ASTM D4220-95(2007)

(Practice)Standard Practices for Preserving and Transporting Soil Samples

Standard Practices for Preserving and Transporting Soil Samples

SIGNIFICANCE AND USE

Use of the various procedures recommended in these practices is dependent on the type of samples obtained (Practice D 420), the type of testing and engineering properties required, the fragility and sensitivity of the soil, and the climatic conditions. In all cases, the primary purpose is to preserve the desired inherent conditions.

The procedures presented in these practices were primarily developed for soil samples that are to be tested for engineering properties, however, they may be applicable for samples of soil and other materials obtained for other purposes.

SCOPE

1.1 These practices cover procedures for preserving soil samples immediately after they are obtained in the field and accompanying procedures for transporting and handling the samples.

1.2 Limitations - These practices are not intended to address requirements applicable to transporting of soil samples known or suspected to contain hazardous materials.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4220 − 95(Reapproved 2007)

Standard Practices for

Preserving and Transporting Soil Samples

This standard is issued under the fixed designation D4220; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* D4564 Test Method for Density and Unit Weight of Soil in

Place by the Sleeve Method

1.1 These practices cover procedures for preserving soil

D4700 Guide for Soil Sampling from the Vadose Zone

samples immediately after they are obtained in the field and

accompanying procedures for transporting and handling the

3. Terminology

samples.

3.1 Terminology in these practices is in accordance with

1.2 Limitations—Thesepracticesarenotintendedtoaddress

Terminology D653.

requirements applicable to transporting of soil samples known

or suspected to contain hazardous materials.

4. Summary of Practices

1.3 This standard does not purport to address all of the

4.1 The various procedures are given under four groupings

safety concerns, if any, associated with its use. It is the

as follows:

responsibility of the user of this standard to establish appro-

4.1.1 Group A—Samples for which only general visual

priate safety and health practices and determine the applica-

identification is necessary.

bility of regulatory limitations prior to use. See Section 7.

4.1.2 Group B—Samples for which only water content and

classification tests, proctor and relative density, or profile

2. Referenced Documents

2 logging is required, and bulk samples that will be remolded or

2.1 ASTM Standards:

compacted into specimens for swell pressure, percent swell,

D420 Guide to Site Characterization for Engineering Design

3 consolidation, permeability, shear testing, CBR, stabilimeter,

and Construction Purposes (Withdrawn 2011)

etc.

D653 Terminology Relating to Soil, Rock, and Contained

4.1.3 Group C—Intact, naturally formed or field fabricated,

Fluids

samples for density determinations; or for swell pressure,

D1452 Practice for Soil Exploration and Sampling byAuger

percent swell, consolidation, permeability testing and shear

Borings

testing with or without stress-strain and volume change

D1586 Test Method for Penetration Test (SPT) and Split-

measurements, to include dynamic and cyclic testing.

Barrel Sampling of Soils

4.1.4 Group D—Samples that are fragile or highly sensitive

D1587 Practice for Thin-Walled Tube Sampling of Soils for

for which tests in Group C are required.

Geotechnical Purposes

D2488 Practice for Description and Identification of Soils 4.2 The procedure(s) to be used should be included in the

(Visual-Manual Procedure) project specifications or defined by the designated responsible

D3550 Practice for Thick Wall, Ring-Lined, Split Barrel, person.

Drive Sampling of Soils

5. Significance and Use

5.1 Use of the various procedures recommended in these

ThesepracticesareunderthejurisdictionofASTMCommitteeD18onSoiland

practices is dependent on the type of samples obtained (Prac-

Rock and are the direct responsibility of Subcommittee D18.02 on Sampling and

tice D420), the type of testing and engineering properties

Related Field Testing for Soil Evaluations.

required, the fragility and sensitivity of the soil, and the

Current edition approved July 1, 2007. Published August 2007. Originally

approved in 1983. Last previous edition approved in 2000 as D4220 – 95 (2000).

climatic conditions. In all cases, the primary purpose is to

DOI: 10.1520/D4220-95R07.

preserve the desired inherent conditions.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.2 The procedures presented in these practices were pri-

Standards volume information, refer to the standard’s Document Summary page on

marily developed for soil samples that are to be tested for

the ASTM website.

engineering properties, however, they may be applicable for

The last approved version of this historical standard is referenced on

www.astm.org. samplesofsoilandothermaterialsobtainedforotherpurposes.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4220 − 95 (2007)

6. Apparatus 7.2 Interstate transportation containment, storage, and dis-

posal of soil samples obtained from certain areas within the

6.1 The type of materials and containers needed depend

United States and the transportation of foreign soils into or

upon the conditions and requirements listed under the four

through the United States are subject to regulations established

groupings A to D in Section 4, and also on the climate and

by the U.S. Department of Agriculture, Animal, and Plant

transporting mode and distance.

Health Service, Plant Protection and Quarantine Programs, and

6.1.1 Sealing Wax, includes microcrystalline wax, paraffin,

possibly to regulations of other federal, state, or local agencies.

beeswax, ceresine, carnaubawax, or combinations thereof.

7.2.1 Samples shipped by way of common carrier or U.S.

6.1.2 Metal Disks, about ⁄16 in. (about 2 mm) thick and

Postal Service must comply with the Department of Transpor-

having a diameter slightly less than the inside diameter of the

tation Hazardous Materials Regulation, 49CRF Part 172.

tube,liner,orringandtobeusedinunionwithwaxorcapsand

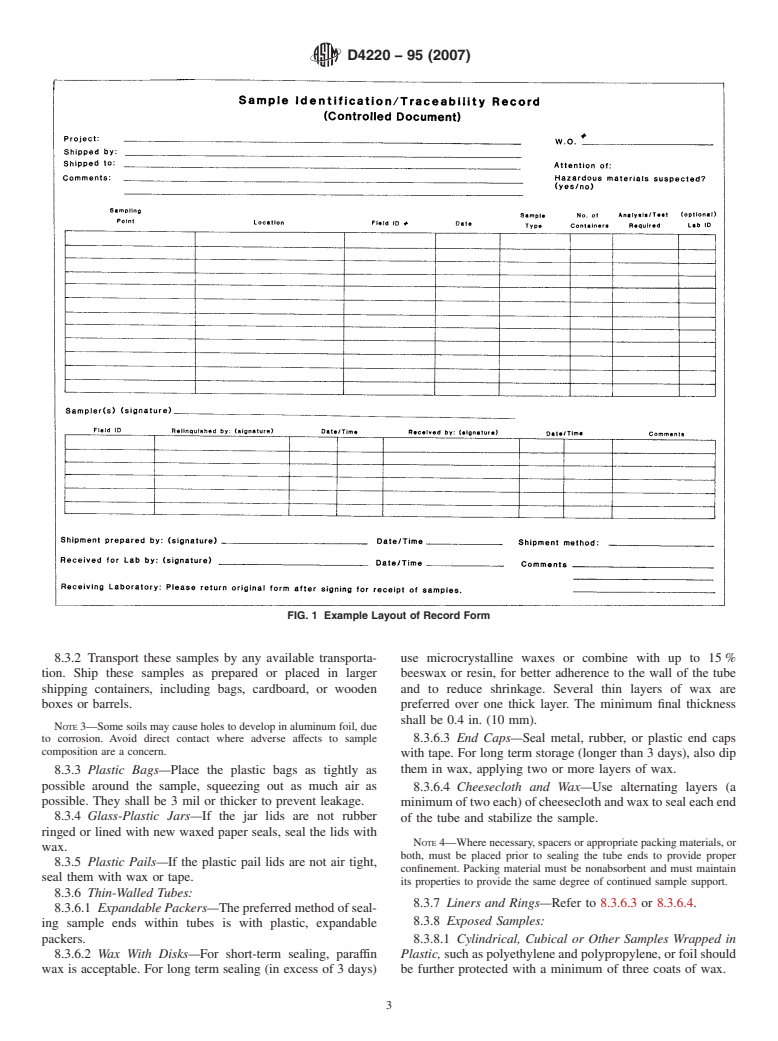

tape, or both. 7.3 Sample traceability records (see Fig. 1) are encouraged

and should be required for suspected contaminated samples.

6.1.3 Wood Disks,prewaxed,1in.(25mm)thickandhaving

7.3.1 The possession of all samples must be traceable, from

a diameter slightly less than the inside diameter of the liner or

tube. collection to shipment to laboratory to disposition, and should

be handled by as few persons as possible.

6.1.4 Tape, either waterproof plastic, adhesive friction, or

duct tape. 7.3.2 The sample collector(s) should be responsible for

initiating the sample traceability record; recording the project,

6.1.5 Cheesecloth, to be used in union with wax in alterna-

sample identification and location, sample type, date, and the

tive layers.

number and types of containers.

6.1.6 Caps, either plastic, rubber or metal, to be placed over

7.3.3 A separate traceability record shall accompany each

the end of thin-walled tubes (Practice D1587), liners and rings

shipment.

(Practice D3550), in union with tape or wax.

7.3.4 When transferring the possession of samples the

6.1.7 O’ring (Sealing End Caps), used to seal the ends of

samples within thin-walled tubes, by mechanically expanding person(s) relinquishing and receiving the samples shall sign,

date, record the time, and check for completeness of the

an O’ring against the tube wall.

traceability record.

NOTE 1—Plastic expandable end caps are preferred. Metal expandable

end caps seal equally well; however, long-term storage may cause

8. Procedure

corrosion problems.

8.1 All Samples—Properly identify samples with tags, la-

6.1.8 Jars, wide mouthed, with rubber-ringed lids or lids

bels, and markings prior to transporting them as follows:

lined with a coated paper seal and of a size to comfortably

receive the sample, commonly ⁄2

pt (250 mL), 1 pt (500 8.1.1 Job name or number, or both,

mL) and quart-sized (1000 mL). 8.1.2 Sampling date,

6.1.9 Bag, either plastic, burlap with liner, burlap or cloth

8.1.3 Sample/boring number and location,

type (Practice D1452).

8.1.4 Depth or elevation, or both,

6.1.10 Packing Material, to protect against vibration and

8.1.5 Sample orientation,

shock.

8.1.6 Special shipping or laboratory handling instructions,

6.1.11 Insulation, either granule (bead), sheet or foam type,

or both, including sampling orientation, and

to resist temperature change of soil or to prevent freezing.

8.1.7 Penetration test data, if applicable (Test Method

6.1.12 Sample Cube Boxes, for transporting cube (block)

D1586).

1 3

samples. Constructed with ⁄2 to ⁄4 in. (13 to 19 mm) thick

8.1.8 Subdivided samples must be identified while main-

plywood (marine type).

taining association to the original sample.

6.1.13 Cylindrical Sample Containers , somewhat larger in

8.1.9 If required, sample traceability record.

dimension than the thin-walled tube or liner samples, such as

8.2 Group A—Transportsamplesinanytypeofcontainerby

cylindrical frozen food cartons.

way of available transportation. If transported commercially,

6.1.14 Shipping Containers, either box or cylindrical type

the container need only meet the minimum requirements of the

and of proper construction to protect against vibration, shock,

transporting agency and any other requirements necessary to

and the elements, to the degree required.

assure against sample loss.

NOTE 2—The length, girth and weight restrictions for commercial

8.3 Group B:

transportation must be considered.

8.3.1 Preserve and transport these samples in sealed, mois-

6.1.15 Identification Material—This includes the necessary

tureproof containers. All containers shall be of sufficient

writing pens, tags, and labels to properly identify the

thickness and strength to ensure against breakage and moisture

sample(s).

loss.The container types include: plastic bags or pails, glass or

plastic (provided they are waterproof) jars, thin walled tubes,

7. Precautions

liners,andrings.Wrapcylindricalandcubesamplesinsuitable

7.1 Special instructions, descriptions, and marking of con- plastic film or aluminum foil, or both, (Note 3) and coat with

tainers must accompany any sample that may include radioac- several layers of wax, or seal in several layers of cheesecloth

tive, chemical, toxic, or other contaminant material. and wax.

D4220 − 95 (2007)

FIG. 1 Example Layout of Record Form

8.3.2 Transport these samples by any available transporta- use microcrystalline waxes or combine with up to 15 %

tion. Ship these samples as prepared or placed in larger beeswax or resin, for better adherence to the wall of the tube

shipping containers, including bags, cardboard, or wooden and to reduce shrinkage. Several thin layers of wax are

boxes or barrels. preferred over one thick layer. The minimum final thickness

shall be 0.4 in. (10 mm).

NOTE 3—Some soils may cause holes to develop in aluminum foil, due

8.3.6.3 End Caps—Seal metal, rubber, or plastic end caps

to corrosion. Avoid direct contact where adverse affects to sample

composition are a concern.

with tape. For long term storage (longer than 3 days), also dip

them in wax, applying two or more layers of wax.

8.3.3 Plastic Bags—Place the plastic bags as tightly as

possible around the s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.