ASTM B208-06

(Practice)Standard Practice for Preparing Tension Test Specimens for Copper Alloy Sand, Permanent Mold, Centrifugal, and Continuous Castings

Standard Practice for Preparing Tension Test Specimens for Copper Alloy Sand, Permanent Mold, Centrifugal, and Continuous Castings

SIGNIFICANCE AND USE

The mechanical properties determined from test bars for sand, permanent mold, and centrifugal castings poured in accordance with this practice represent the properties of the metal going into castings poured from the same heat. These mechanical properties may not be the same as the properties of the corresponding castings because of the solidification effects of varying size, section, and design.

Test bars for continuous castings are taken from the castings and therefore represent the properties of the castings.

SCOPE

1.1 This practice establishes procedures for preparing test coupons and specimens (machined and unmachined) for tension tests of copper alloys for sand, permanent mold, centrifugal and continuous castings.

1.2 The values stated in inch-pound units are the standard. SI values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B208 − 06 Endorsedby

American Foundrymen’s Society

Standard Practice for

Preparing Tension Test Specimens for Copper Alloy Sand,

1

Permanent Mold, Centrifugal, and Continuous Castings

This standard is issued under the fixed designation B208; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* wherever possible. If the castings are cast entirely in green

sand, partial cores shall be permitted for the test bars but in no

1.1 This practice establishes procedures for preparing test

case shall chills be permitted. Unless otherwise agreed upon

coupons and specimens (machined and unmachined) for ten-

between the manufacturer and purchaser, test bars may be

sion tests of copper alloys for sand, permanent mold, centrifu-

poured in cores on a production line. The use of filters in the

gal and continuous castings.

gating system is permitted.

1.2 The values stated in inch-pound units are the standard.

5.1.1 High-ShrinkageSand-CastAlloys—Thetestspecimen

SI values given in parentheses are for information only.

coupons for copper casting alloys exhibiting high shrinkage

during freezing and cooling shall be cast to the form and

2. Referenced Documents

dimensions shown in Fig. 1 (a or b) or 2 (a or b). If specimens

2

2.1 ASTM Standards:

having threaded ends are to be used in the tension tests, the

B846 Terminology for Copper and Copper Alloys 1

length of the keel blocks in Fig. 1a may be reduced to 6 ⁄4 in.

(159 mm). See Appendix X1 for SI equivalents.

3. Terminology

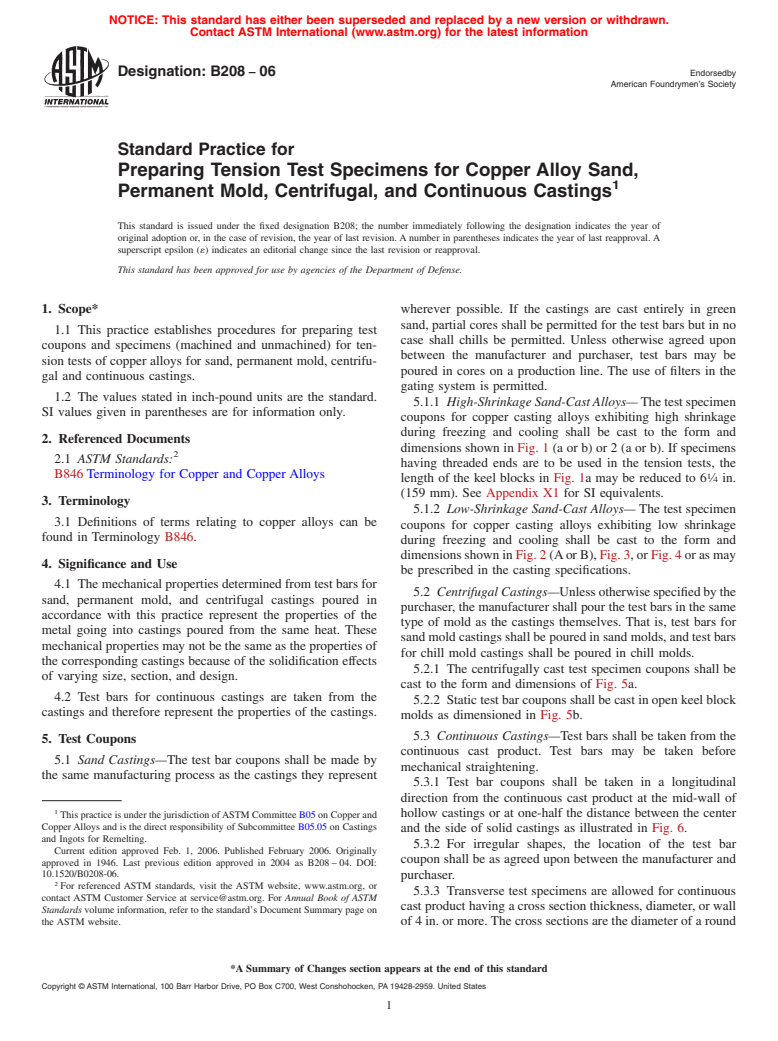

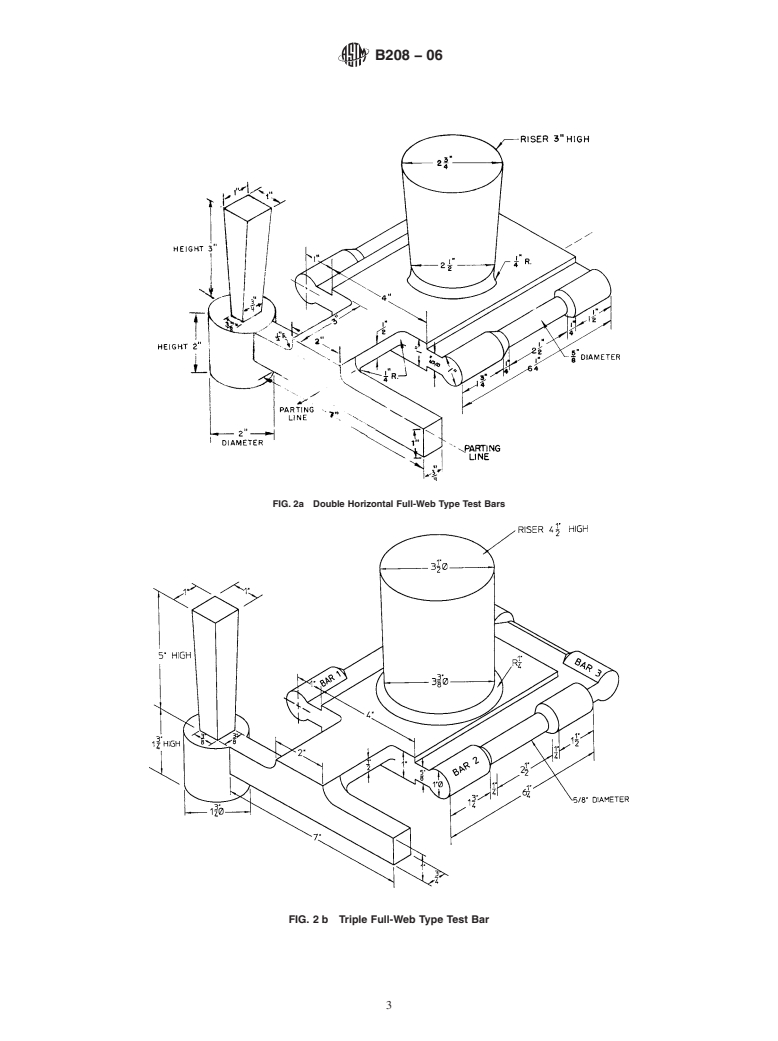

5.1.2 Low-Shrinkage Sand-Cast Alloys— The test specimen

3.1 Definitions of terms relating to copper alloys can be

coupons for copper casting alloys exhibiting low shrinkage

found in Terminology B846.

during freezing and cooling shall be cast to the form and

dimensionsshowninFig.2(AorB),Fig.3,orFig.4orasmay

4. Significance and Use

be prescribed in the casting specifications.

4.1 The mechanical properties determined from test bars for

5.2 CentrifugalCastings—Unlessotherwisespecifiedbythe

sand, permanent mold, and centrifugal castings poured in

purchaser, the manufacturer shall pour the test bars in the same

accordance with this practice represent the properties of the

type of mold as the castings themselves. That is, test bars for

metal going into castings poured from the same heat. These

sand mold castings shall be poured in sand molds, and test bars

mechanical properties may not be the same as the properties of

for chill mold castings shall be poured in chill molds.

the corresponding castings because of the solidification effects

5.2.1 The centrifugally cast test specimen coupons shall be

of varying size, section, and design.

cast to the form and dimensions of Fig. 5a.

4.2 Test bars for continuous castings are taken from the

5.2.2 Static test bar coupons shall be cast in open keel block

castings and therefore represent the properties of the castings.

molds as dimensioned in Fig. 5b.

5.3 Continuous Castings—Test bars shall be taken from the

5. Test Coupons

continuous cast product. Test bars may be taken before

5.1 Sand Castings—The test bar coupons shall be made by

mechanical straightening.

the same manufacturing process as the castings they represent

5.3.1 Test bar coupons shall be taken in a longitudinal

direction from the continuous cast product at the mid-wall of

1

This practice is under the jurisdiction ofASTM Committee B05 on Copper and hollow castings or at one-half the distance between the center

CopperAlloys and is the direct responsibility of Subcommittee B05.05 on Castings

and the side of solid castings as illustrated in Fig. 6.

and Ingots for Remelting.

5.3.2 For irregular shapes, the location of the test bar

Current edition approved Feb. 1, 2006. Published February 2006. Originally

coupon shall be as agreed upon between the manufacturer and

approved in 1946. Last previous edition approved in 2004 as B208 – 04. DOI:

10.1520/B0208-06.

purchaser.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.3.3 Transverse test specimens are allowed for continuous

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

cast product having a cross section thickness, diameter, or wall

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. of 4 in. or more. The cross sections are the diameter of a round

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United State

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.