ASTM E1942-98e1

(Guide)Standard Guide for Evaluating Data Acquisition Systems Used in Cyclic Fatigue and Fracture Mechanics Testing

Standard Guide for Evaluating Data Acquisition Systems Used in Cyclic Fatigue and Fracture Mechanics Testing

SCOPE

1.1 The purpose of this guide is to understand and minimize the errors associated with data acquisition in fatigue and fracture mechanics testing equipment. This guide is not intended to be used instead of certified traceable calibration or verification of data acquisition systems when such certification is required. It does not cover static load verification, for which the user is referred to the current revision of Practices E4, or static extensometer verification, for which the user is referred to the current revision of Practice E83. The use is also referred to Practice E467.

1.2 The output of the fatigue and fracture mechanics data acquisition systems described in this guide is essentially a stream of digital data. Such digital data may be considered to be divided into two types - Basic Data, which are a sequence of digital samples of an equivalent analog waveform representing the output of transducers connected to the specimen under test, and Derived data, which are digital values obtained from the Basic Data by application of appropriate computational algorithms. The purpose of this guide is to provide methods which give confidence that such Basic and Derived Data describe the properties of the material adequately. It does this by setting minimum or maximum targets for key system parameters, suggesting how to measure these parameters it their actual values are not known.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: E 1942 – 98

Standard Guide for

Evaluating Data Acquisition Systems Used in Cyclic Fatigue

and Fracture Mechanics Testing

This standard is issued under the fixed designation E 1942; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Equation A4.1 was editorially revised in April 2000.

1. Scope 3. Terminology

1.1 The purpose of this guide is to understand and minimize 3.1 Definitions:

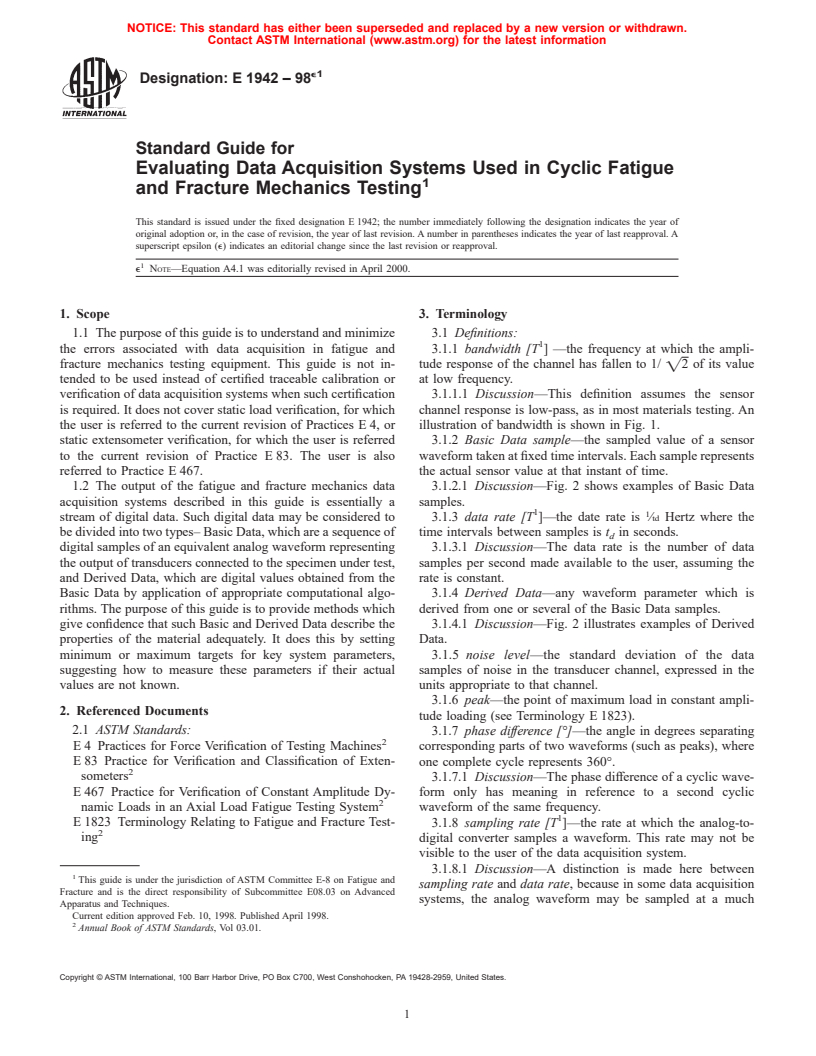

the errors associated with data acquisition in fatigue and 3.1.1 bandwidth [T ] —the frequency at which the ampli-

fracture mechanics testing equipment. This guide is not in- tude response of the channel has fallen to 1/ 2 of its value

=

tended to be used instead of certified traceable calibration or at low frequency.

verification of data acquisition systems when such certification 3.1.1.1 Discussion—This definition assumes the sensor

is required. It does not cover static load verification, for which channel response is low-pass, as in most materials testing. An

the user is referred to the current revision of Practices E 4, or illustration of bandwidth is shown in Fig. 1.

static extensometer verification, for which the user is referred 3.1.2 Basic Data sample—the sampled value of a sensor

to the current revision of Practice E 83. The user is also waveform taken at fixed time intervals. Each sample represents

referred to Practice E 467. the actual sensor value at that instant of time.

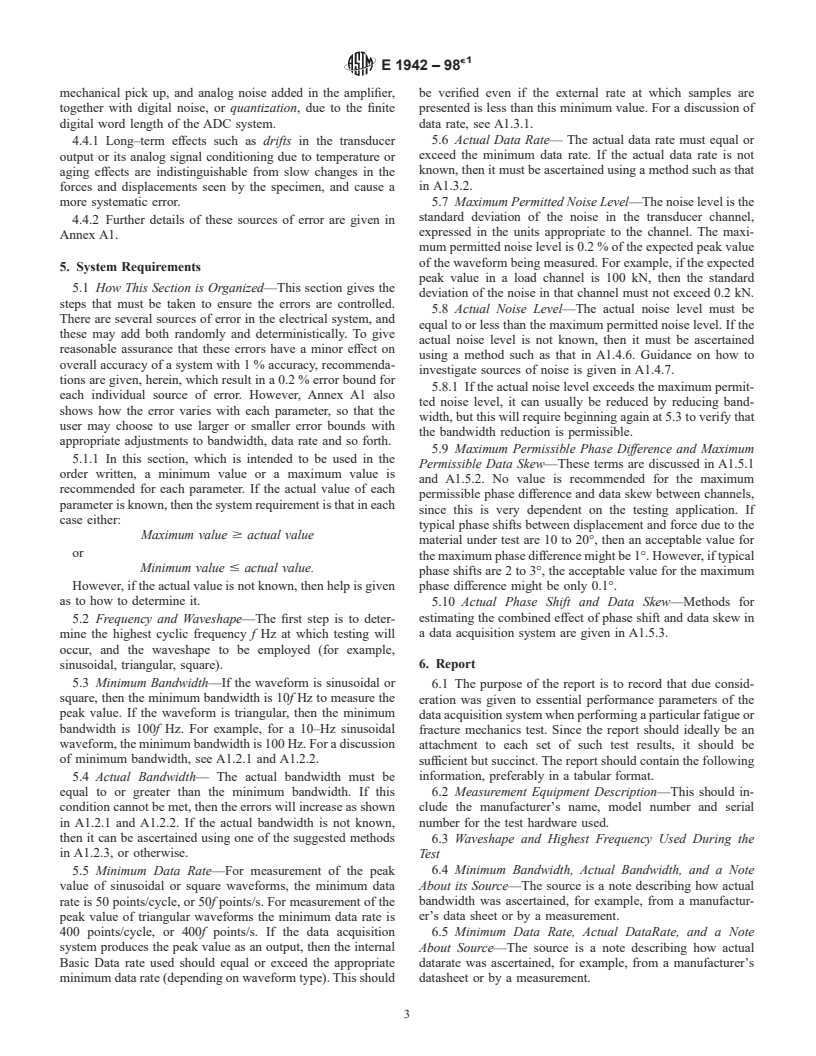

1.2 The output of the fatigue and fracture mechanics data 3.1.2.1 Discussion—Fig. 2 shows examples of Basic Data

acquisition systems described in this guide is essentially a samples.

stream of digital data. Such digital data may be considered to 3.1.3 data rate [T ]—the date rate is ⁄td Hertz where the

be divided into two types– Basic Data, which are a sequence of time intervals between samples is t in seconds.

d

digital samples of an equivalent analog waveform representing 3.1.3.1 Discussion—The data rate is the number of data

the output of transducers connected to the specimen under test, samples per second made available to the user, assuming the

and Derived Data, which are digital values obtained from the rate is constant.

Basic Data by application of appropriate computational algo- 3.1.4 Derived Data—any waveform parameter which is

rithms. The purpose of this guide is to provide methods which derived from one or several of the Basic Data samples.

give confidence that such Basic and Derived Data describe the 3.1.4.1 Discussion—Fig. 2 illustrates examples of Derived

properties of the material adequately. It does this by setting Data.

minimum or maximum targets for key system parameters, 3.1.5 noise level—the standard deviation of the data

suggesting how to measure these parameters if their actual samples of noise in the transducer channel, expressed in the

values are not known. units appropriate to that channel.

3.1.6 peak—the point of maximum load in constant ampli-

2. Referenced Documents

tude loading (see Terminology E 1823).

2.1 ASTM Standards:

3.1.7 phase difference [°]—the angle in degrees separating

E 4 Practices for Force Verification of Testing Machines corresponding parts of two waveforms (such as peaks), where

E 83 Practice for Verification and Classification of Exten-

one complete cycle represents 360°.

someters 3.1.7.1 Discussion—The phase difference of a cyclic wave-

E 467 Practice for Verification of Constant Amplitude Dy-

form only has meaning in reference to a second cyclic

namic Loads in an Axial Load Fatigue Testing System waveform of the same frequency.

E 1823 Terminology Relating to Fatigue and Fracture Test-

3.1.8 sampling rate [T ]—the rate at which the analog-to-

ing digital converter samples a waveform. This rate may not be

visible to the user of the data acquisition system.

3.1.8.1 Discussion—A distinction is made here between

This guide is under the jurisdiction of ASTM Committee E-8 on Fatigue and

sampling rate and data rate, because in some data acquisition

Fracture and is the direct responsibility of Subcommittee E08.03 on Advanced

systems, the analog waveform may be sampled at a much

Apparatus and Techniques.

Current edition approved Feb. 10, 1998. Published April 1998.

Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

E1942–98

FIG. 3 Sources of Error in Data Acquisition Systems

FIG. 1 3dB Bandwidth of Sensor Channel

stresses and strains applied to the specimen and so forth. Such

parameters are the Derived Data.

4.1.1 The whole measurement system may be divided into

three sections for the purpose of verification: the mechanical

test frame and its components, the electrical measurement

system, and the computer processing of data. This guide is

specifically concerned only with the electrical measurement

system commencing at the output of the transducers. Before

the mechanical system is investigated for dynamic errors by the

methods given in Practice E 467, this guide can be used to

ascertain that the electrical measurement system has adequate

performance for the measurements required for Practice E 467.

If the requirements of Practice E 467 for the mechanical

system and the recommendations of this guide are met, then the

user has confidence that the Basic Data produced by the testing

FIG. 2 Basic and Derived Data

system are adequate for processing by subsequent computer

algorithms to produce further Derived Data.

higher rate than the rate at which data are made available to the 4.1.2 At each stage of the flow of data in the electrical

user. (Such a technique is commonly known as over-sampling). measurement system, errors can be introduced. These should

3.1.9 word size—the number of significant bits in a single be considered in the sequence in which these are dealt with in

data sample. this guide. The sequence includes:

3.1.9.1 Discussion—The word size is one parameter which 4.2 Errors Due to Bandwidth Limitations in the Signal

determines the system resolution. Usually it will be determined Conditioning—Where there is analog signal conditioning prior

by the analog-digital converter used, and typically may be 12 to analog-to-digital conversion, there will usually be restric-

or 16 bits. If the word size is w, then the smallest step change tions on the analog bandwidth in order to minimize noise and,

w

in the data that can be seen is 1 part in 2 , that is the in some cases, to eliminate products of demodulation. After

–w

quantization step is d =2 . digital conversion, additional digital filtering may be applied to

3.1.10 valley—The point of minimum load in constant

reduce noise components. These bandwidth restrictions result

amplitude loading (see Terminology E 1823). in cyclic signals at higher frequencies having an apparent

amplitude which is lower than the true value, and if the

4. Description of a Basic Data Acquisition System

waveform is not sinusoidal, also having waveform distortion.

4.1 In its most basic form, a mechanical testing system The bandwidth restrictions also cause phase shifts which result

consists of a test frame with grips which attach to a test in phase measurement errors when comparing phase in two

specimen, a method of applying forces to the specimen, and a channels with different bandwidths.

number of transducers which measure the forces and displace- 4.3 Errors Due to Incorrect Data Rate—Errors can result

ments applied to the specimen (see Fig. 3). The output from from an insufficient data rate, where the intervals between data

these transducers may be in digital or analog form, but if they samples are too large and intervening events are not recorded

are analog, they are first amplified and filtered and then in the Basic Data. These result also in errors in the Derived

converted to digital form using analog-to-digital converters Data for example when the peak value of a waveform is missed

(ADCs). The resulting stream of digital data may be digitally during sampling. Data skew, where the Basic Data are not

filtered and manipulated to result in a stream of output Basic acquired at the same instant in time, can produce similar errors

Data which is presented to the user in the form of a displayed to phase shifts between channels.

or printed output, or as a data file in a computer. Various 4.4 Errors Due to Noise and Drift—Noise added to the

algorithms may be applied to the Basic Data to derive signal being measured causes measurement uncertainty. Short–

parameters representing, for example, the peaks and valleys of term noise causes variability or random error, and includes

the forces and displacements applied to the specimen, or the analog noise at the transducer output due to electrical or

e1

E1942–98

mechanical pick up, and analog noise added in the amplifier, be verified even if the external rate at which samples are

together with digital noise, or quantization, due to the finite presented is less than this minimum value. For a discussion of

digital word length of the ADC system. data rate, see A1.3.1.

5.6 Actual Data Rate— The actual data rate must equal or

4.4.1 Long–term effects such as drifts in the transducer

exceed the minimum data rate. If the actual data rate is not

output or its analog signal conditioning due to temperature or

known, then it must be ascertained using a method such as that

aging effects are indistinguishable from slow changes in the

in A1.3.2.

forces and displacements seen by the specimen, and cause a

more systematic error. 5.7 Maximum Permitted Noise Level—The noise level is the

standard deviation of the noise in the transducer channel,

4.4.2 Further details of these sources of error are given in

expressed in the units appropriate to the channel. The maxi-

Annex A1.

mum permitted noise level is 0.2 % of the expected peak value

of the waveform being measured. For example, if the expected

5. System Requirements

peak value in a load channel is 100 kN, then the standard

5.1 How This Section is Organized—This section gives the

deviation of the noise in that channel must not exceed 0.2 kN.

steps that must be taken to ensure the errors are controlled.

5.8 Actual Noise Level—The actual noise level must be

There are several sources of error in the electrical system, and

equal to or less than the maximum permitted noise level. If the

these may add both randomly and deterministically. To give

actual noise level is not known, then it must be ascertained

reasonable assurance that these errors have a minor effect on

using a method such as that in A1.4.6. Guidance on how to

overall accuracy of a system with 1 % accuracy, recommenda-

investigate sources of noise is given in A1.4.7.

tions are given, herein, which result in a 0.2 % error bound for

5.8.1 If the actual noise level exceeds the maximum permit-

each individual source of error. However, Annex A1 also

ted noise level, it can usually be reduced by reducing band-

shows how the error varies with each parameter, so that the

width, but this will require beginning again at 5.3 to verify that

user may choose to use larger or smaller error bounds with

the bandwidth reduction is permissible.

appropriate adjustments to bandwidth, data rate and so forth.

5.9 Maximum Permissible Phase Difference and Maximum

5.1.1 In this section, which is intended to be used in the

Permissible Data Skew—These terms are discussed in A1.5.1

order written, a minimum value or a maximum value is

and A1.5.2. No value is recommended for the maximum

recommended for each parameter. If the actual value of each

permissible phase difference and data skew between channels,

parameter is known, then the system requirement is that in each

since this is very dependent on the testing application. If

case either:

typical phase shifts between displacement and force due to the

Maximum value $ actual value

material under test are 10 to 20°, then an acceptable value for

or

the maximum phase difference might be 1°. However, if typical

Minimum value # actual value.

phase shifts are 2 to 3°, the acceptable value for the maximum

However, if the actual value is not known, then help is given phase difference might be only 0.1°.

as to how to determine it. 5.10 Actual Phase Shift and Data Skew—Methods for

estimating the combined effect of phase shift and data skew in

5.2 Frequency and Waveshape—The first step is to deter-

a data acquisition system are given in A1.5.3.

mine the highest cyclic frequency f Hz at which testing will

occur, and the waveshape to be employed (for example,

sinusoidal, triangular, square). 6. Report

5.3 Minimum Bandwidth—If the waveform is sinusoidal or

6.1 The purpose of the report is to record that due consid-

square, then the minimum bandwidth is 10f Hz to measure the

eration was given to essential performance parameters of the

peak value. If the waveform is triangular, then the minimum

data acquisition system when performing a particular fatigue or

bandwidth is 100f Hz. For example, for a 10–Hz sinusoidal

fracture mechanics test. Since the report should ideally be an

waveform, the minimum bandwidth is 100 Hz. For a discussion

attachment to each set of such test results, it should be

of minimum bandwidth, see A1.2.1 and A1.2.2.

sufficient but succinct. The report should contain the following

5.4 Actual Bandwidth— The actual bandwidth must be information, preferably in a tabular format.

equal to or greater than the minimum bandwidth. If this 6.2 Measurement Equipment Description—This should in-

condition cannot be met, then the errors will increase as shown clude the manufacturer’s name, model number and serial

in A1.2.1 and A1.2.2. If the actual bandwidth is not known, number for the test hardware used.

then it can be ascertained using one of the suggested methods

6.3 Waveshape and Highest Frequency Used During the

in A1.2.3, or otherwise.

Test

6.4 Minimum Bandwidth, Actual Bandwidth, and a Note

5.5 Minimum Data Rate—For measurement of the peak

value of sinusoidal or square waveforms, the minimum data About its Source—The source is a note describing how actual

bandwidth was ascertained, for example, from a manufactur-

rate is 50 points/cycle, or 50f points/s. For measurement of the

peak value of triangular waveforms the minimum data rate is er’s data sheet or by a measurement.

400 points/cycle, or 400f points/s. If the data acquisition 6.5 Minimum Data Rate, Actual DataRate, and a Note

system produces the peak value as an output, then the internal About Source—The source is a note describing how actual

Basic Da

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.