ASTM F882-84(1996)

(Specification)Standard Performance and Safety Specification for Cryosurgical Medical Instruments

Standard Performance and Safety Specification for Cryosurgical Medical Instruments

SCOPE

1.1 This specification establishes standards a manufacturer shall meet in the designing, manufacturing, testing, labeling, and documenting of cryosurgical medical instruments, but it is not to be construed as production methods, quality control techniques, or manufacturer's lot release criteria, or clinical recommendations.

1.2 This specification represents the best currently available test procedures at this time and is a minimum safety and performance standard.

1.3 This specification covers only those cryosurgical devices intended for use on humans or animals for therapeutic purposes. This specification assumes the user is well-trained in the procedures of cryosurgery and has the ability to determine if an abnormality is treatable by cryosurgery, particularly by the type of equipment to be used.

1.4 Cryosurgical medical instruments produce low temperatures either inside a cryoprobe or directly on the target tissue by the principle of Latent Heat of Vaporization or the Joule-Thompson Effect, or both. The cryogen may be transported from the source as a liquid or a gas. These systems may be closed or open depending on the application and cryogen. In the open cryotip system, the cryogen is applied directly to the target tissue, while in the closed cryotip system, the cryogen is applied indirectly and is exhausted away from the target area.

1.5 Cryosurgical medical instruments are used to produce cryonecrosis, inflammatory response, or cryoadhesion.

1.6 Monitoring the progress of treatment during application is sometimes very important. Such monitoring is done by accessories that indicate the temperature of the cryotip or the target area being frozen. The temperature of the tissue may be measured directly (for example, by a thermocouple). These accessories are also covered by this specification.

1.7 The following precautionary caveat pertains only to the Test Method portion, Sections 8 through 13, of this specification: This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

Designation: F 882 – 84 (Reapproved 1996)

Standard Performance and Safety Specification for

Cryosurgical Medical Instruments

This standard is issued under the fixed designation F 882; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

INTRODUCTION

This performance and safety specification was developed by Task Force F04.08 on Cryosurgical

Medical Instruments.

This specification is intended to provide the user of Cryosurgical Medical Instruments with the

assurance that the equipment will meet or exceed all safety and performance levels established by this

document as claimed by the manufacturer. This is predicated on the requirements that the equipment

is operated according to the manufacturer’s recommendations.

Since, in the pursuit of improved health care and reduced medical costs, the medical industry is

required to be innovative and dynamic, this standard must be capable of being upgraded in a swift and

efficient manner. All inquiries regarding this standard should be addressed to: Committee F-4 Staff

Manager, ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428.

1. Scope 1.5 Cryosurgical medical instruments are used to produce

cryonecrosis, inflammatory response, or cryoadhesion.

1.1 This specification covers standards a manufacturer shall

1.6 Monitoring the progress of treatment during application

meet in the designing, manufacturing, testing, labeling, and

is sometimes very important. Such monitoring is done by

documenting of cryosurgical medical instruments, but it is not

accessories that indicate the temperature of the cryotip or the

to be construed as production methods, quality control tech-

target area being frozen. The temperature of the tissue may be

niques, or manufacturer’s lot release criteria, or clinical rec-

measured directly (for example, by a thermocouple). These

ommendations.

accessories are also covered by this specification.

1.2 This specification represents the best currently available

1.7 The following precautionary caveat pertains only to the

test procedures at this time and is a minimum safety and

Test Method portion, Sections 8-13, of this specification: This

performance standard.

standard may involve hazardous materials, operations, and

1.3 This specification covers only those cryosurgical de-

equipment. This standard does not purport to address all of the

vices intended for use on humans or animals for therapeutic

safety concerns, if any, associated with its use. It is the

purposes. This specification assumes the user is well-trained in

responsibility of the user of this standard to establish appro-

the procedures of cryosurgery and has the ability to determine

priate safety and health practices and determine the applica-

if an abnormality is treatable by cryosurgery, particularly by

bility of regulatory limitations prior to use.

the type of equipment to be used.

1.4 Cryosurgical medical instruments produce low tempera-

2. Referenced Documents

tureseitherinsideacryoprobeordirectlyonthetargettissueby

2.1 ANSI Standard:

the principle of Latent Heat of Vaporization or the Joule-

ANSI B40.1-1974 Use and Installation of Pressure Gauges

Thompson Effect, or both. The cryogen may be transported

2.2 ANSI/AAMI Document:

from the source as a liquid or a gas. These systems may be

ANSI/AAMI SCL 12/78

closed or open depending on the application and cryogen. In

2.3 Canadian Standards Association (C.S.A.) Standard:

the open cryotip system, the cryogen is applied directly to the

C22.2-125 Electromedical Equipment 1973

target tissue, while in the closed cryotip system, the cryogen is

applied indirectly and is exhausted away from the target area.

Available from the American National Standards Institute, 1430 Broadway,

New York, NY 10018.

1 3

ThisspecificationisunderthejurisdictionofASTMCommitteeF-4onMedical Available from the Association for the Advancement of Medical Instrumenta-

and Surgical Materials and Devices and is the direct responsibility of Subcommittee tion (AAMI). 1901 North Fort Myer Drive, Suite 602, Arlington, VA 22209.

F04.65 on Medical/Surgical Instruments. Available from the Canadian Standards Association (C.S.A), 173 Rexdale

Current edition approved Sept. 11, 1984. Published February 1985. Blvd., Rexdale, Ontario M9W 1R3, Canada.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

F 882 – 84 (1996)

2.4 International ElectroTechnical Commission (IEC) 3.1.13 Dewar withdrawal device—a device specifically de-

Document: signed to attach to a dewar for proper and safe removal of its

contents.

IEC 601-1 1977

3.1.14 disposable—any device which is designated to be

2.5 Compressed Gas Association Document:

discarded after use.

CGA V-1 1977

3.1.15 inflammatory response—irritation of tissue cells as a

2.6 FDA Document:

result of using a cryosystem.

21CFR801: Labeling Specifications

3.1.16 mechanical integrity—the ability of all components

2.7 NBS Document:

8 of a cryosystem to withstand the pressures and temperatures

Table IPTS-68 NBS Monograph 125

that may be encountered during use as recommended by the

manufacturer.

3. Terminology

3.1.17 open cryotip—a device specifically designed to ap-

3.1 Definitions:

ply the cryogen directly to the target tissue.

3.1.1 closed cryotip—a hollow, closed end usually shaped

3.1.18 target tissue—the specific anatomical area intended

to fit a particular anatomical site where the cryogen cools the

to be treated.

external surface which is applied to the target tissue.

3.1.19 thermal insulation—a material or technique, or both,

3.1.2 closed cryotip reference temperature—the average of

used to prevent unintended cryonecrosis, inflammatory re-

the minimum/maximum cycle temperature variation at the end

sponses, or cryoadhesion to nontarget tissue.

of the freeze cycle.

3.1.20 thermocouple—a junction of two dissimilar metals

3.1.3 compressed gas cylinder—a container that is specifi-

that produce an output voltage proportional to the temperature

cally designed to store a gas or liquid under elevated pressure

of the junction. When used in conjunction with a cryometer(s),

conditions.

the output is directly correlated to the temperature to which the

3.1.4 compressed gas cylinder connector—a device specifi-

sensing junction is exposed.

cally designed to attach to a cylinder for proper and safe

3.1.21 tractive forge—the cryoadhesive attraction between

removal of its contents.

the cryotip and the target tissue.

3.1.5 cryoadhesion—cryotip attachment to target tissue.

3.1.22 worst case conditions—the maximum pressures or

3.1.6 cryogen—asubstanceusedtoobtainreducedtempera-

temperatures, or both, a cryosystem may encounter when used

tures. Cryogens are usually classed by their boiling points. The

according to the manufacturer’s instructions.

most common cryogens and their respective boiling points are

as follows: 4. Conformance

Cryogen Boiling Point at S.T.P., °C

4.1 Presently, this specification is voluntary and not man-

Freon 12 −29.8

dated by law. A manufacturer may label his product as

Freon 22 −49.8

Carbon Dioxide (CO ) −78.6 conforming to these standards only if the product indeed meets

Nitrous Oxide (N O) −88.5

the requirements of this specification.

Liquid Nitrogen (LN ) −195.8

5. Cryosystem Performance and Reproducibility

3.1.7 cryometer—a device for measuring low tempera-

Requirements

ture(s) when used with a temperature sensor such as a

thermocouple. 5.1 The purpose of these requirements is to ensure that a

3.1.8 cryonecrosis—destruction of tissue cells using a cryo-

cryosystem of the same design or accessories, or both, shall

system. meet the minimum performance and reproducibility require-

3.1.9 cryoprobe—theinstrumentusedtodeliverthecryogen

ments as originally designed. The cryosystem and accessory

to the cryotip or open tip. For a cryotip, a cryoprobe also requirements shall not vary from procedure to procedure

directs the cryogen away from the target tissue.

provided they are used and maintained according to the

3.1.10 cryosystem—all parts of a system excluding the manufacturer’s recommendations.

cryogen and its container, unless supplied by the manufacturer,

5.2 Closed Cryotip Temperature Reproducibility:

that is designed to apply or use a cryogen. 5.2.1 Cryosystem requirements are divided into three pri-

3.1.11 defrost—the ability to return the cryotip to ambient mary categories in accordance with their clinical application:

temperature.

cryonecrosis, inflammatory response, and cryoadhesion. The

3.1.12 Dewar—a vacuum insulated container that is specifi- manufacturer’s test procedures must be categorized into these

cally designed to store a liquid cryogen.

groups and tested accordingly.

5.2.2 All cryosystems manufactured with closed cryotips of

the same model, temperature sensing or nontemperature sens-

ing, shall meet the requirements of Table 1.

Available from the International Electro-Technical Commission (IEC), Com-

5.2.3 Test Method—See Section 11.

mittee 62D, Rue de Varembe, CH-1211, NIOSH, Geneva 20, Switzerland.

5.3 Closed Cryotip Tractive Force:

Available from the Compressed Gas Association, 500 Fifth Ave., New York,

NY 10036.

5.3.1 All cryosystems specifically designed for cryoadhe-

Available from the Food and Drug Administration (FDA), Bureau of Medical

sion shall be capable of attaching to, lifting, and holding a

Devices, 8757 Georgia Ave., Silver Spring, MD 20910.

minimum weight of 60 g for a minimum of 45 s.

Available from the National Bureau of Standards-Monograph 125, Gaithers-

burg, MD 10877. 5.3.2 Test Method—See Section 12.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

F 882 – 84 (1996)

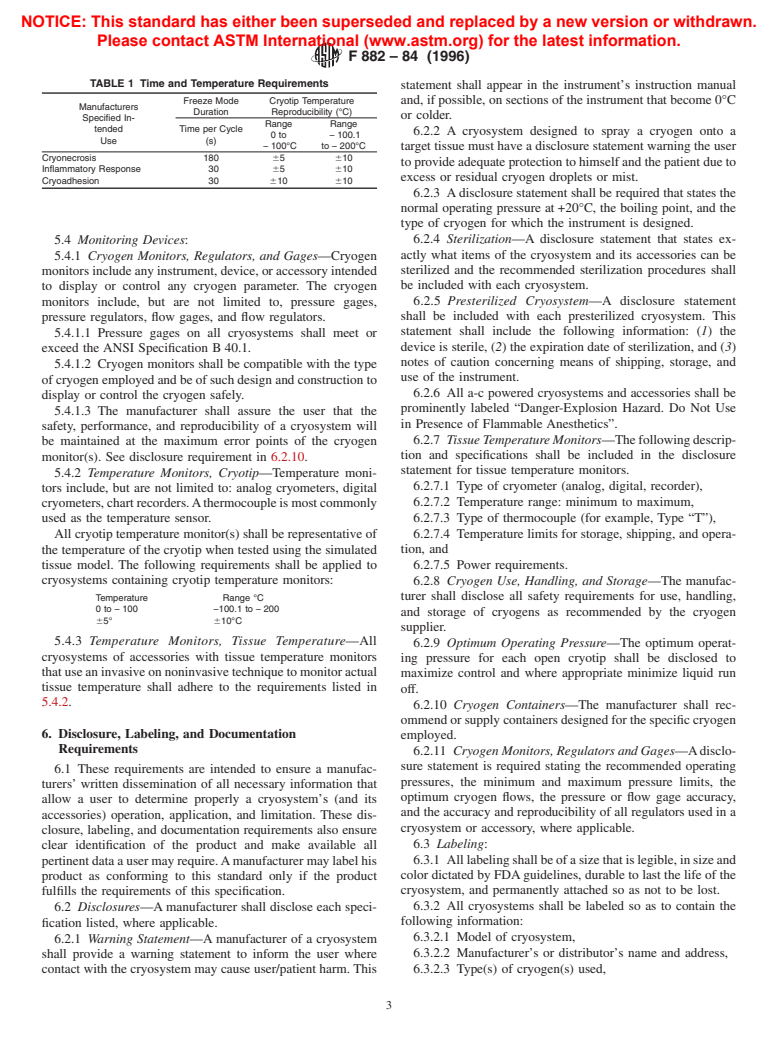

TABLE 1 Time and Temperature Requirements

statement shall appear in the instrument’s instruction manual

Freeze Mode Cryotip Temperature and, if possible, on sections of the instrument that become 0°C

Manufacturers

Duration Reproducibility (°C)

or colder.

Specified In-

Range Range

tended Time per Cycle

6.2.2 A cryosystem designed to spray a cryogen onto a

0to − 100.1

Use (s)

− 100°C to − 200°C

target tissue must have a disclosure statement warning the user

Cryonecrosis 180 65 610

to provide adequate protection to himself and the patient due to

Inflammatory Response 30 65 610

excess or residual cryogen droplets or mist.

Cryoadhesion 30 610 610

6.2.3 Adisclosure statement shall be required that states the

normal operating pressure at +20°C, the boiling point, and the

type of cryogen for which the instrument is designed.

6.2.4 Sterilization—A disclosure statement that states ex-

5.4 Monitoring Devices:

actly what items of the cryosystem and its accessories can be

5.4.1 Cryogen Monitors, Regulators, and Gages—Cryogen

sterilized and the recommended sterilization procedures shall

monitors include any instrument, device, or accessory intended

be included with each cryosystem.

to display or control any cryogen parameter. The cryogen

monitors include, but are not limited to, pressure gages, 6.2.5 Presterilized Cryosystem—A disclosure statement

shall be included with each presterilized cryosystem. This

pressure regulators, flow gages, and flow regulators.

statement shall include the following information: (1) the

5.4.1.1 Pressure gages on all cryosystems shall meet or

device is sterile, (2) the expiration date of sterilization, and (3)

exceed the ANSI Specification B 40.1.

notes of caution concerning means of shipping, storage, and

5.4.1.2 Cryogen monitors shall be compatible with the type

use of the instrument.

of cryogen employed and be of such design and construction to

6.2.6 All a-c powered cryosystems and accessories shall be

display or control the cryogen safely.

prominently labeled “Danger-Explosion Hazard. Do Not Use

5.4.1.3 The manufacturer shall assure the user that the

in Presence of Flammable Anesthetics”.

safety, performance, and reproducibility of a cryosystem will

6.2.7 TissueTemperatureMonitors—Thefollowingdescrip-

be maintained at the maximum error points of the cryogen

tion and specifications shall be included in the disclosure

monitor(s). See disclosure requirement in 6.2.10.

statement for tissue temperature monitors.

5.4.2 Temperature Monitors, Cryotip—Temperature moni-

6.2.7.1 Type of cryometer (analog, digital, recorder),

tors include, but are not limited to: analog cryometers, digital

6.2.7.2 Temperature range: minimum to maximum,

cryometers,chartrecorders.Athermocoupleismostcommonly

6.2.7.3 Type of thermocouple (for example, Type “T”),

used as the temperature sensor.

6.2.7.4 Temperature limits for storage, shipping, and opera-

All cryotip temperature monitor(s) shall be representative of

the temperature of the cryotip when tested using the simulated tion, and

tissue model. The following requirements shall be applied to 6.2.7.5 Power requirements.

cryosystems containing cryotip temperature monitors:

6.2.8 Cryogen Use, Handling, and Storage—The manufac-

turer shall disclose all safety requirements for use, handling,

Temperature Range °C

0 to − 100 −100.1 to − 200

and storage of cryogens as recommended by the cryogen

65° 610°C

supplier.

5.4.3 Temperature Monitors, Tissue Temperature—All

6.2.9 Optimum Operating Pressure—The optimum operat-

cryosystems of accessories with tissue temperature monitors

ing pressure for each open cryotip shall be disclosed to

thatuseaninvasiveonnoninvasivetechniquetomonitoractual

maximize control and where appropriate minimize liquid run

tissue temperature shall adhere to the requirements listed in

off.

5.4.2.

6.2.10 Cryogen Containers—The manufacturer shall rec-

ommendorsupplycontainersdesignedforthespecificcryogen

6. Disclosure, Labeling, and Documentation

employed.

Requirements

6.2.11 CryogenMonitors,RegulatorsandGages—Adisclo-

sure statement is required stating the recommended operating

6.1 These requirements are intended to ensure a manufac-

pressures, the minimum and maximum pressure limits, the

turers’ written dissemination of all necessary information that

optimum cryogen flows, the pressure or flow gage accuracy,

allow a user to determine properly a cryosystem’s (and its

and the accuracy and reproducibility of all regulators used in a

accessories) ope

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.