ASTM F392-93(1999)

(Test Method)Standard Test Method for Flex Durability of Flexible Barrier Materials

Standard Test Method for Flex Durability of Flexible Barrier Materials

SCOPE

1.1 This test method covers the determination of the flex resistance of flexible barrier materials. Pinhole formation is the criterion presented for measuring failure, but other tests such as gas-transmission rates can be used in place of the pinhole test.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 5.7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 392 – 93 (Reapproved 1999)

Standard Test Method for

Flex Durability of Flexible Barrier Materials

This standard is issued under the fixed designation F 392; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.3.1 Condition A— Full flex for 1 h (that is, 2700 cycles).

3.3.2 Condition B— Full flex for 20 min (that is, 900

1.1 This test method covers the determination of the flex

cycles).

resistance of flexible barrier materials. Pinhole formation is the

3.3.3 Condition C— Full flex for 6 min (that is, 270 cycles).

criterion presented for measuring failure, but other tests such as

3.3.4 Condition D— Full flex for 20 cycles.

gas-transmission rates can be used in place of the pinhole test.

3.3.5 Condition E— Partial flex only for 20 cycles.

1.2 This standard does not purport to address all of the

safety problems, if any, associated with its use. It is the

4. Significance and Use

responsibility of the user of this standard to establish appro-

4.1 This test method is valuable in determining the resis-

priate safety and health practices and determine the applica-

tance of flexible-packaging materials to flex-formed pinhole

bility of regulatory limitations prior to use. Specific precau-

failures.

tionary statements are given in 5.7.

4.2 This test method does not measure any abrasion com-

2. Referenced Documents ponent relating to flex failure.

4.3 Physical holes completely through the structure are the

2.1 ASTM Standards:

only failures measured by the colored-turpentine-pinhole por-

D 618 Practice for Conditioning Plastics and Electrical

tion of this test. Failures in the integrity of one of the plies of

Insulating Materials for Testing

a multi-ply structure will not be determined by the colored-

D 722 Test Method for Grease Resistance of Paper

turpentine test. Gas permeation or moisture vapor transmission

E 691 Practice for Conducting an Interlaboratory Study to

tests, or both, can be used in conjunction with the flex test to

Determine the Precision of a Test Method

measure the loss of ply integrity. However, any permeation test

3. Summary of Test Method requiring a pressure differential will not measure the perme-

ation coefficient in the presence of pinholes.

3.1 Specimens of flexible materials are flexed at standard

4.3.1 The various conditions described in this procedure are

atmospheric conditions (23°C and 50 % relative humidity),

to prevent testing a structure under conditions that either give

unless otherwise specified. Flexing conditions and number and

too many holes to effectively count and be significant (nor-

severity of flexing strokes vary with the type of structure being

mally greater than 50), or too few to be significant (normally

tested. The flexing action consists of a twisting motion fol-

less than five per sample).

lowed, in most cases, by a horizontal motion, thus, repeatedly

4.4 Measurements on nylon film, possibly because of its

twisting and crushing the film. The frequency is at a rate of 45

hydrophilic nature, have not shown good reproducibility (be-

cpm.

tween laboratories), although the repeatability of the data

3.2 Flex failure is determined by measuring the pinholes

within a laboratory was good.

formed in the structure. These pinholes are determined by

using colored turpentine and allowing it to stain through the

5. Apparatus and Reagent

holes onto a white backing. In addition, other failure criteria

5.1 Flex Tester, designed so that it can be set up in

such as gas permeation or moisture-vapor transmission can be

accordance with the specifications listed in Section 8. This

used at the discretion of the tester.

apparatus shall consist essentially of a 90-mm (3.5-in.) diam-

3.3 The various test conditions are summarized as follows:

eter stationary mandrel and a 90-mm diameter movable man-

drel spaced at a distance of 180 mm (7 in.) apart from

face-to-face at the starting position (that is, maximum distance)

This test method is under the jurisdiction of ASTM Committee F-2 on Flexible

of the stroke. Mandrels shall contain vents to prevent pressur-

Barrier Materials and is the direct responsibility of Subcommittee F02.30 on Test

ization of samples. The specimen supporting shoulders on the

Methods.

Current edition approved May 15, 1993. Published August 1993. Originally

published as F 392 – 74. Last previous edition F 392 – 74 (1987).

2 5

Annual Book of ASTM Standards, Vol 08.01. The Gelbo Tester, which is capable of producing the prescribed flexing action,

Discontinued; see 1978 Annual Book of ASTM Standards, Part 20. available from the United States Testing Co., Inc., 1415 Park Ave., Hoboken,

Annual Book of ASTM Standards, Vol 14.02. NJ 07030, or its equivalent, has been found satisfactory for this test method.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

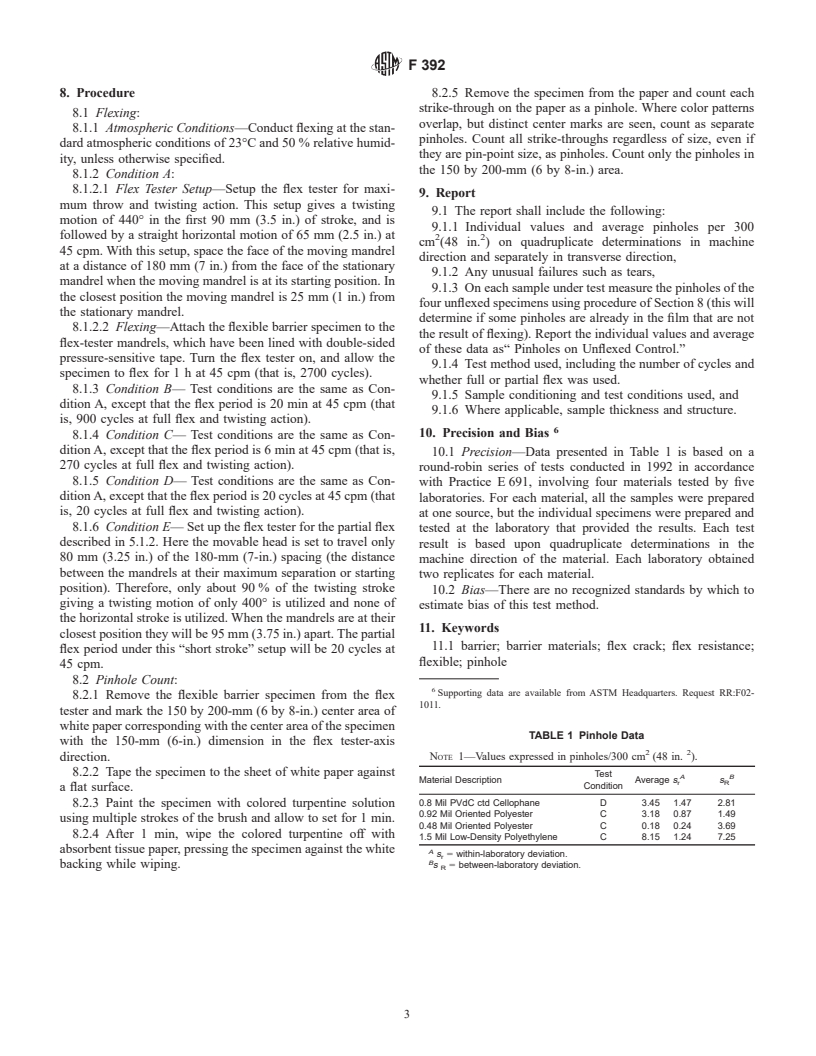

F 392

mandrels shall be 13 mm (0.5 in.) wide. The motion of the 0.875 at 15°C) add5gof anhydrous calcium chloride (CaCl )

movable mandrel is controlled by a grooved shaft to which it and 1.0 g of oil-soluble red dye. Stopper the container, shake

is attached. For the full or maximum stroke the groove is well, and let stand for at least 10 h, shaking occasionally. Then

designed to give a twisting motion of 440° in the first 90 mm filter through a dry filter paper at a temperature of approxi-

of the stroke of the movable mandrel, followed by a straight mately 21°C, and store in an airtight bottle.

horizontal motion of 65 mm (2.5 in.), so that at the closed

NOTE 1—Caution: Use of these materials requires that appropriate

position the mandrels are 25 mm (1 in.) apart. The motion of

safeguards be used to avoid hazards of skin contact, inhalation, and

the machine is reciprocal with a full cycle consisting of the

flammability.

forward and return strokes. The machine operates at 45 cpm.

6. Test Specimens—All Conditions

5.1.1 Fig. 1 shows the planar evolution of the helical groove

in the driven shaft to give the required 440° (37° helix angle)

6.1 Cut the samples into 200 by 280-mm (8 by 11-in.) flat

twisting motion and the straight horizontal motion.

sheets with the 200-mm dimension in the direction to be tested.

5.1.2 For the partial flex used with Condition E the movable

This will also be in the direction of the flex-tester axis.

head is set to travel only 80 mm (3.25 in.) of the 180-mm

6.2 Flex test four specimens in their machine direction and

(7-in.) spacing. Therefore, only approximately 90 % of the

four in their transverse direction. In addition, test a control set

twisting stroke is utilized giving a twisting motion of only

of four, adjacent, unflexed specimens (either direction) for

400°, and none of the horizontal stroke is utilized.

pinholes.

5.2 Tape, flexible, double-sided, pressure-sensitive, not

6.3 Do not seal or tape the sides of the specimens, but leave

more than 13 mm (0.5 in.)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.