ASTM D4475-96

(Test Method)Standard Test Method for Apparent Horizontal Shear Strength of Pultruded Reinforced Plastic Rods By The Short-Beam Method

Standard Test Method for Apparent Horizontal Shear Strength of Pultruded Reinforced Plastic Rods By The Short-Beam Method

SCOPE

1.1 This test method covers the determination of the apparent horizontal shear strength of fiber reinforced plastic rods. The specimen is a short beam in the form of lengths of pultruded rods. This test method is applicable to all types of parallel-fiber-reinforced plastic rod samples.

1.2 This test method is primarily used for quality control and specification purposes (see 4.1).

1.3 The values states in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4475 – 96

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Apparent Horizontal Shear Strength of Pultruded Reinforced

Plastic Rods By the Short-Beam Method

This standard is issued under the fixed designation D 4475; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the appar-

ent horizontal shear strength of fiber reinforced plastic rods.

The specimen is a short beam in the form of lengths of

pultruded rods. This test method is applicable to all types of

parallel-fiber-reinforced plastic rod samples.

1.2 This test method is primarily used for quality control

and specification purposes (see 4.1).

1.3 The values stated in SI units are to be regarded as the

standard.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

NOTE 1—There is no similar or equivalent ISO standard.

2. Referenced Documents

2.1 ASTM Standards:

D 618 Practice for Conditioning Plastics for Testing

E 4 Practices for Force Verification of Testing Machines

E 691 Practice for Conducting an Interlaboratory Study to

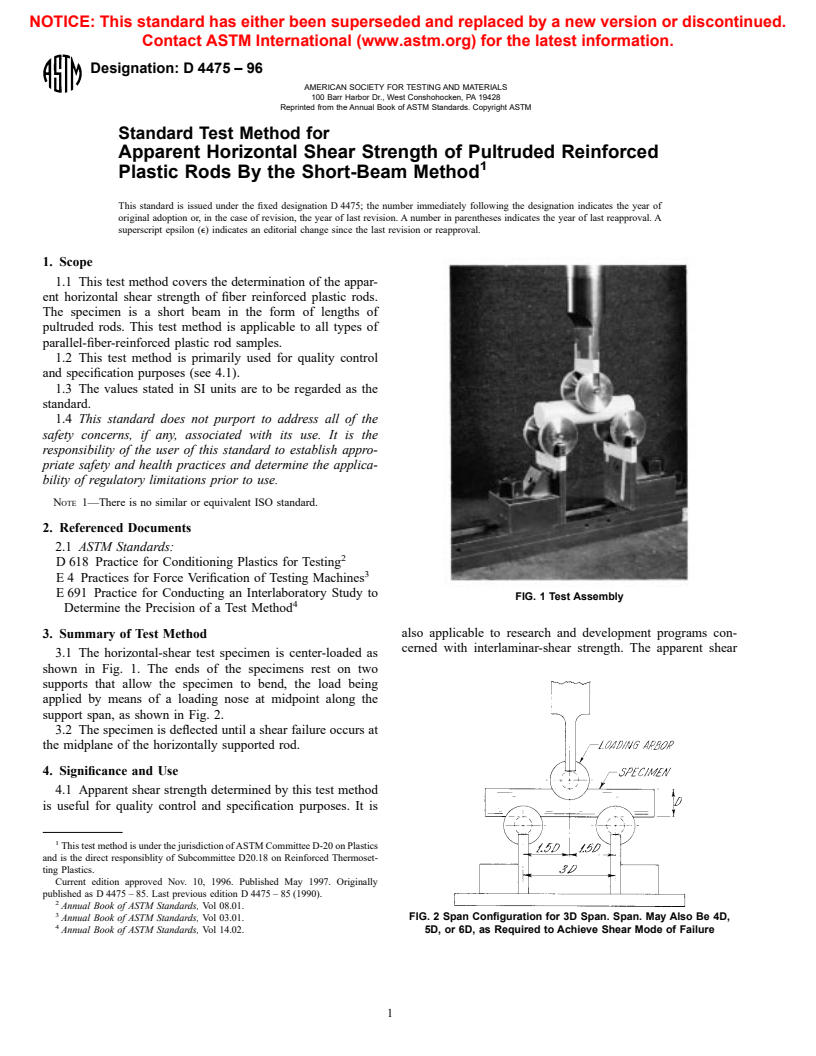

FIG. 1 Test Assembly

Determine the Precision of a Test Method

also applicable to research and development programs con-

3. Summary of Test Method

cerned with interlaminar-shear strength. The apparent shear

3.1 The horizontal-shear test specimen is center-loaded as

shown in Fig. 1. The ends of the specimens rest on two

supports that allow the specimen to bend, the load being

applied by means of a loading nose at midpoint along the

support span, as shown in Fig. 2.

3.2 The specimen is deflected until a shear failure occurs at

the midplane of the horizontally supported rod.

4. Significance and Use

4.1 Apparent shear strength determined by this test method

is useful for quality control and specification purposes. It is

This test method is under the jurisdiction of ASTM Committee D-20 on Plastics

and is the direct responsiblity of Subcommittee D20.18 on Reinforced Thermoset-

ting Plastics.

Current edition approved Nov. 10, 1996. Published May 1997. Originally

published as D 4475 – 85. Last previous edition D 4475 – 85 (1990).

Annual Book of ASTM Standards, Vol 08.01.

Annual Book of ASTM Standards, Vol 03.01. FIG. 2 Span Configuration for 3D Span. Span. May Also Be 4D,

Annual Book of ASTM Standards, Vol 14.02. 5D, or 6D, as Required to Achieve Shear Mode of Failure

D 4475

strength obtained by this test method cannot be used for design than 40 h prior to test, in accordance with Procedure A of

purposes, but can be utilized for comparative testing of Practice D 618 for those tests where conditioning is required.

composite materials, if all failures are in horizontal shear. In cases of disagreement, the tolerances shall be 6 1°C

4.2 It is recommended that control samples be fabricated (61.8°F) and 62 % relative humidity. These conditions are

with each research test series and that care be used to compare recommended for research and development trials, but not

each set of controls with corresponding test series run at necessarily for quality control. However, temperature control

different times. to 22.26 5.6°C (72 6 10°F) is recommended for quality

control.

5. Apparatus

7.2 Test Conditions—Conduct tests in the standard labora-

5.1 Testing Machine—A properly calibrated testing ma-

tory atmosphere of 23 6 2°C (73.4 6 3.6°F) and 50 6 5%

chine that can be operated at a constant rate of crosshead

relative humidity, unless otherwise specified in the test meth-

motion, and in which the error in the load measuring system

ods. In cases of disagreement, the tolerances shall be61°C

shall not exceed 61 % of the maximum load expected to be

(61.8°F) and 62 % relative humidity.

measured. The load-indicating mechanism shall be essentially

7.3 Preconditioning in other environments to simulate

free of inertia lag at the crosshead rate used. The accuracy of

specified conditions and durations is permissible.

the testing machine shall be verified in accordance with

7.4 Testing in other environmental conditions is permis-

Practices E 4.

sible.

5.2 Loading Nose and Supports—Shown in Fig. 2 and Fig.

8. Speed of Testing

3. The loading nose shall be a suitable steel rod with a groove

8.1 Test the specimen at a rate of crosshead motion of 1.3

in the diameter of the pultruded rod machined in its lower end.

mm (0.05 in.)/min.

The groove diameter shall always have a plus tolerance and

zero negative tolerance. The bottom support shall be adjustable

NOTE 2—The test time should be recorded, and, if the test takes less

to allow for testing at various span/diameter ratios. The surface

than 20 s, the rate of crosshead motion should be decreased. If the test

of the groove shall be free of indentation and burrs, with all

takes over 200 s, the crosshead rate should be increased gradually, or in

steps, until the time to complete the test is less than 200 s.

sharp edges relieved.

5.3 Micrometers—Suitable micrometers for measuring the

9. Procedure

diameter of the test specimen to an incremental discrimination

9.1 Before conditioning or testing, measure the diameter of

of at least 0.025 mm (0.001 in.) shall be used.

each specimen to the nearest 0.025 mm (0.001 in.) at midpoint.

6. Test Specimen

9.2 Place the rod test specimen in the test fixture, as shown

in Fig. 1. Align the specimen so that its midpoint is centered

6.1 The specimen shall be cut from the pultruded rod to a

and its long axis is perpendicular to the loading nose. Adjust

length of one diameter greater than the test span and to a

tolerance of plus or minus 0.1 times the diameter. the side supports to the span previously determined. Suggested

span-to-diameter ratios are from 3 to 1 up to 6 to 1. The

6.2 Number of Specimens—The number of test specimens is

optional. However, a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.