ASTM D5572-95(2005)

(Specification)Standard Specification for Adhesives Used for Finger Joints in Nonstructural Lumber Products

Standard Specification for Adhesives Used for Finger Joints in Nonstructural Lumber Products

ABSTRACT

This specification establishes the performance levels for adhesives to be used in finger joints in nonstructural bonded-lumber products. Such products include, but are not limited to, interior and exterior mouldings, window and door components or parts, and bonded-lumber panels. The apparatus shall consist of environmental chamber for moist-heat aging, oven with sufficient air circulation to remove moisture from the chamber, tanks for soaking and boiling, testing machines for the flexure and tension specimens, and vacuum-pressure vessel. Tests shall be conducted such as dry, soak, elevated-temperature, and temperature-humidity tests for dry-use classification and dry, boil, elevated-temperature, and vacuum-pressure tests for the wet-use classification. The adhesives shall be tested for performance which shall meet the following requirements: moisture content; specific gravities of wood species; tensile strength; wood failure for soft and hard woods; and rupture modulus.

SCOPE

1.1 This specification establishes performance levels for adhesives to be used in finger joints in nonstructural bonded-lumber products. Such products include, but are not limited to, interior and exterior mouldings, window and door components or parts, and bonded-lumber panels. Adhesives that meet the requirements of the various performance classes are considered capable of providing an adequate bond for use under the conditions described for the class. This specification is to be used to evaluate adhesives as well as the adhesive bonds in the finger joints. See Section , Significance and Use, for limitations when using this specification to evaluate industrially manufactured finger joints. Note 1This specification supersedes the finger-joint portion of the 1990 edition of Specification D 3110.

1.2 The following index is provided as a guide to the test methods in this specification: SectionApparatusEquipment, Material, and Preparation of Assemblies and SpecimensConditioning for Factory-Manufactured Assemblies, Laboratory-Made Assemblies, and Test SpecimensTesting in FlexureTesting in TensionExposure Conditions and Treatments1.Dry Use Tests: Dry, 3-cycle Soak, Elevated Temperature, and Temperature-Humidity2.Wet Use Tests: Dry, Boil, Elevated Temperature, and Vacuum-PressureNote 2

The conditioning needed for various stages in the preparation of both types of specimens and for the exposure tests are given. Note 3

Specific guidelines for specimen size, exposure conditions, testing, calculation, and reporting are given for flexure specimens in Sections and , and for tension specimens in Sections and .

1.3 For the definitions of dry useand wet use, see and .

1.4 The values stated in inch-pound units are to be regarded as standard. The SI units given in parentheses are for information only.

The following precautionary caveat pertains only to the apparatus and test methods portions, Sections of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5572 −95(Reapproved2005)

Standard Specification for

Adhesives Used for Finger Joints in Nonstructural Lumber

Products

This standard is issued under the fixed designation D5572; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 The following precautionary caveat pertains only to the

apparatus and test methods portions, Sections 6-11 of this

1.1 This specification establishes performance levels for

specification: This standard does not purport to address all of

adhesives to be used in finger joints in nonstructural bonded-

the safety concerns, if any, associated with its use. It is the

lumber products. Such products include, but are not limited to,

responsibility of the user of this standard to establish appro-

interior and exterior mouldings, window and door components

priate safety and health practices and determine the applica-

or parts, and bonded-lumber panels. Adhesives that meet the

bility of regulatory limitations prior to use.

requirementsofthevariousperformanceclassesareconsidered

capable of providing an adequate bond for use under the

2. Referenced Documents

conditions described for the class. This specification is to be

2.1 ASTM Standards:

usedtoevaluateadhesivesaswellastheadhesivebondsinthe

D143Test Methods for Small Clear Specimens of Timber

finger joints. See Section 5, Significance and Use, for limita-

D907Terminology of Adhesives

tions when using this specification to evaluate industrially

D2016Methods of Test for Moisture Content of Wood

manufactured finger joints.

(Withdrawn 1987)

NOTE 1—This specification supersedes the finger-joint portion of the

D3110Specification forAdhesives Used in Laminate Joints

1990 edition of Specification D3110.

for Nonstructural Glued Lumber Products (Withdrawn

1.2 The following index is provided as a guide to the test

1996)

methods in this specification:

D4688Test Method for Evaluating StructuralAdhesives for

Section

Finger Jointing Lumber

Apparatus 6

D5266Practice for Estimating the Percentage of Wood

Equipment, Material, and Preparation of Assemblies and Specimens 7

Conditioning for Factory-Manufactured Assemblies, Laboratory-Made 8 Failure in Adhesive Bonded Joints

Assemblies, and Test Specimens

E4Practices for Force Verification of Testing Machines

Testing in Flexure 9

E6Terminology Relating to Methods of MechanicalTesting

Testing in Tension 10

Exposure Conditions and Treatments 11 E41Terminology Relating To Conditioning

1. Dry Use Tests: Dry, 3-cycle Soak, Elevated Temperature, 11.1

E177Practice for Use of the Terms Precision and Bias in

and Temperature-Humidity

ASTM Test Methods

2. Wet Use Tests: Dry, Boil, Elevated Temperature, and 11.2

Vacuum-Pressure

E691Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

NOTE 2—The conditioning needed for various stages in the preparation

of both types of specimens and for the exposure tests are given.

NOTE 3—Specific guidelines for specimen size, exposure conditions, 3. Terminology

testing, calculation, and reporting are given for flexure specimens in

3.1 Definitions:

Sections 9 and 11, and for tension specimens in Sections 10 and 11.

3.1.1 Many terms in this specification are defined in Termi-

1.3 For the definitions of dry use and wet use, see 3.2.1.1

nology D907 and Terminology E41.

and 3.2.1.2.

3.1.2 bond, n—the union of materials by adhesives.

1.4 Thevaluesstatedininch-poundunitsaretoberegarded

3.1.3 finger joint, n—a joint formed by bonding two precut

as standard. The SI units given in parentheses are for informa-

members shaped like fingers. (See Figs. 1 and 2.)

tion only.

1 2

This specification is under the jurisdiction of ASTM Committee D14 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Adhesives and is the direct responsibility of Subcommittee D14.30 on Wood contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Adhesives. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved April 1, 2005. Published May 2005. Originally the ASTM website.

approved in 1994. Last previous edition approved in 1999 as D5572–95(1999). The last approved version of this historical standard is referenced on

DOI: 10.1520/D5572-95R05. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5572−95(2005)

wood-failure requirements for hardwood are 50% of the

requirements for softwoods.

4.2 Industrially Manufactured Finger Joint—An industri-

ally manufactured finger joint may be used to evaluate the

adhesive, provided its construction meets the requirements set

forth in Sections 7-10, and the joint is tested against the

FIG. 1 Horizontal Joint

requirements in Table 1.

FIG. 2 Vertical Joint

3.2 Definitions of Terms Specific to This Standard:

3.2.1 nonstructural adhesive:

3.2.1.1 dry use nonstructural adhesive, n—an adhesive

capable of producing sufficient strength and durability to make

the bonded lumber product serviceable in nonstructural use,

under conditions in which the equilibrium moisture content

Example Dimensions for Fig. 3 Test Standard Finger Joint:

(EMC) of the wood does not exceed 16%.

A

Code Dimensions, in. (mm) Degrees

3.2.1.2 wet use nonstructural adhesive, n—an adhesive

a 1.312 (33.32) .

capable of producing sufficient strength and durability to make

f 0.250 (6.25) .

wt 0.047 (1.19) .

the bonded lumber product serviceable in nonstructural use,

wb 0.092 (2.34) .

under conditions in which the EMC of the wood may be 16%

s (Slope) 5°

or greater.

A

The dimensions given are for a typical horizontal finger joint and are examples

3.3 Abbreviations:

only.

3.3.1 EMC—equilibrium moisture content.

FIG. 3 Test Standard Finger-Joint Form

3.3.2 MC—moisture content.

4. Test Requirements

5. Significance and Use

4.1 Adhesives:

5.1 Adhesives are classified as dry use or wet use. Each

4.1.1 To comply with this specification the test adhesive

classification includes consideration of short-term in-transit

shall be tested for performance in accordance with Sections

exposure conditions at elevated temperatures up to 220°F

8.1.1-11, and it shall meet the requirements in Table 1 for the

(104°C).

selected testing mode and performance classification.

5.2 The initial development of Specification D3110 was

4.1.2 Compliance with this specification shall warrant cer-

based on finger-joint assemblies made under controlled labo-

tification of the adhesive for use on the species of wood that is

ratory conditions. In the development of this revised specifi-

used for the tests, or for use on a designated group of species

cation the results obtained with laboratory-made specimens

whentestedandfoundtobeincomplianceforanyonemember

(see 12.1.2) were compared to those obtained with industrially

of said group of species. The designated species groupings for

manufactured specimens (see 12.1.1). These finger joints were

commonly used domestic and imported woods, as accepted in

prepared using previously certified adhesives in cooperation

thisspecification,aregiveninTable2.Intheeventthattheuser

with a manufacturer or equipment supplier who had the

or supplier of the adhesive, or both, cannot accept the desig-

necessary finger-joint cutter and assembly equipment. These

natedgroupingsinTable2,eitherpartyshallhavetheoptionof

finger joints may vary in geometry and length from manufac-

requesting a test on an individual species. Furthermore, the

turer to manufacturer, and this variation could affect the

user and supplier may agree to change any of the wood-failure

performance of the bonded-finger-joint assembly. (See 12.1,

requirements of Table 1 when applied to tests on Groups 3 and

12.4, and 12.5.) Fig. 3 depicts a sample finger-joint configu-

4 hardwoods from Table 2. For wood-property information on

ration.

imported woods, see the Wood Handbook.

5.2.1 When changes are made in the design of the industri-

4.1.2.1 The wood-failure requirements listed in Table 1 are

ally manufactured finger joint, the new design should be

given for softwoods and hardwoods. Table 1 shows that the

compared to a control design that has been used successfully.

4 5

U.S.DepartmentofAgricultureForestService;AgriculturalHandbook,No.72, Selbo, M. L., “Effects of Joint Geometry onTensile Strength of Finger Joints,”

Wood Handbook, Tables3 and 4, 1987 edition, pp. 3–11. Forest Products Journal, Vol 13, No. 9, September 1963, pp. 390–400.

D5572−95(2005)

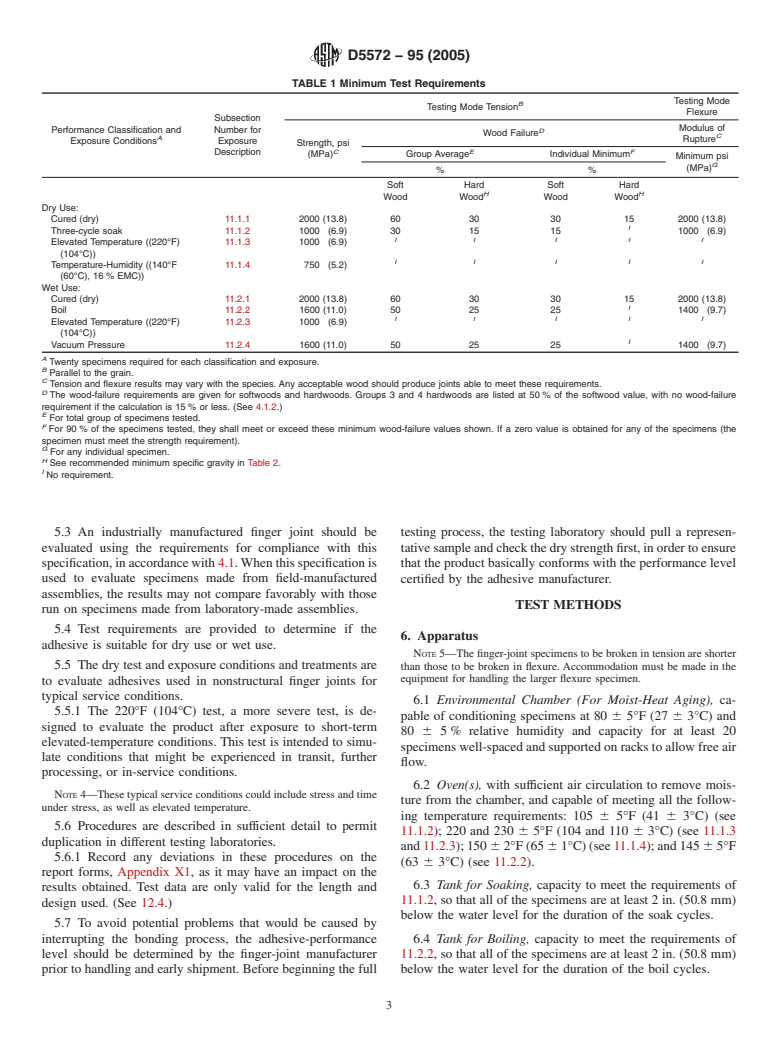

TABLE 1 Minimum Test Requirements

Testing Mode

B

Testing Mode Tension

Flexure

Subsection

Modulus of

Performance Classification and Number for D

Wood Failure

C

A

Rupture

Exposure Conditions Exposure

Strength, psi

C E F

Description

(MPa) Group Average Individual Minimum

Minimum psi

G

(MPa)

%%

Soft Hard Soft Hard

H H

Wood Wood Wood Wood

Dry Use:

Cured (dry) 11.1.1 2000 (13.8) 60 30 30 15 2000 (13.8)

I

Three-cycle soak 11.1.2 1000 (6.9) 30 15 15 1000 (6.9)

II I I I

Elevated Temperature ((220°F) 11.1.3 1000 (6.9)

(104°C))

II I I I

Temperature-Humidity ((140°F 11.1.4 750 (5.2)

(60°C), 16 % EMC))

Wet Use:

Cured (dry) 11.2.1 2000 (13.8) 60 30 30 15 2000 (13.8)

I

Boil 11.2.2 1600 (11.0) 50 25 25 1400 (9.7)

II I I I

Elevated Temperature ((220°F) 11.2.3 1000 (6.9)

(104°C))

I

Vacuum Pressure 11.2.4 1600 (11.0) 50 25 25 1400 (9.7)

A

Twenty specimens required for each classification and exposure.

B

Parallel to the grain.

C

Tension and flexure results may vary with the species. Any acceptable wood should produce joints able to meet these requirements.

D

The wood-failure requirements are given for softwoods and hardwoods. Groups 3 and 4 hardwoods are listed at 50 % of the softwood value, with no wood-failure

requirement if the calculation is 15 % or less. (See 4.1.2.)

E

For total group of specimens tested.

F

For 90 % of the specimens tested, they shall meet or exceed these minimum wood-failure values shown. If a zero value is obtained for any of the specimens (the

specimen must meet the strength requirement).

G

For any individual specimen.

H

See recommended minimum specific gravity in Table 2.

I

No requirement.

5.3 An industrially manufactured finger joint should be testing process, the testing laboratory should pull a represen-

evaluated using the requirements for compliance with this tativesampleandcheckthedrystrengthfirst,inordertoensure

specification,inaccordancewith4.1.Whenthisspecificationis that the product basically conforms with the performance level

used to evaluate specimens made from field-manufactured certified by the adhesive manufacturer.

assemblies, the results may not compare favorably with those

TEST METHODS

run on specimens made from laboratory-made assemblies.

5.4 Test requirements are provided to determine if the

6. Apparatus

adhesive is suitable for dry use or wet use.

NOTE 5—The finger-joint specimens to be broken in tension are shorter

5.5 The dry test and exposure conditions and treatments are than those to be broken in flexure. Accommodation must be made in the

equipment for handling the larger flexure specimen.

to evaluate adhesives used in nonstructural finger joints for

typical service conditions.

6.1 Environmental Chamber (For Moist-Heat Aging), ca-

5.5.1 The 220°F (104°C) test, a more severe test, is de-

pable of conditioning specimens at 80 6 5°F (27 6 3°C) and

signed to evaluate the product after exposure to short-term

80 6 5% relative humidity and capacity for at least 20

elevated-temperature conditions. This test is intended to simu-

specimenswell-spacedandsupportedonrackstoallowfreeair

late conditions that might be experienced in transit, further

flow.

processing, or in-service conditions.

6.2 Oven(s), with sufficient air circulation to remove mois-

NOTE4—Thesetypicalserviceconditionscouldincludestressandtime

ture from the chamber, and capable of meeting all the follow-

under stress, as well as elevated temperature.

ing temperature requirements: 105 6 5°F (41 6 3°C) (see

5.6 Procedures are described in sufficient detail to permit

11.1.2); 220 and 230 6 5°F (104 and 110 6 3°C) (see 11.1.3

duplication in different testing laboratories.

and11.2.3);150 62°F(65 61°C)(see11.1.4);and145 65°F

5.6.1 Record any deviations in these procedures on the

(63 6 3°C) (see 11.2.2).

report forms, Appendix X1, as it may have an impact on the

6.3 Tank for Soaking, capacity to meet the requirements of

results obtained. Test data are only valid for the length and

11.1.2, so that all of the specimens are at least 2 in. (50.8 mm)

design used. (See 12.4.)

below the water level for the duration of the soak cycles.

5.7 To avoid potential problems that would be caused by

interrupting the bonding process, the adhesive-performance 6.4 Tank for Boiling, capacity to meet the requirements of

level should be determined by the finger-joint manufacturer 11.2.2, so that all of the specimens are at least 2 in. (50.8 mm)

priortohandlingandearlyshipment.Beforebeginningthefull below the water level for the duration of the boil cycles.

D5572−95(2005)

TABLE 2 Bondability Groupings of Commonly Used Domestic

A

and Imported Wood

U.S. Hardwoods U.S. Softwoods Imported Woods

B

Group 1—Bond Easily

Alder Cedar, incense Balsa Hura

Aspen Fir: Cativo Purpleheart

Basswood White Courbaril Roble

C

Cottonwood Grand Determa

Chestnut, Noble

American

Magnolia Pacific

Willow, black Pine:

Eastern white

Western white

Redcedar, western

Redwood

Spruce, Sitka

D

Group 2—Bond Well

Butternut Douglas-fir Afrormosia Meranti (lauan):

E

Example Dimensions for Fig. 4 Flexure Test Specimen:

Elm: Larch, western Andiroba White

American Pine: Angelique Light red A

Code Dimension, in. (mm)

Rock Sugar Avodire Yellow

Ls 12.0 (307.2)

Hackberry Ponderosa Banak Obeche

b 0.75 (19.2)

Maple, soft Redcedar, eastern Iroko Okoume

d 0.5 (12.8)

Sweetgum Jarrah Opepe

e (see 9.2.1)

Sycamore Limba Peroba rosa

A

Tupelo Mahogany: Sapele

These dimensions are given as examples of a finger-joint assembly. Use the

Walnut, black African Spanish-cedar

actual measurements of “b” and “d.” Code “b” may be the width of a vertical joint,

Yellow-poplar True Sucupira

or the thickness of a horizontal joint. Code “e” is the extended dimension of the

Wallaba

length of the assembly that falls outside the reaction points.

F

Group 3—Bond Satisfactory

FIG. 4 Flexure Test Form and Dimension

Ash, white Alaska-cedar Angelin Meranti (lauan),

dark red

Beech, American Port-Orford-cedar Azobe Pau marfim

Birch: Pine, southern Benge Parana-pine

motion of the movable head to maximum at a rat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.