ASTM D2784-06

(Test Method)Standard Test Method for Sulfur in Liquefied Petroleum Gases (Oxy-Hydrogen Burner or Lamp)

Standard Test Method for Sulfur in Liquefied Petroleum Gases (Oxy-Hydrogen Burner or Lamp)

SIGNIFICANCE AND USE

It is important to have the sulfur content of liquefied petroleum gases at low enough concentration to meet government regulations. The presence of sulfur can result in corrosion of metal surfaces. Sulfur can be poisonous to catalysts in subsequent processing.

SCOPE

1.1 This test method covers the determination of total sulfur in liquefied petroleum gases containing more than 1 g/g. Specimens should not contain more than 100 g/g of halogens.

1.2 To attain the quantitative detectability that the test method is capable of, stringent techniques must be employed and all possible sources of sulfur contamination must be eliminated. In particular, cleaning agents, such as common household detergents which contain sulfates, should be avoided.

1.3 &si-value;

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2784 – 06

Standard Test Method for

Sulfur in Liquefied Petroleum Gases (Oxy-Hydrogen Burner

1

or Lamp)

This standard is issued under the fixed designation D2784; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope* 2.2 Energy Institute Standard:

IP 181 Sampling Petroleum Gases, Including Liquefied

1.1 This test method covers the determination of total sulfur

Petroleum Gases

in liquefied petroleum gases containing more than 1 µg/g.

Specimens should not contain more than 100 µg/g of halogens.

3. Summary of Test Method

1.2 To attain the quantitative detectability that the test

3.1 The sample is burned in an oxy-hydrogen burner, or in

method is capable of, stringent techniques must be employed

a lamp in a closed system in a carbon dioxide-oxygen

and all possible sources of sulfur contamination must be

atmosphere. The latter is not recommended for trace quantities

eliminated. In particular, cleaning agents, such as common

ofsulfurduetotheinordinatelylongcombustiontimesneeded.

household detergents which contain sulfates, should be

The oxides of sulfur are absorbed and oxidized to sulfuric acid

avoided.

in a hydrogen peroxide solution. The sulfate ions are then

1.3 The values stated in SI units are to be regarded as

determined by either of the following finishes:

standard. The values given in parentheses are for information

3.1.1 Barium Perchlorate Titration—The sulfate is titrated

only.

with barium perchlorate using a thorin-methylene blue mixed

1.4 This standard does not purport to address all of the

indicator.

safety concerns, if any, associated with its use. It is the

3.1.2 Turbidimetric—The sulfate is precipitated as barium

responsibility of the user of this standard to establish appro-

sulfate and the turbidity of a suspension of the precipitate is

priate safety and health practices and determine the applica-

measured with a photometer.

bility of regulatory limitations prior to use.

4. Significance and Use

2. Referenced Documents

2 4.1 It is important to have the sulfur content of liquefied

2.1 ASTM Standards:

petroleum gases at low enough concentration to meet govern-

D156 Test Method for Saybolt Color of Petroleum Products

mentregulations.Thepresenceofsulfurcanresultincorrosion

(Saybolt Chromometer Method)

of metal surfaces. Sulfur can be poisonous to catalysts in

D1193 Specification for Reagent Water

subsequent processing.

D1265 Practice for Sampling Liquefied Petroleum (LP)

Gases, Manual Method

5. Apparatus

D1266 Test Method for Sulfur in Petroleum Products

5.1 Oxy-Hydrogen Combustion Assembly—The two types

(Lamp Method)

listed below are recommended. Any combustion apparatus

D1657 Test Method for Density or Relative Density of

giving equivalent results, however, is satisfactory.

Light Hydrocarbons by Pressure Hydrometer

5.1.1 Wickbold-Type Combustion Apparatus, as shown in

E11 SpecificationforWovenWireTestSieveClothandTest

Fig. 1.

Sieves

,

4 5

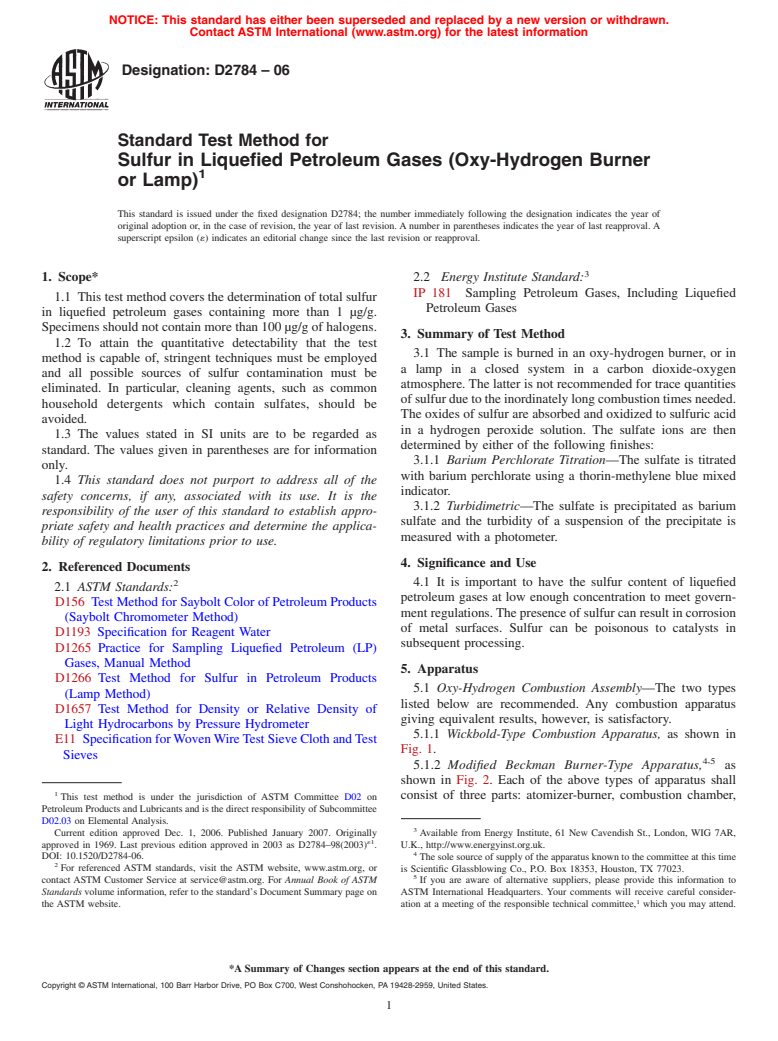

5.1.2 Modified Beckman Burner-Type Apparatus, as

shown in Fig. 2. Each of the above types of apparatus shall

1

This test method is under the jurisdiction of ASTM Committee D02 on consist of three parts: atomizer-burner, combustion chamber,

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.03 on Elemental Analysis.

3

Current edition approved Dec. 1, 2006. Published January 2007. Originally Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

´1

approved in 1969. Last previous edition approved in 2003 as D2784–98(2003) . U.K., http://www.energyinst.org.uk.

4

DOI: 10.1520/D2784-06. The sole source of supply of the apparatus known to the committee at this time

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or is Scientific Glassblowing Co., P.O. Box 18353, Houston, TX 77023.

5

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM If you are aware of alternative suppliers, please provide this information to

Standards volume information, refer to the standard’s Document Summary page on ASTM International Headquarters. Your comments will receive careful consider-

1

the ASTM website. ation at a meeting of the responsible technical committee, which you may attend.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2784 – 06

5.4 Corrosion-Resistant Metal Cylinder, 75-mL—It shall be

testedatapressureof600psig(4.14MPagage)andshallshow

no leaks when filled with air or ni

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.