ASTM D6229-98

(Test Method)Standard Test Method for Trace Benezene in Hydrocarbon Solvents by Capillary Gas Chromatography

Standard Test Method for Trace Benezene in Hydrocarbon Solvents by Capillary Gas Chromatography

SCOPE

1.1 This test method covers the determination by capillary gas chromatography of trace benzene in hydrocarbon solvents at levels from 1.0 to 2400 vppm.

Note 1--Lower levels of benzene may be determined by this test method. However the gas chromatography (GC) will have to be modified from those specified in this test method. The precision of the method may not apply to these lower benzene levels.

1.2 For hazard information and guidance, see the supplier's Material Safety Data Sheet.

1.3 The values stated in SI units are to be regarded as the statement. The values in parenthesis are given for information only and are not necessarily the exact equivalent of the SI unit values.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: D 6229 – 98

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Trace Benezene in Hydrocarbon Solvents by Capillary Gas

1

Chromatography

This standard is issued under the fixed designation D 6229; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope nents are detected by a flame ionization detecter, and the peak

areas are integrated electronically. The concentration of ben-

1.1 This test method covers the determination by capillary

zene is calculated by a data processor using a response factor

gas chromatography of trace benzene in hydrocarbon solvents

determined by external standard technique.

at levels from 1.0 to 2400 vppm.

NOTE 1—Lower levels of benzene may be determined by this test

4. Significance and Use

method. However the gas chromatography (GC) will have to be modified

4.1 This test method is similar to Test Method D 4367 with

from those specified in this test method. The precision of the method may

the exception that capillary columns are used and intended for

not apply to these lower benzene levels.

trace level of benzene in hydrocarbon solvents. The need for

1.2 For hazard information and guidance, see the supplier’s

trace benzene analysis in hydrocarbon solvents arose because

Material Safety Data Sheet.

of the increase of more stringent regulation of benzene level in

1.3 The values stated in SI units are to be regarded as the

these materials.

statement. The values in parenthesis are given for information

only and are not necessarily the exact equivalent of the SI unit

5. Apparatus

values.

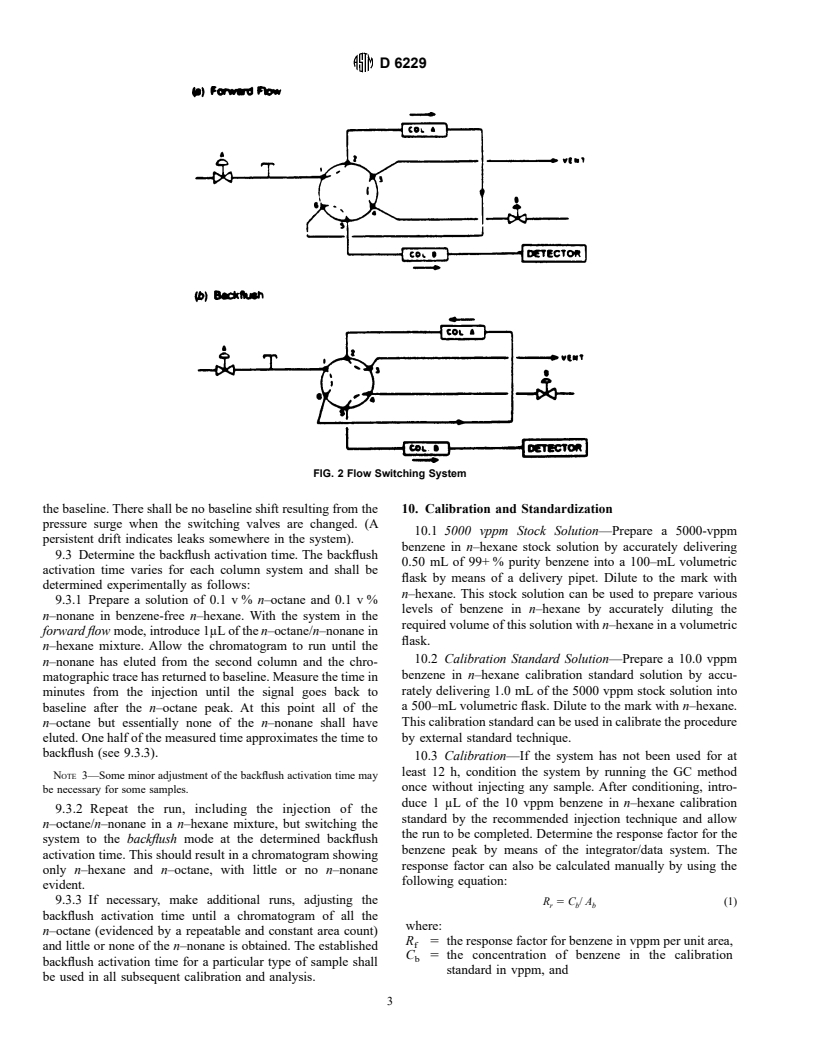

5.1 Chromatograph—Any gas chromatographic instrument

1.4 This standard does not purport to address all of the

that has a backflush system operated by a switching valve

safety concerns, if any, associated with its use. It is the

automatically, flame ionization detector, and can be operated at

responsibility of the user of this standard to establish appro-

the conditions given in Table 1.

priate safety and health practices and determine the applica-

5.2 Detector—The flame ionization detector shall have

bility of regulatory limitations prior to use.

sufficient sensitivity to detect 0.1 vppm of benzene at a peak

height of 3 times the noise level.

2. Referenced Documents

5.3 Columns—one 2–m (6.5–ft), 0.53 mm inside diameter

2.1 ASTM Standards:

fused silica capillary with 5-μm thick bounded methyl silicone

D 4367 Test Method for Benzene in Hydrocarbon Solvents

column and one 30–m (98.5–ft), 0.53-mm inside diameter

2

by Gas Chromatography

fused silica capillary with 0.5-μm thick bounded polyethylene

3

E 300 Practice for Sampling Industrial Chemicals

glycol column.

5.4 Switching Valve—A 6–port switching valve 175°C (347

3. Summary of Test Method

°F) maximum temperature, housed in a separate, temperature-

3.1 A given volume of the sample is introduced into a gas

controlled oven, that can be activated automatically by the gas

chromatograph equipped with two capillary columns con-

chromatograph.

nected in series by switching valve. The specimen passes first

5.5 Sample Inlet System—The sample inlet system shall be

through a short capillary column with a bounded nonpolar

capable of split injection typically at a 1:10 split ratio.

phase where the components are separated by boiling point.

NOTE 2—An auto injector was used in the generation of the repeatabil-

After octane has eluted from the first column, the components

ity value of this test method, and is recommended. Manual injection with

heavier than octane are back-flushed to vent. The octane and

a syringe is acceptable; however, the observed precision may not apply.

lighter components then pass through a second capillary

5.6 Data Acquisition System:

column with bounded polar phase where the aromatic and

5.6.1 Recorder—A 0 to 1 mv range recorder or equivalent,

nonaromatic components are separated. The eluted compo-

with a full-scale response time of 2 s shall be used.

5.6.2 Integrator—Means shall be provided for determining

1

the area of the benzene peak. This can be done by means of an

This test method is under the jurisdiction of ASTM Committee D-1 on Paint

and Related Coatings, Materials, and Applications, and is the direct responsibility of

electronic integrator or a computer based chromatography data

Subcommittee 01.35 on Solvents, Plasticizers, and Chemical Intermediates.

system. The integrator/computer system shall have standard

Current edition approved Feb. 10, 1998. Published April 1998.

2

chromatographic software f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.