ASTM F1228-89(1994)E01

(Test Method)Test Method for Oxidizable (Organic) Carbon on Wafer Surfaces (By Persulfate) (Withdrawn 2001)

Test Method for Oxidizable (Organic) Carbon on Wafer Surfaces (By Persulfate) (Withdrawn 2001)

SCOPE

1.1 This test method covers wafers composed of silicon and other materials used in the semiconductor industry.

1.2 The test method is used to determine the mass of organic (oxidizable) carbon deposited on all exposed wafer surfaces. It is not used to determine total carbon content of the wafer material.

1.3 This test method is limited to carbon determinations in the range from 0.1 to 50 [mu]g/sample. The detection limit is defined as 2 X standard deviation (2[sigma]).

1.4 Volatiles may be lost during storage or handling, or both, of wafers. This test method is not used to quantify volatile organic compounds.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: F 1228 – 89 (Reapproved 1994)

Standard Test Method for

Oxidizable (Organic) Carbon on Wafer Surfaces

(By Persulfate)

This standard is issued under the fixed designation F 1228; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Keywords were added editorially in September 1994.

1. Scope lar sieve trap held at room temperature (25 to 28°C). The

carbon dioxide is then thermally desorbed by heating the trap

1.1 This test method covers wafers composed of silicon and

to 200 6 10°C and is carried by nitrogen into a nondispersive

other materials used in the semiconductor industry.

infrared (NDIR) detector sensitized to carbon dioxide. The

1.2 The test method is used to determine the mass of organic

resulting detector signal (less the procedural blank) represents

(oxidizable) carbon deposited on all exposed wafer surfaces. It

the mass of carbon oxide from the wafer surface. The carbon

is not used to determine total carbon content of the wafer

dioxide peak is quantized to carbon mass by either a linearized

material.

calibrated direct readout or comparison with signals resulting

1.3 This test method is limited to carbon determinations in

from oxidation of solutions of carbon standards.

the range from 0.1 to 50 μg/sample. The detection limit is

defined as 2 3 standard deviation (2s).

5. Significance and Use

1.4 Volatiles may be lost during storage or handling, or

5.1 Organic carbon contaminants deposited on semiconduc-

both, of wafers. This test method is not used to quantify

tor wafers can cause losses in product yield. This test method

volatile organic compounds.

makes possible a rapid quantification of surface contamination

1.5 This standard does not purport to address all of the

by carbon. Wafers can be tested before and after various stages

safety concerns, if any, associated with its use. It is the

of the wafer fabrication process. Results can be obtained within

responsibility of the user of this standard to establish appro-

a few minutes of wafer sampling to aid in decisions concerning

priate safety and health practices and determine the applica-

the wafer production process.

bility of regulatory limitations prior to use.

6. Interferences

2. Referenced Documents

6.1 Direct contact of a wafer with the human body or

2.1 ASTM Standards:

materials containing even small amounts of organic carbon

D 1129 Terminology Relating to Water

2 compounds can cause a positive interference. Wafers must be

D 1193 Specification for Reagent Water

handled with tools that have been cleaned of organic carbon.

3. Terminology 6.2 Prolonged exposure of a clean wafer to the atmosphere

can cause a positive interference due to adsorption of organics

3.1 Definitions:

and carbon dioxide from the air or due to particle settling on

3.1.1 For definitions of terms used in this test method, refer

the wafer. Wafers should be tested at time frame relevant to

to Terminology D 1129.

process.

4. Summary of Test Method 6.3 Organic compounds are not oxidized at the same rates.

Compounds may exist that are not completely oxidized in the

4.1 Carbon on wafer surfaces is determined by oxidation to

standard time (4 min) allowed for reaction. In this case, a

carbon dioxide using a persulfate oxidant solution at 100 6

negative interference (loss of recovery) will result and if the

1°C. The wafer is placed in a chamber filled with a clean,

slowly oxidizing compounds in question partition into the

acidified persulfate solution and the heated chamber is sealed.

reaction solution, a positive interference (carry-over) may

Susceptible organic carbon is submitted to a 4 min digestion at

occur with the next sample. Thus, time of reaction must be

100°C to form carbon dioxide in solution. The resulting carbon

demonstrated to be sufficient for complete oxidation of com-

dioxide is purged from solution and concentrated on a molecu-

pounds present. Reaction time may be evaluated by analyzing

a single wafer in replicate (without removing it from the

This test method is under the jurisdiction of ASTM Committee F-1 on

chamber). If the result from the second carbon determination is

Electronics and is the direct responsibility of Subcommittee F01.10 on Contamina-

tion Control Processing. greater than the blank by more than 0.1 μg, carbon was not

Current edition approved May 26, 1989. Published July 1989.

sufficiently oxidized in the first determination. In this case,

Annual Book of ASTM Standards, Vol 11.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

F 1228

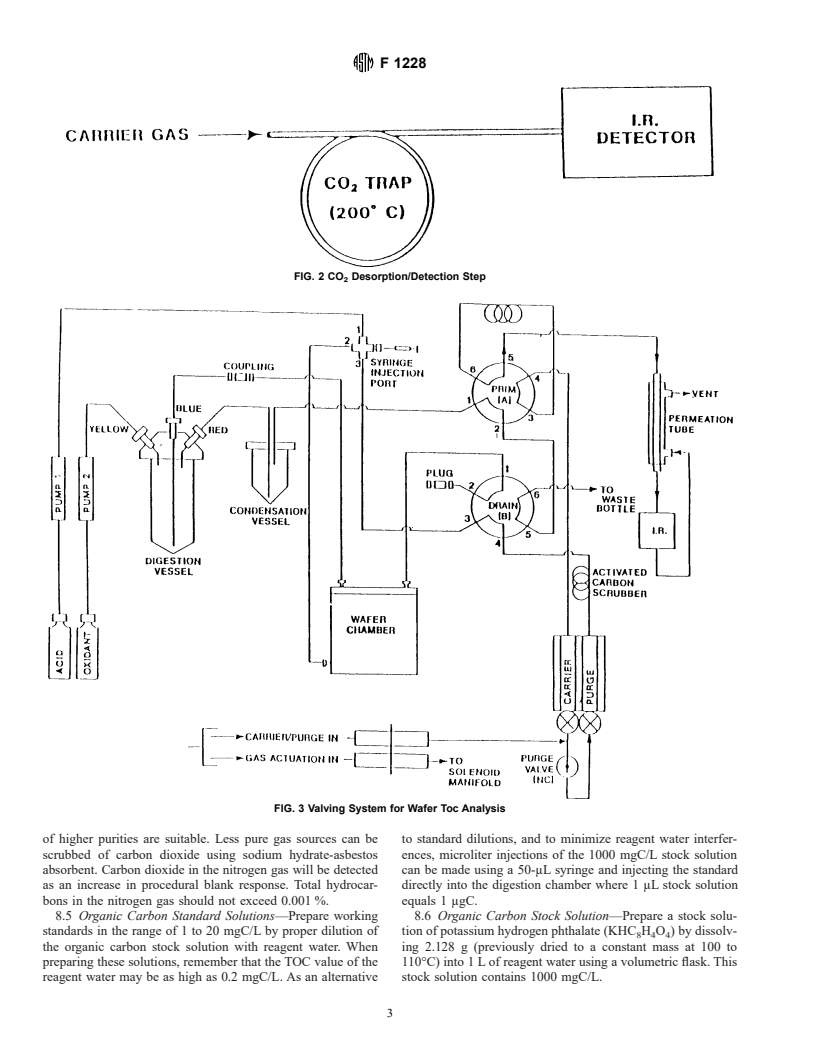

reaction time should be increased 1 min and the replicate test while in-line with the detector is needed. The valving system

repeated with a new wafer until acceptable results are obtained. should be designed to minimize contamination and handling of

6.4 Opening the digestion chamber introduces ambient car- plumbing components. Fig. 3 shows a diagrammatic presenta-

bon dioxide, that must be flushed from the chamber head space tion of a suitable analyzer.

before each analysis. Carbon dioxide left in the head space will 7.5 Tweezers—A pair of clean TFE-fluorocarbon tweezers is

introduce a positive error in the results. needed to transfer wafers to and from the digestion chamber.

7. Apparatus 8. Reagents and Materials

7.1 Sealable Chamber, suitable for maintaining a persulfate 8.1 Purity of Reagents—Reagent grade chemicals shall be

solution at 100 6 1°C without corroding or producing carbon used. Unless otherwise indicated, it is intended that all reagents

dioxide from the chamber materials is necessary. The chamber conform to the specifications of the Committee on Analytical

shall be of a configuration to accept wafers to be analyzed and

Reagents of the American Chemical Society where such

must permit passage of nitrogen purge gas through the con- specifications are available. Inferior grades may cause an

tained solution for purging of carbon dioxide (see Fig. 1).

increase in the procedural blank due to higher concentrations of

˚

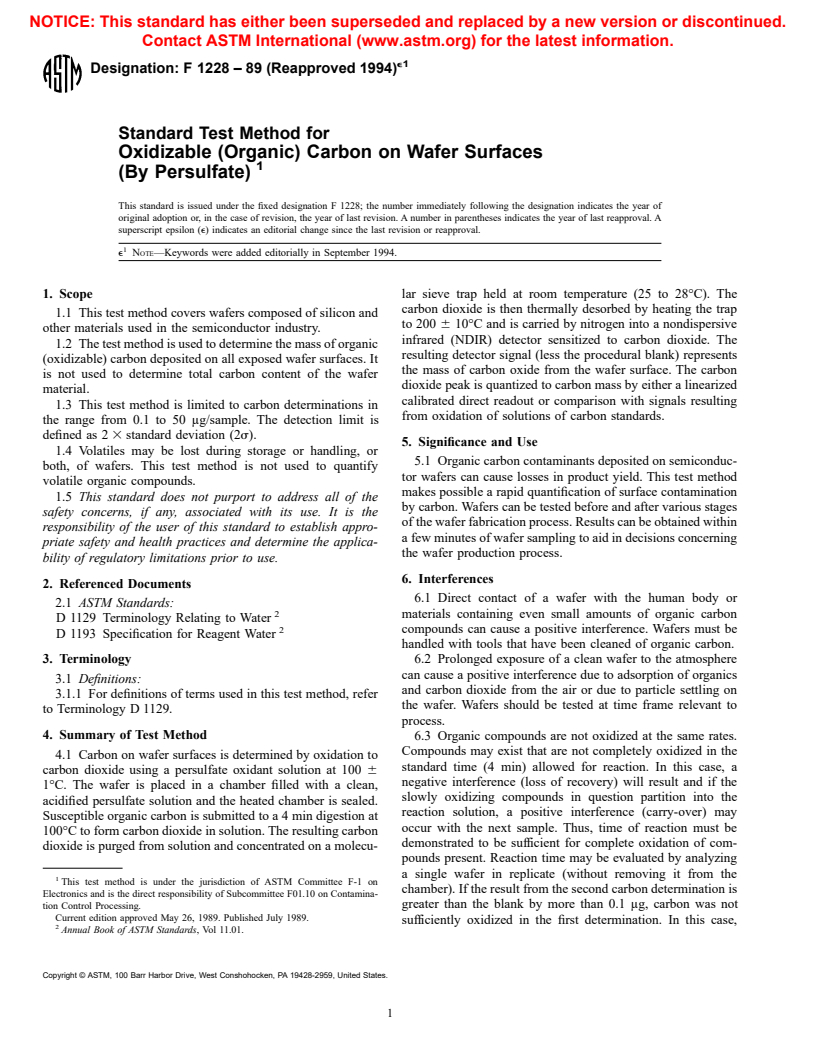

7.2 Molecular Sieve Trap—A trap containing 5A molecular carbon contaminants in the reagent.

sieve, 30 to 60-mesh and a method of rapid trap heating

8.2 Purity of Water—Unless otherwise indicated, references

capable of maintaining a trap temperature of 200 6 10°C is to water shall be understood to mean reagent water as defined

required. The trap should rise from 25 to 200°C in less than 30

by Type II of Specification D 1193. This water should contain

s. A stainless steel tube of 3.2-mm outside diameter and less than 0.2 mg/L Total Oxidizable Carbon, (TOC).

2.7-mm inside diameter packed with 15 cm of 30 to 60-mesh

8.3 Acidified Sodium Persulfate (10 %) Solution—Prepare

molecular sieve is suitable as a trap (see Fig. 2). by dissolving 100 6 1 g of sodium persulfate (Na S O ) into

2 2 8

7.3 Non-Dispersive Infrared Detector—A NDIR capable of

1 L of reagent water. Add 5 mL of 85 % phosphoric acid

detecting carbon dioxide in the range of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.