ASTM D5075-01(2022)

(Test Method)Standard Test Method for Nicotine and 3-Ethenylpyridine in Indoor Air

Standard Test Method for Nicotine and 3-Ethenylpyridine in Indoor Air

SIGNIFICANCE AND USE

5.1 In order to estimate ETS concentrations, there needs to be a marker or tracer for ETS that is unique or highly specific to tobacco smoke, in sufficient concentrations in air to be measured easily at realistic smoking rates, and in constant proportion to the other components of ETS for a variety of tobacco blends and environmental conditions. Nicotine and 3-ethenylpyridine have been used as tracers of the vapor phase of ETS. Nicotine is the major alkaloid of tobacco and a major constituent of ETS. The determination of nicotine concentration has often been used to estimate the concentration of ETS; however, due to its unpredictable decay kinetics, nicotine may not be an ideal tracer. Because nicotine readily adsorbs to building materials and room furnishings and is depleted from ETS at a rate faster than most other components, some have suggested that nicotine concentrations underestimate ETS concentrations. Although this is true in many environments during the generation of smoke, the converse is true in environments with a recent past history of smoking. The adsorbed nicotine slowly desorbs over time, resulting in an overestimation of ETS concentrations. Thus, measured concentrations of nicotine precisely assess only airborne nicotine and indicate only that smoking has taken place; they do not necessarily indicate the presence, and certainly not the concentrations, of other ETS constituents. 3-Ethenylpyridine, on the other hand, has been shown to track exactly the vapor phase of ETS as measured by CO and FID response (3). It is for these reasons that 3-ethenylpyridine may be a better tracer of ETS (1, 4, 5). The ETS at high concentrations is known to be annoying and irritating to individuals, and concerns over potential health effects have also been expressed. There is a definite need to have reliable methods for the estimation of ETS levels in order to evaluate its effect. The NIOSH has previously set a recommended exposure limit (REL) for nicotine in the workp...

SCOPE

1.1 This test method covers the sampling/analysis of nicotine and 3-ethenylpyridine (3-EP) in indoor air. This test method is based upon the collection of nicotine and 3-EP by adsorption on a sorbent resin, extraction of nicotine and 3-EP from the sorbent resin, and determination by gas chromatography (GC) with nitrogen selective detection (1).2

1.2 The active samplers consist of an macroreticular polystyrene-divinylbenzene copolymer (for example, XAD-4) sorbent tube attached to a sampling pump. Macroreticular polystyrene-divinylbenzene copolymer is referred to “sorbent resin” throughout this method. This test method is applicable to personal or area sampling.

1.3 This test method is limited in sample duration by the capacity of the sorbent tube for nicotine (about 300 μg). This test method has been evaluated up to 24-h sample duration; however, samples are typically acquired for at least 1 h (sometimes only 1 h) (2).

1.4 For this test method, limits of detection (LOD) and quantitation (LOQ) for nicotine at a sampling rate of 1.5 L/min are, respectively, 0.11 μg/m3 and 0.37 μg/m 3 for 1-h sample duration and 0.01 μg/m3 and 0.05 μg/m3 for 8-h sample duration. The LOD and LOQ for 3-EP at a sampling rate of 1.5 L/min are, respectively, 0.06 μg/m 3 and 0.19 μg/m3 for 1-h sample duration and 0.01 μg/m3 and 0.02 μg/m3 for 8-h sample duration (2). Both LOD and LOQ can be reduced by increasing the sensitivity of the thermionic specific detector.

1.5 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific precautionary infor...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5075 − 01 (Reapproved 2022)

Standard Test Method for

Nicotine and 3-Ethenylpyridine in Indoor Air

This standard is issued under the fixed designation D5075; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope mine the applicability of regulatory limitations prior to use.

Specific precautionary information is given in 13.6.

1.1 This test method covers the sampling/analysis of nico-

1.7 This international standard was developed in accor-

tine and 3-ethenylpyridine (3-EP) in indoor air. This test

dance with internationally recognized principles on standard-

method is based upon the collection of nicotine and 3-EP by

ization established in the Decision on Principles for the

adsorption on a sorbent resin, extraction of nicotine and 3-EP

Development of International Standards, Guides and Recom-

from the sorbent resin, and determination by gas chromatog-

2 mendations issued by the World Trade Organization Technical

raphy (GC) with nitrogen selective detection (1).

Barriers to Trade (TBT) Committee.

1.2 The active samplers consist of an macroreticular

polystyrene-divinylbenzene copolymer (for example, XAD-4)

2. Referenced Documents

sorbent tube attached to a sampling pump. Macroreticular

2.1 ASTM Standards:

polystyrene-divinylbenzene copolymer is referred to “sorbent

D1356Terminology Relating to Sampling and Analysis of

resin”throughoutthismethod.Thistestmethodisapplicableto

Atmospheres

personal or area sampling.

D1357Practice for Planning the Sampling of the Ambient

1.3 This test method is limited in sample duration by the

Atmosphere

capacity of the sorbent tube for nicotine (about 300 µg). This

D3631Test Methods for Measuring Surface Atmospheric

test method has been evaluated up to 24-h sample duration;

Pressure

however, samples are typically acquired for at least 1h

D5337Practice for Flow RateAdjustment of Personal Sam-

(sometimes only1h) (2).

pling Pumps

E260Practice for Packed Column Gas Chromatography

1.4 For this test method, limits of detection (LOD) and

E355PracticeforGasChromatographyTermsandRelation-

quantitation(LOQ)fornicotineatasamplingrateof1.5L/min

3 3

ships

are, respectively, 0.11 µg/m and 0.37 µg/m for 1-h sample

3 3

duration and 0.01 µg/m and 0.05 µg/m for 8-h sample

3. Terminology

duration.TheLODandLOQfor3-EPatasamplingrateof1.5

3 3

3.1 Definitions—For definitions of terms used in this test

L/min are, respectively, 0.06 µg/m and 0.19 µg/m for 1-h

3 3

sampledurationand0.01µg/m and0.02µg/m for8-hsample method, refer to Terminology D1356 and Practice E355.

3.2 Definitions of Terms Specific to This Standard:

duration (2).BothLODandLOQcanbereducedbyincreasing

the sensitivity of the thermionic specific detector. 3.2.1 environmental tobacco smoke (ETS)—an aged, dilute

composite of exhaled tobacco smoke (exhaled mainstream

1.5 Units—The values stated in SI units are to be regarded

smoke) and smoke from tobacco products (sidestream smoke).

asstandard.Nootherunitsofmeasurementareincludedinthis

3.2.2 nitrogen-phosphorus detector (NPD)—a highly sensi-

standard.

tivedeviceselectivefordetectionofnitrogen-andphosphorus-

1.6 This standard does not purport to address all of the

containing organic compounds.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Summary of Test Method

priate safety, health, and environmental practices and deter-

4.1 A known volume of air is drawn through a sorbent

samplingtubecontainingresintoadsorbthenicotineand3-EP

present.

This test method is under the jurisdiction of ASTM Committee D22 on Air

Quality and is the direct responsibility of Subcommittee D22.05 on Indoor Air.

Current edition approved March 1, 2022. Published April 2022. Originally

ɛ1

approved in 1990. Last previous edition approved in 2017 as D5075–01 (2017) . For referenced ASTM standards, visit the ASTM website, www.astm.org, or

DOI: 10.1520/D5075-01R22. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The boldface numbers in parentheses refer to a list of references at the end of Standards volume information, refer to the standard’s Document Summary page on

the text. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5075 − 01 (2022)

4.2 The sorbent tube contents are transferred to a 2-mL values usually at the lower end of this range (9). Because such

autosampler vial, and the nicotine and 3-EP are desorbed with low concentrations of nicotine are often encountered, sophis-

ethyl acetate containing 0.01% triethylamine and a known ticated analytical procedures and equipment are required for

quantity of quinoline, the internal standard. quantifying nicotine in indoor air. Other methods for the

determination of nicotine in indoor air have also been reported

4.3 An aliquot of the desorbed sample is injected into a gas

(6, 10, 11, 12). 3-Ethenylpyridine concentrations typically are

chromatograph equipped with a thermionic-specific (nitrogen-

about one third the concentrations of nicotine in real-world

phosphorus) detector.

environments (13).

4.4 The areas of the resulting nicotine and 3-EP peaks are

each divided by the area of the internal standard peak and

6. Interferences

compared with area ratios obtained from the injection of

6.1 UseofpackedGCcolumnsmayresultinreadingslower

standards.

than expected because nicotine can adsorb onto undeactivated

5. Significance and Use

glass, metal, and solid support particles. Fused silica capillary

5.1 In order to estimate ETS concentrations, there needs to

columns and the modified extraction solvent prescribed here

be a marker or tracer for ETS that is unique or highly specific

can circumvent this problem.

to tobacco smoke, in sufficient concentrations in air to be

6.2 Quinoline (internal standard) is present in ETS at a

measured easily at realistic smoking rates, and in constant

concentration approximately 1% of that for nicotine and is

proportion to the other components of ETS for a variety of

collected by the resin. If >10 µg nicotine is collected on the

tobacco blends and environmental conditions. Nicotine and

resin, there will be sufficient quinoline present to cause a

3-ethenylpyridine have been used as tracers of the vapor phase

detectable bias in results (approximately 1%). (For example,

of ETS. Nicotine is the major alkaloid of tobacco and a major

this quantity of nicotine would be collected if a nicotine

constituent of ETS. The determination of nicotine concentra-

concentrationof167µg/m wassampledat1L/minfor1h.)In

tion has often been used to estimate the concentration of ETS;

these cases, one of the following alternative procedures should

however, due to its unpredictable decay kinetics, nicotine may

be followed:

not be an ideal tracer. Because nicotine readily adsorbs to

6.2.1 Quantitatively dilute the sample with the same modi-

building materials and room furnishings and is depleted from

fied solvent containing internal standard (described in 11.2)

ETS at a rate faster than most other components, some have

usedtoextracttheoriginalsample;thatis,decreasetheamount

suggested that nicotine concentrations underestimate ETS

of quinoline (and also nicotine) present in the sample while

concentrations. Although this is true in many environments

keeping the quinoline concentration in the solvent constant.To

during the generation of smoke, the converse is true in

prevent significant interference, the nicotine concentration in

environments with a recent past history of smoking. The

the most concentrated sample should be less than or equal to

adsorbed nicotine slowly desorbs over time, resulting in an

the quinoline concentration in the solvent.

overestimationofETSconcentrations.Thus,measuredconcen-

6.2.2 Use an alternate internal standard [N'-ethylnornico-

trations of nicotine precisely assess only airborne nicotine and

tine is recommended (14)].

indicate only that smoking has taken place; they do not

necessarily indicate the presence, and certainly not the

7. Apparatus

concentrations, of other ETS constituents. 3-Ethenylpyridine,

7.1 Sample Collection:

on the other hand, has been shown to track exactly the vapor

phase of ETS as measured by CO and FID response (3).Itis 7.1.1 Sorbent Tube—Glass tube with both ends flame-

sealed, approximately 7 cm long with 6-mm outside diameter

for these reasons that 3-ethenylpyridine may be a better tracer

of ETS (1, 4, 5). The ETS at high concentrations is known to and4-mminsidediameter,containingonesectionof120mgof

20/40 mesh resin.Aglass wool plug is located at the front end

be annoying and irritating to individuals, and concerns over

potential health effects have also been expressed. There is a (inlet)andbackendofthetube.Theglasswoolplugattheinlet

end of the tube is held in place with a metal lockspring.

definite need to have reliable methods for the estimation of

ETS levels in order to evaluate its effect. The NIOSH has 7.1.2 Tube Holder,withclipattachmentforattachingtubeto

clothing or objects.

previously set a recommended exposure limit (REL) for

nicotine in the workplace of 0.5 mg/m . 7.1.3 Tube Breaker,tobreaksealedendsfromsampletubes.

7.1.4 NIOSH-approved Plastic Caps,forcappingtubesafter

5.2 Studies show that more than 90% of nicotine in indoor

sampling.

airisfoundinthevaporphase (6, 7).Thedescribedtestmethod

7.1.5 Barometer and Thermometer, for taking pressure and

collects vapor-phase nicotine quantitatively. Early studies on

temperature readings at the sampling site (optional).

freshly generated ETS indicated that some but not all of the

7.1.6 Bubble Flowmeter, for sample pump calibration.

particulate phase was trapped on the resin (7). A more recent

7.1.7 Personal Sampling Pump,portableconstant-flowsam-

investigationofthetrappingofparticulatematerialsbysorbent

pling pump calibrated for the flow rate desired (up to 1.5

beds suggests that the trapping of the particles from indoor air

L/min).

may be nearly quantitative (8). 3-Ethenylpyridine is found

exclusively in the vapor phase.

7.2 Analytical System:

5.3 Nicotine concentrations typically range from ND (not 7.2.1 Gas Chromatograph, with a nitrogen-phosphorus

detected) to 70 µg/m in various indoor environments with (thermionic) detector and autosampler.

D5075 − 01 (2022)

7.2.2 GC Column—A 30-m by 0.32-mm inside diameter in litres per minute. Refer to Practice D5337 for standard

fusedsilicacapillarycolumn,coatedwitha1.0-µmfilmof5% practice in calibrating personal sampling pumps.

phenyl methylpolysiloxane (DB-5). 9.2.3 After the sorbent tube is correctly inserted and

7.2.3 Chromatography Data Acquisition System, for mea- positioned, turn on the power switch for the pump to begin

sampling. Record the start time.

suring peak areas electronically.

7.2.4 Sample Containers, borosilicate glass autosampler

NOTE 1—Most pumps have microprocessing capabilities for preset

vials, 2-mL capacity, with PTFE-lined septum closures.

sampling periods.

7.2.5 Dispensing Pipets, 1.25-mL.

9.2.4 Record the barometric pressure and ambient tempera-

7.2.6 Triangular File,forscoringandbreakingopensample

ture (optional).

tubes.

9.2.5 Turn off the pump at the end of the desired sampling

7.2.7 Forceps,forassistingtransferofsorbenttubecontents

period, and record the elapsed time in minutes.

from tube to autosampler vial.

9.2.6 Measure and record the flow rate after sampling so

7.2.8 Glass Wool Removal Tool, for assisting transfer of

that an average of initial and final flow rates can be used in

sorbent tube contents from tube to autosampler vial.

subsequent calculations.

7.2.9 Wrist-action Shaking Device, for solvent extraction.

9.2.7 Remove the sorbent tube from the sampling system

and place plastic caps over both ends of the tube.

8. Reagents and Materials

9.2.8 Treat a minimum of two sorbent tubes in the same

manner as the sample tubes (break, measure flows, cap, and

8.1 Purity of Reagents—Reagent grade chemicals shall be

transport). Label and process these tubes as flow blanks.

used in all tests. Unless otherwise indicated, it is intended that

9.2.9 Transport capped sorbent tubes to the laboratory for

all reagents conform to the specifications of the Committee on

analysis.

Analytical Reagents of theAmerican Chemical Society where

such specifications are available. Other grades may be used,

NOTE 2—If the samples are not prepared and analyzed immediately,

provided it is first ascertained that the reagent is of sufficiently

they should be stored at 0°C or less.All sorbent tube samples should be

analyzed within eight weeks after sample collection. It has been estab-

high purity to permit its use without lessening the accuracy of

lished that samples are stable for at least eight weeks at−10°C.

the determination.

10. Analysis

8.2 Ethyl Acetate, chromatographic quality.

10.1 System Description:

8.3 Quinoline (internal standard), 99+%.

10.1.1 Analysis is performed using a GC fitted with a

8.4 Triethylamine, 99+%.

nitrogen-phosphorus detector and an autosampler equipped for

8.5 Nicotine, 99+%.

split/splitless injection.

10.1.2 The GC column is as listed in 7.2.2.

8.6 4-Ethenylpyridine (4-EP), 95%, commercially avail-

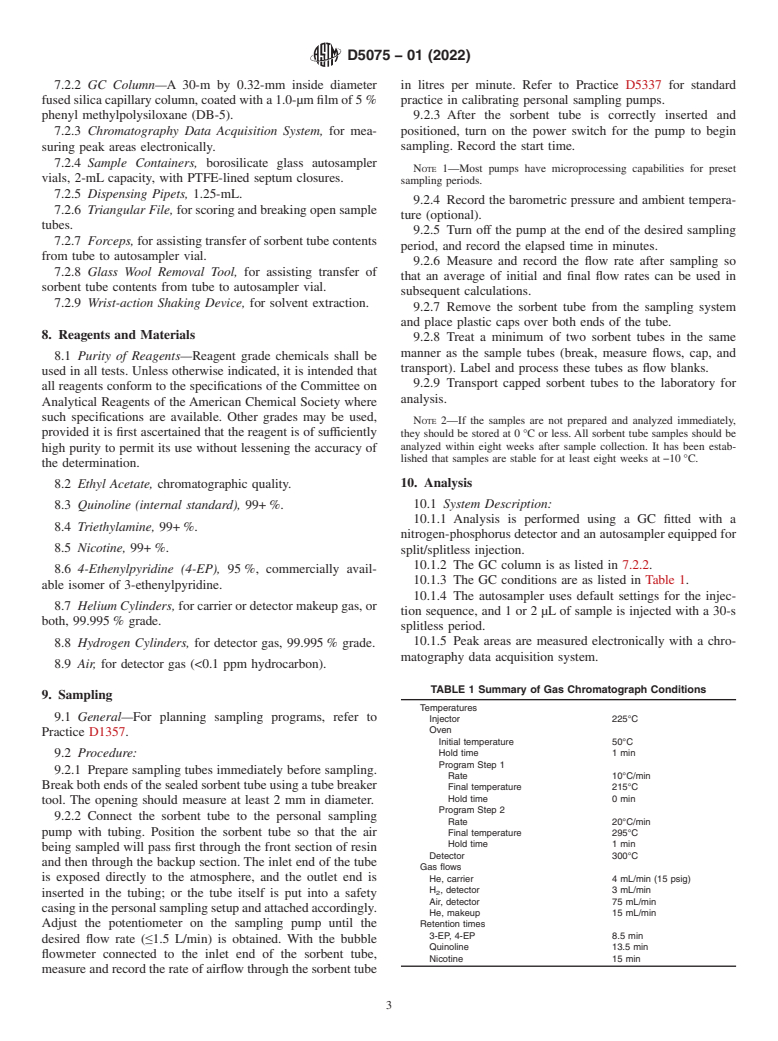

10.1.3 The GC conditions are as listed in Table 1.

able isomer of 3-ethenylpyridine.

10.1.4 The autosampler uses default settings for the injec-

8.7 Helium Cylinders,forcarrierordetectormakeupgas,or

tion sequence, and 1 or 2 µL of sample is injected with a 30-s

both, 99.995% grade.

splitless period.

10.1.5 Peak areas are measured electronically with a chro-

8.8 Hydrogen Cylinders, for detector gas, 99.995% grade.

matography data acquisition system.

8.9 Air, for detector gas (<0.1 ppm hydrocarbon).

TABLE 1 Summary of Gas Chromatograph Conditions

9. Sampling

Temperatures

9.1 General—For planning sampling programs, refer to

Injector 225°C

Oven

Practice D1357.

Initial temperature 50°C

Hold time 1 min

9.2 Procedure:

Program Step 1

9.2.1 Prepare sampling tubes immediately before sampling.

Rate 10°C/min

Breakbothendsofthesealedsorbenttubeusingatubebreaker

Final temperature 215°C

Hold time 0 min

tool. The opening should measure at least 2 mm in diameter.

Program Step 2

9.2.2 Connect the sorbent tube to the personal sampling

Rate 20°C/min

pump with tubing. Position the sorbent tube so that the air Final temperature 295°C

Hold time 1 min

being sampled will pa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.