ASTM E1465-92

(Guide)Guide for Radon Control Options for the Design and Construction of New Low Rise Residential Buildings (Withdrawn 2001)

Guide for Radon Control Options for the Design and Construction of New Low Rise Residential Buildings (Withdrawn 2001)

SCOPE

1.1 This guide covers design and construction methods for reducing radon entry into new low-rise residential buildings, and methods for facilitating postconstruction radon mitigation.

1.2 These methods are based on radon mitigation procedures that have been used successfully for various foundation types, and include options to accommodate regional construction practices and site conditions.

1.3 These methods should not be considered as the only acceptable methods available to reduce indoor radon levels, and are not intended to preclude or limit the use of other effective options.

1.4 This guide is intended to assist designers, builders, building officials and others involved in the construction of low-rise residential buildings.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

An American National Standard

Designation:E1465–92

Standard Guide for

Radon Control Options for the Design and Construction of

New Low Rise Residential Buildings

This standard is issued under the fixed designation E1465; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.4 passive ventilation—ventilation of a space provided

through a stand-pipe, vent or other opening to the outside that

1.1 This guide covers design and construction methods for

permits air flow without mechanical assistance.

reducing radon entry into new low-rise residential buildings,

3.2.5 soil-gas retarder—a continuous membrane material

and methods for facilitating postconstruction radon mitigation.

designed and installed to retard or prevent the flow of soil gas

1.2 These methods are based on radon mitigation proce-

into the building. (Materials approved for waterproofing in

dures that have been used successfully for various foundation

Sections 1224.4.1.1 and 1224.4.2.2 of the 1990 BOCA Na-

types, and include options to accommodate regional construc-

tional Building Code (1) are considered acceptable for this

tion practices and site conditions.

purpose.)

1.3 These methods should not be considered as the only

3.2.6 stem-wall type slab-on-grade—a concrete slab-on-

acceptable methods available to reduce indoor radon levels,

grade cast independently of and within the boundaries of

and are not intended to preclude or limit the use of other

concrete or masonry stem walls that support the above grade

effective options.

exterior walls of a building.

1.4 This guide is intended to assist designers, builders,

3.2.7 subslab depressurization—the use of a fan-driven

building officials and others involved in the construction of

systemdesignedtodepressurizethesubslabareaandwithdraw

low-rise residential buildings.

soil gas from near the foundation.

2. Referenced Documents

3.2.8 subslab pressurization—the use of a fan-driven sys-

tem designed to pressurize the subslab area and direct soil gas

2.1 ASTM Standards:

away from the foundation.

E631 Terminology of Building Constructions

4. Summary of Guide

3. Terminology

4.1 Predicting indoor radon levels prior to construction is

3.1 Definitions:

notfeasibleatthistime.Asaresult,thisguidedoesnotaddress

3.1.1 Definitions for standard terminology can be found in

when or where to use radon-resistant construction. However, it

Terminology E631.

doesprovideinformationonradonmitigationmethodsthatwill

3.2 Definitions of Terms Specific to This Standard:

assist the user in selecting appropriate techniques for a given

3.2.1 channel drain—an interior basement water drainage

building.

system typically consisting ofa1to 2-in. gap between the

4.2 Methods for constructing radon-resistant buildings ac-

interior of a basement wall and the concrete floor slab.

cordingtofoundationtypeareprovidedintwomainsectionsof

3.2.2 low-rise residential building—a structure for perma-

this guide. Section 6 describes methods that limit radon entry

nent human occupancy having three or fewer stories.

routesusingbarriertechniquesandmethodsthatfacilitatelater

3.2.3 passive stack—a ventilation system powered by tem-

installation of a supplemental depressurization or pressuriza-

perature differentials, which typically consists of a vent stack

tion system. Section 7 provides guidance for completing the

running from the area under a slab up through the conditioned

supplemental systems described in Section 6 and for other

spaceofthebuilding,andexitingoutdoors.Whentheairinside

systems generally installed after construction.

the stack is warmer than outside air, it can produce a negative

4.3 Although radon concentrations can sometimes be re-

pressure differential across the slab that can withdraw soil gas

duced by sealing entry routes with barrier techniques, results

before it can enter the building.

are highly variable. These methods are rarely adequate as a

stand-alone mitigation technique. However, if an active or

passive subslab mitigation system is needed later, barrier

This guide is under the jurisdiction ofASTM Committee E-6 on Performance

of Buildings and is the direct responsibility of Subcommittee E6.41 onAir Leakage

and Ventilation.

Current edition approved Apr. 15, 1992. Published August 1992. Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

Annual Book of ASTM Standards, Vol 04.11. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

E1465–92

techniquesimprovetheeffectivenessofthesystembyavoiding

excessive physical openings between the subslab area and the

interior of the building.

4.4 For slab-on-grade and basement foundations, subslab

depressurization is the primary supplemental system discussed

in this guide, since it has been shown to be one of the most

cost-effective mitigation techniques. Subslab pressurization is

also discussed, although its effectiveness is not as predictable

as depressurization.

4.5 There are several options for radon control in homes

built on crawl space foundations. Natural ventilation through

crawlspace foundation vents is one of the more cost-effective

optionsbutmaynotbeeffectivebyitselfifahighradonsource

strength exists. Therefore, additional features for later instal-

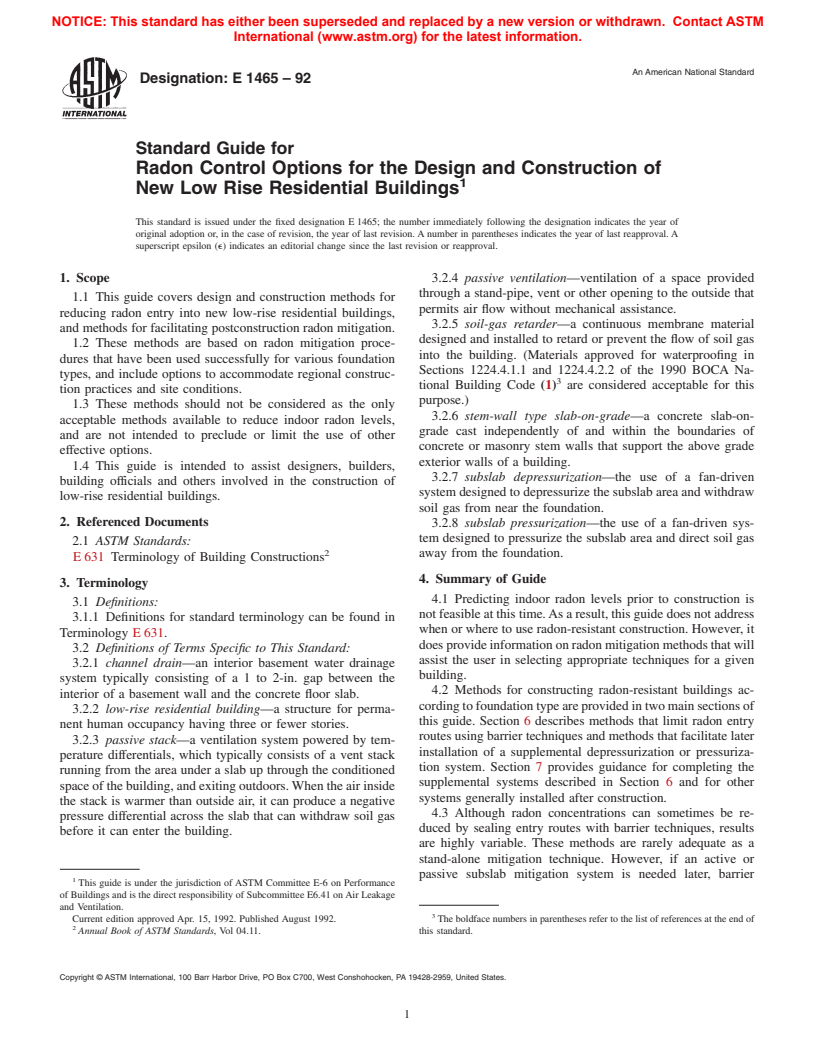

lation of a submembrane depressurization system are dis- FIG. 1 Stem-Wall Slab-on-Grade

cussed. In colder climates, natural ventilation may not be

practical and other options may have better application. In

addition to sub-membrane depressurization, other options for

crawl spaces include active crawlspace depressurization and

mechanical ventilation.

4.6 Other methods suggested in the literature as possibly

contributing to reduced indoor radon levels include techniques

to reduce depressurization of buildings due to thermal stack

effect and the operation of appliances and air handling equip-

ment.Althoughthesemethodsmaybesignificantundercertain

circumstances, there is insufficient data to confidently evaluate

their performance at this time. General information on these

methods is provided in Appendix X1.

5. Significance and Use

5.1 This guide is not intended to represent either minimum

FIG. 2 Monolithic Slab-on-Grade

ormaximumacceptablepracticesandshouldnotbeuniversally

applied. Other innovative and effective methods, systems,

designs and materials that meet the intent of these practices

surization or pressurization system. This layer can consist of a

may be used to control indoor radon levels.

3 1

nominal 4 in. of ⁄8 to 1 ⁄2-in. diameter aggregate. Use geotex-

5.2 The methods described here have been shown to have a

tile drainage matting with smaller aggregate or where aggre-

high probability of success in mitigating radon in residential

gate is not available.

buildingsoftypicaldesignandconstruction.Thesemethodsdo

6.1.2 Access to the Gas-Permeable Layer—In order to

not guarantee reduction of radon levels below any specific

facilitate installation of a subslab depressurization or pressur-

level, since the performance of the methods will vary with site

ization system if needed later,a3or 4-in. vent stack may be

conditions, construction characteristics, and occupant habits.

installed. The top of the vent stack should be located away

5.3 Foundations constructed on expansive soils should not

from any fresh air intakes or operable windows and doors. In

be built using the methods in this guide unless approved by a

split-level construction, connect each separate foundation area

qualified foundation design engineer.

to the vent stack.

6. Construction Methods

6.1.2.1 Vent stacks may operate as passive mitigation sys-

tems by relying on temperature differentials to induce a low

6.1 Slab-on-Grade Foundations—This section provides

pressure field across the gas-permeable layer beneath the slab.

guidance for providing buildings constructed on slab-on-grade

To increase the temperature differential across the stack, locate

foundations with certain basic features that limit radon entry

passive vents within the thermal envelope of the building and

routes, and that could ultimately become part of a fully

terminate the vents above the roof in a manner similar to a

functional subslab depressurization or pressurization system.

plumbing vent stack.

Figs. 1 and 2 illustrate these construction methods.

6.1.1 Subslab Preparation—Properly prepare the subslab 6.1.2.2 Connect the stack to the gas-permeable layer di-

area to minimize cracks in the concrete slab that could permit rectly through the slab into the top of the layer; through a

radon entry and to facilitate later installation of a passive or sealed sump cover; or through an interior or exterior loop of

active mitigation system. Minimize cracking by providing a drain-tile or perforated pipe that connects to the subslab gas

uniform subgrade of compacted or undisturbed soil under permeablelayer,providedthedrainisnotopentooutsideairat

ground-supported concrete floor slabs. Provide a gas- its termination. If inserted directly into the gas-permeable

permeable layer over the subgrade for a future subslab depres- layer, install a plumbing “T” as shown in Figs. 1 and 2 on the

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

E1465–92

bottom of the stack prior to casting the slab to prevent the pipe preclude the need for a large opening. Where it is necessary to

from bottoming out on the subgrade. provide a larger opening to accommodate plumbing rough-ins,

the opening should be subsequently filled with a non-shrink

6.1.3 Subslab Ground Cover—Place a soil-gas retarder on

grout or equivalent sealant.

topofthegas-permeablelayerpriortocastingtheconcreteslab

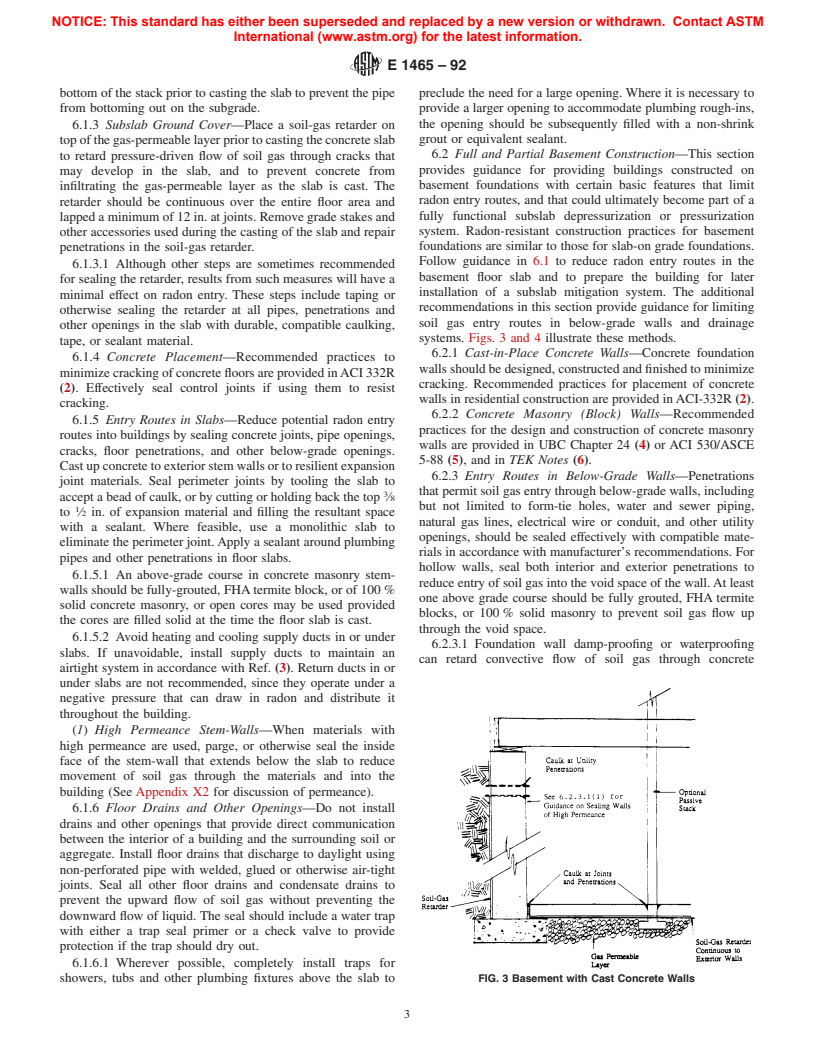

6.2 Full and Partial Basement Construction—This section

to retard pressure-driven flow of soil gas through cracks that

provides guidance for providing buildings constructed on

may develop in the slab, and to prevent concrete from

basement foundations with certain basic features that limit

infiltrating the gas-permeable layer as the slab is cast. The

radon entry routes, and that could ultimately become part of a

retarder should be continuous over the entire floor area and

fully functional subslab depressurization or pressurization

lappedaminimumof12in.atjoints.Removegradestakesand

system. Radon-resistant construction practices for basement

other accessories used during the casting of the slab and repair

foundations are similar to those for slab-on grade foundations.

penetrations in the soil-gas retarder.

Follow guidance in 6.1 to reduce radon entry routes in the

6.1.3.1 Although other steps are sometimes recommended

basement floor slab and to prepare the building for later

for sealing the retarder, results from such measures will have a

installation of a subslab mitigation system. The additional

minimal effect on radon entry. These steps include taping or

recommendations in this section provide guidance for limiting

otherwise sealing the retarder at all pipes, penetrations and

soil gas entry routes in below-grade walls and drainage

other openings in the slab with durable, compatible caulking,

systems. Figs. 3 and 4 illustrate these methods.

tape, or sealant material.

6.2.1 Cast-in-Place Concrete Walls—Concrete foundation

6.1.4 Concrete Placement—Recommended practices to

wallsshouldbedesigned,constructedandfinishedtominimize

minimizecrackingofconcretefloorsareprovidedinACI332R

cracking. Recommended practices for placement of concrete

(2). Effectively seal control joints if using them to resist

wallsinresidentialconstructionareprovidedinACI-332R (2).

cracking.

6.2.2 Concrete Masonry (Block) Walls—Recommended

6.1.5 Entry Routes in Slabs—Reduce potential radon entry

practices for the design and construction of concrete masonry

routes into buildings by sealing concrete joints, pipe openings,

walls are provided in UBC Chapter 24 (4) or ACI 530/ASCE

cracks, floor penetrations, and other below-grade openings.

5-88 (5), and in TEK Notes (6).

Castupconcretetoexteriorstemwallsortoresilientexpansion

6.2.3 Entry Routes in Below-Grade Walls—Penetrations

joint materials. Seal perimeter joints by tooling the slab to

thatpermitsoilgasentrythroughbelow-gradewalls,including

acceptabeadofcaulk,orbycuttingorholdingbackthetop ⁄8

but not limited to form-tie holes, water and sewer piping,

to ⁄2 in. of expansion material and filling the resultant space

natural gas lines, electrical wire or conduit, and other utility

with a sealant. Where feasible, use a monolithic slab to

openings, should be sealed effectively with compatible mate-

eliminatetheperimeterjoint.Applyasealantaroundplumbing

rials in accordance with manufacturer’s recommendations. For

pipes and other penetrations in floor slabs.

hollow walls, seal both interior and exterior penetrations to

6.1.5.1 An above-grade course in concrete masonry stem-

reduceentryofsoilgasintothevoidspaceofthewall.Atleast

walls should be fully-grouted, FHAtermite block, or of 100%

one above grade course should be fully grouted, FHA termite

solid concrete masonry, or open cores may be used provided

blocks, or 100% solid masonry to prevent soil gas flow up

the cores are filled solid at the time the floor slab is cast.

through the void space.

6.1.5.2 Avoid heating and cooling supply ducts in or under

6.2.3.1 Foundation wall damp-proofing or waterproofing

slabs. If unavoidable, install supply ducts to maintain an

can retard convective flow of soil gas through concrete

airtight system in accordance with Ref. (3). Return ducts in or

under slabs are not recommended, since they operate under a

negative pressure that can draw in radon and distribute it

throughout the building.

(1) High Permeance Stem-Walls—When materials with

high permeance are used, parge, or otherwise seal the inside

face of the stem-wall that extends below the slab to reduce

movement of soil gas through the materials and into the

building (See Appendix X2 for discussion of permeance).

6.1.6 Floor Drains and Other Openings—Do not install

drains and other openings that provide direct communication

between the interior of a building and the surrounding soil or

aggregate. Install floor drains that discharge to daylight using

non-perforated pipe with welded, glued or otherwise air-tight

joints. Seal all other floor drains and cond

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.