ASTM D4385-19

(Practice)Standard Practice for Classifying Visual Defects in Thermosetting Reinforced Plastic Pultruded Products

Standard Practice for Classifying Visual Defects in Thermosetting Reinforced Plastic Pultruded Products

ABSTRACT

This practice focuses on the establishment of acceptance levels and criteria upon inspection of visual defects in thermosetting reinforced plastic pultruded rods, bars, shapes, and sheets. Presented here is the definition of possible defects to serve as a guide for contracts, drawings, product specifications, and final inspection. This practice also categorizes different inspection requirements for three grades of product quality.

SCOPE

1.1 This practice covers acceptance criteria for visual acceptance of thermosetting reinforced plastic pultruded rods, bars, shapes, and sheets.

1.2 This practice presents definitions of possible defects to serve as a guide for contracts, drawings, product specifications, and final inspection.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: There is no known ISO equivalent to this standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4385 − 19

Standard Practice for

Classifying Visual Defects in Thermosetting Reinforced

1

Plastic Pultruded Products

This standard is issued under the fixed designation D4385; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Terminology

1.1 This practice covers acceptance criteria for visual ac- 3.1 Definitions—The definitions in this practice are in ac-

cordance with Terminology D883.

ceptance of thermosetting reinforced plastic pultruded rods,

bars, shapes, and sheets.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 connection areas—areas associated with a pultruded

1.2 This practice presents definitions of possible defects to

member that form a connection in some form or fashion that

serve as a guide for contracts, drawings, product specifications,

will not be visible after fabrication.

and final inspection.

3.2.2 fiber blooming—exposed reinforcements on the sur-

1.3 The values stated in inch-pound units are to be regarded

face of a profile as a result of veil slippage or lack of resin.

as standard. The values given in parentheses are mathematical

Such defects will cause the exposed fiber to “bloom” when

conversions to SI units that are provided for information only

exposed to ultraviolet light.

and are not considered standard.

3.2.3 internal layer—refers to individual layers of unidirec-

1.4 This standard does not purport to address all of the

tional or transverse reinforcements in the form of roving/tows,

safety concerns, if any, associated with its use. It is the

continuous filament, woven or stitched mats formed and

responsibility of the user of this standard to establish appro-

laminated via the pultrusion process to produce a specific

priate safety, health, and environmental practices and deter-

thickness of or as part of a pultruded profile. A stitched or

mine the applicability of regulatory limitations prior to use.

woven mat is made up of individual layers of roving woven or

NOTE 1—There is no known ISO equivalent to this standard.

stitched together to form a single mat

1.5 This international standard was developed in accor-

3.2.4 mat discoloration—a discoloration (typically yellow-

dance with internationally recognized principles on standard-

ing) of the reinforcing mats caused by binder migration. The

ization established in the Decision on Principles for the

discoloration can cause visual streaks on the surface of the

Development of International Standards, Guides and Recom-

pultrusion.

mendations issued by the World Trade Organization Technical

3.2.5 test requirement—minimum design, characteristic or

Barriers to Trade (TBT) Committee.

specified values as dictated and or specified by codes,

standards, industry, end customers, the manufacturer or the

2. Referenced Documents

Engineer of Record.

2

2.1 ASTM Standards:

D883 Terminology Relating to Plastics 4. Acceptance Criteria

D3917 Specification for Dimensional Tolerance of Thermo-

4.1 The method and frequency of inspection shall be the

setting Glass-Reinforced Plastic Pultruded Shapes

responsibility of the pultruder as deemed necessary to maintain

compliance to this specification, unless the purchaser and seller

agree on other terms.

1

This practice is under the jurisdiction ofASTM Committee D20 on Plastics and

4.2 Dimensions and Tolerances—Refer to specifications in

is the direct responsibility of Subcommittee D20.18 on Reinforced Thermosetting

Plastics. accordance with product drawing or in accordance with Speci-

Current edition approved Nov. 1, 2019. Published December 2019. Originally

fication D3917.

approved in 1984. Last previous edition approved in 2013 as D4385 - 13. DOI:

10.1520/D4385-19.

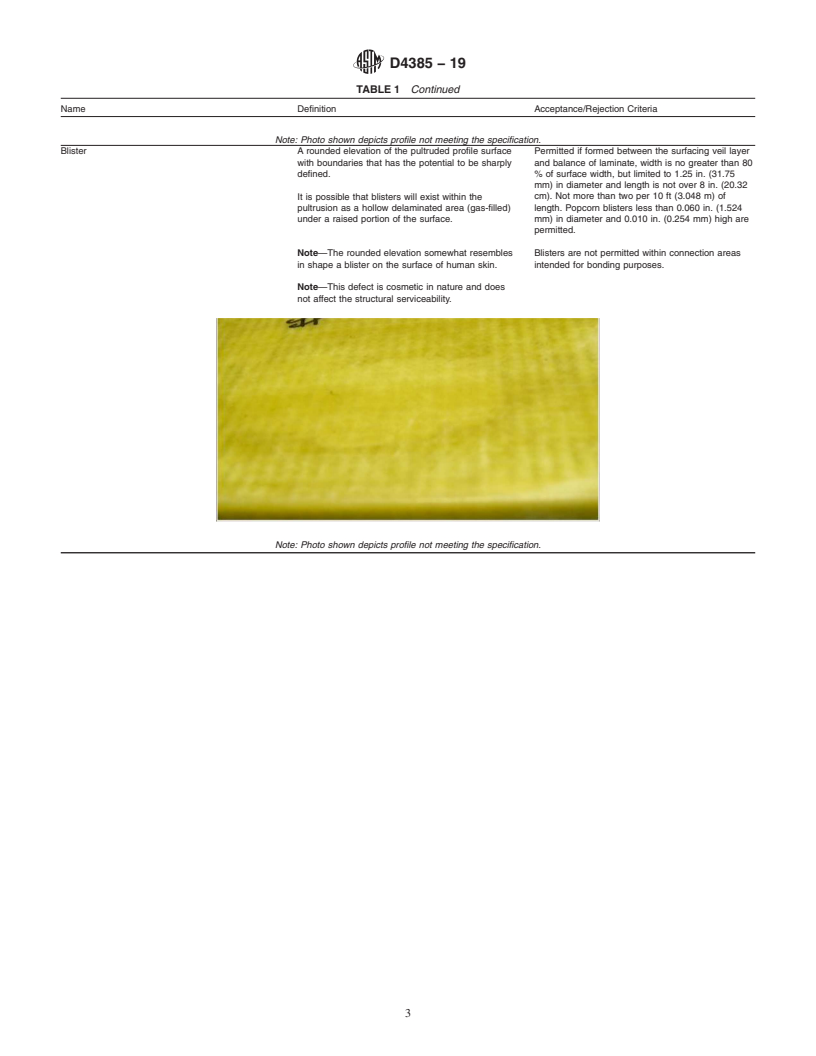

4.3 Allowable Defects—Defects that by nature, number, or

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

frequency of occurrence do not affect the serviceability of the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

product. Allowable defects shall be fully described as to the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. type, size, number, extent allowed, and spacing. Defects in

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4385 − 19

excess of those listed as allowable defec

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4385 − 13 D4385 − 19

Standard Practice for

Classifying Visual Defects in Thermosetting Reinforced

1

Plastic Pultruded Products

This standard is issued under the fixed designation D4385; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice covers acceptance criteria for visual acceptance of thermosetting reinforced plastic pultruded rods, bars,

shapes, and sheets.

1.2 This practice presents definitions of possible defects to serve as a guide for contracts, drawings, product specifications, and

final inspection.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

NOTE 1—There is no known ISO equivalent to this standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D883 Terminology Relating to Plastics

D3917 Specification for Dimensional Tolerance of Thermosetting Glass-Reinforced Plastic Pultruded Shapes

3. Terminology

3.1 mat discoloration—a yellowing of the reinforcing mats caused by binder migration. The discoloration can cause visual

streaks on the surface of the pultrusion.

3.1 Definitions—The definitions in this practice are in accordance with Terminology D883.

3.2 test requirement—minimum design, characteristic or specified values as dictated and or specified by codes, standards,

industry, end customers, the manufacturer or the Engineer of Record.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 connection areas—areas associated with a pultruded member that form a connection in some form or fashion that will not

be visible after fabrication.

3.2.2 fiber blooming—exposed reinforcements on the surface of a profile as a result of veil slippage or lack of resin. Such defects

will cause the exposed fiber to “bloom” when exposed to ultraviolet light.

3.2.3 internal layer—refers to individual layers of unidirectional or transverse reinforcements in the form of roving/tows,

continuous filament, woven or stitched mats formed and laminated via the pultrusion process to produce a specific thickness of

or as part of a pultruded profile. A stitched or woven mat is made up of individual layers of roving woven or stitched together to

form a single mat

1

This practice is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.18 on Reinforced Thermosetting Plastics.

Current edition approved Nov. 15, 2013Nov. 1, 2019. Published December 2013December 2019. Originally approved in 1984. Last previous edition approved in 20102013

as D4385 - 10.D4385 - 13. DOI: 10.1520/D4385-13.10.1520/D4385-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4385 − 19

3.2.4 mat discoloration—a discoloration (typically yellowing) of the reinforcing mats caused by binder migration. The

discoloration can cause visual streaks on the surface of the pultrusion.

3.2.5 test requirement—minimum design, characteristic or specified values as dictated and or specified by codes, standards,

industry, end customers, the manufacturer or the Engineer of Record.

3.3 connection areas—areas associated with a pultruded member that form a connection in some form or fashion th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.