ASTM D6217-98(2003)e1

(Test Method)Standard Test Method for Particulate Contamination in Middle Distillate Fuels by Laboratory Filtration

Standard Test Method for Particulate Contamination in Middle Distillate Fuels by Laboratory Filtration

SIGNIFICANCE AND USE

This is the first ASTM standard test method for assessing the mass quantity of particulates in middle distillate fuels. Test Method D 5452 and its predecessor Test Method D 2276 were developed for aviation fuels and used 1 gal or 5 L of fuel sample. Using 1 gal of a middle distillate fuel, which can contain greater particulate levels, often required excessive time to complete the filtration. This test method used about a quarter of the volume used in the aviation fuel methods.

The mass of particulates present in a fuel is a significant factor, along with the size and nature of the individual particles, in the rapidity with which fuel system filters and other small orifices in fuel systems can become plugged. This test method provides a means of assessing the mass of particulates present in a fuel sample.

The test method can be used in specifications and purchase documents as a means of controlling particulate contamination levels in the fuels purchased. Maximum particulate levels are specified in several military fuel specifications.

SCOPE

1.1 This test method covers the determination of the mass of particulate contamination in a middle distillate fuel by filtration. This test method is suitable for all No. 1 and No. 2 grades in Specifications D 396, D 975, D 2880 and D 3699 and for grades DMA and DMB in Specification D 2069.

1.2 This test method is not suitable for fuels whose flash point as determined by Test Methods D 56, D 93 or D 3828 is less than 38C.

Note 1—Middle distillate fuels with flash points less than 38C have been ignited by discharges of static electricity when the fuels have been filtered through inadequately bonded or grounded membrane filter systems. See Test Methods D 2276 and D 5452 for means of determining particulate contamination in Specification D 1655 aviation turbine fuels and other similar aviation fuels. See Guide D 4865 for a more detailed discussion of static electricity formation and discharge.

1.3 The precision of this test method is applicable to particulate contaminant levels between 0 to 25 g/m3 provided that 1 L samples are used and the 1 L is filtered completely. Higher levels of particulate contaminant can be measured, but are subject to uncertain precision.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

´1

Designation:D6217–98 (Reapproved 2003)

Designation: 415/98

Standard Test Method for

Particulate Contamination in Middle Distillate Fuels by

Laboratory Filtration

This standard is issued under the fixed designation D 6217; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Warning notes were editorially moved into the standard text in August 2003.

1. Scope D93 Test Methods for Flash Point by Pensky-Martens

Closed Cup Tester

1.1 Thistestmethodcoversthedeterminationofthemassof

D 396 Specification for Fuel Oils

particulate contamination in a middle distillate fuel by filtra-

D 975 Specification for Diesel Fuel Oils

tion. This test method is suitable for all No. 1 and No. 2 grades

D 1193 Specification for Reagent Water

in Specifications D 396, D 975, D 2880 and D 3699 and for

D 1655 Specification for Aviation Turbine Fuels

grades DMA and DMB in Specification D 2069.

D 2069 Specification for Marine Fuels

1.2 This test method is not suitable for fuels whose flash

D 2276 Test Method for Particulate Contaminant in Avia-

point as determined by Test MethodsD56,D93 or D 3828 is

tion Fuel by Line Sampling

less than 38°C.

D 2880 Specification for Gas Turbine Fuel Oils

NOTE 1—Middle distillate fuels with flash points less than 38°C have 4

D 3699 Specification for Kerosine

been ignited by discharges of static electricity when the fuels have been

D3828 TestMethodsforFlashPointbySmallScaleClosed

filtered through inadequately bonded or grounded membrane filter sys-

Tester

tems. See Test Methods D 2276 and D 5452 for means of determining

D 4057 Practice for Manual Sampling of Petroleum and

particulate contamination in Specification D 1655 aviation turbine fuels

and other similar aviation fuels. See Guide D 4865 for a more detailed Petroleum Products

discussion of static electricity formation and discharge.

D 4865 Guide for Generation and Dissipation of Static

Electricity in Petroleum Fuel Systems

1.3 The precision of this test method is applicable to

D 5452 Test Method for Particulate Contamination inAvia-

particulate contaminant levels between 0 to 25 g/m provided

tion Fuels by Laboratory Filtration

that 1 L samples are used and the 1 L is filtered completely.

Higher levels of particulate contaminant can be measured, but

3. Terminology

are subject to uncertain precision.

3.1 Definitions:

1.4 The values stated in SI units are to be regarded as the

3.1.1 bond, v—to connect two parts of a system electrically

standard.

by means of a conductive wire to eliminate voltage differences.

1.5 This standard does not purport to address all of the

3.1.2 ground, v—to connect electrically with earth.

safety concerns, if any, associated with its use. It is the

3.1.3 membrane filter, n—a thin medium of closely con-

responsibility of the user of this standard to establish appro-

trolled pore size through which a liquid is passed and on which

priate safety and health practices and determine the applica-

particulate matter in suspension is retained.

bility of regulatory limitations prior to use.

3.2 Definitions of Terms Specific to This Standard:

2. Referenced Documents 3.2.1 control membrane, n—the lower of the two stacked

membrane filters used in this test method.

2.1 ASTM Standards:

3.2.2 filtered flushing fluids, n—either of two solvents,

D56 Test Method for Flash Point by Tag Closed Tester

heptane or 2,2,4-trimethylpentane, filtered through a nominal

0.45 µm membrane filter.

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.14 on Stability and Cleanliness of Liquid Fuels.

Current edition approved June 10, 2003. Published August 2003. Originally Annual Book of ASTM Standards, Vol 11.01.

approved in 1998. Last previous edition approved in 1998 as D 6217–98. Annual Book of ASTM Standards, Vol 05.02.

2 5

Annual Book of ASTM Standards, Vol 05.01. Annual Book of ASTM Standards, Vol 05.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D6217–98 (2003)

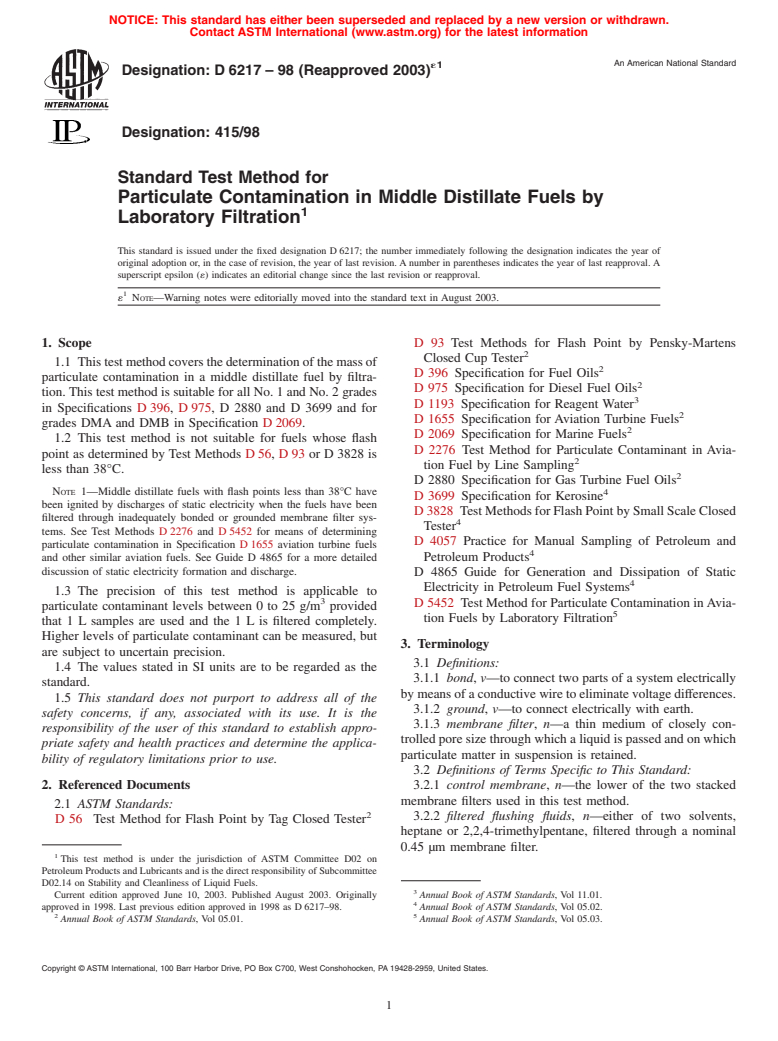

FIG. 1 Schematic of Filtration System

3.2.3 test membrane, n—the upper of the two stacked 6.1.2 Ground/Bond Wire, 0.912-2.59 mm (No. 10 through

membrane filters used in this test method. No. 19) bare stranded flexible, stainless steel or copper

installed in the flasks and grounded as shown in Fig. 1.

4. Summary of Test Method

NOTE 2—The electrical bonding apparatus described in Test Method

4.1 A measured volume of about 1 L of fuel is vacuum

D 5452 or other suitable means of electrical grounding which ensure safe

filtered through one or more sets of 0.8 µm membranes. Each

operation of the filtration apparatus and flask can be used. If the filtrate is

membrane set consists of a tared nylon test membrane and a

to be subsequently tested for stability it is advisable not to use copper as

copper ions catalyze gum formation during the stability test.

tared nylon control membrane. When the level of particulate

contamination is low, a single set will usually suffice; when the

6.1.3 Receiving Flask, 1.5 L or larger borosilicate glass

contamination is high or of a nature that induces slow filtration

vacuum filter flask, which the filtration apparatus fits into,

rates, two or more sets may be required to complete filtration

equipped with a sidearm to connect to the safety flask.

in a reasonable time.

6.1.4 Safety Flask, 1.5 Lor larger borosilicate glass vacuum

4.2 After the filtration has been completed, the membranes

filter flask equipped with a sidearm to connect the vacuum

are washed with solvent, dried, and weighed. The particulate

system. A fuel and solvent resistance rubber hose through

contamination level is determined from the increase in the

which the grounding wire passes shall connect the sidearm of

mass of the test membranes relative to the control membranes,

the receiving flask to the tube passing through the rubber

and is reported in units of g/m or its equivalent mg/L.

stopper in the top of the safety flask.

6.1.5 Vacuum System, either a water aspirated or a mechani-

5. Significance and Use

cal vacuum pump may be used if capable of producing a

5.1 This is the first ASTM standard test method for assess-

vacuum of 1 to 100 kPa below atmospheric pressure when

ing the mass quantity of particulates in middle distillate fuels.

measured at the receiving flask.

Test Method D 5452 and its predecessor Test Method D 2276

6.2 Other Apparatus:

were developed for aviation fuels and used 1 gal or 5 Lof fuel

6.2.1 Air Ionizer, for the balance case. Air ionizers shall be

sample. Using 1 gal of a middle distillate fuel, which can

replaced within one year of manufacture.

contain greater particulate levels, often required excessive time

NOTE 3—When using a solid-pan balance, the air ionizer may be

to complete the filtration.This test method used about a quarter

omitted provided that, when weighing a membrane filter, it is placed on

of the volume used in the aviation fuel methods.

the pan so that no part protrudes over the edge of the pan.

5.2 The mass of particulates present in a fuel is a significant

6.2.2 Analytical Balance, single- or double-pan, the preci-

factor, along with the size and nature of the individual

sion standard deviation of which must be 0.07 mg or less.

particles, in the rapidity with which fuel system filters and

6.2.3 Crucible Tongs, for handling clean sample container

other small orifices in fuel systems can become plugged. This

lids.

test method provides a means of assessing the mass of

6.2.4 Drying Oven, naturally convected (without fan-

particulates present in a fuel sample.

assisted air circulation), controlling to 90 6 5°C.

5.3 The test method can be used in specifications and

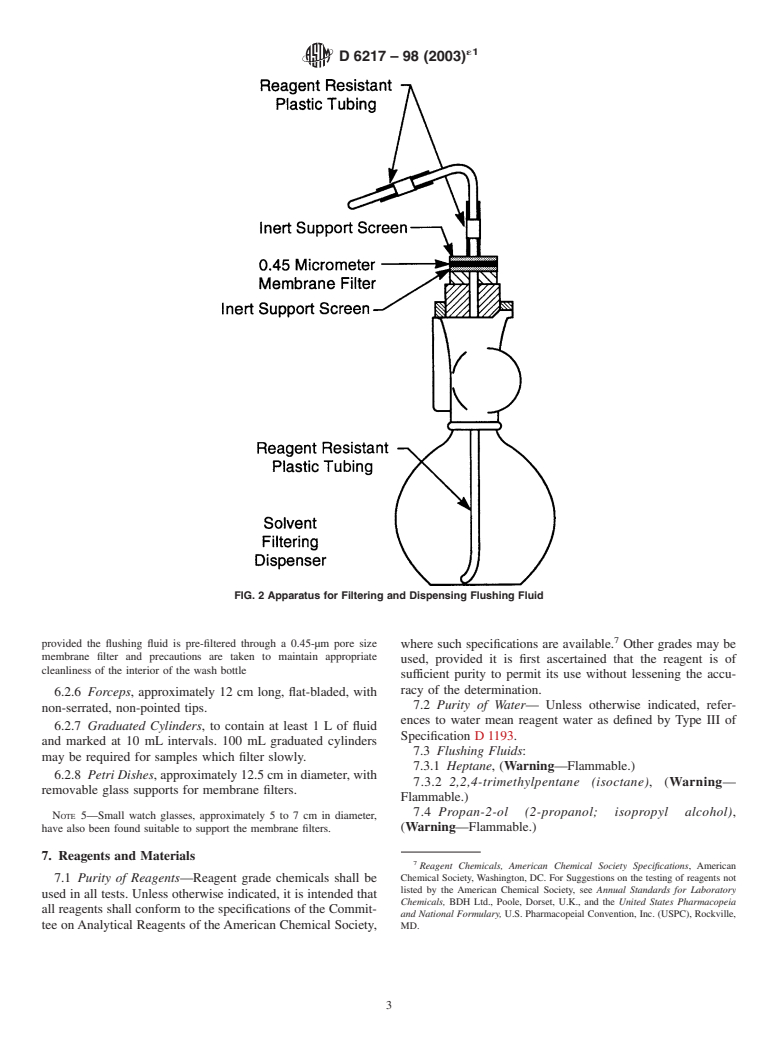

6.2.5 Flushing Fluid Dispenser, an apparatus for dispensing

purchase documents as a means of controlling particulate

flushing fluid through a nominal 0.45 µm membrane filter.

contaminationlevelsinthefuelspurchased.Maximumparticu-

late levels are specified in several military fuel specifications.

NOTE 4—An apparatus such as pictured in Fig. 2 has been found

suitable for this task. A standard laboratory wash bottle can also be used

6. Apparatus

6.1 Filtration System—Arrange the following components

as shown in Fig. 1.

Supporting data (a membrane approval procedure) have been filed at ASTM

6.1.1 Funnel and Funnel Base, with filter support for a 47

International Headquarters and may be obtained by requesting Research Report RR:

mmdiametermembrane,andlockingringorspringactionclip. D02-1012.

´1

D6217–98 (2003)

FIG. 2 Apparatus for Filtering and Dispensing Flushing Fluid

provided the flushing fluid is pre-filtered through a 0.45-µm pore size

where such specifications are available. Other grades may be

membrane filter and precautions are taken to maintain appropriate

used, provided it is first ascertained that the reagent is of

cleanliness of the interior of the wash bottle

sufficient purity to permit its use without lessening the accu-

racy of the determination.

6.2.6 Forceps, approximately 12 cm long, flat-bladed, with

7.2 Purity of Water— Unless otherwise indicated, refer-

non-serrated, non-pointed tips.

ences to water mean reagent water as defined by Type III of

6.2.7 Graduated Cylinders, to contain at least 1 L of fluid

Specification D 1193.

and marked at 10 mL intervals. 100 mL graduated cylinders

7.3 Flushing Fluids:

may be required for samples which filter slowly.

7.3.1 Heptane,(Warning—Flammable.)

6.2.8 Petri Dishes, approximately 12.5 cm in diameter, with

7.3.2 2,2,4-trimethylpentane (isoctane),(Warning—

removable glass supports for membrane filters.

Flammable.)

7.4 Propan-2-ol (2-propanol; isopropyl alcohol),

NOTE 5—Small watch glasses, approximately 5 to 7 cm in diameter,

have also been found suitable to support the membrane filters. (Warning—Flammable.)

7. Reagents and Materials

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

7.1 Purity of Reagents—Reagent grade chemicals shall be

listed by the American Chemical Society, see Annual Standards for Laboratory

used in all tests. Unless otherwise indicated, it is intended that

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

all reagents shall conform to the specifications of the Commit-

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

tee onAnalytical Reagents of theAmerican Chemical Society, MD.

´1

D6217–98 (2003)

7.5 Liquid or Powder Detergent, water-soluble, for cleaning kit. Ensure that the line to be sampled is flushed with fuel

glassware. before taking the sample.

7.6 Nylon Test Membrane Filters, plain, 47-mm diameter, 9.3.1 Where it is desirable or only possible to obtain

nominal pore size 0.8-µm. samples from static storage, follow the procedures given in

7.7 Nylon Control Membrane Filters (see Note 6), 47-mm Practice D 4057 or equivalent, taking precautions for cleanli-

diameter, nominal pore size 0.8-µm. ness of all equipment used. Ensure that the sample has not

passed through intermediate containers prior to placement in

NOTE 6—Membrane filters with a grid imprinted on their surface, may

the prepared container. (Warning—Samples obtained from

be used as control membrane filters for identification.

static storage may give results which are not representative of

7.8 Protective Cover, polyethylene film or clean aluminum

the bulk contents of the tank because of particulate matter

foil.

settling. Where possible, the contents of the tank should be

circulated or agitated before sampling, or the sampling per-

8. Preparation of Apparatus and Sample Containers

formed shortly after a tank has been filled.)

8.1 Clean all components of the filtration apparatus, sample

9.4 Visually inspect the sample container before taking the

containers, their caps and petri dishes as described in 8.1.1-

samples to verify that there are no visible particles present

8.1.7.

inside the container. Fill the sample container 95 volume %

8.1.1 Remove any labels, tags, and so forth.

full, leaving space for vapor expansion. Protect the fuel sample

8.1.2 Wash with warm tap water containing detergent.

from prolonged exposure to light by wrapping the container in

8.1.3 Rinse thoroughly with warm tap water.

aluminum foil or storing it in the dark to reduce the possibility

8.1.4 Rinse thoroughly with reagent water. Container caps

of particulate formation by light-promoted reactions. Do not

should be handled only externally with clean laboratory

transfer the fuel sample from its original sample container into

crucible tongs during this and subsequent washings.

an intermediate storage container. If the original sample

8.1.5 Rinse thoroughly with propan-2-ol that has been

container is damaged or leaking, then a new sample must be

filtered through a 0.45 µm membrane filter.

obtained.

8.1.6 Rinse thoroughly with filtered flushing fluid and dry.

9.5 Analyzefuelsamplesassoonaspossibleaftersampling.

8.1.7 Keepacleanprotectivecover(thecovermayberinsed

When a fuel cannot be analyzed within one day, blanket it with

with filtered flushing fluid), over the top of the sample

an inert gas such as oxygen-free nitrogen, argon, or helium and

container until the cap is installed. Similarly protect the funnel

store it at a temperature no higher than 10°C (50°F), except for

opening of the assembled filtration apparatus with a clean

samples with cloud points above 10°C which are to be stored

protective cover until ready for use.

at a temperature 2°C above their cloud point.

9. Sampling 10. Preparation of Membrane Filters

9.1 The sample container shall be 1 L (60.15 L) in volume 10.1 Each set of test filters consists of one test membrane

and have a screw on cap. Glass containers are preferred to filter and one control membrane filter. For fuels containing

facilitate a visual inspection of the contents and the container little particulate materials, only one set of filters is required. If

before and after filling. Glass containers also allow for visual the fuel is highly contaminated, more than one set of filters

inspection of the container, after the sample is emptied, to may be required (see Section 11). The two membrane filters

confirm complete rinsing of the container. Epoxy lined sample used for each individual test shall be identified by marking the

cans, polytetrafluoroethylene (PTFE) bottles, and high density petri d

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.