ASTM D5343-06(2012)e1

(Guide)Standard Guide for Evaluating Cleaning Performance of Ceramic Tile Cleaners

Standard Guide for Evaluating Cleaning Performance of Ceramic Tile Cleaners

SIGNIFICANCE AND USE

This guide suggests methodology for cleaning tests. This methodology can only be applied to assess product performance on typical bathroom soils and is not inclusive of all potential soils present on ceramic tiles or other bathroom surfaces. An assessment of cleaning performance on surfaces other than ceramic tile cannot be presumed since there is no confirmed basis for correlation for this soil on other surface or substrate types.

The results of tests based on this guide are regarded as diagnostic screening values useful in formulation studies, quality control, and ingredient raw material qualification. The results of this guide should be compared to control treatments, which are incorporated into each performance evaluation. These results should be considered to be relative to all other treatments in the study and are not absolute values. For interlaboratory comparisons, exact treatment conditions must be established and then results should be compared as relative ranking to the control treatments rather than as absolute values.

This guide is applicable to testing all types of multi-purpose household and bathroom cleaners, whether the detergent is prepared by dissolving a soluble powder, a dilutable liquid, or is a non-dilutable product. It may also be useful for evaluation of products or conditions normally associated with industrial or institutional cleaners.

SCOPE

1.1 This guide covers the evaluation of the cleaning performance of products intended for use on ceramic tiles. This guide provides techniques for soiling, cleaning, and evaluating performance of detergent systems under controlled, but practical, hard-surface cleaning conditions.

Note 1—The soils described in this guide are known in the industry as “soap scum.”

1.2 Such systems include any detergent, cleaner, or abrasive cleanser intended for cleaning hard surfaces composed of ceramic tile. This guide is not appropriate for evaluating performance on grout. This guide also excludes other surfaces such as glass, resilient flooring, synthetic countertop surfaces or washable wall surfaces. The products for which this guide is intended include solutions of soluble powdered detergent, dilutions of concentrated liquid detergent, or products intended to be used full strength, for example, foams, sprays, liquid, wipes, powders, or paste.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Material Safety Data Sheets are available for reagents. Review them for hazards prior to usage.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D5343 − 06 (Reapproved 2012)

Standard Guide for

Evaluating Cleaning Performance of Ceramic Tile Cleaners

This standard is issued under the fixed designation D5343; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorial updates were made in March 2012.

1. Scope* rally Soiled Fabrics and Household Appliances (With-

drawn 2013)

1.1 This guide covers the evaluation of the cleaning perfor-

manceofproductsintendedforuseonceramictiles.Thisguide

3. Terminology

provides techniques for soiling, cleaning, and evaluating per-

3.1 Definitions of Terms Specific to This Standard:

formance of detergent systems under controlled, but practical,

3.1.1 bathroom soil—thesoilcomposedofmaterialspresent

hard-surface cleaning conditions.

on typical bathroom surfaces.

NOTE 1—The soils described in this guide are known in the industry as

3.1.2 cycle—a cycle is defined as being both the back and

“soap scum.”

forth strokes on the scrubbing apparatus.

1.2 Such systems include any detergent, cleaner, or abrasive

3.1.3 soil—in hard surface cleaning, foreign matter on a

cleanser intended for cleaning hard surfaces composed of

hard surface such as a ceramic tile.

ceramic tile. This guide is not appropriate for evaluating

performance on grout. This guide also excludes other surfaces 3.1.4 substrate—the soiled surface that is being cleaned.

such as glass, resilient flooring, synthetic countertop surfaces

4. Summary of Guide

or washable wall surfaces.The products for which this guide is

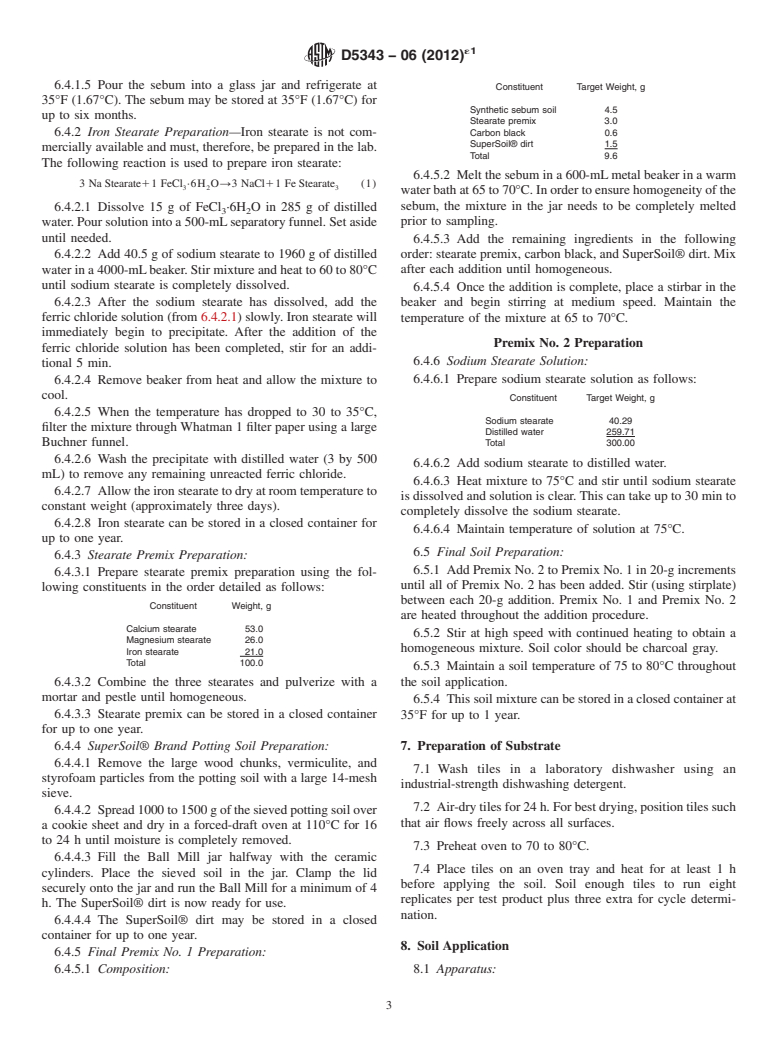

intended include solutions of soluble powdered detergent, 4.1 Soils are artificially applied in a standardized manner to

dilutions of concentrated liquid detergent, or products intended

a ceramic tile surface. The soiled surfaces are cleaned using a

to be used full strength, for example, foams, sprays, liquid, straight-line washability apparatus, and the cleaned substrates

wipes, powders, or paste.

are evaluated using reflectance measurements, or visually by a

panelofjudges.Aschematicdiagramofthesoilcompositionis

1.3 This standard does not purport to address all of the

summarized in Fig. 1.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety and health practices and determine the applica-

5.1 This guide suggests methodology for cleaning tests.

bility of regulatory limitations prior to use. Material Safety

This methodology can only be applied to assess product

Data Sheets are available for reagents. Review them for

performance on typical bathroom soils and is not inclusive of

hazards prior to usage.

all potential soils present on ceramic tiles or other bathroom

surfaces. An assessment of cleaning performance on surfaces

2. Referenced Documents

other than ceramic tile cannot be presumed since there is no

2.1 ASTM Standards:

confirmed basis for correlation for this soil on other surface or

D1729 Practice for Visual Appraisal of Colors and Color

substrate types.

Differences of Diffusely-Illuminated Opaque Materials

5.2 The results of tests based on this guide are regarded as

D2960 Guide for Controlled Laundering Test Using Natu-

diagnostic screening values useful in formulation studies,

quality control, and ingredient raw material qualification. The

1 results of this guide should be compared to control treatments,

This guide is under the jurisdiction of ASTM Committee D12 on Soaps and

Other Detergents and is the direct responsibility of Subcommittee D12.16 on Hard

which are incorporated into each performance evaluation.

Surface Cleaning.

These results should be considered to be relative to all other

Current edition approved Feb. 15, 2012. Published March 2012. Originally

treatments in the study and are not absolute values. For

approved in 1993. Last previous edition approved in 2012 as D5343 – 06(2012).

interlaboratory comparisons, exact treatment conditions must

DOI: 10.1520/D5343-06R12E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

´1

D5343 − 06 (2012)

6.2.12 Sodium Stearate, technical grade,

6.2.13 Ferric Chloride, hexahydrate, FeCl ·6H O,

3 2

6.2.14 Calcium Stearate, technical grade,

6.2.15 Magnesium Stearate,

6.2.16 Carbon Lampblack,

6.2.17 Distilled Water, and

6.2.18 Synthetic Hard Water, 100 ppm hardness, as CaCO ,

+2 +2

3:1 Ca :Mg .

6.3 Equipment:

6.3.1 Balance,

6.3.2 Stirplate/Hotplate, two,

6.3.3 Magnetic Stirbars, two,

6.3.4 Beakers, 4000 mL, 2000 mL, 1000 mL, 600 mL

(metal), and 500 mL,

6.3.5 Forced Draft Oven, capable of 110 6 5°C,

FIG. 1 Bathroom Soil Composition 6.3.6 Buchner Funnel, 500 mL,

6.3.7 Vacuum Flask, 2000 mL,

6.3.8 Filter Paper, Whatman 1,

be established and then results should be compared as relative

6.3.9 Separatory Funnel, 500 mL,

rankingtothecontroltreatmentsratherthanasabsolutevalues.

6.3.10 Ring Stand and Ring, to fit separatory funnel,

5.3 This guide is applicable to testing all types of multi-

6.3.11 Mortar and Pestle,

purpose household and bathroom cleaners, whether the deter-

6.3.12 Sieve, 14 mesh,

gent is prepared by dissolving a soluble powder, a dilutable

6.3.13 Ball Mill and Ceramic Jar, with 1-in. diameter

liquid, or is a non-dilutable product. It may also be useful for

ceramic cylinders,

evaluation of products or conditions normally associated with

6.3.14 Cookie Sheet,

industrial or institutional cleaners.

6.3.15 Replacement Mini Trimmer Paint Pads, two,

6. Preparation of Soil

6.3.16 Refrigeration, for storage, 35°F (1.67°C), and

6.3.17 Plastic Disposable Pipets.

6.1 Summary of Method—White ceramic tiles are soiled

with a composite soil composed of two separate preblends.

6.4 Procedure:

One preblend consists of a mixture of synthetic sebum, metal

stearates, carbon black, and dirt. The second preblend is a Pre-mix No. 1 Preparation

predissolved sodium stearate solution. Soil is applied using a 6.4.1 Synthetic Sebum Soil :

painting pad applicator. The soiled tiles can be stored for up to

6.4.1.1 Prepare synthetic sebum soil using the following

three months when stored at 35°F (1.67°C). The soiled constituents:

substrate is scrubbed with a fine-celled sponge, to which the

Constituent Weight %

detergent system being tested has been applied, or with a damp

Palmitic acid 10.0

sponge when the product is to be applied to the soil surface.

Stearic acid 5.0

Cleaning performance is evaluated by comparing reflectance

Coconut oil 15.0

measurements made on the clean/unsoiled test panel, soiled Paraffin wax 10.0

Sperm wax 15.0

panel (untreated), and on the soiled panel after scrubbing with

Olive oil 20.0

a straight-line washability apparatus. Results can be either a

Squalene 5.0

visual rating or calculated as a percentage of soil removed. Cholesterol 5.0

Oleic acid 10.0

6.2 Materials:

Linoleic acid 5.0

Total 100.0

6.2.1 Super Soil® Brand Potting Soil , from local store,

6.2.2 Palmitic Acid, reagent grade,

6.4.1.2 Weigh the oils out into one beaker. Then weigh the

6.2.3 Stearic Acid, powder, triple pressed,

powders out into another beaker. Weigh the paraffin wax and

6.2.4 Coconut Oil,

sperm wax into a third beaker.

6.2.5 Paraffın Wax,

6.4.1.3 Warm the oils on a hot plate, but do not allow

6.2.6 Sperm Wax,

mixture temperature to exceed 54°C. Add powders and stir

6.2.7 Olive Oil,

until dissolved.

6.2.8 Squalene,

6.4.1.4 Addtheparaffinwaxandspermwaxandstiruntilall

6.2.9 Cholesterol,

ingredients are dissolved.

6.2.10 Oleic Acid,

6.2.11 Linoleic Acid, purified,

SpanglersSebumiscommerciallyavailableandhasbeenfoundsuitableforthis

(Since 1954); a subsidiary of The Scotts Miracle-Gro Company, 14111 Scotts purpose.ScientificServicesS/D,Inc.,42MainSt.,P.O.Box778,SparrowBush,NY

Lawn Rd., Marysville, OH 43041. 12780.

´1

D5343 − 06 (2012)

6.4.1.5 Pour the sebum into a glass jar and refrigerate at

Constituent Target Weight, g

35°F (1.67°C). The sebum may be stored at 35°F (1.67°C) for

Synthetic sebum soil 4.5

up to six months.

Stearate premix 3.0

6.4.2 Iron Stearate Preparation—Iron stearate is not com- Carbon black 0.6

SuperSoil® dirt 1.5

mercially available and must, therefore, be prepared in the lab.

Total 9.6

The following reaction is used to prepare iron stearate:

6.4.5.2 Melt the sebum in a 600-mLmetal beaker in a warm

3 Na Stearate11 FeCl ·6H O→3 NaCl11 FeStearate (1)

3 2 3

waterbathat65to70°C.Inordertoensurehomogeneityofthe

sebum, the mixture in the jar needs to be completely melted

6.4.2.1 Dissolve 15 g of FeCl ·6H O in 285 g of distilled

3 2

prior to sampling.

water.Poursolutionintoa500-mLseparatoryfunnel.Setaside

until needed.

6.4.5.3 Add the remaining ingredients in the following

order: stearate premix, carbon black, and SuperSoil® dirt. Mix

6.4.2.2 Add 40.5 g of sodium stearate to 1960 g of distilled

waterina4000-mLbeaker.Stirmixtureandheatto60to80°C after each addition until homogeneous.

until sodium stearate is completely dissolved.

6.4.5.4 Once the addition is complete, place a stirbar in the

6.4.2.3 After the sodium stearate has dissolved, add the

beaker and begin stirring at medium speed. Maintain the

ferric chloride solution (from 6.4.2.1) slowly. Iron stearate will temperature of the mixture at 65 to 70°C.

immediately begin to precipitate. After the addition of the

Premix No. 2 Preparation

ferric chloride solution has been completed, stir for an addi-

6.4.6 Sodium Stearate Solution:

tional 5 min.

6.4.6.1 Prepare sodium stearate solution as follows:

6.4.2.4 Remove beaker from heat and allow the mixture to

cool.

Constituent Target Weight, g

6.4.2.5 When the temperature has dropped to 30 to 35°C,

Sodium stearate 40.29

filter the mixture through Whatman 1 filter paper using a large

Distilled water 259.71

Buchner funnel. Total 300.00

6.4.2.6 Wash the precipitate with distilled water (3 by 500

6.4.6.2 Add sodium stearate to distilled water.

mL) to remove any remaining unreacted ferric chloride.

6.4.6.3 Heat mixture to 75°C and stir until sodium stearate

6.4.2.7 Allowtheironstearatetodryatroomtemperatureto

is dissolved and solution is clear.This can take up to 30 min to

constant weight (approximately three days).

completely dissolve the sodium stearate.

6.4.2.8 Iron stearate can be stored in a closed container for

6.4.6.4 Maintain temperature of solution at 75°C.

up to one year.

6.5 Final Soil Preparation:

6.4.3 Stearate Premix Preparation:

6.5.1 Add Premix No. 2 to Premix No. 1 in 20-g increments

6.4.3.1 Prepare stearate premix preparation using the fol-

until all of Premix No. 2 has been added. Stir (using stirplate)

lowing constituents in the order detailed as follows:

between each 20-g addition. Premix No. 1 and Premix No. 2

Constituent Weight, g

are heated throughout the addition procedure.

Calcium stearate 53.0

6.5.2 Stir at high speed with continued heating to obtain a

Magnesium stearate 26.0

homogeneous mixture. Soil color should be charcoal gray.

Iron stearate 21.0

Total 100.0

6.5.3 Maintain a soil temperature of 75 to 80°C throughout

6.4.3.2 Combine the three stearates and pulverize with a the soil application.

mortar and pestle until homogeneous.

6.5.4 Thissoilmixturecanbestoredinaclosedcontainerat

6.4.3.3 Stearate premix can be stored in a closed container

35°F for up to 1 year.

for up to one year.

6.4.4 SuperSoil® Brand Potting Soil Preparation:

7. Preparation of Substrate

6.4.4.1 Remove the large wood chunks, vermiculite, and

7.1 Wash tiles in a laboratory dishwasher using an

styrofoam particles from the potting soil with a large 14-mesh

industrial-strength dishwashing detergent.

sieve.

7.2 Air-drytilesfor24h.Forbestdrying,positiontilessuch

6.4.4.2 Spread1000to1500gofthesievedpottingsoilover

that air flows freely across all surfaces.

a cookie sheet and dry in a forced-draft oven at 110°C for 16

to 24 h until moisture is completely removed.

7.3 Preheat oven to 70 to 80°C.

6.4.4.3 Fill the Ball Mill jar halfway with the ceramic

7.4 Place tiles on an oven tray and heat for at least 1 h

cylinders. Place the sieved soil in the jar. Clamp the lid

before applying the soil. Soil enough tiles to run eight

securely onto the jar and run the Ball Mill for a minimum of 4

replicates per test product plus three extra for cycle determi-

h. The SuperSoil® dirt is now ready for use.

nation.

6.4.4.4 The SuperSoil® dirt may be stored in a closed

container for up to one year.

8. Soil Application

6.4.5 Final Premix No. 1 Preparation:

6.4.5.1 Composition: 8.1 Apparatus:

´1

D5343 − 06 (2012)

8.1.1 Soil Applicator, mini trimmer paint applicator (3.175 dry. Discard sponges with surface imperfections, uneven

by 6.985 cm). thickness, or other obvious deformities. If sponges have been

8.1.2 Test Substrate,whiteceramicglazedwalltiles(10.795 washed by the manufacturer, then just air dry.

by 10.795 cm).

9.2.1.2 Prior to applying product, tare a clean, dry sponge.

Submerge the sponge in synthetic hard water (100 ppm as

8.2 Tile Preparation:

+2 +2

CaCO , 3:1 Ca :Mg ) and squeeze out all but 17.560.5gof

8.2.1 Remove the tray of tiles from the oven immediately 3

water.

prior to soil application. Tiles can be soiled while hot or

allowed to cool to room temperature. 9.2.2 Application of Test Product—Test product dilutions

8.2.2 Use the mini trimmer paint pad and applicator to

should be prepared from synthetic hard water (100 ppm as

+2 +2

applyasinglelayerofhotsoildownthecenterofahottile.Dip CaCO ,3:1Ca :Mg )atambienttemperature.Dilutionsused

the pad in the soil as it is stirring and squeeze out the excess by

should be prepared fresh for each test, and should be made at

pressing pad against the side of the beaker. It is easiest to soil

the manufacturer’s recommended cleaning dilution.

an entire row of tiles with one stroke of the applicator (line the

9.2.2.1 Dilutable Products—Dilutions should be made on a

tiles up in a row so that the tile edges are touching each other

weight/weight basis (for example, a 1-oz to 1-gal dilution

and apply the soil with a broad stroke of the applicator).

would be made by diluting 1 g product with 127 g water). For

8.2.3 Place the soiled tiles back in t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.