ASTM C1298-95(2001)

(Guide)Standard Guide for the Design and Construction of Brick Liners for Industrial Chimneys

Standard Guide for the Design and Construction of Brick Liners for Industrial Chimneys

SCOPE

1.1 This guide covers procedures for the design, construction, and serviceability of brick liners for industrial chimneys. The structural design criteria are applicable to vertical masonry cantilever structures supported only at their base, either by a foundation, a concrete pedestal, or by some means from the outer concrete shell. Excluded from direct consideration are single-wythe, sectional brick linings that are supported on a series of corbels cast in the outer chimney shell.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1298–95 (Reapproved 2001)

Standard Guide for

Design and Construction of Brick Liners for Industrial

Chimneys

This standard is issued under the fixed designation C 1298; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1991 Uniform Building Code, International Conference of

Building Code Officials, California

1.1 This guide covers procedures for the design, construc-

tion, and serviceability of brick liners for industrial chimneys.

3. Terminology

Thestructuraldesigncriteriaareapplicabletoverticalmasonry

3.1 Notations:

cantilever structures supported only at their base, either by a

foundation, a concrete pedestal, or by some means from the

a = brick dimension in radial direction (in.)

outer concrete shell. Excluded from direct consideration are

b = brick dimension in tangential direction (in.)

single-wythe, sectional brick linings that are supported on a

c = brick chamfer (in.)

series of corbels cast in the outer chimney shell. C = chimney deflection due to earthquake loads (in.)

e

d = outside diameter of brick liner (in.)

1.2 The values stated in inch-pound units are to be regarded

D = mean liner diameter at a given elevation (in.)

as the standard. The values given in parentheses are for

E = masonry modulus of elasticity as established by performing brick prism

m

information only. test or by past experience, psi

f = critical liner buckling stress, psi

b

1.3 This standard does not purport to address all of the

f = maximum vertical compressive stress due to dead load, psi

d

safety concerns, if any, associated with its use. It is the

f = maximum vertical compressive stress due to the combined effect of

de

earthquake and dead load, psi

responsibility of the user of this standard to establish appro-

f = maximum vertical compressive stress due to the combined effect of

dw

priate safety and health practices and determine the applica-

wind and dead load, psi

bility of regulatory limitations prior to use.

f = average ultimate masonry compressive strength established by perform-

m

ing brick prism test or by past experience, psi

2. Referenced Documents f = maximum shear stress due to wind or earthquake, psi

v

F.S. = factor of safety

2.1 ASTM Standards:

h = total liner height (ft)

C 395 Specification for Chemical-Resistant Resin Mortars h = height of liner above elevation being checked for buckling (ft)

e

L = liner deflection due to earthquake loads (in.)

e

C 466 Specification for Chemically Setting Silicate and

P = constructional out-of-plumbness of liner with respect to shell (in.)

Silica Chemical-Resistant Mortars

r = average mean radius of liner (ft)

C 980 Specification for Industrial Chimney Lining Brick S = shell deflection due to sun effect (in.)

T = liner deflection due to differential temperature effects (in.)

E 447 Test Methods for Compressive Strength of Masonry

t = wall thickness (in.)

Prisms

v = coefficient of variation in brick prism tests

W = shell deflection due to design wind loads (in.)

E 111 TestMethodforYoung’sModulus,TangentModulus,

−6

3 a = coefficient of thermal expansion for brick liner (use 3.5 3 10 unless

and Chord Modulus

otherwise established) (in./in./°F)

2.2 ACI Standard:

307–88 Practice for the Design and Construction of Cast- 4. Significance and Use

In-Place Reinforced Concrete Chimneys

4.1 History:

2.3 ASCE Standard:

4.1.1 For many years, brick liners have been used with an

ASCE 7-88 Minimum Design Loads for Buildings and

excellent record of performance. For the most part, however,

Other Structures (Formerly ANSI A58.1)

the design and construction of brick liners has been based on

2.4 Other Standard:

past industry practice due to the lack of available information

and knowledge of the physical properties of the brick and

mortar, the thermal and seismic behavior of brick liners, and

This guide is under the jurisdiction ofASTM Committee C15 on Manufactured

many related characteristics that were not properly or accu-

Masonry Units and is the direct responsibility of Subcommittee C15.05 on Masonry

rately defined.

Assemblies.

Current edition approved June 15, 1995. Published August 1995.

Annual Book of ASTM Standards, Vol 04.05.

Annual Book of ASTM Standards, Vol 03.01.

4 5

Available from American Concrete Institute, P.O. Box 19150, Detroit, MI Available from International Conference of Building Officials, 5360 South

48219. Workman Mill Road, Whittier, CA 90601.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1298–95 (2001)

4.1.2 The use of scrubbers, which lower gas temperatures 5.3.1 Unless specific application requirements dictate oth-

and introduce highly corrosive condensates into the flue gas erwise, mortar should conform to the requirements of one of

system, requires many new design considerations. The effect the brick types listed herein.

that scrubbers have on brick liners is an ongoing area of study, 5.3.1.1 Specification C 466—These widely-used mortars

exhibit excellent resistance to most acids (except hydrofluoric

since a number of liners have experienced growth- and

deflection-related problems which may be attributable, at least acid), water, solvents, and temperatures to 1200°F. These

mortars are also resistant to intermittent exposure to mild

in part, to nonuniform temperature and moisture conditions

within the liners. alkalies, but their primary capability is resisting the strong

acids commonly found in fossil-fuel flue gas environments.

4.2 Purpose—The recommendations contained herein rep-

5.3.1.2 Specification C 395—Organic resin-type mortars

resent current industry practices and serve to define the

(such as Furan mortar) have been used in brick chimney liners,

pertinent considerations that should be followed in the design

mainly due to their capacity to resist a wider variety of

and construction of brick chimney liners.

chemicals than inorganic mortars. Generally suitable for use

over a wider pH range, they resist non-oxidizing acids,

5. Materials

alkalies, salts, water, and temperatures to 350°F.

5.1 General—The selection of suitable liner materials,

5.3.1.3 High alumina cement (HAC) mortars, while not

those capable of resisting the environment to which they will

generally used in brick chimney linings, also are available.

be exposed, should be based on an evaluation of the unique

They are usually used in conjunction with heat-resistive

operating conditions that exist in each application.Although it

aggregatesandmaybesuitableforsomechimneyapplications.

is not the intent to restrict the applicability of this guide, and

5.3.2 It is important to recognize that the selection of the

while other materials may be appropriate in some applications,

proper mortar is essential to successful functioning of a brick

the chemical-resistant brick and mortar standards set forth in

liner.Thevarioustypesofchemical-resistantmortarsshouldbe

5.2 and 5.3 define the type of materials used in the majority of

evaluated to determine which is the most suitable for a given

brick liners that are specified, designed, and erected today.All

application and set of operating conditions.

portionsofthisguidereflecttestdata,designrequirements,and

5.4 Appurtenances—Due to the availability of a wide vari-

other practices as they relate to these materials. The provisions

ety of metallic materials and the great variations in the flue gas

of this guide should be carefully reviewed for applicability if

conditions to which materials are exposed, it is beyond the

other materials are specified or used. Due to a greater knowl-

scope of this document to make recommendations regarding

edge of overall plant operation, material capabilities, and the

the suitability of materials for liner appurtenances such as

flue gas environment, the owner’s technical representative

breeching ducts, bands, lintels, buckstays, hoods, caps, and

should be responsible for selecting all liner materials.

doors. The selection of these materials can be made only by

evaluating the specific factors and conditions that exist on each

5.2 Brick:

individual project. One must evaluate the operating environ-

5.2.1 Unless the specific application precludes their use,

ment, projected maintenance requirements, and other such

brick conforming to the requirements of Specification C 980

technical and economic evaluation factors commonly associ-

should be used. Specification C 980 covers solid kiln-fired

ated with the process of material selection.

brick made of clay, shale, or mixtures thereof.

5.5 Field Testing—If it is determined that field testing is

5.2.2 Three types of brick are defined in Specification

required for a particular project, the test methods and accep-

C 980: Types I, II, and III. By definition, the brick types vary,

tance criteria should be agreed upon mutually by the material

respectively, in decreasing degrees of absorption and acid

manufacturers, the contractor, and the owner’s technical rep-

solubility. These bricks generally are resistant to all acids and

resentative. Certification that the materials shipped for use on

alkalies (with the exception of acid fluorides and strong, hot

the project conform to the requirements of their respective

caustics). Types I, II, and III brick safely will withstand

ASTM specifications should be obtained from the manufac-

continuoustemperaturesupto750°F.Generally,thebrickswill

turer.

withstand short-term exposure to temperatures in excess of

750°F, but the capability of the bricks to resist higher tempera-

6. Construction Requirements

tures should be studied case by case. The selection of the brick

6.1 Handling and Storage of Materials:

type and the potential need for testing beyond the requirements

6.1.1 Brick pallets and the individual brick units should be

of Specification C 980 should be determined on an individual

handledaslittleaspossibletoreducethelikelihoodofcracking

project basis.

and chipping. While it is obviously beneficial to keep the

5.2.3 Specification C 980 brick Types I and II generally are

amount of chipping and cracking to a minimum, no criteria

available from any manufacturer who makes double-sized,

currently exist to evaluate what constitutes acceptability.

kiln-fired, solid brick for corrosion-resistant applications. The

Therefore, if deemed necessary, the specifier should include

stringent requirements for Type III brick, however, make it

acceptance criteria in the project specification. Cracking is not

more difficult and expensive to manufacture. Consequently,

always evident, and pallets suspected of containing cracked

availability of Type III brick is limited; therefore, before

brick should be checked closely by removing individual

specifying Type III brick, determine both the necessity of its

samples. Badly damaged or cracked brick should not be used.

use and its availability.

6.1.2 Mortar and brick should be kept dry and free from

5.3 Mortar: frost during construction. Heated storage sheds should be used

C1298–95 (2001)

when the ambient temperature during construction is below in handling, mixing, and setting characteristics immediately

40°F (4°C) unless otherwise recommended by the manufactur- should be brought to the attention of the manufacturer.

ers of the brick or mortar.

6.4.3 The working time for a chemically-setting mortar is

6.2 Brick Sizing: short compared to that for a portland cement mortar. Only

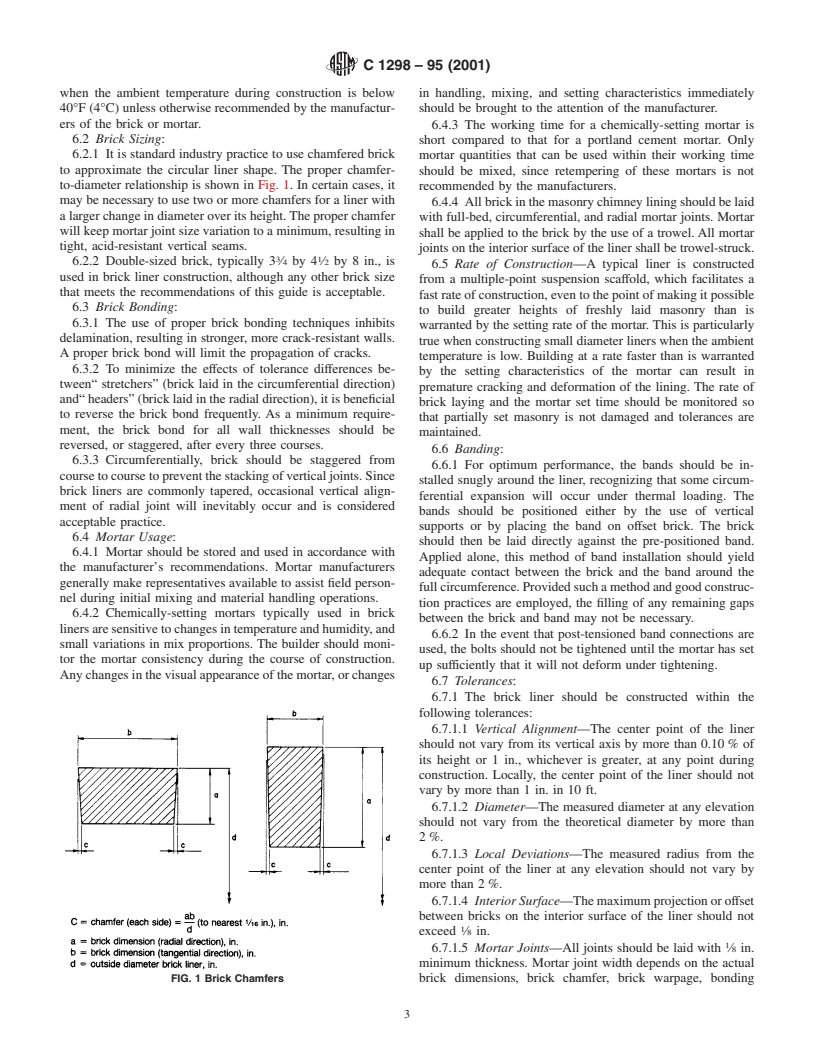

6.2.1 It is standard industry practice to use chamfered brick

mortar quantities that can be used within their working time

to approximate the circular liner shape. The proper chamfer- should be mixed, since retempering of these mortars is not

to-diameter relationship is shown in Fig. 1. In certain cases, it

recommended by the manufacturers.

may be necessary to use two or more chamfers for a liner with

6.4.4 Allbrickinthemasonrychimneyliningshouldbelaid

a larger change in diameter over its height.The proper chamfer

with full-bed, circumferential, and radial mortar joints. Mortar

will keep mortar joint size variation to a minimum, resulting in

shall be applied to the brick by the use of a trowel. All mortar

tight, acid-resistant vertical seams.

joints on the interior surface of the liner shall be trowel-struck.

3 1

6.2.2 Double-sized brick, typically 3 ⁄4 by 4 ⁄2 by 8 in., is

6.5 Rate of Construction—A typical liner is constructed

used in brick liner construction, although any other brick size

from a multiple-point suspension scaffold, which facilitates a

that meets the recommendations of this guide is acceptable.

fast rate of construction, even to the point of making it possible

6.3 Brick Bonding:

to build greater heights of freshly laid masonry than is

6.3.1 The use of proper brick bonding techniques inhibits

warranted by the setting rate of the mortar. This is particularly

delamination, resulting in stronger, more crack-resistant walls.

true when constructing small diameter liners when the ambient

A proper brick bond will limit the propagation of cracks.

temperature is low. Building at a rate faster than is warranted

6.3.2 To minimize the effects of tolerance differences be-

by the setting characteristics of the mortar can result in

tween“ stretchers” (brick laid in the circumferential direction)

premature cracking and deformation of the lining. The rate of

and“ headers” (brick laid in the radial direction), it is beneficial

brick laying and the mortar set time should be monitored so

to reverse the brick bond frequently. As a minimum require-

that partially set masonry is not damaged and tolerances are

ment, the brick bond for all wall thicknesses should be

maintained.

reversed, or staggered, after every three courses.

6.6 Banding:

6.3.3 Circumferentially, brick should be staggered from

6.6.1 For optimum performance, the bands should be in-

coursetocoursetopreventthestackingofverticaljoints.Since

stalled snugly around the liner, recognizing that some circum-

brick liners are commonly tapered, occasional vertical align-

ferential expansion will occur under thermal loading. The

ment of radial joint will inevitably occur and is considered

bands should be positioned either by the use of vertical

acceptable practice.

supports or by placing the band on offset brick. The brick

6.4 Mortar Usage:

should then be laid directly against the pre-positioned band.

6.4.1 Mortar should be stored and used in accordance with

Applied alone, this method of band installation should yield

the manufacturer’s recommendations. Mortar manufacturers

adequate contact between the brick and the band around the

genera

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.