ASTM C925-79(1995)e1

(Test Method)Standard Test Method for Precision Electroformed Wet Sieve Analysis of Nonplastic Ceramic Powders

Standard Test Method for Precision Electroformed Wet Sieve Analysis of Nonplastic Ceramic Powders

SCOPE

1.1 This test method covers the determination of the particle size distribution of pulverized alumina and quartz for particle sizes from 45 to 5 µm by wet sieving.

1.2 This standard does not purport to address the safety concerns associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: C 925 – 79 (Reapproved 1995)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Precision Electroformed Wet Sieve Analysis of Nonplastic

Ceramic Powders

This standard is issued under the fixed designation C 925; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Section 13 was added editorially in May 1995.

1. Scope

1.1 This test method covers the determination of the particle

size distribution of pulverized alumina and quartz for particle

sizes from 45 to 5 μm by wet sieving.

1.2 This standard does not purport to address the safety

concerns associated with its use. It is the responsibility of the

user of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

tions prior to use.

2. Referenced Documents

2.1 ASTM Standards:

E 161 Specification for Precision Electroformed Sieves

(Square Opening Series)

3. Summary of Test Method

3.1 A separate dispersed suspension of the powder is wet

sieved through each sieve, using vacuum and vibration. The

sieve and sample are dried and weighed.

4. Significance and Use

4.1 Both suppliers and users of pulverized ceramic powders

will find this test method useful to determine particle size

distributions for materials specifications, manufacturing con-

trol, development, and research.

4.2 The test method is simple, although tedious, uses

inexpensive equipment, and will provide a continuous curve

with data obtained with standardized woven sieves.

5. Apparatus

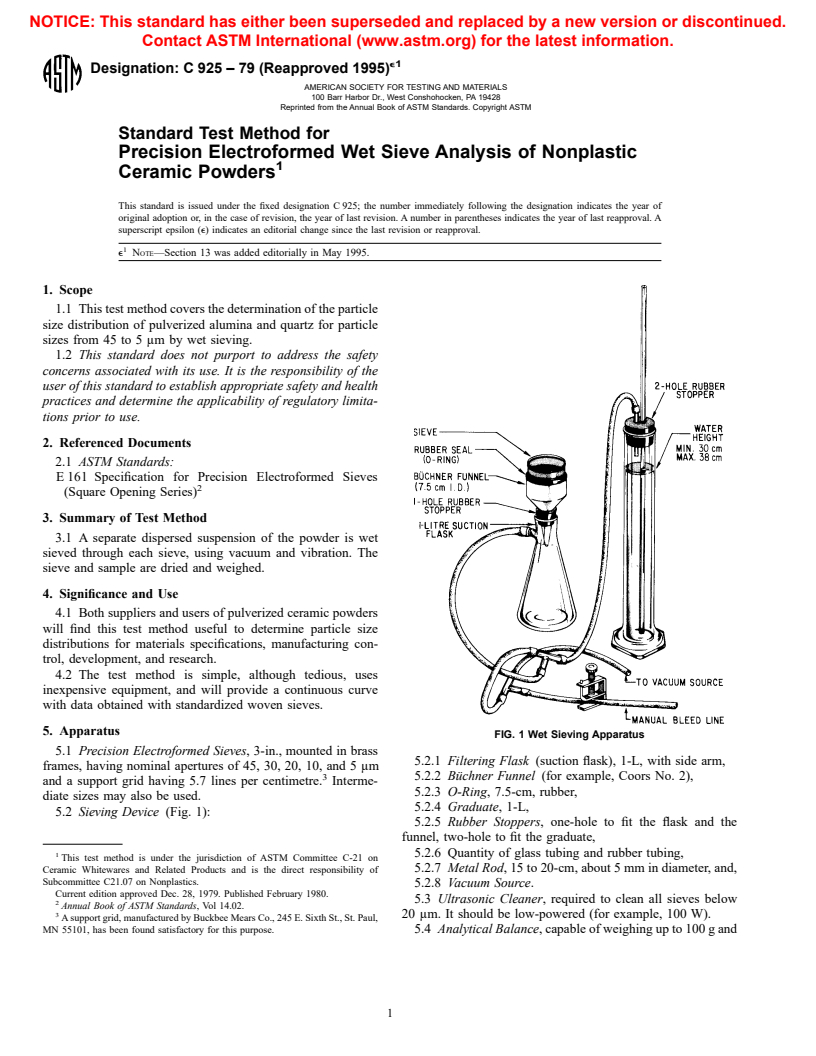

FIG. 1 Wet Sieving Apparatus

5.1 Precision Electroformed Sieves, 3-in., mounted in brass

5.2.1 Filtering Flask (suction flask), 1-L, with side arm,

frames, having nominal apertures of 45, 30, 20, 10, and 5 μm

3 5.2.2 Büchner Funnel (for example, Coors No. 2),

and a support grid having 5.7 lines per centimetre. Interme-

5.2.3 O-Ring, 7.5-cm, rubber,

diate sizes may also be used.

5.2.4 Graduate, 1-L,

5.2 Sieving Device (Fig. 1):

5.2.5 Rubber Stoppers, one-hole to fit the flask and the

funnel, two-hole to fit the graduate,

1 5.2.6 Quantity of glass tubing and rubber tubing,

This test method is under the jurisdiction of ASTM Committee C-21 on

Ceramic Whitewares and Related Products and is the direct responsibility of 5.2.7 Metal Rod, 15 to 20-cm, about 5 mm in diameter, and,

Subcommittee C21.07 on Nonplastics.

5.2.8 Vacuum Source.

Current edition approved Dec. 28, 1979. Published February 1980.

5.3 Ultrasonic Cleaner, required to clean all sieves below

Annual Book of ASTM Standards, Vol 14.02.

20 μm. It should be low-powered (for example, 100 W).

A support grid, manufactured by Buckbee Mears Co., 245 E. Sixth St., St. Paul,

MN 55101, has been found satisfactory for this purpose. 5.4 Analytical Balance, capable of weighing up to 100 g and

C 925

having at least three significant digits after the decimal. agent), and disperse by placing beaker in ultrasonic bath for 1

5.5 Drying Oven, capable of maintaining 110 6 5°C. min. Microscopical examination of the particles after disper-

5.6 Desiccator, containing magnesium perchlorate or other sion may be helpful in determining if the dispersion is

suitable desiccant. complete.

10.4 Wash the dispersed sample onto the sieve using a wash

6. Reagents and Materials

bottle containing the sieving solution, turn on vacuum (a

6.1 Water, visually clear and particle free, not necessarily

maximum of 15 in. of water), and agitate. Continuously add

distilled, at room temperature or slightly above.

sieving solution, at a rate sufficient to maintain a small amount

6.2 Sieving Solution, a dispersing media consisting of 0.1

in the sieve, until about 1 L has passed. Below 6 μm the amount

weight % solution of sodium hexametaphosphate or sodium

of liquid required is less due to the time for sieving. Agitate by

pyrophosphate in water.

sharp tapping on the sieve frame with the metal rod. For sieves

6.3 Drying Agents, acetone or methyl alcohol, commercial

above 30 μm the liquid runs quickly enough without vacuum so

grade.

that the air-bleed valve can be opened. The bleed-line should

be pinched occasionally, however, to draw the larger particles

7. Sampling

through, bu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.