ASTM B187/B187M-06

(Specification)Standard Specification for Copper, Bus Bar, Rod, and Shapes and General Purpose Rod, Bar, and Shapes

Standard Specification for Copper, Bus Bar, Rod, and Shapes and General Purpose Rod, Bar, and Shapes

ABSTRACT

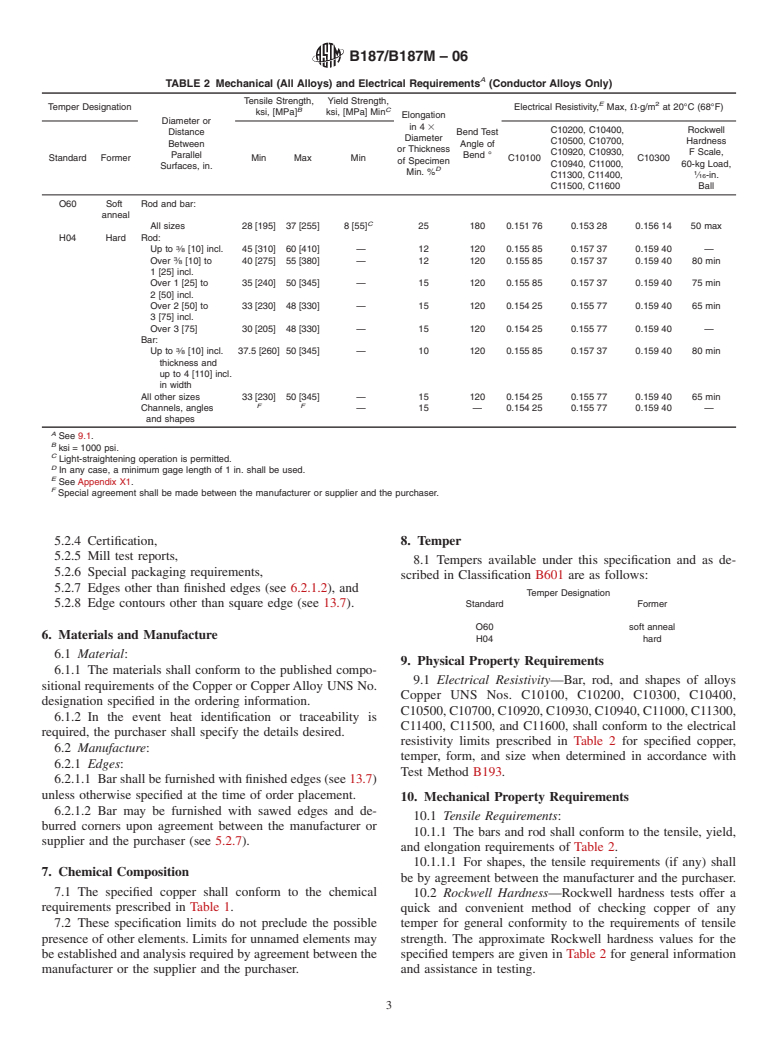

This specification establishes the requirements for copper conductor bars, rods, and shapes for both electrical (bus) and general applications. Products shall be produced in tempers O60 (soft annealed), and H04 (hard). Products shall be sampled and prepared, then tested accordingly to examine their conformance to dimensional (mass, diameter, thickness, width, shape, specified and stock lengths, straightness, edge contour, and radius of edges or corners), mechanical (tensile, yield and bend strengths, elongation, Rockwell hardness, and embrittlement), electrical resistivity, and chemical composition requirements.

SCOPE

1.1 This specification establishes the requirements for copper conductor bar, rod, and shapes for electrical (bus) applications and rod, bar, and shapes for general applications.

1.1.1 The products for electrical (bus) applications shall be made from the following coppers:

The product may be furnished from any copper listed unless otherwise specified in the contract or purchase order.

1.2 The product for general applications shall be made from any of the coppers in or the following coppers:

1.2.1 The product may be furnished from any copper listed above unless otherwise specified in the contract or purchase order. Other coppers may be used upon agreement between supplier and purchaserer.

1.3 Units - The values stated in either inch-pound units or in SI units are to be regarded separately as the standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.Note 1

Material for hot forging will be found in Specification B 124/B 124M.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B187/B187M – 06

Standard Specification for

Copper, Bus Bar, Rod, and Shapes and General Purpose

1

Rod, Bar, and Shapes

This standard is issued under the fixed designation B187/B187M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* values from the two systems may result in nonconformance

2 with the specification.

1.1 This specification establishes the requirements for cop-

per conductor bar, rod, and shapes for electrical (bus) applica-

NOTE 1—Material for hot forging will be found in Specification

tions and rod, bar, and shapes for general applications.

B124/B124M.

1.1.1 The products for electrical (bus) applications shall be

3 2. Referenced Documents

made from the following coppers:

4

3

2.1 ASTM Standards:

Copper UNS No. Reference Designation

B124/B124M Specification for Copper and Copper Alloy

C10100 OFE

Forging Rod, Bar, and Shapes

C10200 OF

B170 Specification for Oxygen-Free Electrolytic Copper—

C10300 OFXLP

C10400, C10500, C10700 OFS

Refinery Shapes

C10920, C10930, C10940 —

B193 Test Method for Resistivity of Electrical Conductor

C11000 ETP

Materials

C11300, C11400, C11500, STP

C11600

B216 Specification for Tough-Pitch Fire-Refined Copper—

Refinery Shapes

1.1.1.1 The product may be furnished from any copper

B224 Classification of Coppers

listed unless otherwise specified in the contract or purchase

B249/B249M Specification for General Requirements for

order.

Wrought Copper and Copper-Alloy Rod, Bar, Shapes and

1.2 The product for general applications shall be made from

Forgings

any of the coppers in 1.1.1 or the following coppers:

3 B577 Test Methods for Detection of Cuprous Oxide (Hy-

Copper UNS No. Reference Designation

drogen Embrittlement Susceptibility) in Copper

C10800 OFLP

B601 Classification for Temper Designations for Copper

C12000 DLP

and Copper Alloys—Wrought and Cast

C12200 DHP

B846 Terminology for Copper and Copper Alloys

1.2.1 The product may be furnished from any copper listed

E53 Test Method for Determination of Copper in Unalloyed

above unless otherwise specified in the contract or purchase

Copper by Gravimetry

order. Other coppers may be used upon agreement between

E62 Test Methods for Chemical Analysis of Copper and

supplier and purchaserer.

Copper Alloys (Photometric Methods)

1.3 Units—The values stated in either inch-pound units or

E255 Practice for Sampling Copper and Copper Alloys for

in SI units are to be regarded separately as the standard.Within

the Determination of Chemical Composition

the text, the SI units are shown in brackets. The values stated

E478 TestMethodsforChemicalAnalysisofCopperAlloys

in each system are not exact equivalents; therefore, each

E527 Practice for Numbering Metals and Alloys in the

system shall be used independently of the other. Combining

Unified Numbering System (UNS)

3. Terminology

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

3.1 For definitions of terms related to copper and copper

and CopperAlloys and is the direct responsibility of Subcommittee B05.02 on Rod,

alloys, refer to Terminology B846.

Bar, Wire, Shapes, and Forgings.

Current edition approved Oct. 1, 2006. Published October 2006. Originally

approved in 1944. Last previous edition approved in 2003 as B187 – 03. DOI:

4

10.1520/B0187_B0187M-06. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

2

For ASME Boiler and Pressure Vessel Code applications, see related Specifi- contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

cation SB-187 in Section II of that Code. Standards volume information, refer to the standard’s Document Summary page on

3

Refer to Practice E527 for an explanation of the Unified Numbering System. the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B187/B187M – 06

3.2 Definitions: 4.1.8 Significance of Numerical Limits,

3.2.1 bus bar, n—includes material of solid rectangular or 4.1.9 Inspection,

square cross section or a solid section with two plane parallel 4.1.10 Rejection and Rehearing,

surfaces and round or other simple regularly shaped edges up 4.1.11 Certification,

to and including 12 in. in width and 0.090 in. and over in 4.1.12 Test Reports, and

thickness. 4.1.13 Packaging and Package Marking.

3.2.2 bus conductor stock, n—a bar, rod, or shape of high 4.2 Identical sections in this specification supplemen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.