the fastener.

3.2.13.1 Discussion—The width to diameter ratio may be

either a nominal value determined from nominal dimensions or

NOTE 2—For compressive loadings the gross and net bypass stresses

an actual value, determined as the ratio of the actual specimen

are equal and are calculated using the force that bypasses the fastener hole

width to the actual hole diameter.

(since for the compressive loading case the bearing stress reaction is on

bru

the same side of the fastener as the applied force, the force reacted in

3.2.14 ultimate bearing strength, F [ML-1T-2], n—the

x

bearing does not bypass the fastener hole).

value of bearing stress, in the direction specified by the

NOTE 3—Several alternate definitions for gross and net bypass stress

subscript, at the maximum force capability of a bearing

have been used historically in the aerospace industry. Comparison of data

specimen.

from tests conforming to this standard with historical data may need to

gr_byp

3.2.15 ultimate gross bypass strength, F [ML-1T-2],

account for differences in the bypass definitions.

x

n—the value of gross bypass stress, in the direction specified

3.2.3 bearing area, [L ], n—the area of that portion of a

by the subscript, at the maximum force capability of the

specimen used to normalize applied loading into an effective

specimen.

bearing stress; equal to the diameter of the fastener multiplied

net_byp

3.2.16 ultimate net bypass strength, F [ML-1T-2],

x

by the thickness of the specimen.

br n—the value of net bypass stress, in the direction specified by

3.2.4 bearing chord stiffness, E [ML-1T-2], n—the chord

thesubscript,atthemaximumforcecapabilityofthespecimen.

stiffness between two specific bearing stress or bearing strain

3.3 Symbols:

points in the linear portion of the bearing stress/bearing strain

A = cross-sectional area of a specimen

curve.

CV = coefficient of variation statistic of a sample population

for a given property (in percent)

d = fastener or pin diameter

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Robbins Ave., Philadelphia, PA 19111-5098, Attn: NPODS. D = specimen hole diameter

D7248/D7248M–07

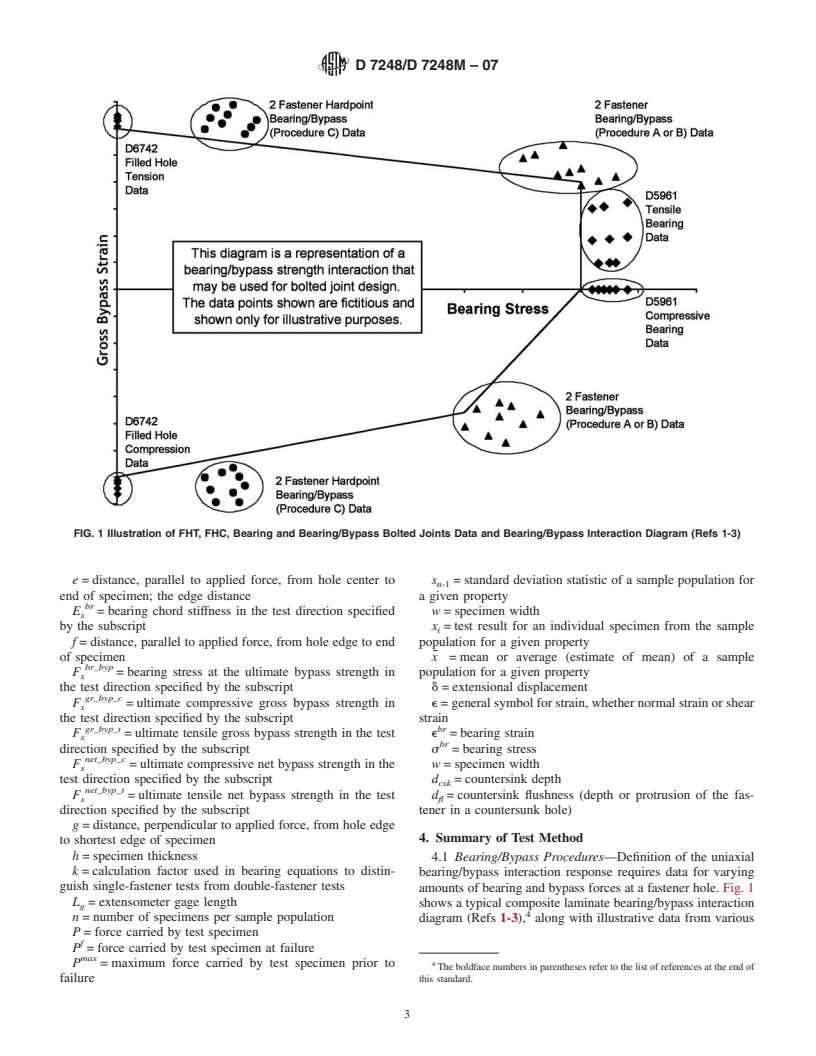

FIG. 1 Illustration of FHT, FHC, Bearing and Bearing/Bypass Bolted Joints Data and Bearing/Bypass Interaction Diagram (Refs 1-3)

e = distance, parallel to applied force, from hole center to s = standard deviation statistic of a sample population for

n-1

end of specimen; the edge distance a given property

br

E = bearing chord stiffness in the test direction specified w = specimen width

x

by the subscript x = test result for an individual specimen from the sample

i

f = distance, parallel to applied force, from hole edge to end population for a given property

of specimen x = mean or average (estimate of mean) of a sample

br_byp

F = bearing stress at the ultimate bypass strength in population for a given property

x

the test direction specified by the subscript d = extensional displacement

gr_byp_c

F = ultimate compressive gross bypass strength in e = general symbol for strain, whether normal strain or shear

x

the test direction specified by the subscript strain

gr_byp_t br

F = ultimate tensile gross bypass strength in the test e = bearing strain

x

br

direction specified by the subscript s = bearing stress

net_byp_c

F = ultimate compressive net bypass strength in the w = specimen width

x

test direction specified by the subscript d = countersink depth

csk

net_byp_t

F = ultimate tensile net bypass strength in the test d = countersink flushness (depth or protrusion of the fas-

x fl

direction specified by the subscript tener in a countersunk hole)

g = distance, perpendicular to applied force, from hole edge

4. Summary of Test Method

to shortest edge of specimen

h = specimen thickness

4.1 Bearing/Bypass Procedures—Definition of the uniaxial

k = calculation factor used in bearing equations to distin-

bearing/bypass interaction response requires data for varying

guish single-fastener tests from double-fastener tests

amounts of bearing and bypass forces at a fastener hole. Fig. 1

L = extensometer gage length

shows a typical composite laminate bearing/bypass interaction

g

n = number of specimens per sample population

diagram (Refs 1-3), along with illustrative data from various

P = force carried by test specimen

f

P = force carried by test specimen at failure

max

P = maximum force carried by test specimen prior to

The boldface numbers in parentheses refer to the list of references at the end of

failure this standard.

D7248/D7248M–07

test types. Data from Practice D 6742/D 6742M and Test as the values of all variant test parameters are prominently

MethodD 5961/D 5961Mdefinethe100 %bypassandbearing documented with the results.

ends of the interaction diagram. Rationale for the baseline

Parameter Standard Variation

Loading condition double-shear none

bearing/bypass specimen geometry and fastener torques are

Loading type tensile none

given in 6.7 and 6.8. Procedures A and B of this test method

Mating material steel fixture any, if documented

provide data in the bypass/high bearing region, while Proce-

Number of holes 2 3

Countersink none none

dure C provides data in the bypass/low bearing region. More

Hole fit tight any, if documented

complicated test setups have been used to develop data across

Fastener torque 9.0-10.7 N·m [90-95 lbf-in.] any, if documented

the full range of bearing/bypass interaction.This test method is

Laminate quasi-isotropic any, if documented

Fastener diameter 6 mm [0.250 in.] any, if documented

limitedtocaseswherethebearingandbypassloadsarealigned

Edge distance ratio 3 any, if documented

in the same direction. It is also limited to uniaxial tensile or

w/D ratio 5 any, if documented

compressive bypass loads. Test procedures for cases where the D/h ratio 1.2-2 any, if documented

bearing and bypass loads act at different directions, or cases

4.3 Procedure B, Bypass/High Bearing Single Shear:

with biaxial or shear bypass loads are outside the scope of this

4.3.1 The flat, constant rectangular cross-section test speci-

standard.

men is composed o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.