ASTM D6988-21

(Guide)Standard Guide for Determination of Thickness of Plastic Film Test Specimens

Standard Guide for Determination of Thickness of Plastic Film Test Specimens

SIGNIFICANCE AND USE

5.1 This guide is intended to provide recommendations and suggested good practices to determine precise dimensions when necessary for the calculation of properties expressed in physical units. It is not intended to replace practical thickness measurements based on commercial portable tools, nor is it implied that thickness measurements made by the procedures will agree exactly.

SCOPE

1.1 This guide covers the determination of the thickness of plastic films where the thickness is used directly in determining the results of tests for various properties. Use this practice except as otherwise required in material specifications or in applicable test standards.

Note 1: Film is defined in Terminology D883 as an optional term for sheeting having a nominal thickness no greater than 0.25 mm (0.010 in.).

Note 2: Alternative methods are acceptable if they meet the requirements of measurement precision as noted in this guide.

Note 3: This guide is not intended to address the sampling techniques or the measurement of film thickness for the commercial classification of commercial products or for quality control purposes.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 4: This standard and ISO 4593 address the same subject matter but differ in technical content.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6988 − 21

Standard Guide for

1

Determination of Thickness of Plastic Film Test Specimens

This standard is issued under the fixed designation D6988; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D6287 Practice for Cutting Film and Sheeting Test Speci-

mens

1.1 This guide covers the determination of the thickness of

2.2 ISO Standard:

plasticfilmswherethethicknessisuseddirectlyindetermining

3

ISO 472 Plastics—Vocabulary

the results of tests for various properties. Use this practice

except as otherwise required in material specifications or in

3. Terminology

applicable test standards.

3.1 Definitions—See Terminologies D883 and ISO 472 for

NOTE 1—Film is defined in Terminology D883 as an optional term for

sheeting having a nominal thickness no greater than 0.25 mm (0.010 in.).

definitions pertinent to this guide.

NOTE 2—Alternative methods are acceptable if they meet the require-

3.2 Definitions of Terms Specific to This Standard:

ments of measurement precision as noted in this guide.

NOTE 3—This guide is not intended to address the sampling techniques 3.2.1 absolute uncertainty (of a measurement), n—the

or the measurement of film thickness for the commercial classification of

smallest division that can be read directly on the instrument

commercial products or for quality control purposes.

used for measurement.

1.2 The values stated in SI units are to be regarded as the

3.2.2 calibration, n—the set of operations that establishes,

standard.

under specified conditions, the relationship between values

1.3 This standard does not purport to address all of the

measured or indicated by an instrument or system, and the

safety concerns, if any, associated with its use. It is the corresponding reference standard or known values derived

responsibility of the user of this standard to establish appro-

from the appropriate reference standards.

priate safety, health, and environmental practices and deter-

3.2.3 dead-weight micrometer, n—an instrument capable of

mine the applicability of regulatory limitations prior to use.

measuringthethicknessofthinfilmsutilizingaweighttoapply

uniform pressure to the specimen.

NOTE 4—This standard and ISO 4593 address the same subject matter

but differ in technical content.

3.2.4 verification, n—proof, with the use of calibrated stan-

1.4 This international standard was developed in accor-

dards or standard reference materials that the calibrated instru-

dance with internationally recognized principles on standard-

ment is operating within specified requirements.

ization established in the Decision on Principles for the

4. Summary of Methods

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

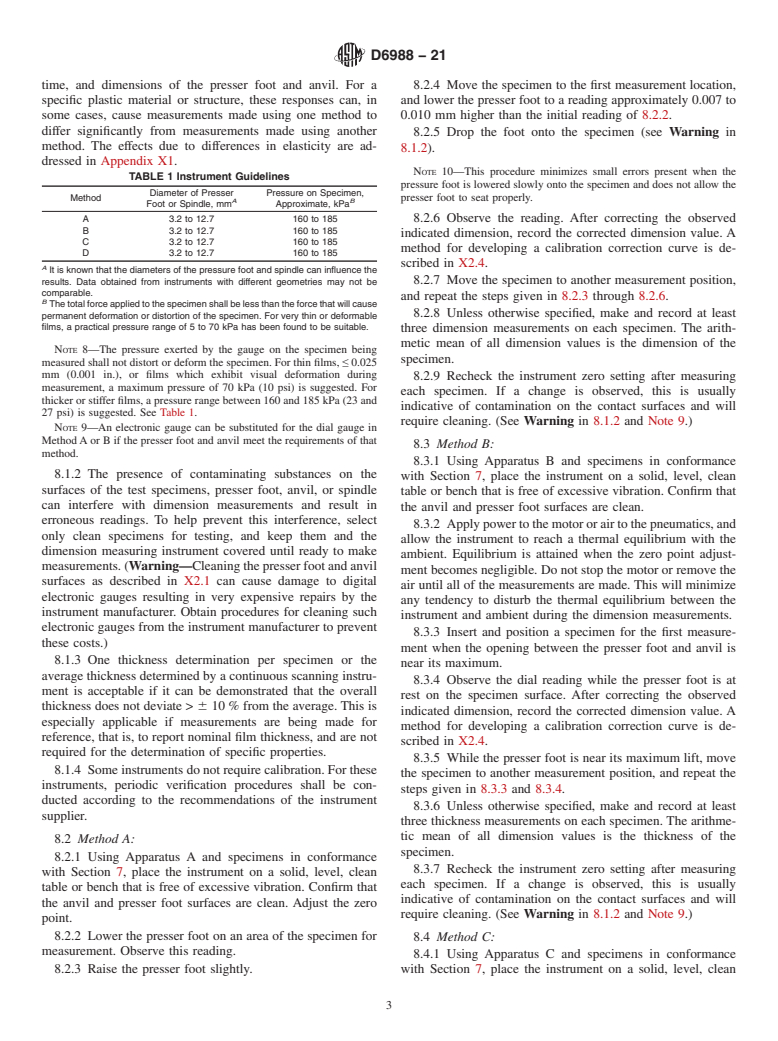

4.1 This guide describes four different methods for the

Barriers to Trade (TBT) Committee.

thickness measurement of plastic film specimens.The methods

(identified as Methods A, B, C, and D) use different microm-

2. Referenced Documents

eters that actuate the weights in different manners or utilize

2

2.1 ASTM Standards:

different means of reading the thickness.

D618 Practice for Conditioning Plastics for Testing

4.2 It is permissible to use other instruments, including

D883 Terminology Relating to Plastics

non-contact instruments and instruments using alternative

D5947 Test Methods for Physical Dimensions of Solid

readout systems in place of dials provided they meet or exceed

Plastics Specimens

the precision requirements noted in this practice.

1

This guide is under the jurisdiction of ASTM Committee D20 on Plastics and

5. Significance and Use

is the direct responsibility of Subcommittee D20.19 on Film, Sheeting, and Molded

Products.

5.1 This guide is intended to provide recommendations and

Current edition approved Oct. 1, 2021. Published November 2021. Originally

suggested good practices to determine precise dimensions

approved in 2003. Last previous edition approved in 2013 as D6988 - 13. DOI:

when necessary for the calculation of properties expressed in

10.1520/D6988-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6988 − 13 D6988 − 21

Standard Guide for

1

Determination of Thickness of Plastic Film Test Specimens

This standard is issued under the fixed designation D6988; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*Scope

1.1 This guide covers the determination of the thickness of plastic films where the thickness is used directly in determining the

results of tests for various properties. Use this practice except as otherwise required in material specifications or in applicable test

standards.

NOTE 1—Film is defined in Terminology D883 as an optional term for sheeting having a nominal thickness no greater than 0.25 mm (0.010 in).in.).

NOTE 2—Alternative methods are acceptable if they meet the requirements of measurement precision as noted in this guide.

NOTE 3—This guide is not intended to address the sampling techniques or the measurement of film thickness for the commercial classification of

commercial products or for quality control purposes.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory requirementslimitations prior to use.

NOTE 4—This standard and ISO 4593 address the same subject matter but differ in technical content.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D883 Terminology Relating to Plastics

D5947 Test Methods for Physical Dimensions of Solid Plastics Specimens

D6287 Practice for Cutting Film and Sheeting Test Specimens

2.2 ISO Standard:

3

ISO 472 Plastics—Vocabulary

1

This guide is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting, and Molded

Products.

Current edition approved April 1, 2013Oct. 1, 2021. Published April 2013November 2021. Originally approved in 2003. Last previous edition approved in 20082013 as

D6988 - 08.D6988 - 13. DOI: 10.1520/D6988-13.10.1520/D6988-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6988 − 21

3. Terminology

3.1 Definitions—See Terminologies D883 and ISO 472 for definitions pertinent to this guide.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 absolute uncertainty (of a measurement), n—the smallest division that can be read directly on the instrument used for

measurement.

3.2.2 calibration, n—the set of operations that establishes, under specified conditions, the relationship between values measured

or indicated by an instrument or system, and the corresponding reference standard or known values derived from the appropriate

reference standards.

3.2.3 dead-weight micrometer, n—an instrument capable of measuring the thickness of thin films utilizing a weight to apply

uniform pressure to the specimen.

3.2.4 verification, n—proof, with the use of calibrated standards or standard reference materials that the calibrated instrument is

operating within specified requirements.

4. Summary of Methods

4.1 This guide describes four different methods for the thickness measurement of plastic film specimens. The methods (identified

as Methods A, B, C, and D) use different micrometers that actuate the weights in different manners or utilize different means of

reading the thickness.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.