ASTM B317-00

(Specification)Standard Specification for Aluminum-Alloy Extruded Bar, Rod, Tube, Pipe, and Structural Profiles for Electrical Purposes (Bus Conductor)

Standard Specification for Aluminum-Alloy Extruded Bar, Rod, Tube, Pipe, and Structural Profiles for Electrical Purposes (Bus Conductor)

SCOPE

1.1 This specification covers 6101 aluminum-alloy extruded bar, rod, tube, pipe (Schedules 40 and 80), and structural profiles (channels and angles) in selected tempers for use as electric conductors as follows:

1.1.1 Type B -Hot-finished bar, rod, tube, pipe and structural profiles in T6, T61, T63, T64, T65, and H111 tempers with Type B tolerances, as shown in the "List of ANSI Tables of Dimensional Tolerances."

1.1.2 Type C -Hot-finished rectangular bar in T6, T61, T63, T64, T65, and H111 tempers with Type C tolerances as listed in the tolerances and permissible variations tables.

1.2 Alloy and temper designations are in accordance with ANSI H35.1. The equivalent Unified Numbering System alloy designation in accordance with Practice E527 is A96101 for Alloy 6101. Note 1-Type A material, last covered in the 1966 issue of this specification, is no longer available; therefore, requirements for cold-finished rectangular bar have been deleted.

1.3 For acceptance criteria for inclusion of new aluminum and aluminum alloys in this specification, see Annex A2.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 317 – 00

Standard Specification for

Aluminum-Alloy Extruded Bar, Rod, Tube, Pipe, and

Structural Profiles for Electrical Purposes (Bus Conductor)

This standard is issued under the fixed designation B 317; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope * Aluminum- and Magnesium-Alloy Products

B 597 Practice for Heat Treatment of Aluminum Alloys

1.1 This specification covers 6101 aluminum-alloy extruded

B 660 Practices for Packaging/Packing of Aluminum and

bar, rod, tube, pipe (Schedules 40 and 80), and structural

Magnesium Products

profiles (channels and angles) in selected tempers for use as

B 666/B 666M Practice for Identification Marking of Alu-

electric conductors as follows:

minum Products

1.1.1 Type B—Hot-finished bar, rod, tube, pipe and struc-

B 807 Practice for Extrusion Press Solution Heat Treatment

tural profiles in T6, T61, T63, T64, T65, and H111 tempers

of Aluminum Alloys

with Type B tolerances, as shown in the “List of ANSI Tables

E 29 Practice for Using Significant Digits in Test Data to

of Dimensional Tolerances.”

Determine Conformance with Specifications

1.1.2 Type C—Hot-finished rectangular bar in T6, T61, T63,

E 34 Test Methods for Chemical Analysis of Aluminum and

T64, T65, and H111 tempers with Type C tolerances as listed

Aluminum Base Alloys

in the tolerances and permissible variations tables.

E 55 Practice for Sampling Wrought Nonferrous Metals and

1.2 Alloy and temper designations are in accordance with

Alloys for Determination of Chemical Composition

ANSI H35.1. The equivalent Unified Numbering System alloy

E 227 Test Method for Optical Emission Spectrometric

designation in accordance with Practice E 527 is A96101 for

Analysis of Aluminum and Aluminum Alloys by the

Alloy 6101.

Point-to-Plane Technique

NOTE 1—Type A material, last covered in the 1966 issue of this

E 290 Test Method for Semi-Guided Bend Test for Ductility

specification, is no longer available; therefore, requirements for cold-

of Metallic Materials

finished rectangular bar have been deleted.

E 527 Practice for Numbering Metals and Alloys (UNS)

1.3 For acceptance criteria for inclusion of new aluminum

E 607 Test Method for Optical Emission Spectrometric

and aluminum alloys in this specification, see Annex A2.

Analysis of Aluminum and Aluminum Alloys by the

1.4 The values stated in inch-pound units are to be regarded

Point-to-Plane Technique, Nitrogen Atmosphere

as the standard. The values given in parentheses are for

E 716 Practices for Sampling Aluminum and Aluminum

information only.

Alloys for Spectrochemical Analysis

E 1004 Test Method for Electromagnetic (Eddy-Current)

2. Referenced Documents

Measurements of Electrical Conductivity

2.1 The following documents of the issue in effect on the

E 1251 Test Method for Optical Emission Spectrometric

date of material purchase form a part of this specification to the

Analysis of Aluminum and Aluminum Alloys by the Argon

extent referenced herein:

Atmosphere, Point-to-Plane, Unipolar Self-Initiating Ca-

2.2 ASTM Standards: 9

pacitor Discharge

B 193 Test Method for Resistivity of Electrical Conductor 4

2.3 ANSI Standards:

Materials

H35.1 Alloy and Temper Designation Systems for Alumi-

B 253 Guide for Preparation of Aluminum Alloys for Elec-

num

troplating

H35.2 Dimensional Tolerances for Aluminum Mill Products

B 557 Test Methods of Tension Testing Wrought and Cast

1 4

This specification is under the jurisdiction of ASTM Committee B07 on Light Annual Book of ASTM Standards, Vol 02.02.

Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on Annual Book of ASTM Standards, Vol 14.02.

Aluminum-Alloy Wrought Products. Annual Book of ASTM Standards, Vol 03.05.

Current edition approved May 10, 2000. Published August 2000. Originally Annual Book of ASTM Standards, Vol 03.01.

published as B 317–57 T. Last previous edition B 317–96. Annual Book of ASTM Standards, Vol 01.01.

2 9

Annual Book of ASTM Standards, Vol 02.03. Annual Book of ASTM Standards, Vol 03.06.

3 10

Annual Book of ASTM Standards, Vol 02.05. Annual Book of ASTM Standards, Vol 03.03.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B 317

A,B,C

TABLE 1 Chemical Composition Limits

2.4 Military Standard:

MIL-STD-129 Marking for Shipment and Storage Alloy Designation 6101

Element

11 Composition, %

2.5 Federal Standard:

Silicon 0.30–0.7

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

Iron 0.50

Copper 0.10

3. Terminology

Manganese 0.03

Magnesium 0.35–0.8

3.1 Definitions:

Chromium 0.03

3.1.1 bus conductor—a rigid electric conductor of any cross

Zinc 0.10

Boron 0.06

section.

Other

3.1.2 extruded bar—an extruded solid section long in rela-

D

elements:

tion to its cross-sectional dimensions, having a symmetrical

Each 0.03

E

cross section that is square or rectangular (excluding flattened Total 0.10

Aluminum remainder

wire) with sharp or rounded corners or edges, or is a regular

A

Limits are in weight percent maximum unless shown as a range.

hexagon or octagon, and whose width or greatest distance

B

Analysis shall be made for the elements for which limits are shown in this table.

between parallel faces is ⁄8 in. (9.5 mm) or greater. C

To determine conformance to these limits, an observed value or a calculated

3.1.3 extruded rod—an extruded solid round section ⁄8 in. value obtained from analysis shall be rounded off to the nearest unit in the last

right-hand place of the figures used in expressing the specified limit, in accordance

(9.5 mm) or greater in diameter, whose length is great in

with the rounding-off method of Practice E 29.

relation to its diameter. D

Others includes all unlisted metallic elements. The producer may analyze

3.1.4 extruded tube—an extruded hollow wrought product samples for trace elements not specified in the specification. However, such

analysis is not required and may not cover all metallic Others elements. Should

that is long in relation to its cross section, that is round, a

any analysis by the producer or the purchaser establish that an Others element

regular hexagon, a regular octagon, elliptical, square, or

exceeds the limit of Each or that the aggregate of several Others elements

exceeds the limit of Total, the material shall be considered nonconforming.

rectangular with sharp or round corners, and that has uniform

E

Other Elements—Total shall be the sum of unspecified metallic elements

wall thickness except as affected by corner radii.

0.010 % or more, rounded to the second decimal before determining the sum.

3.1.5 extruded pipe—extruded tube in standardized combi-

nations of outside diameter and wall thickness, commonly

ber (40 or 80); Structural Profile—Nominal dimensions and

designated by “Nominal Pipe Sizes” and “ANSI Schedule

type of section; Round Tube—Outside or inside diameter and

Numbers.”

wall thickness; Square or Sharp-Cornered Tube—Distance

3.1.6 extruded structural profile—an extruded profile, com-

across flats and wall thickness; Round-Cornered Tube Other

monly used for structural purposes but limited to profiles

than Round—A drawing is required,

producible by rolling, such as angles and channels.

4.1.7 Length,

4.2 Additionally, orders for material to this specification

NOTE 2—Tees, zees, I-beams, and H-sections are rarely used as

shall include the following information when required by the

conductors.

purchaser:

3.1.7 producer—the primary manufacturer of the material.

4.2.1 Whether solution heat treatment at the extrusion press

3.1.8 supplier—includes only the category of jobbers and

is unacceptable (8.2),

distributors as distinct from producers.

4.2.2 Whether witness of inspection by the purchaser’s

3.2 Definitions of Terms Specific to This Standard:

representative is required prior to material shipment (Section

3.2.1 capable of—The term capable of as used in this

16),

specification means that the test need not be performed by the

4.2.3 Whether marking for identification is required (Sec-

producer of the material. However, should subsequent testing

tion 18),

by the purchaser establish that the material does not meet these

4.2.4 Whether certification is required (Section 20), and

requirements, the material shall be subject to rejection.

4.2.5 Whether Practices B 660 applies and, if so, the levels

of preservation, packaging, packing and marking required

4. Ordering Information

(Section 19).

4.1 Orders for material to this specification shall include the

following information: 5. Manufacture

4.1.1 This specification designation (which includes the

5.1 The bars, rods, tubes, pipe, or structural profiles shall be

number, the year, and the revision letter, if applicable),

produced by hot extrusion or by similar methods at the option

4.1.2 Quantity in pounds or pieces,

of the producer, provided that the production method results in

4.1.3 Type (1.1.1 and 1.1.2),

material that meets all requirements of this specification.

4.1.4 Temper (Section 9, Table 2),

6. Quality Assurance

4.1.5 Type of section (Section 3),

4.1.6 Cross-Sectional Dimensions: Bar— Thickness and 6.1 Responsibility for Inspection and Tests—Unless other-

width, or distance across flats, and edge contour (Section 13); wise specified in the contract or purchase order, the producer is

Rod—Diameter; Pipe—Nominal pipe size and schedule num- responsible for the performance of all inspection and test

requirements specified herein. The producer may use his own

or any other suitable facilities for the performance of the

inspection and test requirements specified herein, unless dis-

Available from Standardization Documents Order Desk, Bldg. 4 Section D,

700 Robbins Ave., Philadelphia, PA 19111-5094 Attn: NPODS. approved by the purchaser in the order or at the time of contract

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B 317

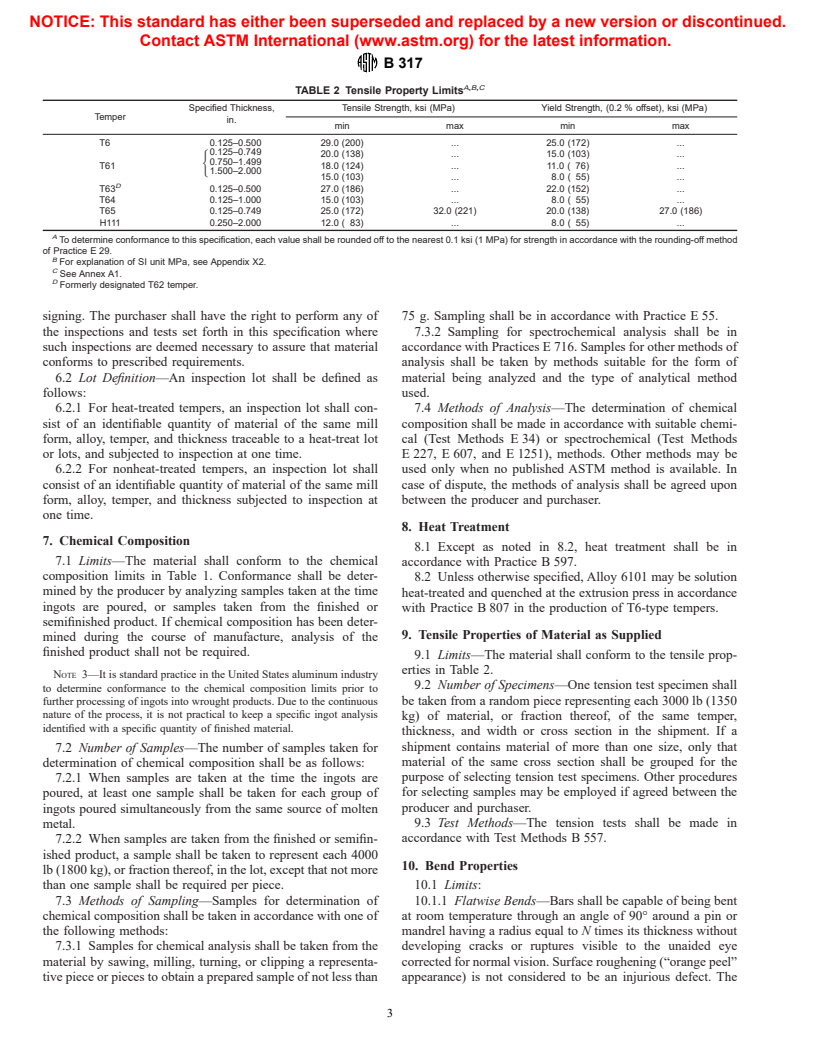

A,B,C

TABLE 2 Tensile Property Limits

Specified Thickness, Tensile Strength, ksi (MPa) Yield Strength, (0.2 % offset), ksi (MPa)

Temper

in.

min max min max

T6 0.125–0.500 29.0 (200) . 25.0 (172) .

0.125–0.749

20.0 (138) . 15.0 (103) .

0.750–1.499

T61 H 18.0 (124) . 11.0 ( 76) .

1.500–2.000

15.0 (103) . 8.0 ( 55) .

D

T63 0.125–0.500 27.0 (186) . 22.0 (152) .

T64 0.125–1.000 15.0 (103) . 8.0 ( 55) .

T65 0.125–0.749 25.0 (172) 32.0 (221) 20.0 (138) 27.0 (186)

H111 0.250–2.000 12.0 ( 83) . 8.0 ( 55) .

A

To determine conformance to this specification, each value shall be rounded off to the nearest 0.1 ksi (1 MPa) for strength in accordance with the rounding-off method

of Practice E 29.

B

For explanation of SI unit MPa, see Appendix X2.

C

See Annex A1.

D

Formerly designated T62 temper.

signing. The purchaser shall have the right to perform any of 75 g. Sampling shall be in accordance with Practice E 55.

the inspections and tests set forth in this specification where 7.3.2 Sampling for spectrochemical analysis shall be in

such inspections are deemed necessary to assure that material accordance with Practices E 716. Samples for other methods of

conforms to prescribed requirements. analysis shall be taken by methods suitable for the form of

6.2 Lot Definition—An inspection lot shall be defined as material being analyzed and the type of analytical method

follows: used.

6.2.1 For heat-treated tempers, an inspection lot shall con- 7.4 Methods of Analysis—The determination of chemical

sist of an identifiable quantity of material of the same mill composition shall be made in accordance with suitable chemi-

form, alloy, temper, and thickness traceable to a heat-treat lot cal (Test Methods E 34) or spectrochemical (Test Methods

or lots, and subjected to inspection at one time. E 227, E 607, and E 1251), methods. Other methods may be

6.2.2 For nonheat-treated tempers, an inspection lot shall used only when no published ASTM method is available. In

consist of an identifiable quantity of material of the same mill case of dispute, the methods of analysis shall be agreed upon

form, alloy, temper, and thickness subjected to inspection at between the producer and purchaser.

one time.

8. Heat Treatment

7. Chemical Composition

8.1 Except as noted in 8.2, heat treatment shall be in

7.1 Limits—The material shall conform to the chemical

accordance with Practice B 597.

composition limits in Table 1. Conformance shall be deter-

8.2 Unless otherwise specified, Alloy 6101 may be solution

mined by the producer by analyzing samples taken at the time

heat-treated and quenched at the extrusion press in accordance

ingots are poured, or samples taken from the finished or

with Practice B 807 in the production of T6-type tempers.

semifinished product. If chemical composition has been deter-

9. Tensile Properties of Material as Supplied

mined during the course of manufacture, analysis of the

finished product shall not be required.

9.1 Limits—The material shall conform to the tensile prop-

erties in Table 2.

NOTE 3—It is standard practice in the United States aluminum industry

9.2 Number of Specimens—One tension test specimen shall

to determine conformance to the chemical composition limits prior to

further processing of ingots into wrought products. Due to the continuous be taken from a random piece representing each 3000 lb (1350

nature of the process, it is not practical to keep a specific ingot analysis

kg) of material, or fraction thereof, of the same temper,

identified with a specific quantity of finished material.

thickness, and width or cross section in the shipment. If a

shipment contains material of more than one size, only that

7.2 Number of Samples—The number of samples taken for

material of the same cross section shall be grouped for the

determination of chemical composition shall be as follows:

purpose of selecting tension test specimens. Other procedures

7.2.1 When samples are taken at the time the ingots are

for selecting samples may be employed if agreed between the

poured, at least one sample shall be taken for each group of

producer and purchaser.

ingots poured simultaneously from the same source of molten

9.3 Test Methods—The tension tests shall be made in

metal.

ac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.