ASTM F2649-08

(Specification)Standard Specification for Corrugated High Density Polyethylene (HDPE) Grease Interceptor Tanks

Standard Specification for Corrugated High Density Polyethylene (HDPE) Grease Interceptor Tanks

SCOPE

1.1 This specification covers material, design, structural performance, and manufacturing practice requirements for monolithic or sectional corrugated polyethylene grease interceptor tanks with volumes equal to or greater than 333 gallons (1,260 liters ).

1.2 The corrugated high density polyethylene (HDPE) grease interceptor tanks are placed between commercial food service (kitchen) drains and sanitary sewer interceptors to minimize the impact of commercial food service effluent containing grease, oils, soap scum and other typical commercial food service wastes on the sanitary sewer system. Typical sources of commercial kitchen effluent are scullery sinks, pot and pan sinks, dishwashers, soup kettles and floor drains where grease containing materials may exist.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

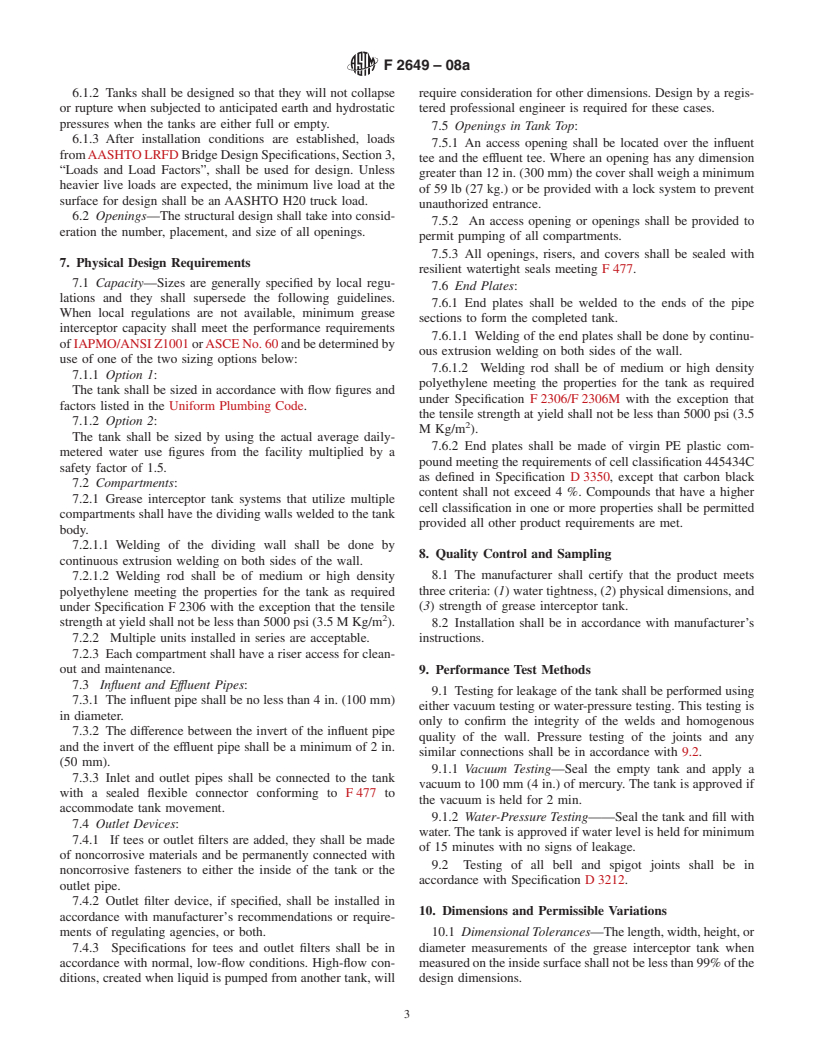

1.4 This specification covers pipe and fittings for horizontally laid corrugated HDPE grease interceptor tanks as illustrated in Fig. 1.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 2649 – 08a

Standard Specification for

Corrugated High Density Polyethylene (HDPE) Grease

Interceptor Tanks

This standard is issued under the fixed designation F 2649; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D 3212 Specification for Joints for Drain and Sewer Plastic

Pipes Using Flexible Elastomeric Seals

1.1 This specification covers material, design, structural

D 3350 Specification for Polyethylene Plastics Pipe and

performance, and manufacturing practice requirements for

Fittings Materials

monolithic or sectional corrugated polyethylene grease inter-

F 412 Terminology Relating to Plastic Piping Systems

ceptor tanks with volumes equal to or greater than 333 gal

F 477 Specification for Elastomeric Seals (Gaskets) for

(1,260 L).

Joining Plastic Pipe

1.2 The corrugated high density polyethylene (HDPE)

F 667 Specification for Large Diameter Corrugated Poly-

grease interceptor tanks are placed between commercial food

ethylene Pipe and Fittings

service (kitchen) drains and sanitary sewer interceptors to

F 714 Specification for Polyethylene (PE) Plastic Pipe

minimize the impact of commercial food service effluent

(SDR-PR) Based on Outside Diameter

containing grease, oils, soap scum and other typical commer-

F 2306/F 2306M Specification for 12 to 60 in. [300 to 1500

cial food service wastes on the sanitary sewer system. Typical

mm] Annular Corrugated Profile-Wall Polyethylene (PE)

sources of commercial kitchen effluent are scullery sinks, pot

Pipe and Fittings for Gravity-Flow Storm Sewer and

andpansinks,dishwashers,soupkettlesandfloordrainswhere

Subsurface Drainage Applications

grease containing materials may exist.

2.2 IAPMO Document:

1.3 The values stated in inch-pound units are to be regarded

Uniform Plumbing Code

as standard. The values given in parentheses are mathematical

IAPMO/ANSI Z1001 Prefabricated Gravity Grease Inter-

conversions to SI units that are provided for information only

ceptors

and are not considered standard.

2.3 American Society of Civil Engineers

1.4 This specification covers pipe and fittings for horizon-

ASCE No.60 Gravity Sanitary Sewer Design and Construc-

tally laid corrugated HDPE grease interceptor tanks as illus-

tion

trated in Fig. 1.

2.4 Plastic Pipe Institute

1.5 This standard does not purport to address all of the

PPI TR-4 PE3408

safety concerns, if any, associated with its use. It is the

2.5 AASHTO Document :

responsibility of the user of this standard to establish appro-

AASHTO LRFD Bridge Specifications

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

3. Terminology

2. Referenced Documents 3.1 For definitions of terms relating to plastics, see Termi-

2 nology F 412 and abbreviations are in accordance with Termi-

2.1 ASTM Standards:

nology D 1600, unless otherwise specified.

D 543 Practices for Evaluating the Resistance of Plastics to

3.2 Definitions of Terms Specific to This Standard:

Chemical Reagents

3.3 access opening, n—a hole in the top or crown of the

D 1600 Terminology for Abbreviated Terms Relating to

tankusedtogainaccesstotheinsideofthetankforthepurpose

Plastics

1 3

This specification is under the jurisdiction ofASTM Committee F17 on Plastic Available from International Association of Plumbing and Mechanical Offi-

Piping Systems and is the direct responsibility of Subcommittee F17.26 on Olefin cials, 5001 E. Philadelphia St., Ontario, CA 91761, http://www.iapmo.org.

Based Pipe. Available from American Society of Civil Engineers (ASCE), 1801 Alexander

Current edition approved June 15, 2008. Published June 2008. Originally Bell Dr., Reston, VA 20191, http://www.asce.org.

approved in 2008. Last previous edition approved in 2008 as F 2649–08. Available from Plastics Pipe Institute (PPI), 105 Decker Court, Suite 825,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Irving, TX 75062, http://www.plasticpipe.org.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from American Association of State Highway and Transportation

Standards volume information, refer to the standard’s Document Summary page on Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

the ASTM website. http://www.transportation.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 2649 – 08a

FIG. 1 Standard Corrugated HDPE Grease Interceptor

of cleaning and removing grease, floating scum and sludge 4.1.4 Application conditions such as effluent and tempera-

without a person actually having to enter the tank. ture of discharge,

3.4 air scum volume, n—the number of cubic in. (cm) in the 4.1.5 Acceptance will be based on a review of the calcula-

space between the liquid surface and the underside of the top tions or on proof tests,

slab.

4.1.6 Design requirements such as depth of earth cover, live

3.5 baffle, n—a partition across the width of the tank that

load applied at the surface, and ground water level, and

extends partially between the top and bottom intended to

4.1.7 Testing for water leakage shall not be required at the

deflect influent downward and increase the length of the flow

job site unless specifically required by the owner at the time of

path of the liquid as it travels through the tank.

ordering.

3.6 grease interceptor tank system, n—a single tank or

series of tanks in which wastes from a kitchen or food service

5. Materials and Manufacture

industry containing no sanitary discharges is received and

5.1 Basic Materials—Materials utilized for the fabrication

retained, and from which the liquid effluent, which is compara-

of a corrugated polyethylene grease interceptor tank shall be

tively free from settleable and floating solids, is then dis-

evaluated for temperature extremes and effluent constituents in

chargedtoapublicsewer,septicsystem,orapprovedtreatment

accordance with Practice D 543.

system.

5.1.1 Tank and Risers—The tank and risers shall be fabri-

3.7 inspection opening, n—a hole in the top or crown of the

cated from pipe and fittings meeting the requirements of

tank used for the purpose of observing conditions inside the

Specification F 2306/F 2306M.

tank.

5.1.2 Inlet and Outlet Tees—Inlet and outlet tees shall be

3.8 joint, n—a physical separation where two pieces of the

fabricated from pipe and fittings meeting the requirements of

tank or pipe-tank interface are in contact.

Specification F 2306/F 2306M or F 714.

3.9 monolithic corrugated high density polyethylene grease

5.1.3 Vent pipes and internal tank piping—Vent pipe and

interceptor tank, n—a single extruded piece of pipe with no

internal piping within the grease interceptor shall be fabricated

internal joints other that end caps that serves as the principal

from pipe and fittings meeting the requirements of Specifica-

tank structure.

tion F 2306/F 2306M for dual wall pipe and Specification

3.10 non-sealed joint, n—a joint where a machined fit will

F 667 for single wall pipe.

minimizethemovementofliquidfromonesideofawalltothe

5.1.4 Baffles and End Caps —Baffles and end caps shall be

opposite side.

fabricated from either flat plates meeting the requirements of

3.11 owner, n—is by definition end user, customer, or

PPI TR-4 PE3408 material or blow molded fittings, rotation-

purchaser.

ally molded fittings or injection molded fittings meeting the

3.12 sealed joint, n—a joint that is sealed to prevent liquid

requirements of Specification F 2306/F 2306M.

passing from one side of a wall to the opposite side.

5.2 Pipe Connections—Pipe-to-tank connections shall em-

3.13 sectional corrugated high density polyethylene grease

ploy flexible connectors conforming to the requirements of

interceptor tank, n—a group or two or more extruded pieces of

Specification F 477. Materials for the connectors shall have

pipe connected with joints that when combined serve as the

demonstrated resistance to the effects of fats, oils, grease, and

principal tank structure.

fluid temperatures specified under Section 4.

4. Ordering Information

6. Structural Design Requirements

4.1 The owner shall include the following information in

bidding documents and on the purchase order, as applicable to 6.1 Structural design of grease interceptor tanks shall be by

calculation.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.