ASTM C943-96

(Practice)Standard Practice for Making Test Cylinders and Prisms for Determining Strength and Density of Preplaced-Aggregate Concrete in the Laboratory

Standard Practice for Making Test Cylinders and Prisms for Determining Strength and Density of Preplaced-Aggregate Concrete in the Laboratory

SCOPE

1.1 This practice covers procedures for making standard test cylinders used to determine the compressive strength and density of preplaced-aggregate (PA) concrete.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 943 – 96

Standard Practice for

Making Test Cylinders and Prisms for Determining

Strength and Density of Preplaced-Aggregate Concrete

in the Laboratory

This standard is issued under the fixed designation C 943; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This practice covers procedures for making standard test 4.1 This practice is used for making test cylinders or prisms

cylinders used to determine the compressive strength and of PA concrete. Cylinders are used for determining compres-

density of preplaced-aggregate (PA) concrete. sive strength and approximate density. Prisms, cut from cylin-

1.2 The values stated in SI units are to be regarded as ders, eliminate the surface effect and thus more accurately

standard. represent the actual density of PA concrete in place.

1.3 This standard does not purport to address all of the

5. Apparatus

safety concerns, if any, associated with its use. It is the

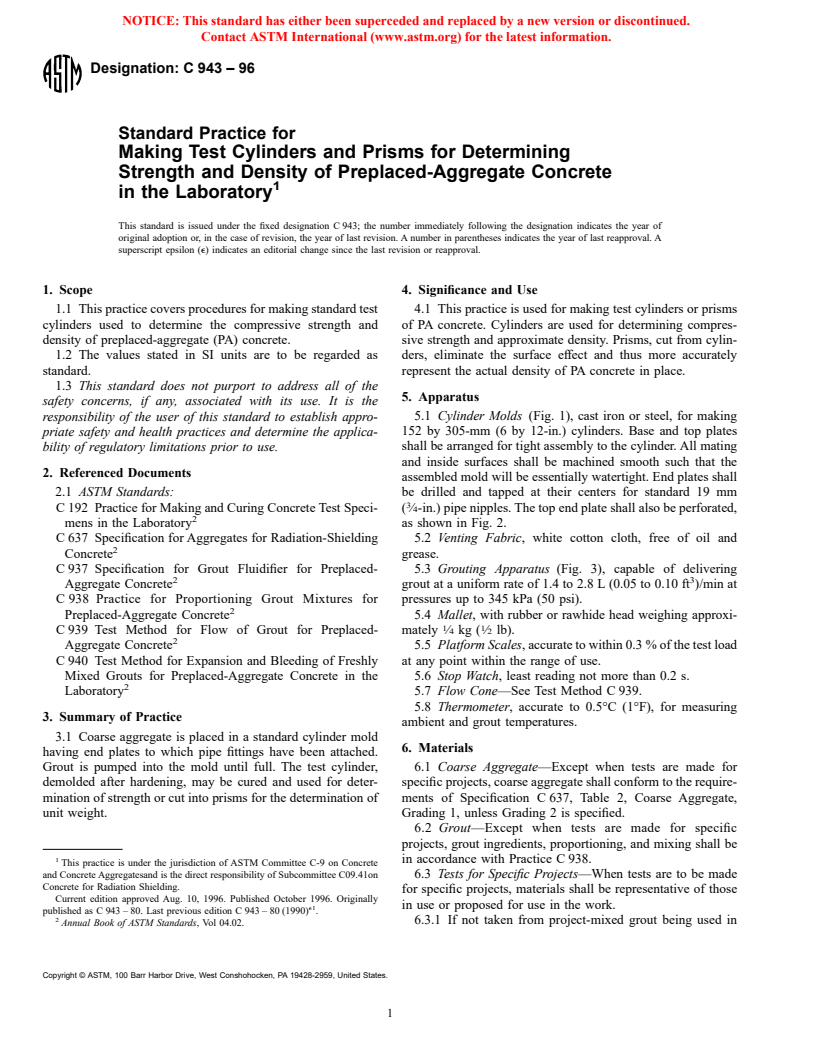

5.1 Cylinder Molds (Fig. 1), cast iron or steel, for making

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 152 by 305-mm (6 by 12-in.) cylinders. Base and top plates

shall be arranged for tight assembly to the cylinder. All mating

bility of regulatory limitations prior to use.

and inside surfaces shall be machined smooth such that the

2. Referenced Documents

assembled mold will be essentially watertight. End plates shall

2.1 ASTM Standards: be drilled and tapped at their centers for standard 19 mm

C 192 Practice for Making and Curing Concrete Test Speci- ( ⁄4-in.) pipe nipples. The top end plate shall also be perforated,

mens in the Laboratory as shown in Fig. 2.

C 637 Specification for Aggregates for Radiation-Shielding 5.2 Venting Fabric, white cotton cloth, free of oil and

Concrete grease.

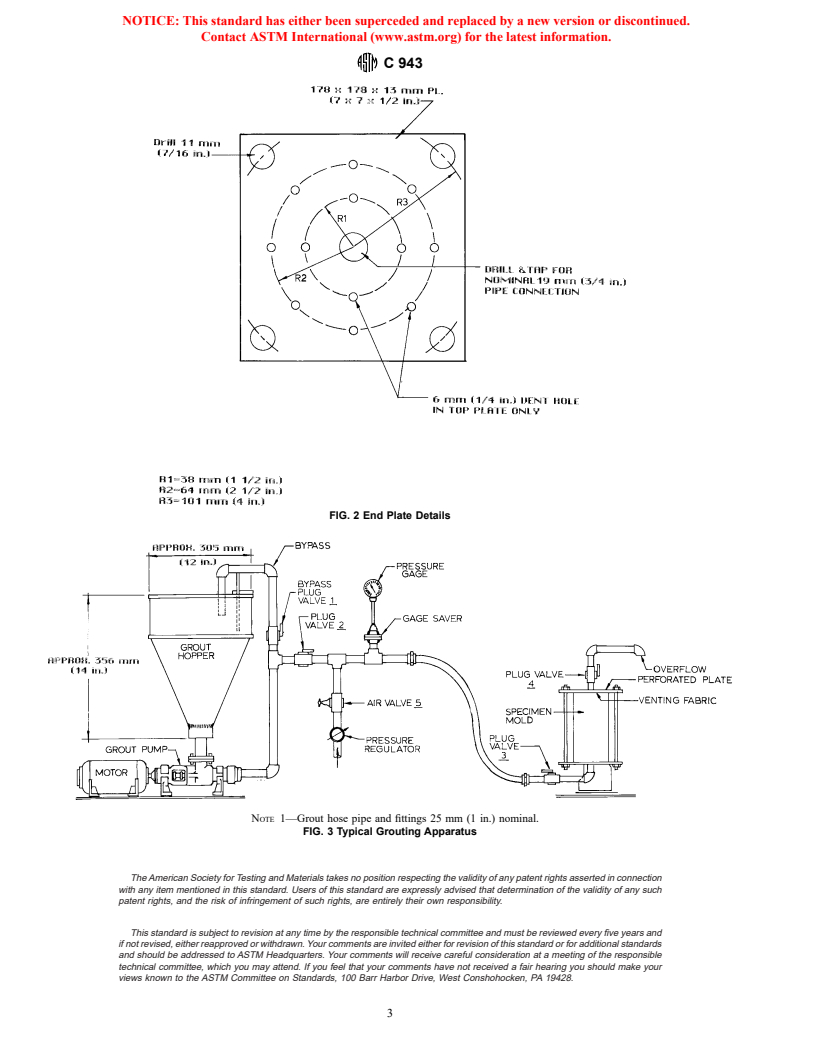

C 937 Specification for Grout Fluidifier for Preplaced- 5.3 Grouting Apparatus (Fig. 3), capable of delivering

Aggregate Concrete grout at a uniform rate of 1.4 to 2.8 L (0.05 to 0.10 ft )/min at

C 938 Practice for Proportioning Grout Mixtures for pressures up to 345 kPa (50 psi).

Preplaced-Aggregate Concrete 5.4 Mallet, with rubber or rawhide head weighing approxi-

1 1

C 939 Test Method for Flow of Grout for Preplaced- mately ⁄4 kg ( ⁄2 lb).

Aggregate Concrete 5.5 Platform Scales, accurate to within 0.3 % of the test load

C 940 Test Method for Expansion and Bleeding of Freshly at any point within the range of use.

Mixed Grouts for Preplaced-Aggregate Concrete in the 5.6 Stop Watch, least reading not more than 0.2 s.

Laboratory 5.7 Flow Cone—See Test Method C 939.

5.8 Thermometer, accurate to 0.5°C (1°F), for measuring

3. Summary of Practice

ambient and grout temperatures.

3.1 Coarse aggregate is placed in a standard cylinder mold

6. Materials

having end plates to which pipe fittings have been attached.

Grout is pumped into the mold until full. The test cylinder, 6.1 Coarse Aggregate—Except when tests are made for

demolded after hardening, may be cured and used for deter- specific projects, coarse aggregate shall conform to the require-

mination of strength or cut into prisms for the determination of ments of Specification C 637, Table 2, Coarse Aggregate,

unit weight. Grading 1, unless Grading 2 is specified.

6.2 Grout—Except when tests are made for specific

projects, grout ingredients, proportioning, and mixing shall be

in accordance with Practice C 938.

This practice is under the jurisdiction of ASTM Committee C-9 on Concrete

and Concrete Aggregatesand is the direct responsibility of Subcommittee C09.41on 6.3 Tests for Specific Projects—When tests are to be made

Concrete for Radiation Shielding.

for specific projects, materials shall be representative of those

Current edition approved Aug. 10, 1996. Published October 1996. Originally

in use or proposed for use in the work.

e1

published as C 943 – 80. Last previous edition C 943 – 80 (1990) .

6.3.1 If not taken from project-mixed grout being used in

Annual Book of ASTM Standards, Vol 04.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 943

plate, over the aggregate. Place the top plate on the mold,

install bolts, and tighten. Attach the top and bottom valve

assemblies and prepare to connect to hose from grout pump, as

shown in Fig. 3.

9.5 Measure flow (Test Method C 939) and temperature of

the representative sample of grout. Pour 800 6 10 mL into a

1000-mL graduate for observation of expansion and bleeding,

Test Method C 940.

9.6 If grout consistency is satisfactory, charge grout hopper

and pump to waste until all water and diluted grout in the pump

system has been expelled. Divert the grout flow to recirculation

(to hopper) and make the connection to the bottom of the

cylinder mold at valve 3, shown in Fig. 3.

9.7 With valves 2, 3, and 4 open, fill the cylinder slowly by

partially closing bypass valve 1. When grout flows freely

through upper plug valve 4, open bypass and close valves 2 and

4. Apply 70 to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.