ASTM E2187-02

(Test Method)Standard Test Method for Measuring the Ignition Strength of Cigarettes

Standard Test Method for Measuring the Ignition Strength of Cigarettes

SCOPE

1.1 This fire-test-response standard provides a standard measure of the capability of a cigarette, positioned on one of three standard substrates, to generate sufficient heat to continue burning and thus potentially cause ignition of bedding or upholstered furniture.

1.2 This method has value as a predictor of the relative propensity of a cigarette to ignite upholstered furnishings.

1.3 This method is applicable to cigarettes that burn along the length of a tobacco column.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard measures and describes the response of materials, products, or assemblies to heat under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products, or assemblies under actual fire conditions.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

Designation: E 2187 – 02

Standard Test Method for

Measuring the Ignition Strength of Cigarettes

This standard is issued under the fixed designation E 2187; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The most common initiating event in a fatal fire in the United States is the dropping of a lit cigarette

onto a bed or piece of upholstered furniture. The cigarette coal heats the furnishing materials to the

point where smoldering combustion begins, perhaps followed by a transition to flaming combustion.

Since limiting the frequency of ignitions is a principal approach to reducing fire loss, it is desirable

to establish a test method for the propensity of a cigarette to ignite soft furnishings. This test method

uses standard substrates to determine the extent to which, as the substrate draws heat from the

cigarette, the cigarette combustion remains strong enough to be capable of initiating a fire.

1. Scope E 691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This fire-test-response standard provides a standard

E 1352 Test Method for Cigarette Ignition Resistance of

measure of the capability of a cigarette, positioned on one of

Mock-up Upholstered Furniture Assemblies

three standard substrates, to generate sufficient heat to continue

E 1353 Test Method for Cigarette Ignition Resistance of

burning and thus potentially cause ignition of bedding or

Components of Upholstered Furniture

upholstered furniture.

2.2 Other Standard:

1.2 This method has value as a predictor of the relative

Standard for the Flammability of Mattresses and Mattress

propensity of a cigarette to ignite upholstered furnishings.

Pads, 16 Code of Federal Regulations, Part 1632

1.3 This method is applicable to cigarettes that burn along

the length of a tobacco column.

3. Terminology

1.4 The values stated in SI units are to be regarded as the

3.1 Definitions—For definitions of terms used in this test

standard. The values given in parentheses are for information

method refer to Terminology E 176E 176.

only.

3.2 Definitions of Terms Specific to This Standard:

1.5 This standard measures and describes the response of

3.2.1 full-length burn, n—the outcome of a determination in

materials, products, or assemblies to heat under controlled

whichthecigaretteburnsatleasttothebeginningofthetipping

conditions, but does not by itself incorporate all factors

paper, which covers the filter and perhaps a short section of the

required for fire hazard or fire risk assessment of the materials,

tobaccocolumninafiltertipcigarette,ortowithin5mmofthe

products, or assemblies under actual fire conditions.

end of the tobacco column if the cigarette has no filter.

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Summary of Test Method

responsibility of the user of this standard to establish appro-

4.1 This test method measures the probability that a ciga-

priate safety and health practices and determine the applica-

rette, placed on a substrate, will generate sufficient heat to

bility of regulatory limitations prior to use. For specific hazard

maintain burning of the tobacco column. Each determination

statements, see Section 6.

consists of placing a lit cigarette on the horizontal surface

2. Referenced Documents consisting of a set number of layers of filter paper. Observation

is made of whether or not the cigarette continues to burn to the

2.1 ASTM Standards:

2 beginning of the tipping paper. Forty determinations (compris-

E 176 Terminology of Fire Standards

ing a test) are performed to obtain the relative probability that

the cigarette will continue burning despite heat abstraction by

This test method is under the jurisdiction of ASTM Committee E05 on Fire

the substrate.

Standards and is the direct responsibility of Subcommittee E05.15 on Furnishings

and Contents.

Current edition approved Feb. 10, 2002. Published April 2002.

2 3

Annual Book of ASTM Standards, Vol 04.07. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

E2187–02

5. Significance and Use 5 % and a temperature of 23°C6 3°C (73°F6 5°F) and shall

be continuously monitored. A tray containing a saturated

5.1 The most common initiating event in a fatal fire is the

solution of sodium bromide (NaBr) in water will provide the

dropping of a cigarette onto a bed or piece of upholstered

appropriate relative humidity when the box temperature is as

furniture, causing 20 % of the estimated U.S. fire deaths from

prescribed. The box shall be located convenient to the test

1992–1996 in residential structures, according to statistics

chamber such that test materials shall not be exposed to a

provided by the U.S. Consumer Product Safety Commission.

non-conditioned environment for more than 5 min between

Test Methods E 1352E 1352 and E 1353E 1353 have been

their removal from the box and the beginning of a test.

developed to evaluate the susceptibility of upholstered furni-

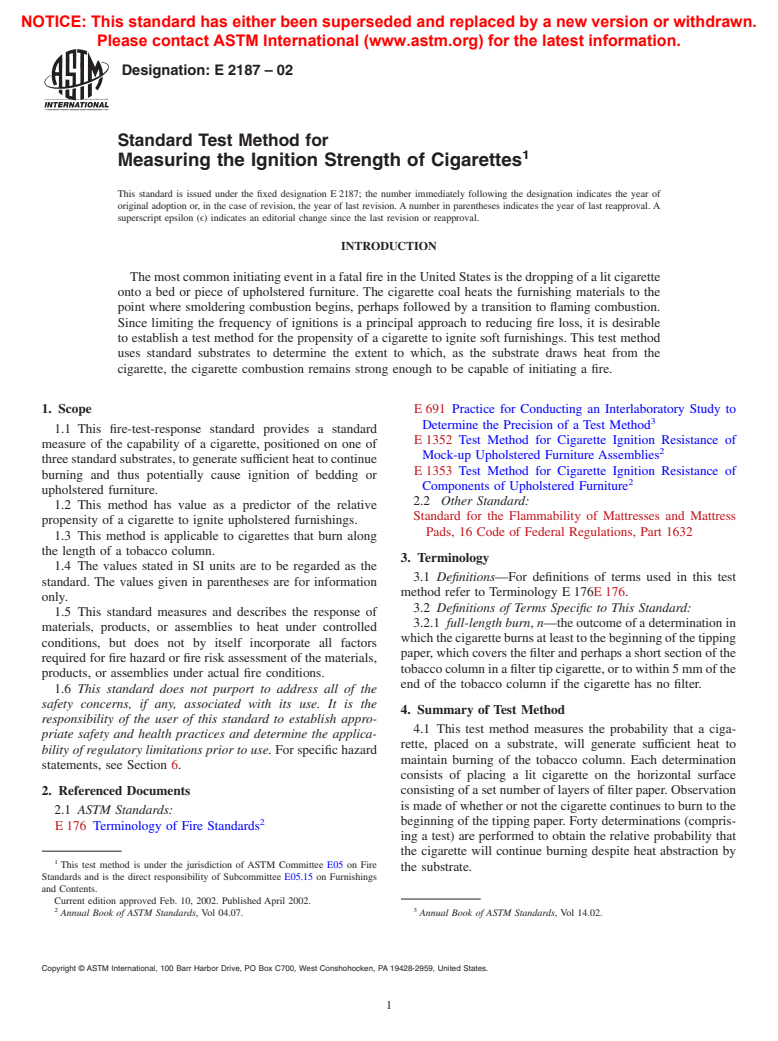

7.3 Test Chamber—A test chamber of the design photo-

ture mock-ups and components to ignition by cigarettes.

graphed in Fig. 1 shall be constructed of clear plastic such as

Federal Standard 16 CFR Part 1632, Standard for the Flam-

PMMA, nominally 6 mm (0.25 in.) in thickness. The inside

mability of Mattresses and Mattress Pads, was promulgated to

dimensions shall be: height: 340 mm6 2 mm (15.5 in.6 0.1

reduce the likelihood that mattresses and mattress pads would

in.), width: 292 mm6 2 mm (11.5 in.6 0.1 in.), depth: 395

ignite from a lighted cigarette.

mm6 2 mm (15.5 in.6 0.1 in.). The full front panel of the

5.2 This test method enables comparison of the relative

chamber shall be hinged, with a latch to effect positive closure.

ignition strength of different cigarette designs.

Thetopofthechambershallhaveaflattopcylindricalchimney

5.3 In this procedure, the specimens are subjected to a set of

of height 178 mm 6 2 mm (6.00 in. 6 0.1 in.) and inside

laboratory conditions. If different conditions are substituted or

diameter 150 mm6 2 mm (6.00 in.6 0.1 in.). The chimney

the end use conditions are changed, it may not be possible,

shall be centered on the chamber top and sealed to the chamber

using this test, to predict quantitative changes in the fire test

top panel.

response characteristics measured. Therefore, the quantitative

results are valid only for the fire test exposure conditions

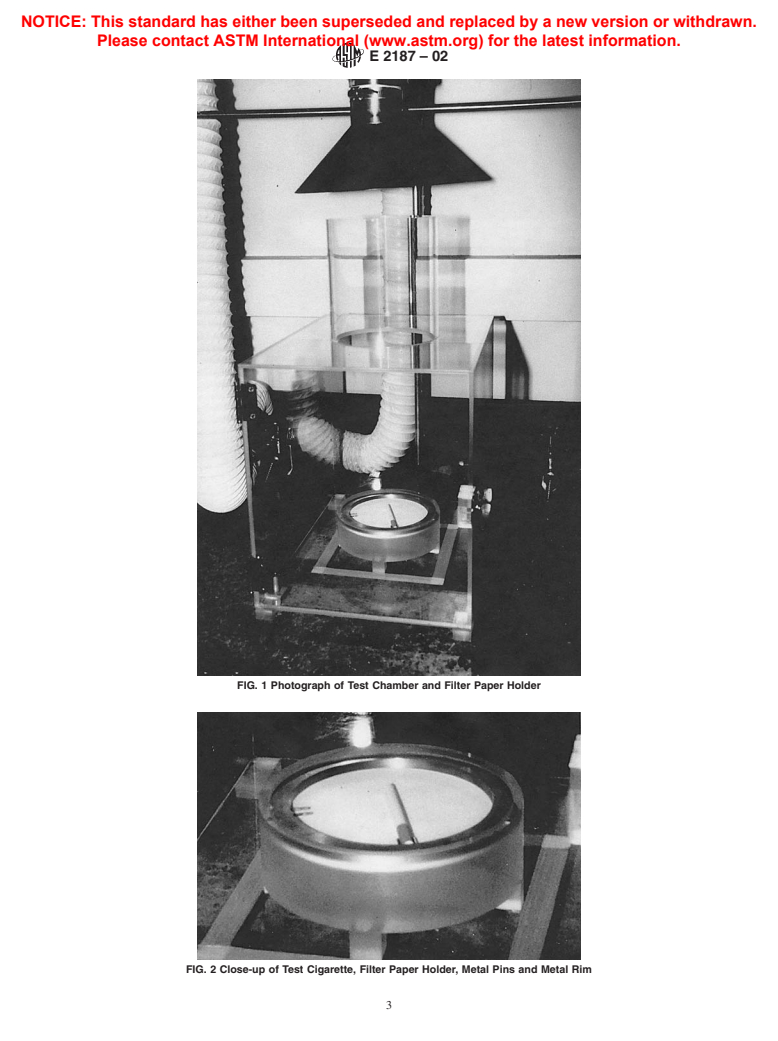

7.4 Filter Paper Holder—A cylindrical support for the

described in this procedure.

layers of filter paper, shown in Fig. 2, shall be made of PMMA

or similarly rigid material, dimensioned as follows. The outer

6. Hazards diameter shall be 165 mm6 1 mm (6.50 in.6 0.04 in.), the

inner diameter shall be 127 mm6 1 mm (5.00 in.6 0.04 in.),

6.1 This test method involves the use of combustible mate-

and the height shall be 50 mm6 1 mm (1.97 in.6 0.04 in.).

rials that are exposed to ignition sources. Consequently, the

A recess in the top, 8 mm6 1 mm (0.31 in.6 0.04 in.) deep,

user shall take proper precautions to avoid thermal injuries.

shall expand the inner diameter to 152 mm6 1 mm (6.00 in.

6.1.1 Personnel shall be instructed on general procedures to

6 0.04 in.). Three or four legs shall raise the bottom of the

handle an unwanted fire.Appropriate fire extinguishing equip-

holder approximately 20 mm (0.8 in) above the chamber floor.

mentshallbeprovidedtosuppressanyfiresthatexceednormal

7.5 Metal Rim—A circular brass or other dense metal rim,

controlled limits.

6.2 Personnel shall take proper precautions to avoid inhal- shown in Fig. 2, shall be used to hold the sheets of filter paper

flat against each other.The outside diameter of the rim shall be

ing combustion products.

6.2.1 Exhaust systems shall be checked regularly to ensure 150 mm6 2 mm (5.90 in6 0.08 in). The inner diameter shall

be 130 mm6 2 mm (5.1 in.6 0.08 in.).The thickness shall be

that they are removing all products of combustion from the

workspace. 3mm6 1 mm (0.12 in.6 0.04 in.). The rim surface shall be

flat and smooth. A pair of parallel metal pins, each approxi-

6.2.2 Respiratory equipment shall be made available for

personnel. mately 1 mm in diameter and 8.1 mm6 0.05 mm (0.32 in.6

0.02 in.) apart, shall protrude 20 mm6 2 mm (0.8 in.6 0.1

6.3 The user shall ensure that all burning has ceased before

discarding used test materials. An appropriate closed metal in.) toward the center of the rim. The pins are to be spaced to

keep the non-ignited end of a conventional 25 mm circumfer-

waste container shall be used in each fire test laboratory for

safe disposal of specimens and test assemblies after being ence cigarette from rolling, but without pressuring the ciga-

rette. If cigarettes of significantly different diameter are to be

exposed to heat and fire.

tested, other pairs of pins, appropriately spaced, shall be

inserted into the rim.

7. Apparatus and Equipment

7.6 Cigarette Holder—Aholder shall be used to support the

7.1 Test and Conditioning Environment—An environmental

lit cigarette in a horizontal position in the test chamber prior to

conditioning room shall be maintained which provides an area

placement of the cigarette onto the filter paper substrate. The

adequate for conditioning both cigarettes and filter paper

holder shall not clamp the cigarette nor stress it in any other

specimens. This room shall be capable of maintaining a

manner, nor shall it contact the cigarette within 30 mm of its lit

relative humidity of 55 %6 5 % and a temperature of 23°C6

end.

3°C (73°F6 5°F) and shall be continuously monitored. The

room in which the tests are conducted, which may also be the 7.7 Cigarette Ignition System—A system consisting of an

conditioning room, shall be maintained within the same tem- air draw component and an ignition source shall be used to

perature and relative humidity ranges. ignite the test cigarettes. The cigarette shall be supported in a

7.2 Constant Humidity Box—Alternatively, cigarettes and horizontal position. A butane gas lighter capable of producing

filter paper shall be stored in a box of sufficient size to hold the a stable luminous flame for 15 mm6 3 mm (0.6 in.6 0.1 in.)

needed quantities of filter paper and cigarettes. The interior of in length or a hot coil igniter shall be used for lighting the

the box shall be maintained at a relative humidity of 55 %6 cigarette. The airflow and the draw time through the lit

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

E2187–02

FIG. 1 Photograph of Test Chamber and Filter Paper Holder

FIG. 2 Close-up of Test Cigarette, Filter Paper Holder, Metal Pins and Metal Rim

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

E2187–02

cigaretteshallbesufficienttoestablishacoaltowithin61mm the specimens are not contaminated while in storage and they

of the pencil mark 5 mm (0.2 in.) from the tip of the cigarette. shall be protected from degradation by insects. If the speci-

Appropriate filtering media shall be used downstream of the mens are to be stored for more than one week, they shall be

cigarette to remove smoke and condensable combustion gases placed in a freezer at approximately 0°C (32°F) reserved for

in order to prevent contamination of the downstream compo- the sole protection of cigarette specimens to minimize the risk

nents. of contamination.

7.8 Exhaust Hood—A chemical or canopy hood shall be 9.2.2 Prior to testing, cigarette test specimens shall be

usedforremovingcombustionproductsfromthetestroom.Air marked, using a #2 or softer graphite pencil, on their paper

flow through the hood shall be sufficient to remove cigarette seam 5 mm6 1 mm and 15 mm6 1 mm (0.2 in. and 0.6 in.,

and substrate combustion products while not being high each6 0.04 in.) from the end of the cigarette that will be lit.

enough to influence the combustion processes in the test These marks are used to establish the start (11.4) and comple-

chamber(s). (See 8.1.2.) tion (11.5.4) of a uniform pre-burn period, respectively.

7.9 Extinguishment—Following a determination, the ciga- 9.3 Filter Paper—The substrates consist of 150 mm (6 in.)

rette and sheets of filter paper shall be completely extin- diameter circles ofWhatman #2 ash-free cellulosic filter paper.

guished,forexample,bysmotheringorbyapplicationofwater. Substrates are formed by placing multiple layers of filter paper

into the holder assembly, then placing the metal rim on top to

8. Calibration and Standardization

ensure good contact between the layers.

8.1 Calibrations of equipment shall be carried out as noted

below and at any time when equipment or test conditions

10. Conditioning

indicate that evaluation and re-calibration are necessary. The

10.1 Cigarettesshallbeconditionedatarelativehumidityof

time intervals for calibrations stated in this method shall be

55 %6 5 % and a temperature of 23°C6 3°C (73°F6 5°F)

considered to be the minimum.

for at least 24 h prior to testing.The cigarettes shall be oriented

8.1.1 The test chambers shall be checked before use to

vertically in a small clean container, with the number of

minimize air leakage so that the smoke plume from a cigarette

cigarettes being sufficiently small as to enable free air access to

rises undisturbed during testing. Door seals shall be checked

the specimens, for example, a maximum of 20 cigarettes in a

visually to ensure that they are closed flush against the

250 mL polyethylene or glass beaker.

chamber’s side wall and the latching device secures the door

10.1.1 Boxesoffilterpapershallbeconditionedatarelative

tightly.Allconstructionseamsshallbeinspectedtoensurethey

humidity of 55 %6 5 % and a temperature of 23°C6 3°C

are airtight and no cracks shall be visible on any surface of the

(73°F6 5°F) for at least one week prior to testing. The top of

test chamber. If leaks are detected, measures shall be taken to

each 100 sheet box of filter paper shall be removed prior to

ensure that these areas are again made sufficiently air tight.

being placed in the conditioning room or box. The

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.