ASTM C860-00(2005)

(Practice)Standard Practice for Determining the Consistency of Refractory Castable Using the Ball-In-Hand Test

Standard Practice for Determining the Consistency of Refractory Castable Using the Ball-In-Hand Test

SIGNIFICANCE AND USE

This practice is used primarily to determine if a freshly mixed refractory castable is of the proper consistency and therefore would most likely provide optimum performance. It can also be used to estimate the correct water addition rate of a castable when either the manufacturer’specified water content is not available or when unique circumstances have rendered that recommendation unusable.

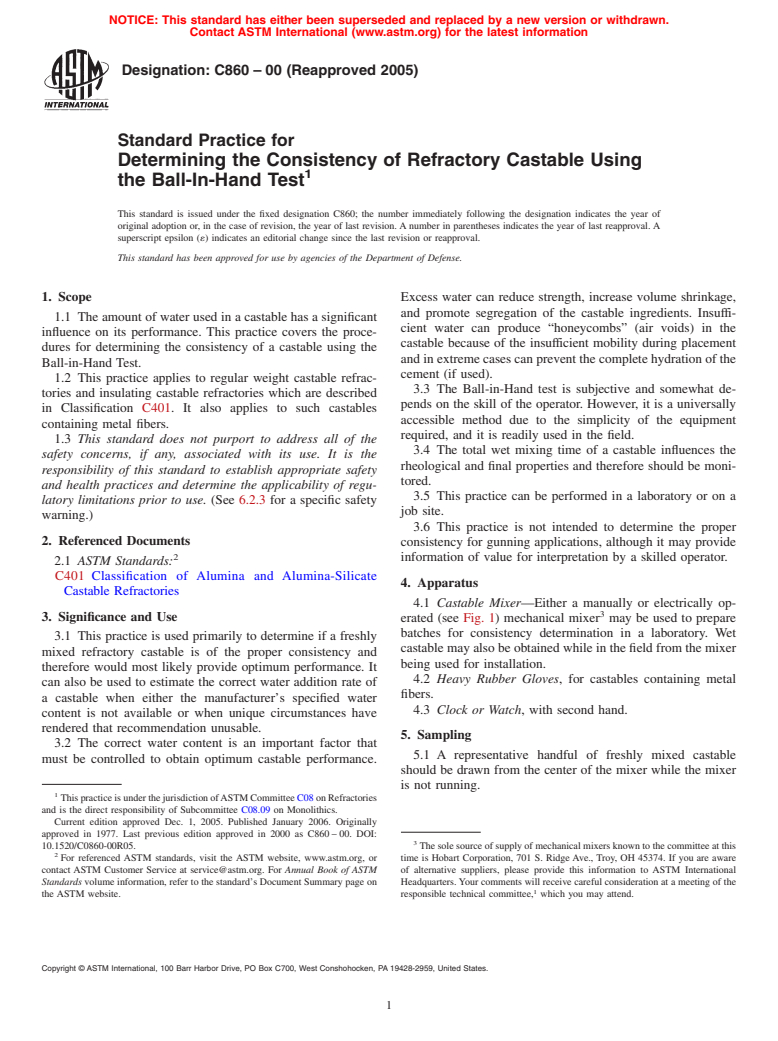

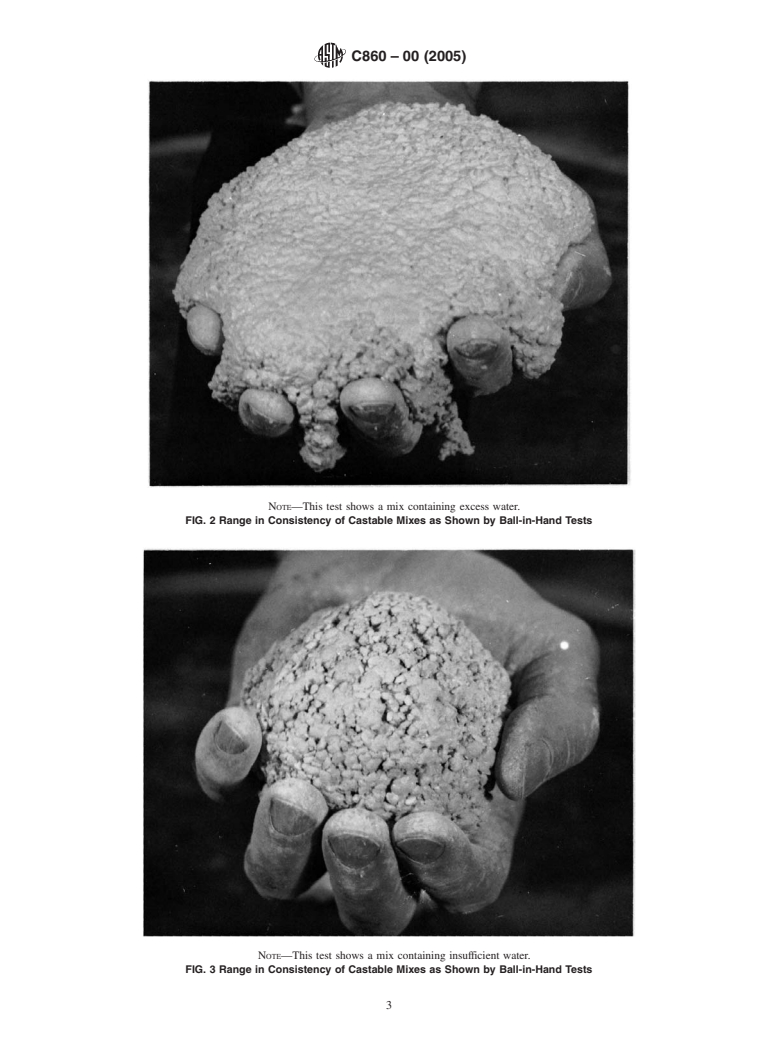

The correct water content is an important factor that must be controlled to obtain optimum castable performance. Excess water can reduce strength, increase volume shrinkage, and promote segregation of the castable ingredients. Insufficient water can produce “honeycombs” (air voids) in the castable because of the insufficient mobility during placement and in extreme cases can prevent the complete hydration of the cement (if used).

The Ball-in-Hand test is subjective and somewhat depends on the skill of the operator. However, it is a universally accessible method due to the simplicity of the equipment required, and it is readily used in the field.

The total wet mixing time of a castable influences the rheological and final properties and therefore should be monitored.

This practice can be performed in a laboratory or on a job site.

This practice is not intended to determine the proper consistency for gunning applications, although it may provide information of value for interpretation by a skilled operator.

SCOPE

1.1 The amount of water used in a castable has a significant influence on its performance. This practice covers the procedures for determining the consistency of a castable using the Ball-in-Hand Test.

1.2 This practice applies to regular weight castable refractories and insulating castable refractories which are described in Classification C 401. It also applies to such castables containing metal fibers.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (See 6.2.3 for a specific safety warning.)

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C860–00 (Reapproved 2005)

Standard Practice for

Determining the Consistency of Refractory Castable Using

the Ball-In-Hand Test

This standard is issued under the fixed designation C860; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Excess water can reduce strength, increase volume shrinkage,

and promote segregation of the castable ingredients. Insuffi-

1.1 The amount of water used in a castable has a significant

cient water can produce “honeycombs” (air voids) in the

influence on its performance. This practice covers the proce-

castable because of the insufficient mobility during placement

dures for determining the consistency of a castable using the

and in extreme cases can prevent the complete hydration of the

Ball-in-Hand Test.

cement (if used).

1.2 This practice applies to regular weight castable refrac-

3.3 The Ball-in-Hand test is subjective and somewhat de-

tories and insulating castable refractories which are described

pends on the skill of the operator. However, it is a universally

in Classification C401. It also applies to such castables

accessible method due to the simplicity of the equipment

containing metal fibers.

required, and it is readily used in the field.

1.3 This standard does not purport to address all of the

3.4 The total wet mixing time of a castable influences the

safety concerns, if any, associated with its use. It is the

rheological and final properties and therefore should be moni-

responsibility of this standard to establish appropriate safety

tored.

and health practices and determine the applicability of regu-

3.5 This practice can be performed in a laboratory or on a

latory limitations prior to use. (See 6.2.3 for a specific safety

job site.

warning.)

3.6 This practice is not intended to determine the proper

2. Referenced Documents

consistency for gunning applications, although it may provide

information of value for interpretation by a skilled operator.

2.1 ASTM Standards:

C401 Classification of Alumina and Alumina-Silicate

4. Apparatus

Castable Refractories

4.1 Castable Mixer—Either a manually or electrically op-

3. Significance and Use erated (see Fig. 1) mechanical mixer may be used to prepare

batches for consistency determination in a laboratory. Wet

3.1 This practice is used primarily to determine if a freshly

castable may also be obtained while in the field from the mixer

mixed refractory castable is of the proper consistency and

being used for installation.

therefore would most likely provide optimum performance. It

4.2 Heavy Rubber Gloves, for castables containing metal

can also be used to estimate the correct water addition rate of

fibers.

a castable when either the manufacturer’s specified water

4.3 Clock or Watch, with second hand.

content is not available or when unique circumstances have

rendered that recommendation unusable.

5. Sampling

3.2 The correct water content is an important factor that

5.1 A representative handful of freshly mixed castable

must be controlled to obtain optimum castable performance.

should be drawn from the center of the mixer while the mixer

is not running.

ThispracticeisunderthejurisdictionofASTMCommitteeC08onRefractories

and is the direct responsibility of Subcommittee C08.09 on Monolithics.

Current edition approved Dec. 1, 2005. Published January 2006. Originally

approved in 1977. Last previous edition approved in 2000 as C860 – 00. DOI:

10.1520/C0860-00R05. The sole source of supply of mechanical mixers known to the committee at this

For referenced ASTM standards, visit the ASTM website, www.astm.org, or time is Hobart Corporation, 701 S. Ridge Ave., Troy, OH 45374. If you are aware

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM of alternative suppliers, please provide this information to ASTM International

Standards volume information, refer to the standard’s Document Summary page on Headquarters.Your comments will receive careful consideration at a meeting of the

the ASTM website. responsible technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.