ASTM A451/A451M-06(2010)

(Specification)Standard Specification for Centrifugally Cast Austenitic Steel Pipe for High-Temperature Service

Standard Specification for Centrifugally Cast Austenitic Steel Pipe for High-Temperature Service

ABSTRACT

This specification covers the standard for centrifugally cast austenitic alloy steel pipe for use in high-temperature, corrosive, or nuclear pressure service. The pipe shall receive a heat treatment at the required temperature and holding time followed by quenching in water or rapid cool by other means. The pipe shall be machined on the inner and outer surfaces and shall conform to specified roughness value. Heat and product analysis shall be done to determine the chemical composition and shall conform to the required carbon, manganese, phosphorus, sulfur, silicon, nickel, chromium, molybdenum, columbium, tantalum, and nitrogen contents. Hydrostatic and tension tests shall be performed and shall conform to the required tensile strength, yield strength, and elongation.

SCOPE

1.1 This specification covers austenitic alloy steel pipe for use in high-temperature, corrosive, or nuclear pressure service.

1.2 Several grades of austenitic stainless steel are covered as indicated in Table 1.

1.3 Optional supplementary requirements are provided when additional testing may be required.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A451/A451M −06(Reapproved 2010)

Standard Specification for

Centrifugally Cast Austenitic Steel Pipe for High-

Temperature Service

This standard is issued under the fixed designationA451/A451M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E165 Practice for Liquid Penetrant Examination for General

2 Industry

1.1 This specification covers austenitic alloy steel pipe for

E186 Reference Radiographs for Heavy-Walled (2 to 4 ⁄2-in.

use in high-temperature, corrosive, or nuclear pressure service.

(50.8 to 114-mm)) Steel Castings

1.2 Severalgradesofausteniticstainlesssteelarecoveredas

E280 Reference Radiographs for Heavy-Walled (4 ⁄2 to 12-

indicated in Table 1.

in. (114 to 305-mm)) Steel Castings

1.3 Optional supplementary requirements are provided E446 Reference Radiographs for Steel Castings Up to 2 in.

(50.8 mm) in Thickness

when additional testing may be required.

1.4 The values stated in either inch-pound units or SI units 2.2 ANSI Standard:

B46.1 Surface Texture

are to be regarded separately as standard. Within the text, the

SI units are shown in brackets. The values stated in each

systemarenotexactlyequivalents;therefore,eachsystemmust 3. Ordering Information

be used independently of each other. Combining values from

3.1 Orders for material to this specification shall include the

the two systems may result in nonconformance with the

following, as required, to describe the desired material ad-

specification.

equately:

3.1.1 Quantity (feet, metres, or number of lengths),

NOTE 1—This specification is not intended to cover centrifugal pipe

made from alloys containing more than 0.20 % carbon, such as are

3.1.2 Name of material (centrifugally cast pipe),

covered by Specification A297/A297M.

3.1.3 Grade (Table 1),

3.1.4 Size (outside or inside diameter and minimum wall

2. Referenced Documents

thickness in inches or millimetres),

2.1 ASTM Standards:

3.1.5 Length (specific or random, Specification A999/

A297/A297M Specification for Steel Castings, Iron-

A999M),

Chromium and Iron-Chromium-Nickel, Heat Resistant,

3.1.6 End Finish of Specification A999/A999M,

for General Application

3.1.7 Optional Requirements (9.4 and Supplementary Re-

A370 Test Methods and Definitions for Mechanical Testing

quirements S1 through S7),

of Steel Products

3.1.8 Test Report Required (Section 14), and

A999/A999M Specification for General Requirements for

3.1.9 Special Requirements or Additions to Specification.

Alloy and Stainless Steel Pipe

E29 Practice for Using Significant Digits in Test Data to

4. Materials and Manufacture

Determine Conformance with Specifications

4.1 Heat-Treatment—The pipe shall receive a heat-

E94 Guide for Radiographic Examination

treatment at the temperature and time specified in Table 2,

followed by a quench in water or rapid cool by other means.

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

4.2 Machining—The pipe shall be machined on the inner

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

and outer surfaces to a roughness value no greater than

A01.18 on Castings.

Current edition approved Oct. 1, 2010. Published December 2010. Originally

250-µin. [6.35-µm] arithmetical average deviation (AA) from

approved in 1961. Last previous edition approved in 2006 as A451/A451M – 06.

the mean line, as defined in American National Standard

DOI: 10.1520/A0451_A0451M-06R10.

B46.1.

For ASME Boiler and Pressure Vessel Code applications see related specifica-

tion SA-451 in Section II of that Code.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A451/A451M−06 (2010)

TABLE 1 Chemical Requirements

Composition, %

Car- Man- Phos- Sul- Sili- Tan-

bon, ga- pho- fur, con, Molybde- ta-

Grade Nickel Chromium Columbium Nitrogen

max nese, rus, max max num lum,

max max max

CPF3 0.03 1.50 0.040 0.040 2.00 8.0–12.0 17.0–21.0 . . . .

CPF3A 0.03 1.50 0.040 0.040 2.00 8.0–12.0 17.0–21.0 . . . .

CPF8 0.08 1.50 0.040 0.040 2.00 8.0–11.0 18.0–21.0 . . . .

CPF8A 0.08 1.50 0.040 0.040 2.00 8.0–11.0 18.0–21.0 . . . .

CPF3M 0.03 1.50 0.040 0.040 1.50 9.0–13.0 17.0–21.0 2.0–3.0 . . .

CPF8M 0.08 1.50 0.040 0.040 1.50 9.0–12.0 18.0–21.0 2.0–3.0 . . .

A

CPF10MC 0.10 1.50 0.040 0.040 1.50 13.0–16.0 15.0–18.0 1.75–2.25 1.2 max, 10×Cmin . .

A

CPF8C 0.08 1.50 0.040 0.040 2.00 9.0–12.0 18.0–21.0 . 1 max,8×Cmin . .

B

CPF8C(Ta max) 0.08 1.50 0.040 0.040 2.00 9.0–12.0 18.0–21.0 . 1 max,8×Cmin 0.10 .

CPH8 0.08 1.50 0.040 0.040 1.50 12.0–15.0 22.0–26.0 . . . .

C

CPH20 or CPH10 0.20 1.50 0.040 0.040 2.00 12.0–15.0 22.0–26.0 . . . .

CPK20 0.20 1.50 0.040 0.040 1.75 19.0–22.0 23.0–27.0 . . . .

CPE20N 0.20 1.50 0.040 0.040 1.50 8.0–11.0 23.0–26.0 . . . 0.08–0.20

A

Grades CPF10MC and CPF8C may have a columbium plus tantalum content maximum of 1.35 %.

B

No designation as yet assigned by ASTM International or Steel Founders’ Society of America.

C

By agreement between the manufacturer and the purchaser, the carbon content of Grade CPH20 may be restricted to 0.10 % max. When so agreed, the grade

designation shall be CPH10.

TABLE 2 Heat-Treatment Requirements TABLE 3 Tensile Requirements

Temperature, min Hold Time, Tensile Yield Elongation

h/in. of Strength, Strength, in2in.

Grade

°F °C

Grade

Thickness min, ksi [MPa] min, ksi or 50 mm,

[MPa] min

CPF3 70 [485] 30 [205] 35

CPF3, CPF3A, CPF8, CPF8A, CPF3M, 1900 1040 1

A

CPF3A 77 [535] 35 [240] 35

CPF8M

CPF3M 70 [485] 30 [205] 30

CPF10MC, CPF8C, CPF8C (Ta max) 1950 1065 2

CPF8 70 [485] 30 [205] 35

CPH8, CPH10, CPH20, CPK20 2100 1150 1

A

CPF8A 77 [535] 35 [240] 35

CPE20N 2225 1220 1

CPF8M 70 [485] 30 [205] 30

CPF10MC 70 [485] 30 [205] 20

CPH10 70 [485] 30 [205] 30

CPF8C (Ta max), CPF8C 70 [485] 30 [205] 30

5. Chemical Analysis

CPH8 65 [448] 28 [195] 30

CPK20 65 [448] 28 [195] 30

5.1 Heat Analysis—An analysis of each heat shall be made

CPH20 70 [485] 30 [205] 30

by the manufacturer to determine the percentages of elements

CPE20N 80 [550] 40 [275] 30

specified in Table 1. The analysis shall be made on a test

A

The properties shown are obtained by adjusting the composition within the

sample taken preferably during the pouring of the heat. The

limitsshowninTable1toobtainaferrite-austeniteratiothatwillresultinthehigher

chemical composition thus determined shall conform to the ultimate and yield strengths indicated.Alowering of impact values may develop in

these materials when exposed to service temperature above 800°F [425°C].

requirements specified in Table 1.

5.2 Product Analysis—A product analysis may be made by

6.1.3 Tension test specimens shall be machined to the form

thepurchaser.Thesampleforanalysisshallbeselectedsoasto

and dimensions of the standard round 2-in. [50-mm] gage

be thoroughly representative of the pipe being analyzed. The

length specimens shown in Fig. 6 of Test Methods and

chemical composition thus determined shall conform to the

Definitions A370.

requirements specified in Table 1.

6.2 Number of Tests:

5.3 To determine conformance with the chemical analysis

6.2.1 Onetensiontestshallbemadefromeachheat.Thebar

requirements, an observed value or calculated value shall be

from which the test specimen is taken shall be heat-treated in

rounded in accordance with Practice E29 to the nearest unit in

the same manner as the castings represented.

the last right-hand place of values listed in Table 1.

6.2.2 If a specimen is machined improperly or flaws are

6. Tensile Requirements

revealed by machining or during testing, the specimen may be

discarded and another substituted from the same heat.

6.1 Test Specimens:

6.1.1 Test specimens shall be prepared in accordance with

6.3 Retests—If the results of the mechanical tests for any

Test Methods and Definitions A370. Test bars shall be poured

heat do not conform to the requirements specified, the castings

in special blocks from the same heat as the castings repre-

may be reheat-treated and

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A451/A451M–06 Designation: A451/A451M – 06 (Reapproved 2010)

Standard Specification for

Centrifugally Cast Austenitic Steel Pipe for High-

Temperature Service

This standard is issued under the fixed designationA451/A451M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers austenitic alloy steel pipe for use in high-temperature, corrosive, or nuclear pressure service.

1.2 Several grades of austenitic stainless steel are covered as indicated in Table 1.

1.3 Optional supplementary requirements are provided when additional testing may be required.

1.4 Thevaluesstatedineitherinch-poundunitsorSIunitsaretoberegardedseparatelyasstandard.Withinthetext,theSIunits

are shown in brackets. The values stated in each system are not exactly equivalents; therefore, each system must be used

independently of each other. Combining values from the two systems may result in nonconformance with the specification.

NOTE 1—This specification is not intended to cover centrifugal pipe made from alloys containing more than 0.20 % carbon, such as are covered by

Specification A297/A297M.

2. Referenced Documents

2.1 ASTM Standards:

A297/A297M Specification for Steel Castings, Iron-Chromium and Iron-Chromium-Nickel, Heat Resistant, for General

Application

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A999/A999M Specification for General Requirements for Alloy and Stainless Steel Pipe

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E94 Guide for Radiographic Examination

E165 Practice for Liquid Penetrant Examination for General Industry

E186 Reference Radiographs for Heavy-Walled (2 to 412-in. (50.8 to 114-mm)) Steel Castings

E280 Reference Radiographs for Heavy-Walled (412 to 12-in. (114 to 305-mm)) Steel Castings

E446 Reference Radiographs for Steel Castings Up to 2 in. (50.8 mm) in Thickness

2.2 ANSI Standard:

B46.1 Surface Texture

3. Ordering Information

3.1 Orders for material to this specification shall include the following, as required, to describe the desired material adequately:

3.1.1 Quantity (feet, metres, or number of lengths),

3.1.2 Name of material (centrifugally cast pipe),

3.1.3 Grade (Table 1),

3.1.4 Size (outside or inside diameter and minimum wall thickness in inches or millimetres),

3.1.5 Length (specific or random, Specification A999/A999M),

3.1.6 End Finish of Specification A999/A999M,

3.1.7 Optional Requirements (9.4 and Supplementary Requirements S1 through S7),

3.1.8 Test Report Required (Section 14), and

3.1.9 Special Requirements or Additions to Specification.

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.18

on Castings.

Current edition approved Sept.Oct. 1, 2006.2010. Published September 2006.December 2010. Originally approved in 1961. Last previous edition approved in 20022006

as A451/A451M – 026. DOI: 10.1520/A0451_A0451M-06R10.

For ASME Boiler and Pressure Vessel Code applications see related specification SA-451 in Section II of that Code.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A451/A451M – 06 (2010)

TABLE 1 Chemical Requirements

Composition, %

Car- Man- Phos- Sul- Sili- Tan-

bon, ga- pho- fur, con, Molybde- ta-

Grade Nickel Chromium Columbium Nitrogen

max nese, rus, max max num lum,

max max max

CPF3 0.03 1.50 0.040 0.040 2.00 8.0–12.0 17.0–21.0 . . . .

CPF3A 0.03 1.50 0.040 0.040 2.00 8.0–12.0 17.0–21.0 . . . .

CPF8 0.08 1.50 0.040 0.040 2.00 8.0–11.0 18.0–21.0 . . . .

CPF8A 0.08 1.50 0.040 0.040 2.00 8.0–11.0 18.0–21.0 . . . .

CPF3M 0.03 1.50 0.040 0.040 1.50 9.0–13.0 17.0–21.0 2.0–3.0 . . .

CPF8M 0.08 1.50 0.040 0.040 1.50 9.0–12.0 18.0–21.0 2.0–3.0 . . .

A

CPF10MC 0.10 1.50 0.040 0.040 1.50 13.0–16.0 15.0–18.0 1.75–2.25 1.2 max, 10 3 C min . .

A

CPF8C 0.08 1.50 0.040 0.040 2.00 9.0–12.0 18.0–21.0 . 1 max, 8 3 C min . .

B

CPF8C(Ta max) 0.08 1.50 0.040 0.040 2.00 9.0–12.0 18.0–21.0 . 1 max, 8 3 C min 0.10 .

CPH8 0.08 1.50 0.040 0.040 1.50 12.0–15.0 22.0–26.0 . . . .

C

CPH20 or CPH10 0.20 1.50 0.040 0.040 2.00 12.0–15.0 22.0–26.0 . . . .

CPK20 0.20 1.50 0.040 0.040 1.75 19.0–22.0 23.0–27.0 . . . .

CPE20N 0.20 1.50 0.040 0.040 1.50 8.0–11.0 23.0–26.0 . . . 0.08–0.20

A

Grades CPF10MC and CPF8C may have a columbium plus tantalum content maximum of 1.35 %.

B

No designation as yet assigned by ASTM International or Steel Founders’ Society of America.

C

By agreement between the manufacturer and the purchaser, the carbon content of Grade CPH20 may be restricted to 0.10 % max. When so agreed, the grade

designation shall be CPH10.

4. Materials and Manufacture

4.1 Heat-Treatment—The pipe shall receive a heat-treatment at the temperature and time specified in Table 2, followed by a

quench in water or rapid cool by other means.

4.2 Machining—The pipe shall be machined on the inner and outer surfaces to a roughness value no greater than 250-µin.

[6.35-µm] arithmetical average deviation (AA) from the mean line, as defined in American National Standard B46.1.

5. Chemical Analysis

5.1 Heat Analysis—An analysis of each heat shall be made by the manufacturer to determine the percentages of elements

specified in Table 1. The analysis shall be made on a test sample taken preferably during the pouring of the heat. The chemical

composition thus determined shall conform to the requirements specified in Table 1.

5.2 Product Analysis—Aproduct analysis may be made by the purchaser. The sample for analysis shall be selected so as to be

thoroughlyrepresentativeofthepipebeinganalyzed.Thechemicalcompositionthusdeterminedshallconformtotherequirements

specified in Table 1.

5.3 To determine conformance with the chemical analysis requirements, an observed value or calculated value shall be rounded

in accordance with Practice E29 to the nearest unit in the last right-hand place of values listed in Table 1.

6. Tensile Requirements

6.1 Test Specimens:

6.1.1 Test specimens shall be prepared in accordance with Test Methods and Definitions A370. Test bars shall be poured in

special blocks from the same heat as the castings represented. Test bars shall be supplied in sufficient number to furnish all

specimens required in 6.2 and 6.3 (see Table 3).

6.1.2 Test specimens may be cut from heat-treated castings instead of from test bars when agreed upon between the

manufacturer and the purchaser.

6.1.3 Tension test specimens shall be machined to the form and dimensions of the standard round 2-in. [50-mm] gage length

specimens shown in Fig. 6 of Test Methods and Definitions A370.

6.2 Number of Tests:

6.2.1 One tension test shall be made from each heat. The bar from which the test specimen is taken shall be heat-treated in the

same manner as the castings represented.

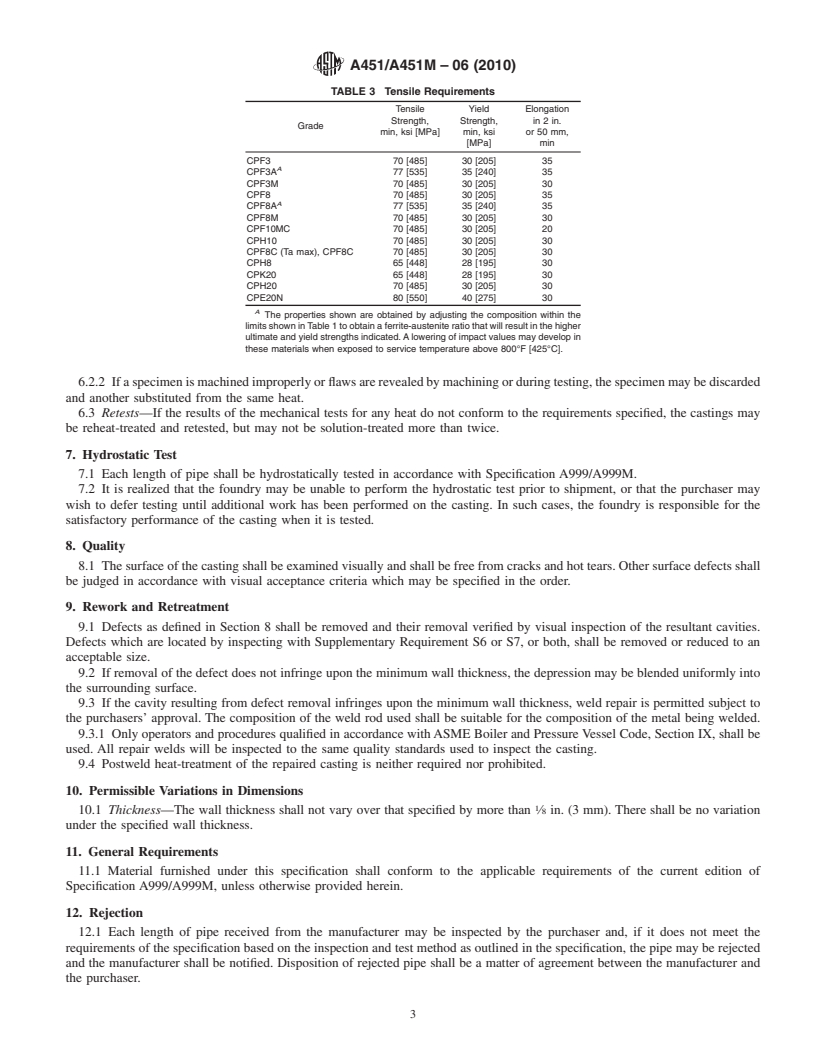

TABLE 2 Heat-Treatment Requirements

Temperature, min Hold Time,

Grade h/in. of

°F °C

Thickness

CPF3, CPF3A, CPF8, CPF8A, CPF3M, 1900 1040 1

CPF8M

CPF10MC, CPF8C, CPF8C (Ta max) 1950 1065 2

CPH8, CPH10, CPH20, CPK20 2100 1150 1

CPE20N 2225 1220 1

A451/A451M – 06 (2010)

TABLE 3 Tensile Requirements

Tensile Yield Elongation

Strength, Strength, in2in.

Grade

min, ksi [MPa] min, ksi or 50 mm,

[MPa] min

CPF3 70 [485] 30 [205] 35

A

CPF3A 77 [535] 35 [240] 35

CPF3M 70 [485] 30 [205] 30

CPF8 70 [485] 30 [205] 35

A

CPF8A 77 [535] 35 [240] 35

CPF8M 70 [485] 30 [205] 30

CPF10MC 70 [485] 30 [205] 20

CPH10 70 [485] 30 [205] 30

CPF8C (Ta max), CPF8C 70 [485] 30 [205] 30

CPH8 65 [448] 28 [195] 30

CPK20 65 [448] 28 [195] 30

CPH20 70 [485] 30 [205] 30

CPE20N 80 [550] 40 [275] 30

A

The properties shown are obtained by adjusting the composition within the

limitsshowninTable1toobtainaferrite-austeniteratiothatwillresultinthehigher

ultimate and yield stren

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.