ASTM E228-95

(Test Method)Standard Test Method for Linear Thermal Expansion of Solid Materials With a Vitreous Silica Dilatometer (Withdrawn 2005)

Standard Test Method for Linear Thermal Expansion of Solid Materials With a Vitreous Silica Dilatometer (Withdrawn 2005)

SCOPE

1.1 This test method covers the determination of the linear thermal expansion of rigid solid materials over the temperature range of -180 to 900°C using vitreous silica push-rod or tube dilatometers. Note 1-The temperature range for push-rod dilatometers can be extended to 1600°C by using high-purity alumina push-rod systems and up to over 2500°C using isotropic graphite systems. The precision and bias of these systems is believed to be of the same order as that for silica systems up to 900°C. However, their precision and bias have not yet been established over the relevant total range of temperature due to the lack of well-characterized reference materials and the need for interlaboratory comparisons.

1.2 For this purpose, a rigid solid is defined as a material that, at test temperature and under the stresses imposed by instrumentation, has a negligible creep or elastic strain rate, or both, regarding significantly affecting the precision of thermal-length change measurements. This includes metals, ceramics, refractories, glasses, rocks and minerals, graphites, plastics, cements, mortars, woods, and fiber, and other reinforced matrix composites.

1.3 Many materials and certain material applications require that detailed preconditioning and specific thermal test schedules be followed for the correct evaluation of thermal expansion. Since a general test method cannot cover all specific requirements, details of this nature should be contained in the relevant material specification.

1.4 The precision of this comparative test method is greater than that of other push-rod dilatometery (for example, Test Method D696) and thermomechanical analysis (for example, Test Method E831) techniques but is significantly lower than that of absolute methods such as interferometry (for example, Test Method E289). It is generally applicable to materials having linear expansion coefficients above 5 [mu]m/m[dot]K and can be used for lower expansion coefficient materials for which a sufficient length of specimen is available.

1.5 Computer- or electronic-based instrumentation, techniques, and data analysis systems equivalent to this test method can be used. Users of the test method are expressly advised that all such instruments or techniques may not be equivalent. It is the responsibility of the user to determine the necessary equivalency prior to use. In the case of dispute only, the manual procedures described herein are to be considered valid.

1.6 The values stated in SI units are to be regarded as the standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers the determination of the linear thermal expansion of rigid solid materials over the temperature range of -180 to 900 C using vitreous silica push-rod or tube dilatometers.

Formerly under the jurisdicition of ASTM Committee E37 on Thermal Measurements, this test method was withdrawn in May 2005.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation:E228–95

Standard Test Method for

Linear Thermal Expansion of Solid Materials With a Vitreous

Silica Dilatometer

This standard is issued under the fixed designation E228; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope canbeused.Usersofthetestmethodareexpresslyadvisedthat

all such instruments or techniques may not be equivalent. It is

1.1 This test method covers the determination of the linear

the responsibility of the user to determine the necessary

thermalexpansionofrigidsolidmaterialsoverthetemperature

equivalencypriortouse.Inthecaseofdisputeonly,themanual

range of−180 to 900°C using vitreous silica push-rod or tube

procedures described herein are to be considered valid.

dilatometers.

1.6 The values stated in SI units are to be regarded as the

NOTE 1—The temperature range for push-rod dilatometers can be

standard.

extended to 1600°C by using high-purity alumina push-rod systems and

1.7 This standard does not purport to address all of the

up to over 2500°C using isotropic graphite systems. The precision and

safety concerns, if any, associated with its use. It is the

bias of these systems is believed to be of the same order as that for silica

responsibility of the user of this standard to establish appro-

systems up to 900°C. However, their precision and bias have not yet been

established over the relevant total range of temperature due to the lack of priate safety and health practices and determine the applica-

well-characterized reference materials and the need for interlaboratory

bility of regulatory limitations prior to use.

comparisons.

2. Referenced Documents

1.2 For this purpose, a rigid solid is defined as a material

2.1 ASTM Standards:

that, at test temperature and under the stresses imposed by

D696 Test Method for Coefficient of Linear Thermal Ex-

instrumentation, has a negligible creep or elastic strain rate, or

pansion of Plastics

both,regardingsignificantlyaffectingtheprecisionofthermal-

E220 Test Method for Calibration of Thermocouples by

length change measurements. This includes metals, ceramics,

Comparison Techniques

refractories, glasses, rocks and minerals, graphites, plastics,

E289 Test Method for Linear Thermal Expansion of Rigid

cements,mortars,woods,andfiber,andotherreinforcedmatrix

Solids with Interferometry

composites.

E473 Terminology Relating to Thermal Analysis

1.3 Manymaterialsandcertainmaterialapplicationsrequire

E644 Test Methods for Industrial Resistance Thermom-

that detailed preconditioning and specific thermal test sched-

eters

ules be followed for the correct evaluation of thermal expan-

E831 Test Method for Linear Thermal Expansion of Solid

sion. Since a general test method cannot cover all specific

Materials by Thermomechanical Analysis

requirements, details of this nature should be contained in the

E1142 Terminology Relating to Thermophysical Proper-

relevant material specification.

ties

1.4 The precision of this comparative test method is greater

than that of other push-rod dilatometery (for example, Test

3. Terminology

Method D696) and thermomechanical analysis (for example,

3.1 Definitions—The following terms are applicable to this

Test Method E831) techniques but is significantly lower than

test method and are listed in Terminologies E473 and E1142:

that of absolute methods such as interferometry (for example,

coeffıcient of linear thermal expansion, thermodilatometry, and

Test Method E289). It is generally applicable to materials

thermomechanical analysis.

having linear expansion coefficients above 5 µm/m·K and can

3.2 Definitions of Terms Specific to This Standard:

be used for lower expansion coefficient materials for which a

3.2.1 mean coeffıcient of linear thermal expansion, a —the

sufficient length of specimen is available. m

average change in length relative to the length of the specimen

1.5 Computer- or electronic-based instrumentation, tech-

accompanying a change in temperature, between temperatures

niques,anddataanalysissystemsequivalenttothistestmethod

T and T , expressed as follows:

1 2

This test method is under the jurisdiction of ASTM Committee E-37 on

Thermal Measurements and is the direct responsibility of Subcommittee E37.05 on

Thermophysical Properties. Annual Book of ASTM Standards, Vol 08.01.

Current edition approved Sept. 10, 1995. Published December 1995. Originally Annual Book of ASTM Standards, Vol 14.03.

published as E228–63T. Last previous edition E228–85 (1989). Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

E228–95

a 5[~L 2 L !/L ~T 2 T !# 5 ~DL/L !/DT (1) stresses that can occur and cause failure of a solid artifact

m 2 1 0 2 1 0

composed of different materials when it is subjected to a

a is, therefore, obtained by dividing the linear thermal

m

temperature excursion(s).

expansion (DL/L ) by the change of temperature (DT). It is

5.2 This test method is a reliable method of determining the

normally expressed as µm/m·K.

linear thermal expansion of solid materials.

3.2.2 thermal expansivity, a —at temperature T, this is

T

5.3 For accurate determinations of thermal expansion, it is

calculated as follows:

absolutely necessary that the vitreous silica dilatometer be

1 ~L 2 L !

limit 2 1

calibrated by using a reference material that has a known

a 5 5 ~dL/d !/L ~T , T , T ! (2)

T →T

T T i 1 1 2

2 1

L T 2 T !

~

i 2 1

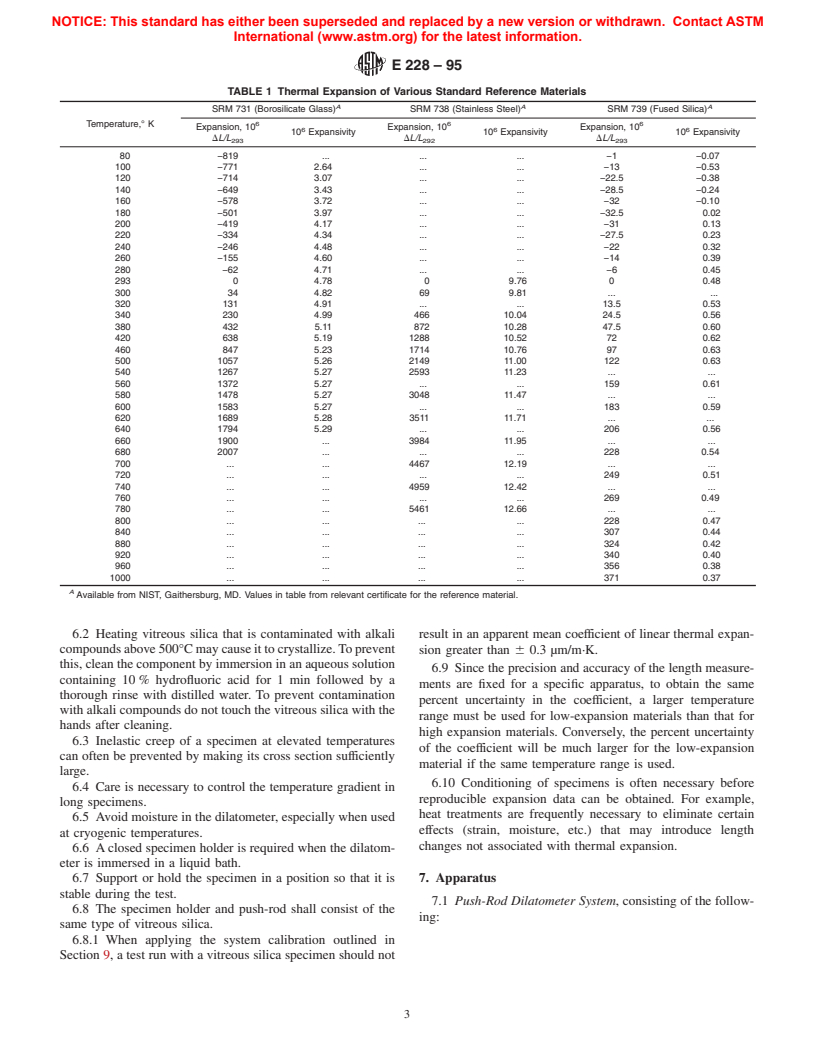

reproducible thermal expansion. Table 1 and Table 2 contain

and expressed as µm/m·K.

information on the current thermal expansion standard refer-

ence materials available for such purposes. Table 3 contains

NOTE 2—Thermal expansivity is sometimes referred to as the instan-

information relating to other reference materials in current

taneous coefficient of linear expansion.

general use.

3.2.3 vitreous silica dilatometer—a device that measures

5.4 The measurement of thermal expansion involves two

the difference in linear thermal expansion between a test

parameters:changeoflengthandchangeoftemperature.Since

specimen and the vitreous silica parts of the dilatometer.

measurements of the first parameter can be made by this test

3.3 Symbols:Symbols:

method with good precision, it is essential that great attention

also be paid to the second. In order to ensure the necessary

a = mean coefficient of linear thermal expansion, uniformity in temperature of the specimen, it is essential that

m

the uniform temperature zone of the surrounding furnace or

(see 3.2.1), µm/m·K

a = expansivity at temperature T (see 3.2.2), µm/ environmental chamber be made significantly longer than the

T

m·K length of the specimen. Temperature gradients depend on the

L = original length of specimen at temperature T ,

length/diameter ratio and insulation quality of the furnace.

0 0

mm

They can be reduced by adjusting the furnace heater windings

L = length at temperature T,mm

1 1 such that they are closer at the ends than at the center. In

L = length at temperature T,mm

2 2 addition, for high-temperature operations, it is recommended

L = length at a particular temperature T,mm

i i

that a heavy metal liner and radiation shields be used. Tem-

DL = changeinlengthofspecimenbetweentempera-

perature control is best attained when the sensing element of

ture T and T,µm

1 2

the controller is either the same as that for measuring the

(DL/L ) = expansion indicated by the measurement trans-

0 a

specimentemperature(radiantheatingfurnace)orverycloseto

ducer, µm

the heating element (resistive heated furnace).

T = temperature at which initial length is L,°K

0 0

5.5 This test method contains essential details of the design

T,T = two temperatures at which measurements are

1 2

principles, specimen configurations, and procedures for pro-

made, °K

vidingprecisevaluesofthermalexpansion.Itisnotpracticalin

T = temperature at which length is T,°K

i i

a test method of this type to try to establish specific details of

DT = temperature difference between T and T,°K

2 1

design, construction, and procedures to cover all contingencies

m = measured expansion of the reference material,

that might present difficulties to an individual not having the

µm

technical knowledge relating to the thermal measurements and

t = true or certified expansion of the reference

general testing practice. Standardization of the test method is

material, µm

not intended to restrict further development of improved

s = assumed or known expansion of the vitreous

methodology in any way.

silica parts of the dilatometer, µm

5.6 The test method can be used for research, development,

A,B = numerical constants (see 9.3.1).

specification acceptance, and quality control (QC) and quality

4. Summary of Test Method

assurance (QA).

4.1 Thistestmethodusesavitreoussilicadilatometerofthe

6. Interferences

single push-rod or tube type to determine the change in length

6.1 Heating unannealed vitreous silica above 800°C may

of a solid material relative to that of the holder as a function of

cause viscous flow and a time-dependent change in its thermal

temperature. A special variation of the basic configuration

expansion. The magnitude of these effects will depend on the

known as a differential dilatometer is sometimes used. This

particular type of vitreous silica.

form is described briefly in Appendix X1.

6.1.1 Recommended Annealing Procedure—Annealing the

4.2 The temperature is controlled either over a series of

vitreous silica specimen and dilatometer parts in the following

steps or at a slow constant heating or cooling rate over the

steps may reduce any excessive lot-to-lot differences in linear

entire range.

thermal expansion:

4.3 The linear thermal expansion and the coefficients of

6.1.1.1 Heat at 100°C/h to 1200°C,

linearthermalexpansionarecalculatedfromtherecordeddata.

6.1.1.2 Hold at 1200°C for 2 h,

5. Significance and Use

6.1.1.3 Cool at 60°C/h to 1000°C,

5.1 Coefficients of linear expansion are required for design 6.1.1.4 Cool at 120°C/h to 600°C, and

purposes and are used, for example, to determine thermal 6.1.1.5 Cool at 200°C/h to room temperature.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

E228–95

TABLE 1 Thermal Expansion of Various Standard Reference Materials

A A A

SRM 731 (Borosilicate Glass) SRM 738 (Stainless Steel) SRM 739 (Fused Silica)

6 6 6

Temperature,° K

Expansion, 10 Expansion, 10 Expansion, 10

6 6 6

10 Expansivity 10 Expansivity 10 Expansivity

DL/L DL/L DL/L

293 292 293

80 −819 . . . −1 −0.07

100 −771 2.64 . . −13 −0.53

120 −714 3.07 . . −22.5 −0.38

140 −649 3.43 . . −28.5 −0.24

160 −578 3.72 . . −32 −0.10

180 −501 3.97 . . −32.5 0.02

200 −419 4.17 . . −31 0.13

220 −334 4.34 . . −27.5 0.23

240 −246 4.48 . . −22 0.32

260 −155 4.60 . . −14 0.39

280 −62 4.71 . . −6 0.45

293 0 4.78 0 9.76 0 0.48

300 34 4.82 69 9.81 . .

320 131 4.91 . . 13.5 0.53

340 230 4.99 466 10.04 24.5 0.56

380 432 5.11 872 10.28 47.5 0.60

420 638 5.19 1288 10.52 72 0.62

460 847 5.23 1714 10.76 97 0.63

500 1057 5.26 2149 11.00 122 0.63

540 1267 5.27 2593 11.23 . .

560 1372 5.27 . . 159 0.61

580 1478 5.27 3048 11.47 . .

600 1583 5.27 . . 183 0.59

620 1689 5.28 3511 11.71 . .

640 1794 5.29 . . 206 0.56

660 1900 . 3984 11.95 . .

680 2007 . . . 228 0.54

700 . . 4467 12.19 . .

720 . . . . 249 0.51

740 . . 4959 12.42 . .

760 . . . . 269 0.49

780 . . 5461 12.66 . .

800 . . . . 228 0.47

840 . . . . 307 0.44

880 . . . . 324 0.42

920 . . . . 340 0.40

960 . . . . 356 0.38

1000 . . . . 371 0.37

A

Available from NIST, Gaithersburg, MD. Values in table from relevant certificate for the reference material.

6.2 Heating vitreous silica that is contaminated with alkali result in an apparent mean coefficient of linear thermal expan-

compoundsabove500°Cmaycauseittocrystallize.Toprevent

sion greater than 6 0.3 µm/m·K.

this,cleanthecomponentbyimmersioninanaqueoussolution

6.9 Since the precision and accuracy of the length measure-

containing 10% hydrofluoric acid for 1 min followed by a

ments are fixed for a specific apparatus, to obtain the same

thorough rinse with distilled water. To prevent contamination

percent uncertainty in the coefficient, a larger temperature

withalkalicompoundsdonottouchthevitreoussilicawiththe

range must be used for low-expansion materials than that for

hands after cleaning.

high expansion materials. Conversely, the percent uncertainty

6.3 Inelastic creep of a specimen at elevated temperatures

of the coefficient will be much larger for the low-expansion

can often be prevented by making its cross section sufficiently

material if the same temperature range is used.

large.

6.10 Conditioning of specimens is often necessary before

6.4 Care is necessary to control the temperature gradient in

reproducible expansion data can be obtained. For example,

long specimens.

heat treatments are frequently necessary to eliminate certain

6.5 Avoid moisture in the dilatometer, especially when used

effects (strain, moisture, etc.) that may introduce length

at cryogenic temperatures.

changes not associated with thermal expansion.

6.6 Aclosed specimen holder is required when the dilatom-

eter is immersed in a liquid bath.

6.7 Support or hold the specimen in a position so that it is 7. Apparatus

stable during the test.

7.1 Push-Rod Dilatometer System, consisting of the follow-

6.8 The specimen holder and push-rod shall consist of the

ing:

same type of vitreous silica.

6.8.1 When applying the system calibration outlined in

Section 9, a test run with a vitreous silica specimen should not

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

E228–95

TABLE 2 Thermal Expansion of Standard Reference Material

A

Kieselglas K001

Temperature, Expansion, Expansivity, 10 a,

6 6 −1

°C 10 DL/L 10 a (t) K

−170 −2.16 60.67 −0.565 60.019 0.013 60.004

−160 −7.35 60.55 −0.475 60.016 0.046 60.003

−140 −15.15 60.44 −0.300 60.011 0.108 60.003

−120 −19.80 60.43 −0.160 60.007 0.165 60.004

−100 −21.67 60.43 −0.030 60.005 0

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.