ASTM F998-12

(Specification)Standard Specification for Centrifugal Pump, Shipboard Use

Standard Specification for Centrifugal Pump, Shipboard Use

ABSTRACT

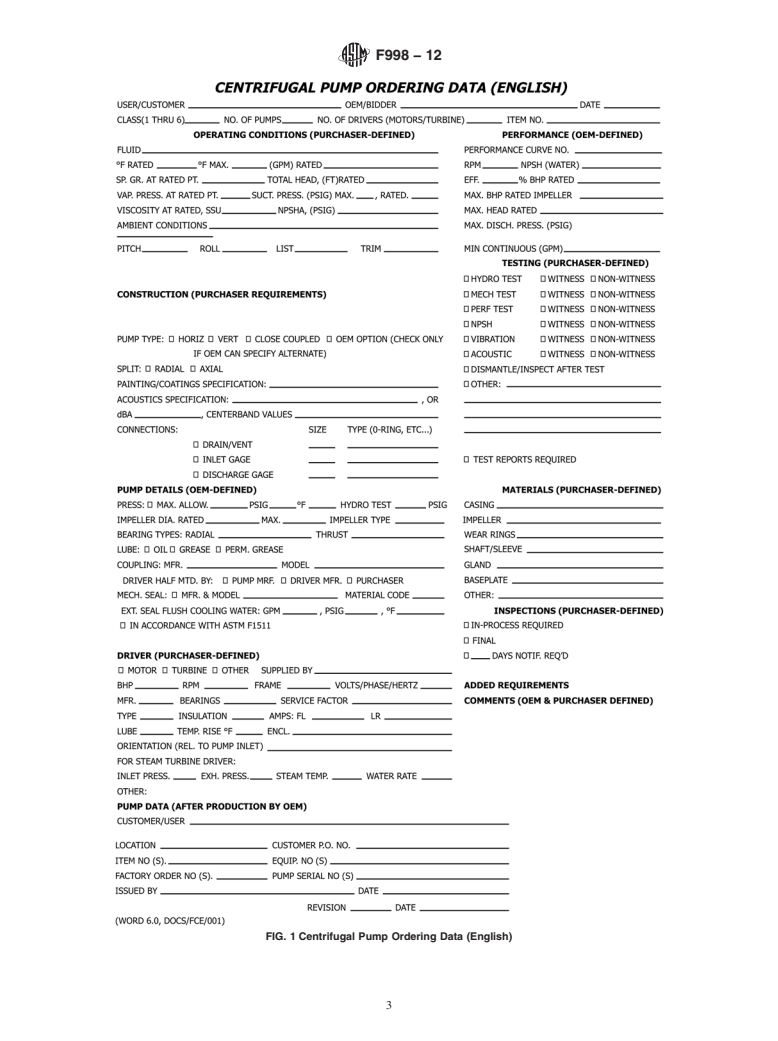

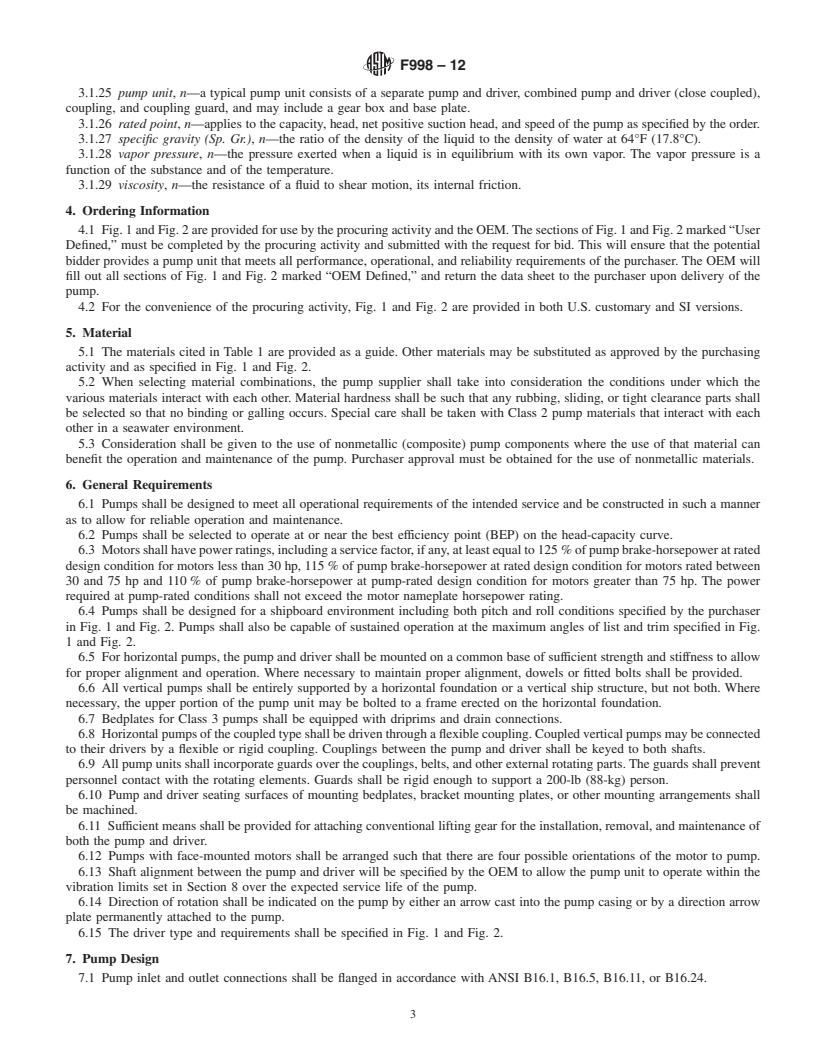

This specification covers the requirements applicable to the design and construction of three classes of centrifugal pump (Class 1, Class 2, and Class 3) for shipboard application. When selecting material combinations, the conditions under which the various materials interact with each other shall be taken into consideration as well as the use of nonmetallic (composite) pump components where the use of that material can benefit the operation and maintenance of the pump. The requirements for the following are detailed: (1) pump design and construction, (2) pump operation (at or near the best efficiency point), (3) motor power ratings, (4) pitch and roll conditions, (5) horizontal pump and driver mounting, (6) vertical pump support, (7) bedplates, (8) pump couplings, (9) guards, (10) pumps with face-mounted motors, (11) shaft alignment, and (12) indication of direction of rotation. Pump design requirements for inlet and outlet connections, casings, radial and thrust bearings, journal and thrust bearings, rolling element bearings, mechanical seals, separate pressure boundary parts, and screw threads are specified. Requirements for paintings and coatings, equipment identification plates, and testing such as hydrostatic, mechanical run, performance, net positive suction head, vibration, and acoustic tests are also specified.

SCOPE

1.1 This specification covers the requirements applicable to the design and construction of centrifugal pumps for shipboard application. The three classes of service covered by this specification are as follows:

1.1.1 Class 1Freshwater,

1.1.2 Class 2Seawater, and

1.1.3 Class 3Hydrocarbon pumps (less than 1500 SSU).

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information purposes only.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F998 −12 An American National Standard

Standard Specification for

1

Centrifugal Pump, Shipboard Use

ThisstandardisissuedunderthefixeddesignationF998;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Iron-Chromium-Nickel, Corrosion Resistant, for General

Application

1.1 This specification covers the requirements applicable to

A747/A747MSpecification for Steel Castings, Stainless,

thedesignandconstructionofcentrifugalpumpsforshipboard

Precipitation Hardening

application. The three classes of service covered by this

A890/A890MSpecification for Castings, Iron-Chromium-

specification are as follows:

Nickel-Molybdenum Corrosion-Resistant, Duplex

1.1.1 Class 1—Freshwater,

(Austenitic/Ferritic) for General Application

1.1.2 Class 2—Seawater, and

A995/A995MSpecification for Castings, Austenitic-Ferritic

1.1.3 Class 3—Hydrocarbon pumps (less than 1500 SSU).

(Duplex) Stainless Steel, for Pressure-Containing Parts

1.2 The values stated in inch-pound units are to be regarded

B148Specification for Aluminum-Bronze Sand Castings

as the standard. The values given in parentheses are provided

B164Specification for Nickel-Copper Alloy Rod, Bar, and

for information purposes only.

Wire

1.3 This international standard was developed in accor-

B271Specification for Copper-BaseAlloy Centrifugal Cast-

dance with internationally recognized principles on standard- ings

ization established in the Decision on Principles for the

B369Specification for Copper-Nickel Alloy Castings

Development of International Standards, Guides and Recom- B505/B505MSpecification for Copper Alloy Continuous

mendations issued by the World Trade Organization Technical

Castings

Barriers to Trade (TBT) Committee. B584Specification for Copper Alloy Sand Castings for

General Applications

2. Referenced Documents

F468Specification for Nonferrous Bolts, Hex Cap Screws,

2

Socket Head Cap Screws, and Studs for General Use

2.1 ASTM Standards:

F1511Specification for Mechanical Seals for Shipboard

A36/A36MSpecification for Carbon Structural Steel

Pump Applications

A193/A193MSpecification for Alloy-Steel and Stainless

Steel Bolting for High Temperature or High Pressure 2.2 ANSI Standards:

3

Service and Other Special Purpose Applications B1ISO Metric Screw Threads (ANSI-B1 Report)

3

A194/A194MSpecification for Carbon Steel, Alloy Steel, B1.1Unified Screw Threads

3

and Stainless Steel Nuts for Bolts for High Pressure or B16.1Cast Iron Pipe Flanges and Flange Fittings

High Temperature Service, or Both B16.5Steel Pipe Flanges, Flanged Valves and Fittings, 150,

3

A276Specification for Stainless Steel Bars and Shapes 300, 400, 600, 900, 1500 and 2500 lb.

3

A494/A494MSpecification for Castings, Nickel and Nickel B16.11ForgedSteelFittings,SocketWeldingandThreaded

3

Alloy B16.24Bronze Flanges and Flanged Fittings, 150, 300lb

A582/A582MSpecification for Free-Machining Stainless

2.3 Hydraulic Institute Standards:

Steel Bars

ANSI/HI 1.1-1.5American National Standard for Centrifu-

A743/A743MSpecification for Castings, Iron-Chromium,

gal Pumps for Nomenclature, Definitions, Applications

3

and Operation

ANSI/HI 1.6American National Standard for Centrifugal

1 3

This specification is under the jurisdiction of Committee F25 on Ships and

Pump Tests

Marine Technology and is the direct responsibility of Subcommittee F25.11 on

ANSI/HI 9.1-9.6American National Standard for Pumps—

Machinery and Piping Systems.

General Guidelines for Types, Definitions, Applications

Current edition approved May 1, 2012. Published June 2012. Originally

3

approved in 1997. Last previous edition approved in 2010 as F998–10. DOI: and Sound Measurements

10.1520/F0998-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F998−12

2.4 AFBMA Standards: 3.1.15 maximum BHP rated impeller, n—the highest power

4

9Load Ratings and Fatigue Life for Ball Bearings required by a pump with the correct impeller diameter for the

4

11Load Ratings and Fatigue Life for Roller Bearings service condition.

2.5 ISO Standards:

3.1.16 minimum continuous flow, n—the lowest possible

ISO 9001Quality Systems and QualityAssurance—Design/

flow rate at which the pump can run without generat

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:F998–10 Designation: F998 – 12

Standard Specification for

1

Centrifugal Pump, Shipboard Use

ThisstandardisissuedunderthefixeddesignationF998;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the requirements applicable to the design and construction of centrifugal pumps for shipboard

application. The three classes of service covered by this specification are as follows:

1.1.1 Class 1—Freshwater,

1.1.2 Class 2—Seawater, and

1.1.3 Class 3—Hydrocarbon pumps (less than 1500 SSU).

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for

information purposes only.

2. Referenced Documents

2

2.1 ASTM Standards:

A36/A36M Specification for Carbon Structural Steel

A193/A193M Specification for Alloy-Steel and Stainless Steel Bolting for High Temperature or High Pressure Service and

Other Special Purpose Applications

A194/A194M Specification for Carbon andAlloy Steel Nuts for Bolts for High Pressure or High Temperature Service, or Both

A276 Specification for Stainless Steel Bars and Shapes

A494/A494M Specification for Castings, Nickel and Nickel Alloy

A582/A582M Specification for Free-Machining Stainless Steel Bars

A743/A743M Specification for Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant, for General Applica-

tion

A747/A747M Specification for Steel Castings, Stainless, Precipitation Hardening

A890/A890M Specification for Castings, Iron-Chromium-Nickel-Molybdenum Corrosion-Resistant, Duplex (Austenitic/

Ferritic) for General Application

A995/A995M Specification for Castings, Austenitic-Ferritic (Duplex) Stainless Steel, for Pressure-Containing Parts

B148 Specification for Aluminum-Bronze Sand Castings

B164 Specification for Nickel-Copper Alloy Rod, Bar, and Wire

B271 Specification for Copper-Base Alloy Centrifugal Castings

B369 Specification for Copper-Nickel Alloy Castings

B505/B505M Specification for Copper Alloy Continuous Castings

B584 Specification for Copper Alloy Sand Castings for General Applications

F468 Specification for Nonferrous Bolts, Hex Cap Screws, and Studs for General Use

F1511 Specification for Mechanical Seals for Shipboard Pump Applications

2.2 ANSI Standards:

3

B1 ISO Metric Screw Threads (ANSI-B1 Report)

3

B1.1 Unified Screw Threads

3

B16.1 Cast Iron Pipe Flanges and Flange Fittings

3

B16.5 Steel Pipe Flanges, Flanged Valves and Fittings, 150, 300, 400, 600, 900, 1500 and 2500 lb.

3

B16.11 Forged Steel Fittings, Socket Welding and Threaded

3

B16.24 Bronze Flanges and Flanged Fittings, 150, 300lb

1

This specification is under the jurisdiction of Committee F25 on Ships and Marine Technology and is the direct responsibility of Subcommittee F25.11 on Machinery

and Piping Systems.

Current edition approved MarchMay 1, 2010.2012. Published March 2010.June 2012. Originally approved in 1997. Last previous edition approved in 20042010 as

F998 – 104. DOI: 10.1520/F0998-102.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F998 – 12

2.3 Hydraulic Institute Standards:

ANSI/HI 1.1-1.5 American National Standard for Centrifugal Pumps for Nomenclature, Definitions, Applications and

3

Operation

3

ANSI/HI 1.6 American National Standard for Centrifugal Pump Tests

ANSI/HI 9.1-9.6 American National Standard for Pumps—General Guidelines for Types, Definitions,Applications and Sound

3

Measurements

2.4 AFBMA Standards:

4

9 Load Ratings and Fatigue Life for Ball Bearings

4

11 Load Ratings and Fatigue Life for Roller Bearings

2.5 ISO Standards:

3

ISO 9001 Quality Systems and Quality Assurance—Design/Development, Production, Installation and Service

3. Terminology

3.1 Definitions:

3.1.1 best effıciency point (BEP), n—the capacity and head in which the pump efficiency is the highest.

3.1.2 BHP, n—power delivered to the pump

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.