ASTM F641-98a

(Specification)Standard Specification for Implantable Epoxy Electronic Encapsulants

Standard Specification for Implantable Epoxy Electronic Encapsulants

SCOPE

1.1 This specification covers thermoset plastics based on diglycidyl ethers of bisphenol A and amino functional curing agents or amine catalysts.

1.2 The epoxy encapsulants covered by this specification are intended to provide a tissue-compatible protective covering for implantable medical devices such as pulse generators, telemetry devices and RF receivers. The biocompatibility of epoxy plastics has not been established. Epoxy plastic is a generic term relating to the class of polymers formed from epoxy resins, certain curing agents or catalysts and various additives. Since many compositions and formulations fall under this category, it is essential that the fabricator assure safety of implantability of the specific composition or formulation for the intended use by current state-of-the-art test methods. This specification can be used as a basis for standardized evaluation of biocompatibility for such implantable encapsulants.

1.3 The encapsulants covered by this specification are for use in devices intended as long-term implants.

1.4 Limitations- This specification covers only the initial qualification of epoxy encapsulants for implantable electronic circuitry. Some of the requirements are not applicable to routine lot to lot quality control.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 641 – 98a

Standard Specification for

Implantable Epoxy Electronic Encapsulants

This standard is issued under the fixed designation F 641; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 150 Test Methods for A-C Loss Characteristics and

Permittivity (Dielectric Constant) of Solid Electrical Insu-

1.1 This specification covers thermoset plastics based on

lating Materials

diglycidyl ethers of bisphenol A and amino functional curing

D 257 Test Methods for D-C Resistance or Conductance of

agents or amine catalysts.

Insulating Materials

1.2 The epoxy encapsulants covered by this specification

D 570 Test Method for Water Absorption of Plastics

are intended to provide a tissue-compatible protective covering

D 638 Test Method for Tensile Properties of Plastics

for implantable medical devices such as pulse generators,

D 790 Test Methods for Flexural Properties of Unreinforced

telemetry devices and RF receivers. The biocompatibility of

and Reinforced Plastics and Electrical Insulating Materi-

epoxy plastics has not been established. Epoxy plastic is a

als

generic term relating to the class of polymers formed from

D 883 Terminology Relating to Plastics

epoxy resins, certain curing agents or catalysts and various

D 1042 Test Method for Linear Dimensional Changes of

additives. Since many compositions and formulations fall

Plastics Under Accelerated Service Conditions

under this category, it is essential that the fabricator assure

D 1239 Test Method for Resistance of Plastic Films to

safety of implantability of the specific composition or formu-

Extraction by Chemicals

lation for the intended use by current state-of-the-art test

D 1434 Test Method for Determining Gas Permeability

methods. This specification can be used as a basis for stan-

Characteristics of Plastic Film and Sheeting

dardized evaluation of biocompatibility for such implantable

D 1763 Specification for Epoxy Resins

encapsulants.

D 1898 Practice for Sampling of Plastics

1.3 The encapsulants covered by this specification are for

D 2240 Test Method for Rubber Property—Durometer

use in devices intended as long-term implants.

Hardness

1.4 Limitations—This specification covers only the initial

D 2471 Test Method for Gel Time and Peak Exothermic

qualification of epoxy encapsulants for implantable electronic

Temperature of Reacting Thermosetting Resins

circuitry. Some of the requirements are not applicable to

D 2562 Practice for Classifying Visual Defects in Parts

routine lot to lot quality control.

Molded from Reinforced Thermosetting Plastics

1.5 This standard does not purport to address all of the

D 2566 Test Method for Linear Shrinkage of Cured Ther-

safety concerns, if any, associated with its use. It is the

mosetting Casting Resins During Cure

responsibility of the user of this standard to establish appro-

D 2734 Test Method for Void Content of Reinforced Plas-

priate safety and health practices and determine the applica-

tics

bility of regulatory limitations prior to use.

D 3137 Test Method for Rubber Property—Hydrolytic Sta-

2. Referenced Documents

bility

F 74 Practice for Determining Hydrolytic Stability of Plas-

2.1 ASTM Standards:

tic Encapsulants for Electronic Devices

D 149 Test Method for Dielectric Breakdown Voltage and

F 135 Test Method for Embedment Stress Caused by Cast-

Dielectric Strength of Solid Electrical Insulating Materials

ing Compounds on Glass-Encased Electronic Components

at Commercial Power Frequencies

F 602 Criteria for Implantable Thermoset Epoxy Plastics

1 3

This specification is under the jurisdiction of ASTM Committee F-4 on Medical Annual Book of ASTM Standards, Vol 08.01.

and Surgical Materials and Devices and is the direct responsibility of Subcommittee Annual Book of ASTM Standards, Vol 15.09.

F04.11 on Polymeric Materials. Annual Book of ASTM Standards, Vol 09.01.

Current edition approved October 10, 1998. Published March 1999. Originally Annual Book of ASTM Standards, Vol 08.02.

published as F 641 – 79. Last previous edition F 641 – 98. Annual Book of ASTM Standards, Vol 10.04.

2 8

Annual Book of ASTM Standards, Vol 10.01. Annual Book of ASTM Standards, Vol 13.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 641 – 98a

F 748 Practice For Selecting Generic Biological Test Meth- 5.1.2 Fully Cured Specimens—The required properties

ods for Materials and Devices measured on fully cured specimens conditioned as in 6.1 are as

F 895 Test Method for Agar Diffusion Cell Culture Screen- follows:

ing for Cytotoxicity 5.1.2.1 Transparency—In cases where no fillers or rein-

F 981 Practice for Assessment of Compatibility of Bioma- forcements are used, the encapsulant shall have sufficient

terials for Surgical Implants with Respect to Effect of transparency so that the circuitry may be visually inspected

Materials on Muscle and Bone after encapsulation.

2.2 AAMI Standard: 5.1.2.2 Foreign Particles—No foreign particles, particulate

EOS-D E-O Sterilization Standard matter and gross contamination shall be observed when

checked under 23 wide field magnification.

3. Classification 5.1.2.3 USP Biological Tests Plastic Containers, Class

IV —Pass.

3.1 Encapsulants shall be classified as follows:

5.1.2.4 USP Pyrogen Test or other Pyrogen methods

3.1.1 Type I—Those encapsulants which contact the tissue

which have been demonstrated to be of equal or greater

directly or indirectly.

sensitivity—Pass.

3.1.2 Type II—Those encapsulants used only within her-

5.1.2.5 Sterilant Residues (AAMI EOS-D)—Where appli-

metically sealed containers. The epoxy encapsulant has no

cable, the concentration of ethylene oxide, ethylene chlorohy-

contact with tissues or physiological fluids.

drin, ethylene glycol, and dichlorodifluoromethane (or the

equivalents) at the time of implant shall be shown to be within

4. Chemical Composition

safe limits prescribed by the device manufacturer.

4.1 Additives (Type I Encapsulants Only):

5.1.2.6 The cure shrinkage (Test Method D 2566) or em-

4.1.1 Reactive Diluents—The following compounds when

bedment stress (Test Method F 135) shall be #2%. The stress

used as reactive diluents shall not be used in concentrations

shall not exceed the limits of the most pressure-sensitive

greater than 12 parts per hundred resin (phr).

components.

4.1.1.1 Butyl glycidyl ether (BGE).

5.1.2.7 Tissue Culture Test (Agar Overlay) or Test Method

4.1.1.2 Phenyl glycidyl ether (PGE).

F 895—Pass.

4.1.2 Other Additives (see Note 1)—Other additives shall be

5.1.2.8 While cell culture methods as described in Test

shown to be nonextractable in 37°C physiological saline for the

Method F 895 may be appropriated for the batch-to-batch

device design life in concentrations sufficient to significantly

screening of fully cured specimens, the basic recipe used

affect the properties of the encapsulant or to produce a

should have been qualified for its overall tissue response by

significant biological reaction.

methods such as those suggested in Practice F 748 for “Im-

NOTE 1—Other additives, as indicated in Criteria F 602, include planted Devices Principally Contacting Tissue and Tissue

compounds such as nonreactive diluents, fillers, release agents, and the

Fluid” including testing according to Practice F 981.

like.

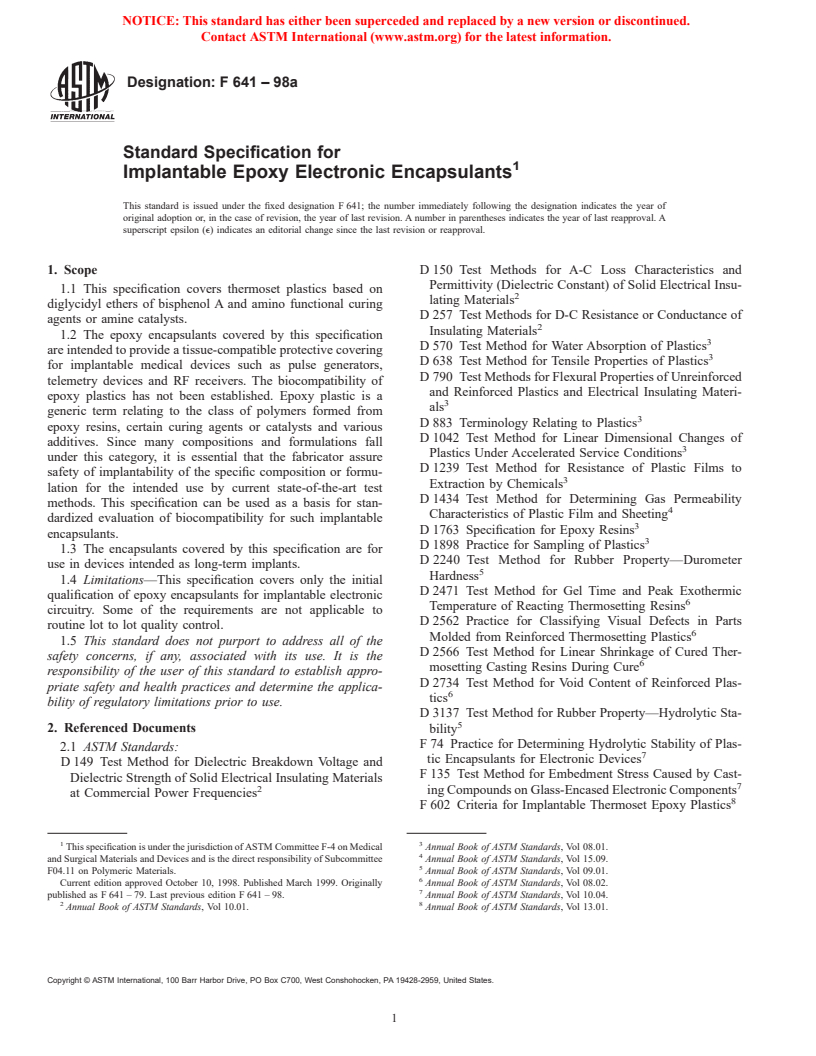

5.1.3 Required Cured Properties Measured in Long-Term

Immersion Tests for Type I Encapsulants—The property values

4.1.3 Phthalate Esters—Phthalate esters such as dibutyl

phthalate shall not be used in concentrations $10 phr. prescribed in Table 1 shall be obtained at 22 6 3°C and 50 6

10 % relative humidity on specimens conditioned as in 6.3.

4.2 Mix Ratios (Type I and Type II Encapsulants):

4.2.1 Amines—The mix ratio shall be maintained at 65 Samples shall be wiped dry prior to test with a lint-free tissue,

as appropriate.

equivalent % of stoichiometry.

5.1.4 Optional cured properties measured after accelerated

4.2.2 Catalysts—The mix ratio shall be maintained within

immersion for Type I encapsulants may be determined for

the ranges recommended by the formulator.

screening purposes after conditioning as in 6.2.

4.3 Carbonates (Type I and Type II Encapsulants)—The

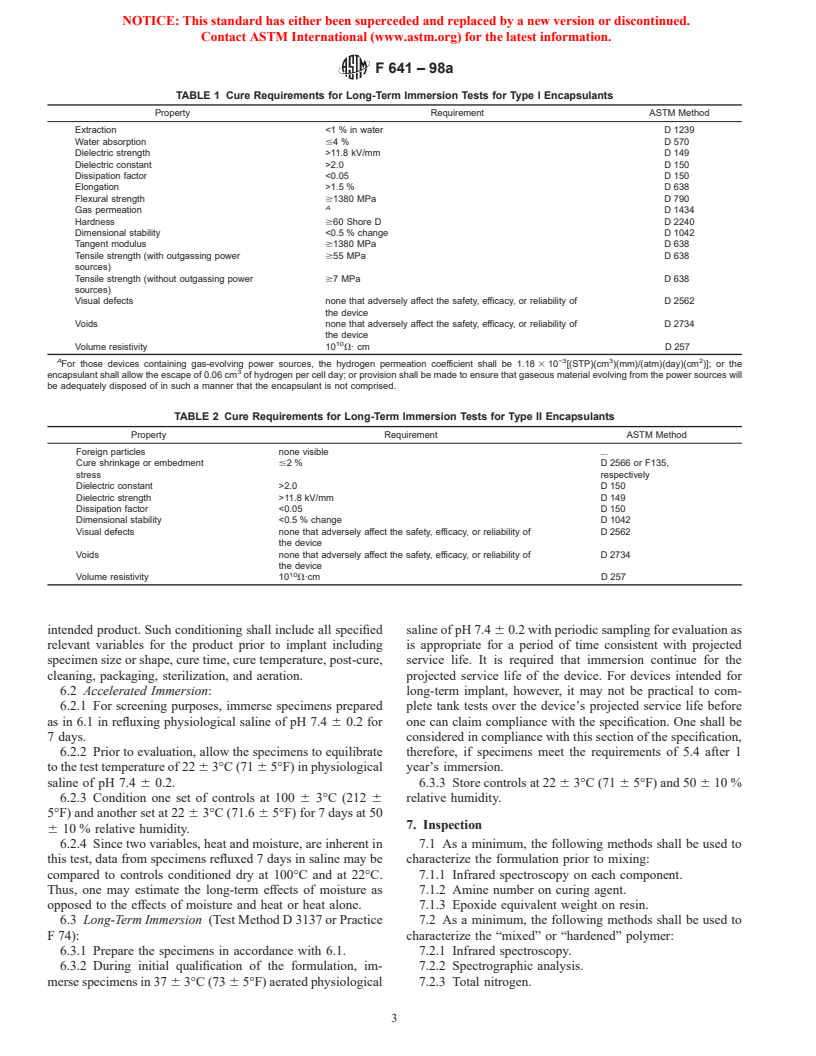

5.2 Type II Encapsulants:

encapsulant shall be poured under conditions such that the

5.2.1 Peak Exotherm Temperature (Test Method D 2471)—

formation of amine carbonates is minimized. The device

The peak exotherm temperature during cure shall be kept

manufacturer may specify maximum limits of carbon dioxide

below the maximum acceptable value for the lowest tempera-

or water vapor, or both, in the atmosphe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.