ASTM D4340-96

(Test Method)Standard Test Method for Corrosion of Cast Aluminum Alloys in Engine Coolants Under Heat-Rejecting Conditions

Standard Test Method for Corrosion of Cast Aluminum Alloys in Engine Coolants Under Heat-Rejecting Conditions

SCOPE

1.1 This test method covers a laboratory screening procedure for evaluating the effectiveness of engine coolants in combating corrosion of aluminum casting alloys under heat-transfer conditions that may be present in aluminum cylinder head engines.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Sections 11 and 12.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4340 – 96 An American National Standard

Standard Test Method for

Corrosion of Cast Aluminum Alloys in Engine Coolants

Under Heat-Rejecting Conditions

This standard is issued under the fixed designation D 4340; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope screening unused engine coolants and will readily distinguish

those coolants that are unsuitable for use with aluminum

1.1 This test method covers a laboratory screening proce-

cylinder head engines. However, satisfactory performance of a

dure for evaluating the effectiveness of engine coolants in

coolant in this test method does not ensure adequate long-term

combating corrosion of aluminum casting alloys under heat-

service performance. Additional, more comprehensive evalua-

transfer conditions that may be present in aluminum cylinder

tions with simulated service, dynamometer, and vehicle tests

head engines.

should be used to establish the long-term effectiveness of the

1.2 This standard does not purport to address all of the

coolant.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Apparatus

priate safety and health practices and determine the applica-

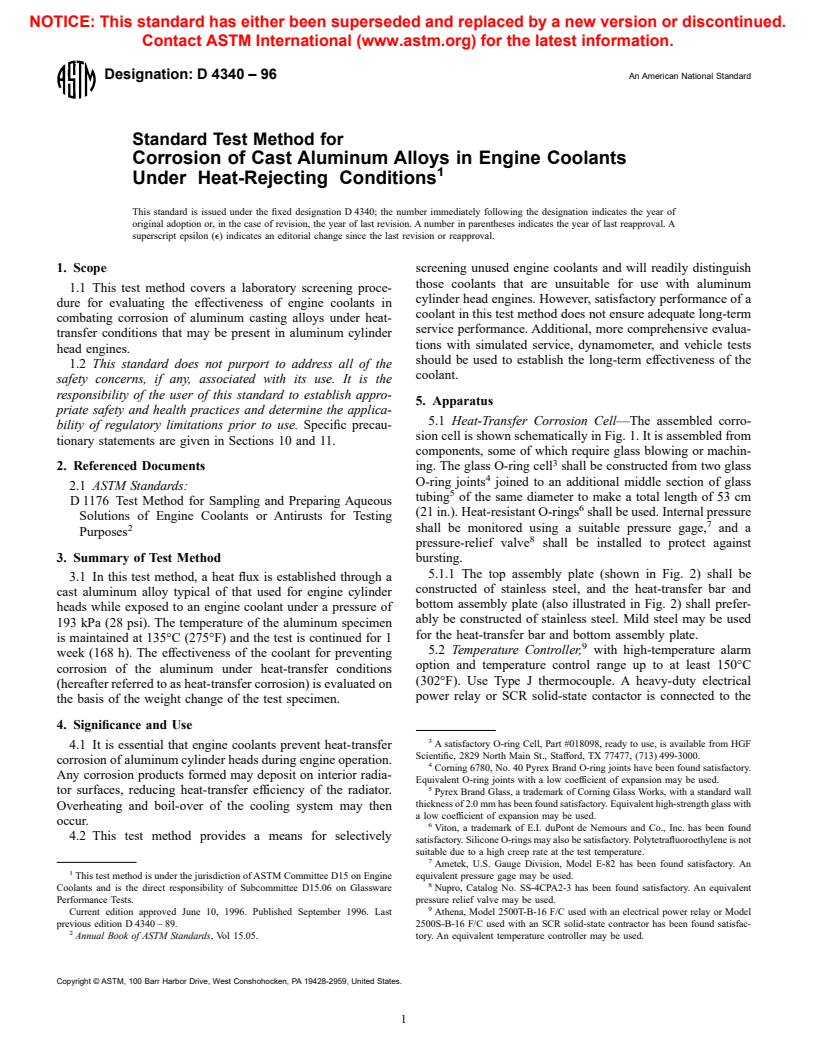

5.1 Heat-Transfer Corrosion Cell—The assembled corro-

bility of regulatory limitations prior to use. Specific precau-

sion cell is shown schematically in Fig. 1. It is assembled from

tionary statements are given in Sections 10 and 11.

components, some of which require glass blowing or machin-

2. Referenced Documents ing. The glass O-ring cell shall be constructed from two glass

O-ring joints joined to an additional middle section of glass

2.1 ASTM Standards:

tubing of the same diameter to make a total length of 53 cm

D 1176 Test Method for Sampling and Preparing Aqueous

(21 in.). Heat-resistant O-rings shall be used. Internal pressure

Solutions of Engine Coolants or Antirusts for Testing

2 shall be monitored using a suitable pressure gage, and a

Purposes

pressure-relief valve shall be installed to protect against

3. Summary of Test Method bursting.

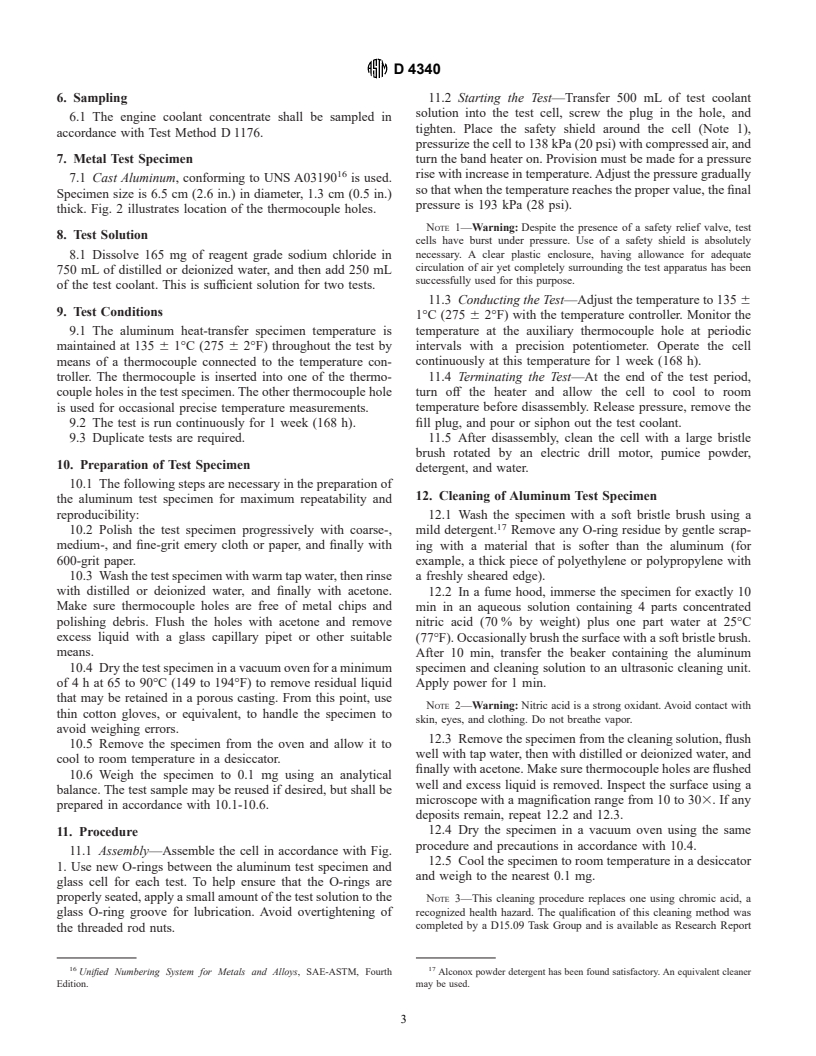

5.1.1 The top assembly plate (shown in Fig. 2) shall be

3.1 In this test method, a heat flux is established through a

constructed of stainless steel, and the heat-transfer bar and

cast aluminum alloy typical of that used for engine cylinder

bottom assembly plate (also illustrated in Fig. 2) shall prefer-

heads while exposed to an engine coolant under a pressure of

ably be constructed of stainless steel. Mild steel may be used

193 kPa (28 psi). The temperature of the aluminum specimen

for the heat-transfer bar and bottom assembly plate.

is maintained at 135°C (275°F) and the test is continued for 1

5.2 Temperature Controller, with high-temperature alarm

week (168 h). The effectiveness of the coolant for preventing

option and temperature control range up to at least 150°C

corrosion of the aluminum under heat-transfer conditions

(302°F). Use Type J thermocouple. A heavy-duty electrical

(hereafter referred to as heat-transfer corrosion) is evaluated on

power relay or SCR solid-state contactor is connected to the

the basis of the weight change of the test specimen.

4. Significance and Use

A satisfactory O-ring Cell, Part #018098, ready to use, is available from HGF

4.1 It is essential that engine coolants prevent heat-transfer

Scientific, 2829 North Main St., Stafford, TX 77477, (713) 499-3000.

corrosion of aluminum cylinder heads during engine operation.

Corning 6780, No. 40 Pyrex Brand O-ring joints have been found satisfactory.

Any corrosion products formed may deposit on interior radia-

Equivalent O-ring joints with a low coefficient of expansion may be used.

tor surfaces, reducing heat-transfer efficiency of the radiator.

Pyrex Brand Glass, a trademark of Corning Glass Works, with a standard wall

thickness of 2.0 mm has been found satisfactory. Equivalent high-strength glass with

Overheating and boil-over of the cooling system may then

a low coefficient of expansion may be used.

occur.

Viton, a trademark of E.I. duPont de Nemours and Co., Inc. has been found

4.2 This test method provides a means for selectively

satisfactory. Silicone O-rings may also be satisfactory. Polytetrafluoroethylene is not

suitable due to a high creep rate at the test temperature.

Ametek, U.S. Gauge Division, Model E-82 has been found satisfactory. An

This test method is under the jurisdiction of ASTM Committee D15 on Engine equivalent pressure gage may be used.

Coolants and is the direct responsibility of Subcommittee D15.06 on Glassware Nupro, Catalog No. SS-4CPA2-3 has been found satisfactory. An equivalent

Performance Tests. pressure relief valve may be used.

Current edition approved June 10, 1996. Published September 1996. Last Athena, Model 2500T-B-16 F/C used with an electrical power relay or Model

previous edition D 4340 – 89. 2500S-B-16 F/C used with an SCR solid-state contractor has been found satisfac-

Annual Book of ASTM Standards, Vol 15.05. tory. An equivalent temperature controller may be used.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 4340

FIG. 1 Heat-Transfer Corrosion Test Assembly

Metric Equivalents

1 1 5 1 1 9 1 1

in. ⁄4 ⁄2 ⁄8 1 ⁄4 22 ⁄16 2 ⁄16 4 ⁄2 5 ⁄4

mm 6.35 12.7 15.88 31.75 50.8 52.39 65.09 114.3 133.35

FIG. 2 Heat-Transfer Corrosion Test Components

temperature controller to carry the current load to the band 5.6 Vacuum Oven, with temperature range up to about

heaters. 150°C (302°F) for thoroughly drying cast aluminum samples.

10 14

5.3 Electrical Relay, 30-amp rating. The relay is changed 5.7 Vacuum Pump, for use with vacuum oven.

after about every 50 000 cycles to prevent contact welding. 5.8 Thermal Cutoff, for over-temperature protection, lo-

5.4 Band Heaters, at least 950 W, 120-V ac, 5.1-cm cated 1.3 cm ( ⁄2 in.) from the heat-transfer bar.

(2-in.) inside diameter, 12.7-cm (5-in.) length. 5.9 Compressed Air, for pressurizing test cell.

5.5 Ultrasonic Cleaner, about 50 W, for cleaning alumi- 5.10 Clear Plastic Safety Shield, for protection against

num test samples. bursting.

10 13

Dayton 5X850A, SPST-NO-DM, 120 V, 30 amp has been found satisfactory. Thelco Model 10 has been found satisfactory. An equivalent vacuum oven may

An equivalent mechanical, solid-state, or mercury-wetted relay may be used. be used.

11 14

Hotwatt, 950-W standard construction band heater, standard tightening clamp, Ace-Nelson Model 911 has been found satisfactory. An equivalent vacuum

Type L terminal has been found satisfactory. An equivalent band heater may be used. pump may be used.

12 15

Bransonic Model 12, 50 W, 1-qt capacity has been found satisfactory. An Sylvania Model ELG 8218 has been found satisfactory. An equivalent thermal

equivalent ultrasonic cleaner may be used. cutoff may be used.

D 4340

6. Sampling 11.2 Starting the Test—Transfer 500 mL of test coolant

solution into the test cell, screw the plug in the hole, and

6.1 The engine coolant concentrate shall be sampled in

tighten. Place the safety shield around the cell (Note 1),

accordance with Test Method D 1176.

pressurize the cell to 138 kPa (20 psi) with compressed air, and

7. Metal Test Specimen turn the band heater on. Provision must be made for a pressure

16 rise with increase in temperature. Adjust the pressure gradually

7.1 Cast Aluminum, conforming to UNS A03190 is used.

so that when the temperature reaches the proper value, the final

Specimen size is 6.5 cm (2.6 in.) in diameter, 1.3 cm (0.5 in.)

pressure is 193 kPa (28 psi).

thick. Fig. 2 illustrates location of the thermocouple holes.

NOTE 1—Warning: Despite the prese

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.