ASTM D7674-14a(2021)

(Test Method)Standard Test Method for Hexane/Petroleum Ether Extract in Wet Blue and Wet White

Standard Test Method for Hexane/Petroleum Ether Extract in Wet Blue and Wet White

SIGNIFICANCE AND USE

4.1 This test method measures the amount of solvent-soluble (hexane or petroleum ether) materials in wet blue and wet white.

SCOPE

1.1 This test method covers the quantitative extraction of all types of wet blue and wet white with hexane or petroleum ether.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For a specific hazard statement, see Section 7.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7674 − 14a (Reapproved 2021)

Standard Test Method for

Hexane/Petroleum Ether Extract in Wet Blue and Wet White

This standard is issued under the fixed designation D7674; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope analysis. The prepared specimen is extracted with solvent.

Another specimen from the same sample is also analyzed for

1.1 This test method covers the quantitative extraction of all

moisture content in accordance with Test Method D6658.

types of wet blue and wet white with hexane or petroleum

Following completion of the extraction process, the extract is

ether.

dried, then cooled and weighed. The extract is reported as

1.2 The values stated in SI units are to be regarded as the

extractables on a moisture-free basis.

standard. The values given in parentheses are for information

only.

4. Significance and Use

1.3 This standard does not purport to address all of the

4.1 This test method measures the amount of solvent-

safety concerns, if any, associated with its use. It is the

soluble (hexane or petroleum ether) materials in wet blue and

responsibility of the user of this standard to establish appro-

wet white.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. 5. Apparatus

For a specific hazard statement, see Section 7.

5.1 Analytical Balance.

1.4 This international standard was developed in accor-

5.2 Extraction Apparatus—Soxhlet, consisting of a boiling

dance with internationally recognized principles on standard-

flask, extraction tube, and condenser. Alternate Extraction

ization established in the Decision on Principles for the

Apparatus: Soxtec-type system consisting of an extraction unit

Development of International Standards, Guides and Recom-

and a control unit.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. 5.3 ForcedCirculatingAirOven,capableofmaintainingthe

specified temperature.

2. Referenced Documents

5.4 Electric Hot Plate (or steam bath).

2.1 ASTM Standards:

5.5 Extraction Thimbles, fat-free: cellulose,Alundum, glass

D3495 Test Method for Hexane Extraction of Leather

microfiber, or fritted glass.

D6658 Test Method for Volatile Matter (Moisture) of Wet

Blue by Oven Drying

5.6 Absorbent Cotton, fat-free, or glass wool.

D6659 Practice for Sampling and Preparation of Wet Blue

6. Reagents and Materials

and Wet White for Physical and Chemical Tests

E177 Practice for Use of the Terms Precision and Bias in

6.1 Hexane, ACS Reagent Grade, or

ASTM Test Methods

6.2 Petroleum Ether, ACS Reagent Grade.

E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

7. Hazards

3. Summary of Test Method

7.1 All reagents and chemicals should be handled with care.

Before using any chemical, read and follow all safety precau-

3.1 A specimen is analyzed as received in wet state, diced;

tions and instructions on the manufacturers’ label or MSDS

or pre-dried at the determined setting then ground prior to

(Material Safety Data Sheet).

This test method is under the jurisdiction ofASTM Committee D31 on Leather

8. Sampling

and is the direct responsibility of Subcommittee D31.02 on Wet Blue.

Current edition approved Sept. 1, 2021. Published October 2021. Originally

8.1 The wet blue or wet white shall be sampled in accor-

approved in 2010 as E7674-10. Last previous edition approved in 2014 as

dance with Test Method D6659.

E7674-14a. DOI: 10.1520/D7674-14AR21.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

9. Procedure

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on NOTE 1—Two sample conditions are listed below. Both sample condi-

the ASTM website. tions produce acceptable results (See Precision and Bias section).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7674 − 14a (2021)

9.1 Condition A—As received in wet state, diced (prepared petroleum ether or hexane. Place the loaded thimble in the

per Test Method D6659 Method A). Soxtec-type apparatus. Extract the sample by using the Soxtec-

9.1.1 Weigh out specimen for both moisture and hexane/

type boiling cycle for 45-50 min, followed by a rinse cycle of

petroleum ether extraction at the same time. For the hexane/

45-50 min. After the rinse cycle, close the condenser and

petroleum ether extraction, weigh an 8-10 g specimen to the

collect the solvent for 10-15 min. Open the Evaporation valve,

nearest 0.001g and record this value as W1. Loosely pack the

press the Air button and pull air through the cups for 10-15

material in an appropriately sized extraction thimble and cover

min. Close the Evaporation valve and release the extraction

with a pad of fat-free cotton or glass wool. Proceed with

cups with the safety catch. Dry the cups in a forced air

extractionusingeithertheSoxhletapparatusortheSoxtec-type

circulating oven at 100 6 2 °C (212 6 3.6 °F) for 60-65 min

apparatus.

or 25-30 min at 125 6 1 °C (257 6 1.8 °F). Cool the cups for

9.1.2 Determine the moisture content of the prepared

30-35 min (or to room temperature) in a desiccator. Continue

sample from which the specimen for extraction is taken (9.1.1)

drying for successive 15-min periods until constant weight is

in accordance with Test Method D6658.

obtained. When successive weighings vary by less than

NOTE 2—The cubed specimen weighed out for extraction may be

60.005 g, consider the weight constant. Record this weight to

air-dried overnight, prior to extraction.

the nearest 0.001 g as W3. If constant weight has not been

9.2 Condition B—Oven or air dried, ground (prepared per

obtained after the third drying, record that weight as the final

Test Method D6659 Method B).

weight.

9.2.1 Weigh a 4-5 g specimen to the nearest 0.001 g and

record this value as W1. Loosely pack the material in an

10. Calculation of Results

appropriately sized extraction thimble and cover with a pad of

10.1 Calculate the percentage of hexane (or petroleum

fat-free cotton or glass wool. Proceed with extraction using

ether) extract, on a moisture-free basis, as follows:

either the Soxhlet apparatus or the Soxtec-type apparatus.

Hexane (or petroleum ether) extract =

9.2.2 Determine the residual moisture content of the pre-

pared sample from which the specimen for extraction is taken

W3 2 W2

3100 (1)

in accordance with Test Method D6658.

100 2 % moisture

~ !

W1 3

9.3 Soxhlet Apparatus—Place the loaded thimble in the

Soxhlet extraction tube. Dry an extraction flask in an oven for

where:

at least1hat100 6 2 °C (212 6 3.6 °F) to remove residual

W1 = weight of specimen, wet blue or wet white,

moisture. Cool in a desiccator, and weigh to the nearest 0.001

W2 = weight of extraction flask,

g. Record this value as W2. Fill the flask approximately

W3 = weight of extraction flask and hexane (or

two-thirds full with hexane or petroleum ether, assemble the

petroleum ether) extract, and

apparatus, circulate the water through the condenser, and heat

% moisture = moisturecontentofthesamplefromwhichthe

the flask until the extraction of the sample has continued for a

specimen was taken.

minimum of 50 cycles. If the Soxhlet drips continuously

instead of cycling, extract the sample for a minimum of5hat

11. Report

that setting. At the end of the extraction period, remove the

11.1 Report the hexane (or petroleum ether) extract in the

flaskcontainingtheextractionsolventanddriveoffthesolvent.

When 10 to 20 mL of solvent remain, heat gently on a steam wet blue or wet white as the average value obtained from the

test results to the nearest 0.01 %.

bath until the odor of the solvent can no longer be detected.

Facilitate removal of the solvent by utilizing a vacuum or a

11.2 State that the results are calculated on a moisture-free

gentle stream of filtered (oil and water-free) air. After the

basis.

solvent has been removed, dry the flask containing the ex-

tracted matter in a forced circulating air oven at 100 62°C 11.3 Report condition of the specimen (that is, Test Method

(212 6 3.6 °F) for 1 h. Cool to room temperature in a

D6659 Method A, or Test Method D6659 Method B).

desiccator and weigh. Continue drying for successive 1-h

11.4 Report extraction apparatus used.

periods at 100 6 2 °C (212 6 3.6 °F) until constant weight is

obtained. When successive weighings vary by less than

12. Precision and Bias

60.005 g, consider the weight constant. Record this weight to

the nearest 0.001 g as W3. If constant weight has not been

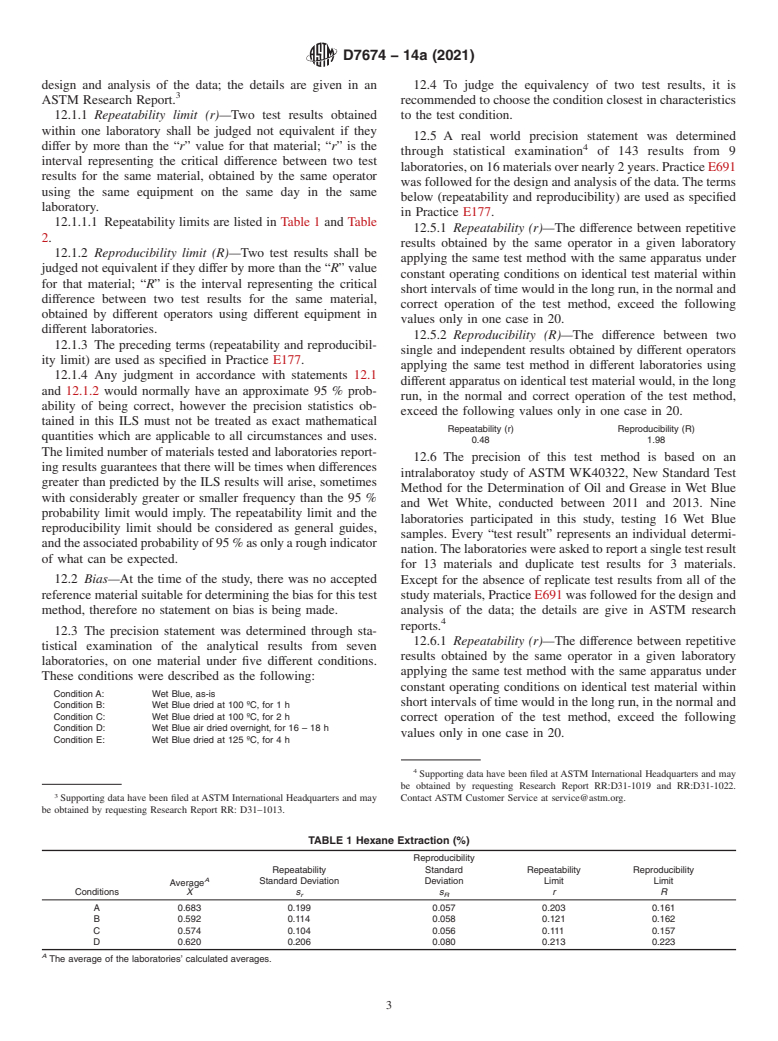

12.1 The precision of this test method is based on an

obtained after the third drying, record that weight as the final

interlaboratory study of WK15217, New Test Method for

weight.

Hexane/Petroleum Ether Extract in Wet Blue or Fats and Oils

in Wet Blue, conducted in 2007. Seven laboratories tested the

9.4 Soxtec-Type Apparatus—Dry an extraction cup in an

same material under five different test conditions using both an

ovenforatleast1hat100 62°C(212 63.6°F)or25-30min

ether and a hexane extraction. Every “test result” represents an

at 125 6 1 °C (257 6 1.8 °F) to remove residual moisture.

individual determination. Each laboratory was asked to submit

Cool in a desiccator, and weigh to the nearest 0.001g. Record

this value asW2. Circulate water through the condensers.Turn two replicate test results, from a single operator, for each

analysis and condition. Except for the limited number of

ontheserviceunitandsetthetemperaturecontrolat90 61°C

(194 6 1.8 °F). Fill the cup approximately two-thirds full with reporting laboratories, Practice E691 was followed for the

D7674 − 14a (2021)

design and analysis of the data; the detail

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.